Stereolithography (SLA) 3D printing is the most common resin 3D printing process and has become vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes and end-use parts. SLA 3D printers enable a range of advanced material properties, superior surface finish, and fine features.

In this comprehensive guide, learn how (SLA) resin 3D printers work, why thousands of professionals use this process today, and how SLA printers can benefit your work.

What Is Stereolithography 3D Printing?

Stereolithography, also known as vat photopolymerization or resin 3D printing, is an additive manufacturing process where a light source cures liquid resin into hardened plastic.

SLA 3D printing offers the fastest speed, highest resolution and accuracy, sharpest details, and smoothest surface finishes of all 3D printing technologies. Another key benefit of resin 3D printing is the versatile range of materials available. Material manufacturers have created innovative SLA resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Advances in 3D printing hardware, software, and materials science have made SLA technology more affordable and accessible, enabling businesses to change the way they approach prototyping, testing, and production.

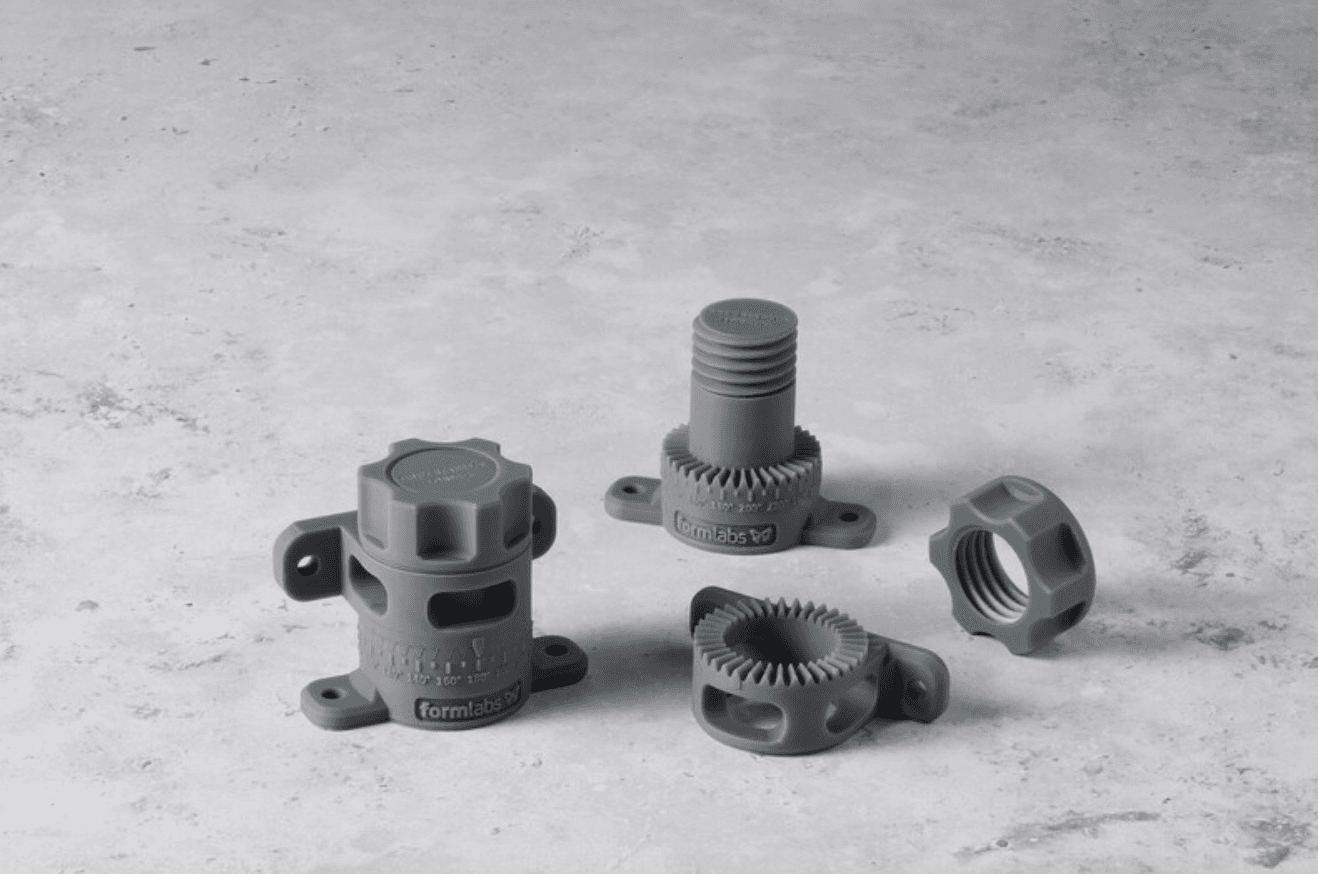

SLA 3D printed parts are being deployed in every industry as end-use products, industrial replacement parts, manufacturing aids, tooling, and more. Their smooth surface finish and tight tolerances make them ideal for use in multi-part assemblies or when a 3D printed part needs to mate to an existing component.

The introduction of affordable and accessible workflows made it possible for businesses of every size to bring high-quality 3D printing in-house. The utilization of this technology has helped hundreds of thousands of professionals reduce operating costs, improve efficiency, and unlock entirely new business models.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

How Does SLA 3D Printing Work?

SLA 3D printing uses a light source to cure liquid resin into three-dimensional objects by exposing a vat or tank of resin to a light source, which hardens it. Traditional, top-down SLA 3D printers had that light source positioned above the vat of liquid resin. Inverted stereolithography, first introduced in 2011 by Formlabs co-founders Max Lobovsky, David Cranor, and Natan Linder, positions the light source below the vat of resin; the cross-section is traced on the bottom-most layer of resin, which is backfilled as the build platform lifts up and allows liquid resin to flow underneath the previously cured layer.

There were several important innovations that led to the invention of inverted stereolithography, including the transparent (and eventually flexible) bottomed resin tank. This new tank design enabled the creation of larger inverted SLA 3D printers because peel forces were mitigated by the flexible surface.

SLA 3D printers use light to cure light-reactive thermoset materials called “resin.” When SLA resins are exposed to certain wavelengths of light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

In the last decade, several new types of stereolithographic 3D printers have been developed, primarily differentiated by the type of light source they use. These include: laser-based stereolithography (SLA), digital light processing (DLP), or masked stereolithography (MSLA, also often used interchangeably with LCD 3D printing). Formlabs introduced the Low Force Display™ (LFD) Print Engine in 2024, an advanced form of MSLA 3D printing that includes the use of a dense LCD screen to selectively mask the light source.

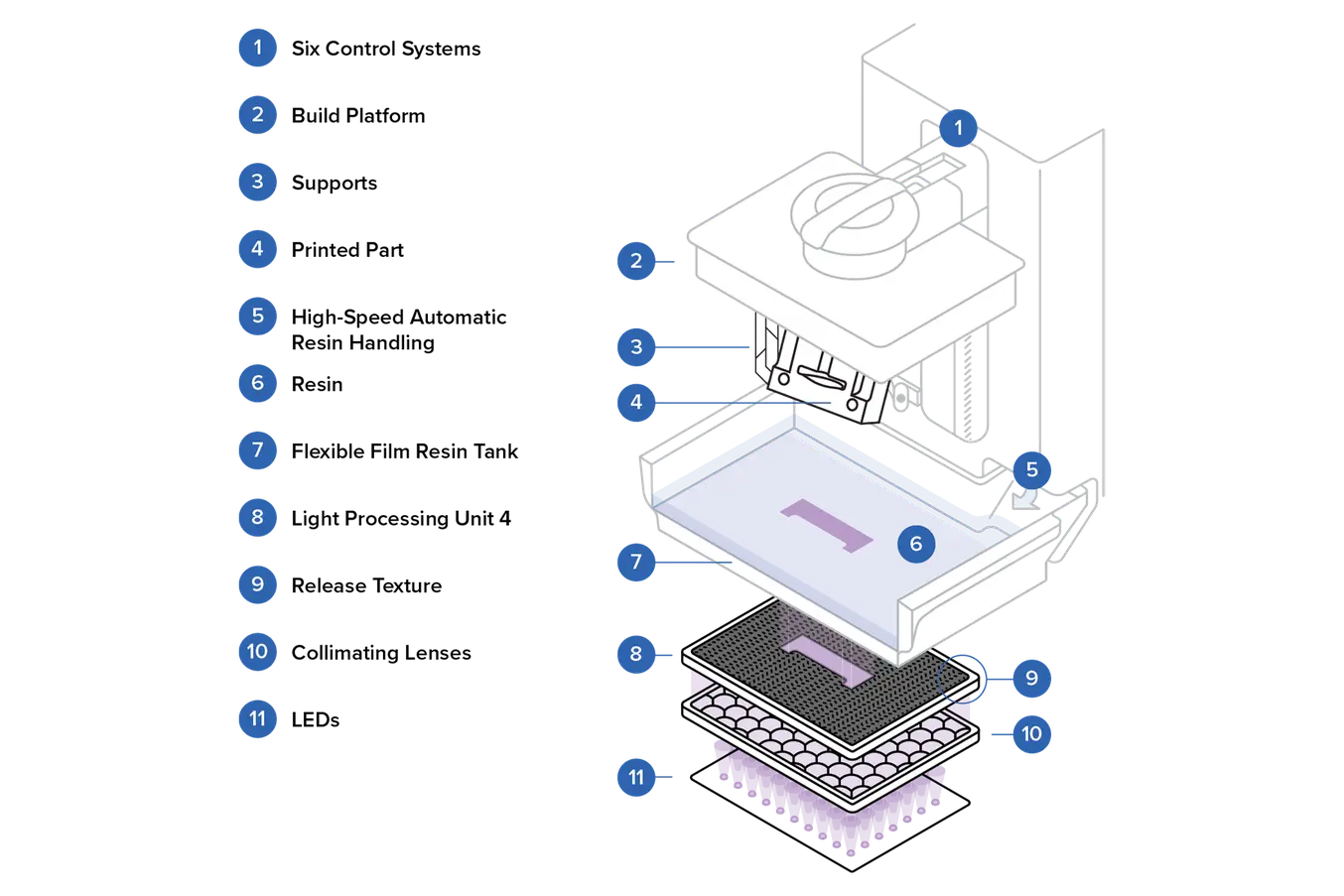

A graphic representation of Formlabs’ Low Force Display™ (LFD) print engine, an advanced form of MSLA 3D printing.

Regardless of the direction from which the light source shines or the type of light source, the SLA 3D printing workflow is straightforward. When the part has finished printing, there is a necessary alcohol wash step to remove excess liquid resin from the surface of the part. Then, depending on the material, a post-cure step may be necessary to finish hardening the surface of the part, helping it reach its optimal material properties. Further post-processing methods like coating or plating may be used for specific applications or aesthetics.

Coating SLA parts can improve their durability and can impart vibrant color.

Metal plating can create end-use parts that look and feel like fully metal objects — without the cost and operational complexity.

A Brief History of Stereolithography

The SLA 3D printing process first appeared in the early 1980s, when Japanese researcher Dr. Hideo Kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. The term stereolithography was coined by Charles (Chuck) W. Hull, who patented the technology in 1986 and founded 3D Systems to commercialize it. Hull described the method as creating 3D objects by successively “printing” thin layers of material curable by ultraviolet light. These first SLA 3D printers were large, industrial systems, often priced above $100,000, that required complex infrastructure and maintenance.

SLA 3D printing, however, was not the first 3D printing technology to gain widespread popularity. As patents for multiple types of 3D printing technology began to expire at the end of the 2000s, the introduction of small-format fused deposition modeling (FDM) 3D printers widened access to additive manufacturing. While this affordable extrusion-based technology sparked the first wave of wide adoption and awareness of 3D printing, FDM 3D printers did not satisfy the spectrum of professional needs.

Desktop SLA Printers Disrupt the Market

Small-format desktop SLA printers brought the promise of high-resolution 3D printing — previously limited to monolithic industrial systems — to those looking for a much smaller and more affordable setup. The Form 1, the first inverted stereolithography solution available, made it possible for customers of all backgrounds and budgets the chance to use this advanced technology.

Formlabs released the Form 2 in 2015 and, with the subsequent release of a wider range of materials, SLA 3D printing became much more accessible for professionals in a range of different environments.

These capabilities expanded access to 3D printing for a variety of custom and high-precision applications across disciplines including engineering, product design, and manufacturing, as well as dental, jewelry, and other industries.

As applications grew, the technology became more popular and widely accepted. Today, stereolithography is one of the three most established plastic 3D printing processes, the other two being fused deposition modeling (FDM) and selective laser sintering (SLS).

In 2019, Formlabs introduced Low Force StereolithographyTM (LFS) with the Form 3 and Form 3L SLA 3D printers, which use flexible-bottomed resin tanks. This drastically reduces the forces exerted on parts when peeling the cured part away from the bottom of the tank during the print process. LFS is an advanced form of stereolithography that delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, enabling larger build volume. The introduction of LFS opened up possibilities for advanced, production-ready materials, including soft, stretchy resins such as SIlicone 40A Resin and highly glass-filled resins like Rigid 10K Resin.

Successive iterations have made the Form Series the world’s leading professional 3D printers, with 140,000 units sold and over 400 million parts printed as of 2024.

The Next Chapter: LFD Print Engine

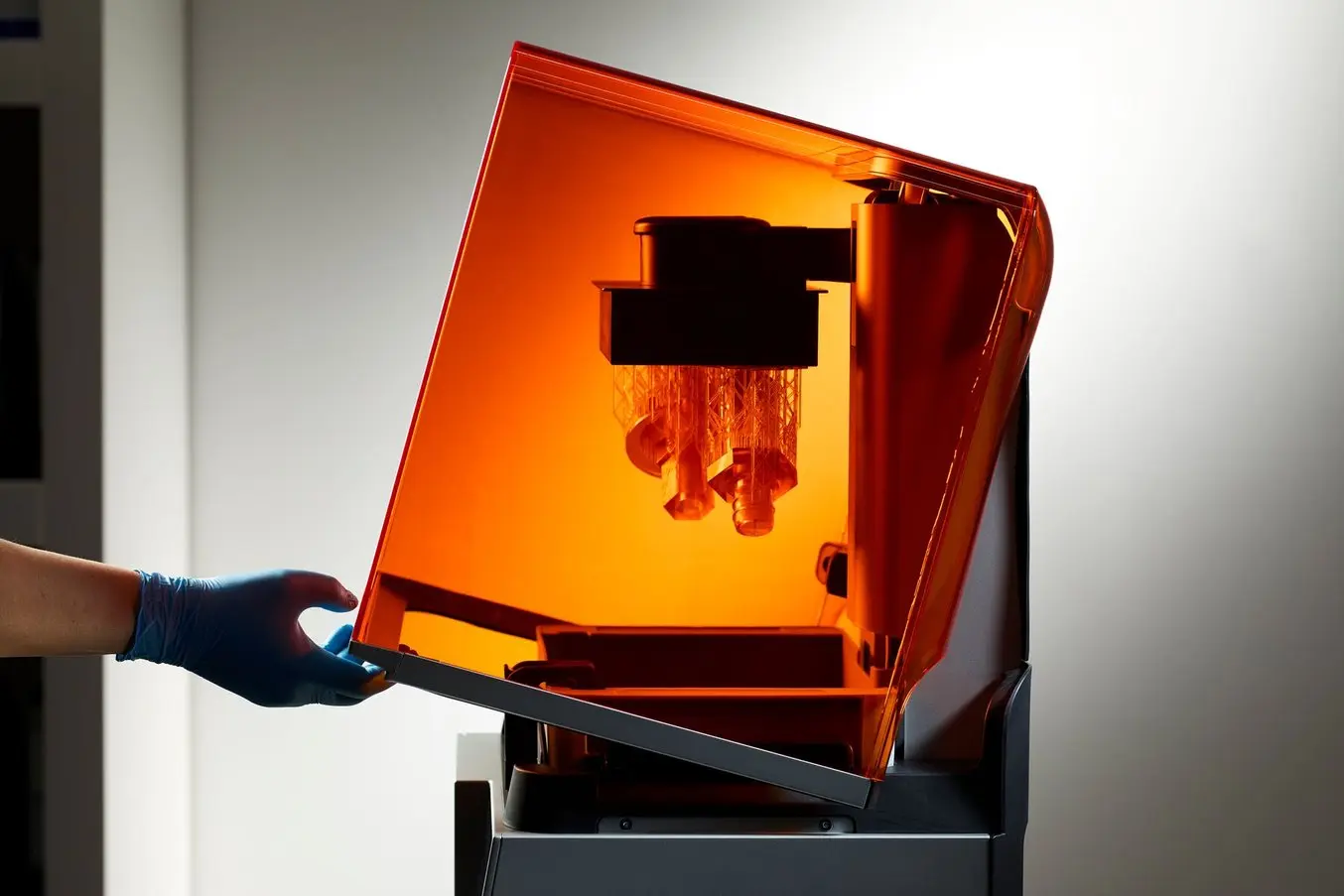

In 2024, Formlabs took powerful, accessible resin 3D printing a step further, releasing Form 4 and Form 4B. Form 4/B is powered by a next-generation MSLA print engine, called Low Force DisplayTM (LFD).

The accessibility and affordability of high-powered desktop and benchtop units have made new modes of production possible. Companies can scale 3D printing output incrementally, bring their supply chain in-house, and increase flexibility and adaptability in the face of uncertain market conditions. By adding new materials, companies can unlock new applications.

At the core of the LFD Print Engine is the Backlight Unit. The ultra-high power light source uses 60 LEDs and collimating lenses to emit a uniform area projection of light. The light passes through the lens array, making it more collimated, or parallel, and more uniform, eliminating dark or bright spots.

From here, the light passes through the Light Processing Unit (LPU) 4, where filters and masks form the light into the shape of the printed layer. Once the light reaches the liquid resin inside the tank, the full area turns into a solid layer. The Build Platform then rises out of the resin and a precision Z-axis peels away the layer from the bottom of the resin tank.

In the past, peel forces have been a major hurdle for SLA printing, forcing users to sacrifice either reliability, part quality, or printing speed when selecting a printer. With Form 4, peel forces are minimized, allowing the printer to optimize for both quality, reliability and speed. The top of the LPU features a Release Texture, a proprietary microtextured optical film that introduces airflow to prevent the resin tank from suctioning to the LPU.

Introducing Form 4: Everything You Come to Expect from Formlabs, Now 4x Faster

In this webinar, Formlabs Chief Product Officer Dávid Lakatos will walk you through an overview of the Form 4, the new materials, and give a hands-on demo of the new products.

SLA 3D Printing Workflow

1. Design

Use any CAD software or 3D scan data to design your model, and export it in a 3D printable file format (STL or OBJ). Then, import the digital design into print preparation software to specify printing settings and slice the digital model into layers for printing. Formlabs’ print preparation software, PreForm, is free to download and can create automated supports and print orientations.

More advanced users may consider specifically designing for SLA, or taking steps like hollowing parts to conserve material.

2. Print

The print preparation software will send the part to the printer, typically over a wireless internet connection, USB, or ethernet.

Inverted SLA printers use removable tanks and build platforms that make it easy to change materials and start a new print.More advanced SLA printers like Formlabs’ Form Series printers also use a cartridge system that automatically refills the material during printing. This means that after a quick confirmation of the correct setup, the printing process begins and the machine can run unattended until the print is complete. An online Dashboard from Formlabs allows you to remotely manage printers, materials, and teams.

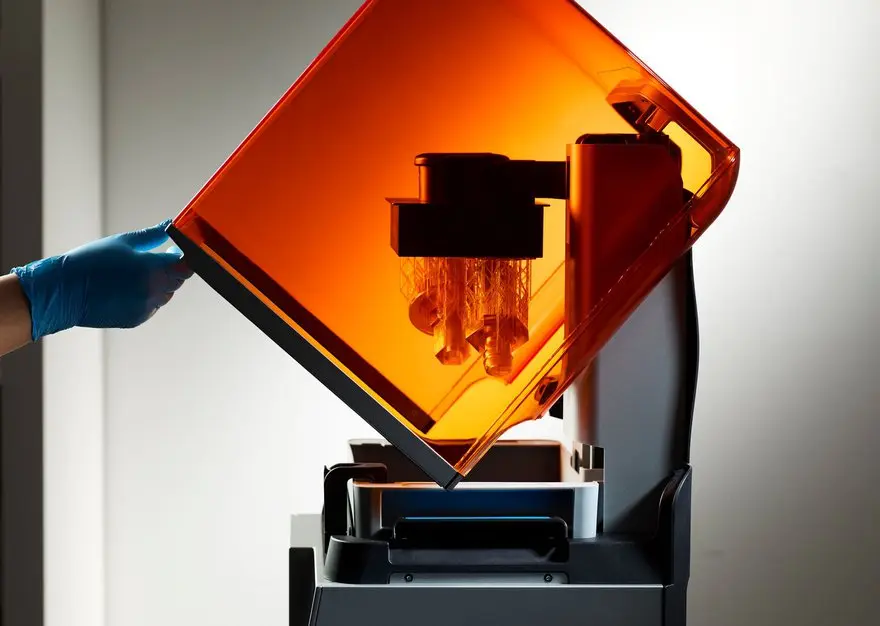

3. Post-Process

To remove parts from the build platform, different SLA 3D printers have various methods; most are manual and require scraping parts off. Formlabs’ Build Platform Flex enables the quick and easy removal of parts from the build platform while cutting down on hands-on labor and improving the quality of your parts by avoiding any chips or scratches.

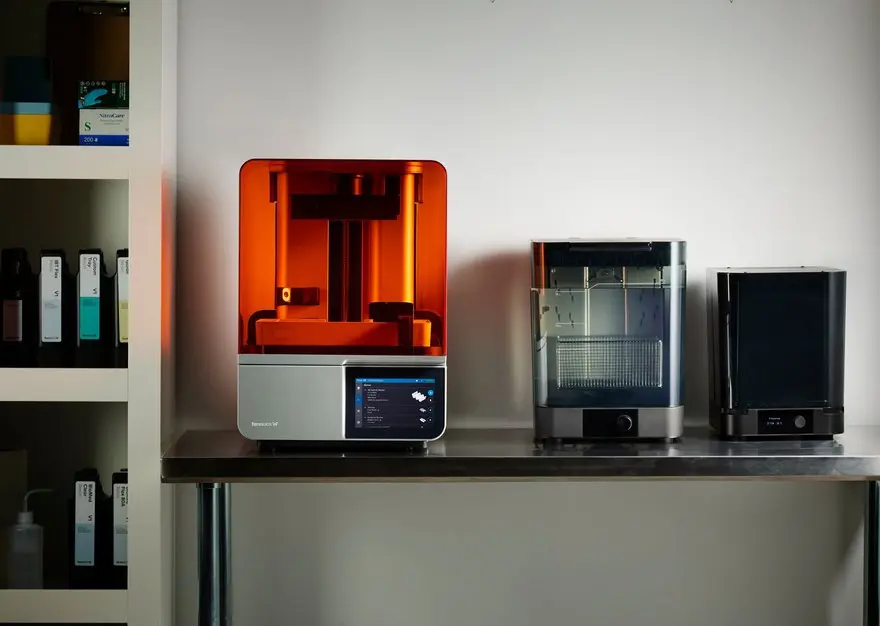

After removing parts from the build platform, parts require rinsing in isopropyl alcohol (IPA) to remove any uncured resin from their surface. Formlabs’ Form Wash and large-format Form Wash L have been engineered to streamline the wash process, easily removing excess resin with an improved agitation system, and shortening overall post-processing time.

After rinsed parts are dry, some materials require post-curing, a process that helps parts to reach their optimal material properties. Formlabs’ Form Cure and large-format Form Cure L are part of a comprehensive SLA ecosystem that makes post-processing simple for resin workflows.

Finally, remove supports from the parts and sand the remaining support marks for a clean finish. SLA parts can be easily machined, primed, painted, and assembled for specific applications or finishes.

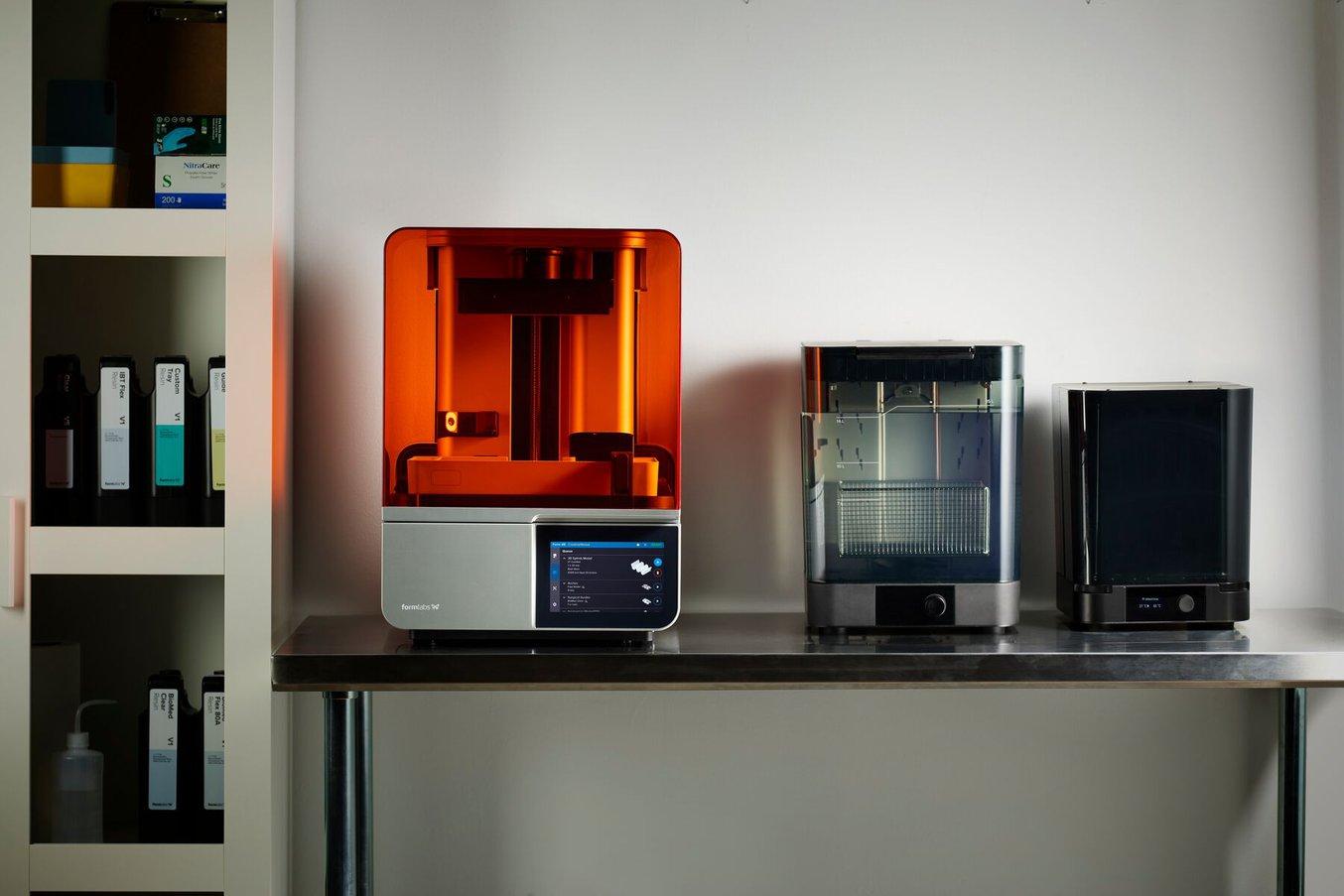

Formlabs' second-generation Form Wash has improved agitation and a larger volume to make cleaning parts easier than ever.

Post-processing SLA parts is simple, efficient, and streamlined with the Formlabs ecosystem: Form 4, Form Wash, and Form Cure.

4. (Optional) Additional Post-Processing

Some parts could also benefit from further steps like sanding, coating, plating, or media blasting. These advanced resin 3D print post-processing methods can achieve a wide range of results, such as making parts better suited for outdoor applications through UV protection, or increasing the mechanical strength of a part by electroplating it in metal or a ceramic coating solution like Cerakote.

Coatings like Cerakote can reinforce SLA 3D printed parts and make them stronger, more durable, and more aesthetically pleasing.

Why Choose SLA 3D Printing?

Professionals choose SLA 3D printing for its fine features, smooth surface finish, ultimate part precision and accuracy, and mechanical attributes like speed, isotropy, watertightness, and material versatility.

Speed and Throughput

Though advances have been made in 3D printing speed across all technologies, SLA 3D printing has established itself as the clear frontrunner for the fastest 3D printing process available. Some resin 3D printing processes are faster than others; laser-powered SLA generally cures each layer more slowly than DLP or MSLA (LCD) technologies that can cure an entire cross-section with one quick exposure of the light source.

Formlabs has made industry-leading print speeds a priority; Form 4 has been engineered to build parts as fast as 100 mm per hour using specifically designed materials like Fast Model Resin, but most Form 4 builds finish in under two hours using any material. Tall parts the full height of the printer can print in five hours using most materials, still allowing for design teams to produce multiple iterations a day.

When that speed is compounded day by day and week by week, the throughput benefits are extraordinary. Some SLA 3D printers, like the Form 3 and Formlabs Automation Ecosystem, have tackled throughput by using automated tools for part removal. Form 4 simply matches the speed of high-throughput technologies such as injection molding. Printing full build chambers over the course of a few hours, multiple times a day, can rival the output of a medium-volume injection molding machine, without the high up-front cost of tooling.

Isotropy

Because 3D printing creates parts one layer at a time, completed prints may have variations in strength based on the orientation of the part relative to the printing process, with different properties in X, Y, and Z axes.

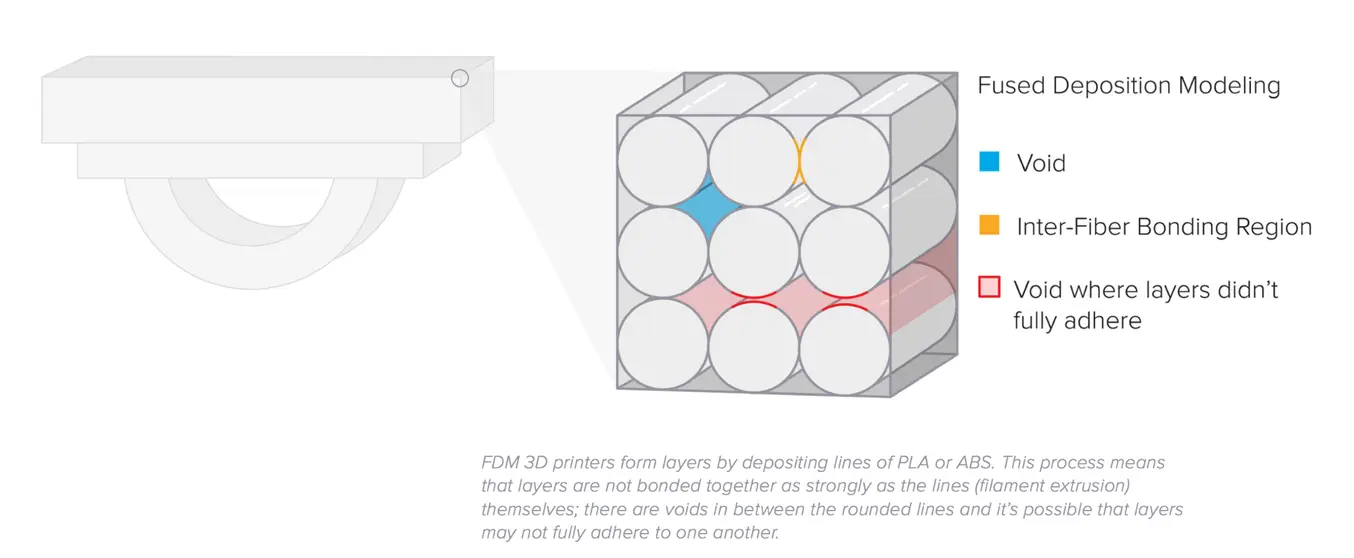

Extrusion-based 3D printing processes like fused deposition modeling (FDM) are known for being anisotropic due to layer-to-layer differences created by the print process. This anisotropy limits the usefulness of FDM for certain applications or requires more adjustments on the part geometry side to compensate for it.

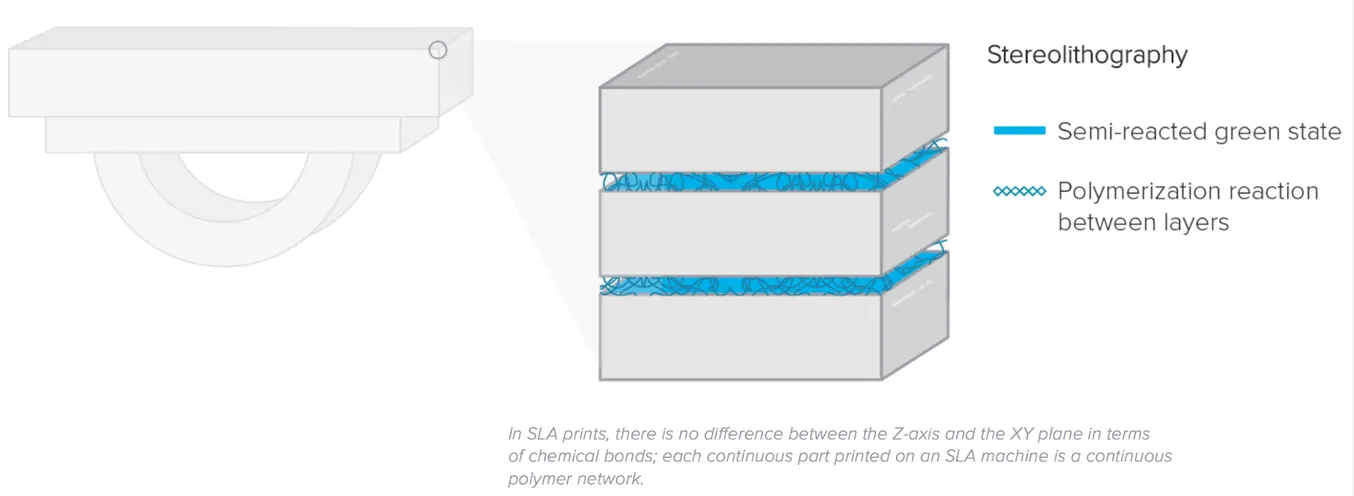

In contrast, SLA resin 3D printers create highly isotropic parts. Achieving part isotropy is based on a number of factors that can be tightly controlled by integrating material chemistry with the print process. During printing, resin components form covalent bonds, but layer to layer, the part remains in a semi-reacted “green state.”

While in the green state, the resin retains polymerizable groups that can form bonds across layers, imparting isotropy and watertightness to the part upon final cure. On the molecular level, there is no difference between X, Y, or Z planes. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

Watertightness

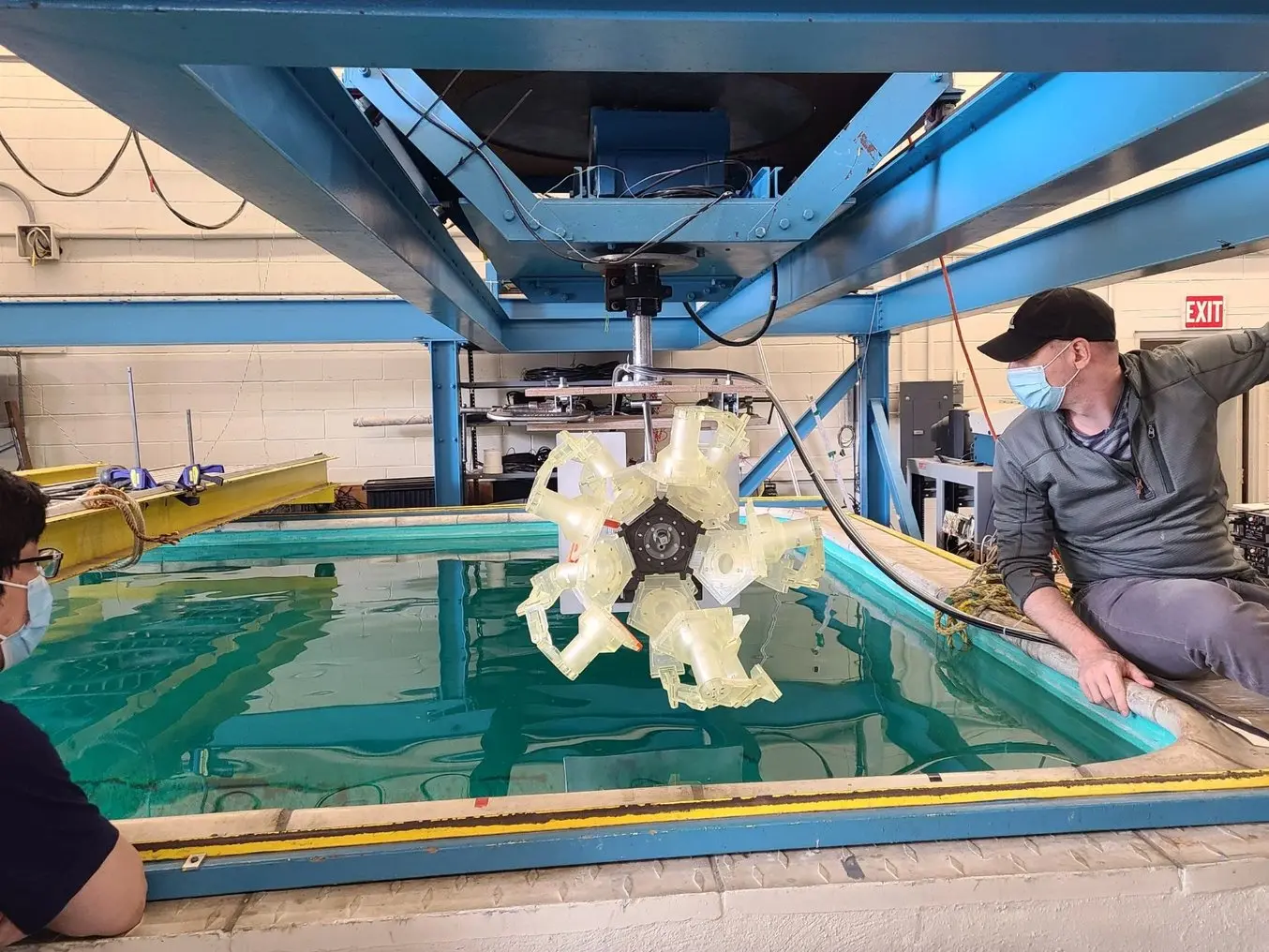

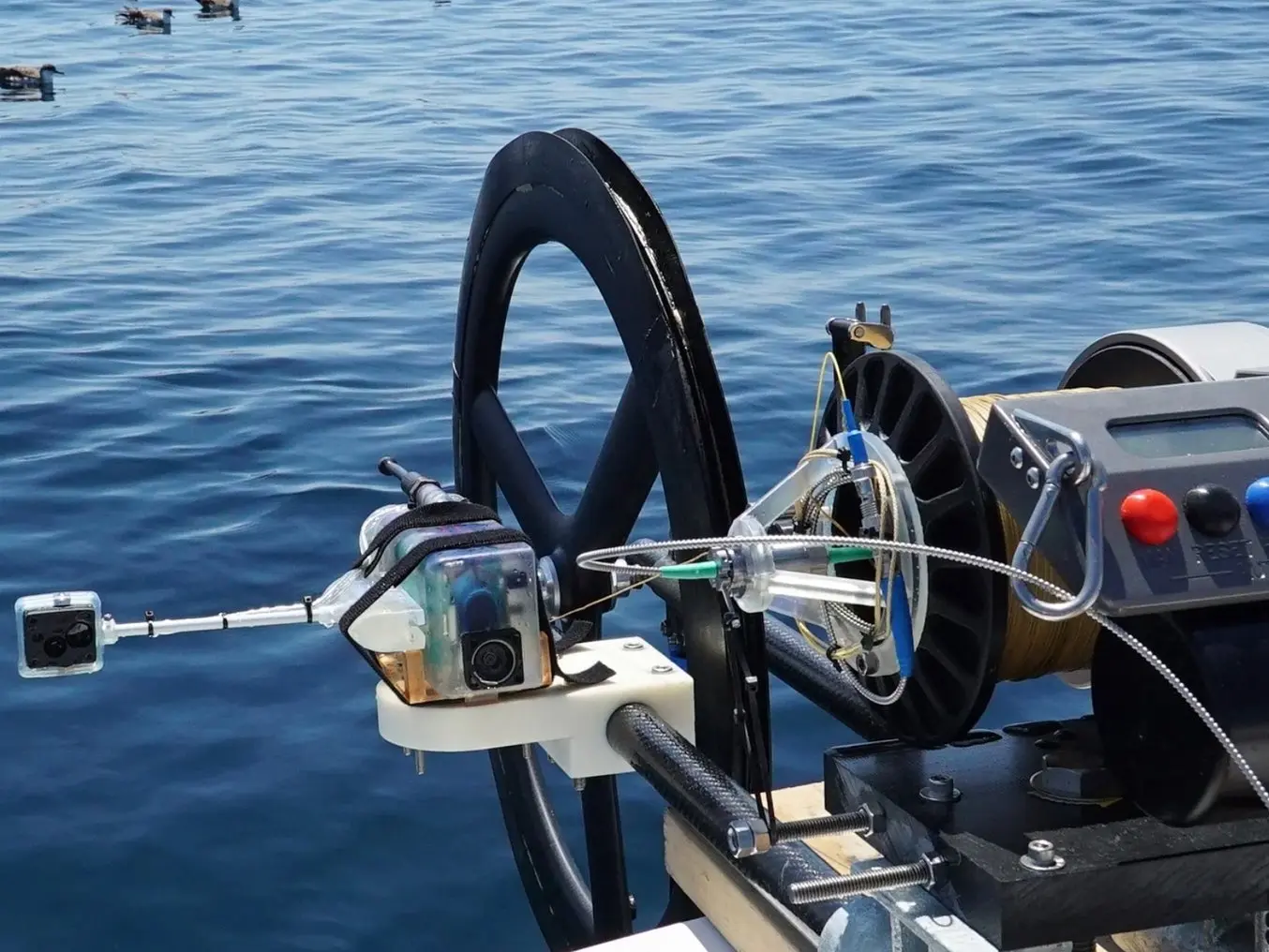

3D printing makes it possible to try out new and complex shapes for testing and sample-gathering equipment, like this tool with components printed in Clear Resin.

Watertight enclosures make it possible to take deep-sea images, like this photo of a vampireoteuthis, even without expensive underwater camera equipment.

The agile nature of on-demand 3D printing makes custom jigs and fixtures for research at sea possible and cost-effective.

There is a widespread need for custom or low-volume watertight and gas-tight parts across several industries, such as marine research, underwater robotics, sustainable technologies engineering, oil and gas industries, and defense. Though some 3D printing technologies present an ideal solution for these parts, the common perception of additively manufactured parts is that they are porous and cannot be deployed in pressurized environments.

In recent years, however, this assumption has been thoroughly disproven. SLA printers can create watertight enclosures and completely waterproof parts. Institutions like National Oceanic and Atmospheric Administration (NOAA) and the University of Rhode Island have made incredible strides in marine research by implementing low-cost, high-quality SLA 3D printed testing and research equipment.

3D Printing Watertight Enclosures and Pressure Testing Results

In this white paper, we will provide the testing results and clear guidelines on how to affordably 3D print customized watertight enclosures.

Accuracy and Precision

SLA 3D printed molds for stretch blow molding (SBM) have such smooth surfaces and high accuracy that they can create bottles that are nearly indistinguishable from those made by traditional steel molds.

Accuracy and precision are paramount for both manufacturers and customers. Accuracy refers to how closely you match the dimensions of the CAD model, and precision is defined as how repeatedly you can produce the same dimension. In general, SLA printing is the most accurate 3D printing process.

Compared to machined accuracy, professional SLA 3D printers are somewhere between standard machining and fine machining. However, accuracy does vary between resin 3D printer manufacturers and can be dependent on the type of light source used to cure the resin, the quality of the components, and the engineering and calibration that go into making those components function together. Accuracy is also dependent on the material — rigid materials are more accurate and easier to print with than flexible materials.

For example, Form 4/B, printing Precision Model Resin is a high-accuracy material for creating restorative models with >99% of printed surface area within 100 μm of the digital model. For larger models (81-150 mm features) the XY dimensional tolerance is typically ±0.3% (lower limit: ±0.15 mm) when using Grey Resin V5.

The heated and enclosed build environment of Form Series SLA printers provides almost identical conditions for each print. Better accuracy is also a function of lower printing temperature compared to thermoplastic-based technologies that melt the raw material. Because stereolithography uses light instead of heat, the printing process takes place at close to room temperature, and printed parts don't suffer from thermal expansion and contraction artifacts.

The Form 4’s LFD Print Engine, especially the high-resolution liquid crystal display and collimating lenses included in the LPU 4, creates hyper-accurate cross-sections of each part. The low peel forces made possible by the Release Texture and Flexible Film Resin Tank makes accuracy repeatable, leading to highly precise parts.

Fine Features and Smooth Surface Finish

Resin 3D printers are considered the gold standard for creating parts with smooth surface finishes and fine features. Resin 3D printed parts can easily have appearances comparable to traditional manufacturing methods like injection molding with barely any post-processing. Conversely, FDM 3D printed parts often have visible layer lines, and SLS 3D printed parts often exhibit a grainy, slightly rough texture on the surface.

The surface quality of SLA 3D printed parts lends itself to the creation of end-use products that look and feel like mass-produced consumer goods. It also makes secondary processes like rapid tooling possible.

SLA 3D printers also can achieve finer features and smaller minimum feature sizes than FDM 3D printers, comparable to SLS 3D printers. The light in resin 3D printers can be controlled in much more precise shapes than a filament extruder and therefore create smaller features or thinner walls. And, because SLA light sources can be lower power than the lasers required to melt powder in SLS 3D printers, they can cure with greater precision, leading to smaller features.

Material Versatility

SLA resins are incredibly versatile, and there are hundreds of different formulations available. Many manufacturers of SLA printers also formulate and manufacture their own resins for use in a closed system, though some offer an open platform for any resin to be used, and others white-label other companies’ resins.

Because these resins are formulated specifically for SLA 3D printers, they are not completely analogous to the familiar thermoplastics like nylon or ABS used in traditional plastic manufacturing methods like injection molding. Though learning which resin is best for a specific application may take testing and consideration of data sheets and application guides, there is an SLA resin for almost every application possible — the enormous variety of mechanical and aesthetic properties available make it easy to create an optimized and efficient workflow.

SLA 3D Printing Applications

Resin 3D printed parts are used in every industry and every application. Advanced materials, incredible dimensional accuracy, and accessible workflows make parts at every stage, from prototyping to production, possible. SLA technologies accelerate innovation. As costs have come down at the same time that the technology has become more affordable and scalable, end-use applications and mass-customization are becoming the norm, not the exception.

Engineering and Product Design

Rapid prototyping with 3D printing empowers engineers and product designers to turn ideas into realistic proofs of concept, advance these concepts to high-fidelity prototypes that look and work like final products, and guide products through a series of validation stages toward mass production.

Applications:

- Rapid prototyping

- Communication models

- Manufacturing validation

Manufacturing

Manufacturers automate production processes and streamline workflows by prototyping tooling and directly 3D printing custom tools, molds, and manufacturing aids at far lower costs and lead times than with traditional manufacturing. This reduces manufacturing costs and defects, increases quality, speeds up assembly, and maximizes labor effectiveness.

Applications:

Automotive

Automotive designers, manufacturers, and engineers use SLA 3D printing for a variety of parts throughout their process. From concept models to aftermarket parts, SLA 3D printing is everywhere, and touches the development or production of every car on the road.

- Go/no-go gauge testing

- Gasket design and testing

- Customization and one-offs

- Remanufacturing of engines and transmissions

- Concept design

- Aftermarket parts and accessories manufacturing

Aerospace

SLA 3D printed parts have been sent to space for testing on the International Space Station, used in manufacturing for commercial airlines, and are used across the world for testing, prototyping, and manufacturing in both the private and federal aerospace industry. From fixtures that help build space mission lasers to ceramics that are used in testing for jet-fuel applications, SLA parts are helping us reach the final frontier.

Dental

Digital dentistry reduces the risks and uncertainties introduced by human factors, providing higher consistency, accuracy, and precision at every stage of the workflow to improve patient care. 3D printers can produce a range of high-quality custom products and appliances at low unit costs with superior fit and repeatable results.

Applications:

Medical

Affordable, professional-grade desktop 3D printing helps doctors deliver treatments and devices with a high level of customization, to better serve each unique individual, opening the door to high-impact medical applications while saving organizations significant time and costs from the lab to the operating room.

Applications:

Education

Resin 3D printers are multifunctional tools for immersive learning and advanced research. They can encourage creativity and expose students to professional-level technology while supporting STEAM curricula across science, engineering, art, and design.

Applications:

Entertainment

High-definition physical models are widely used in sculpting, character modeling, and prop making. 3D printed parts have starred in stop-motion films, video games, bespoke costumes, and even special effects for blockbuster movies.

Applications:

Jewelry

Jewelry professionals use CAD and 3D printing to rapidly prototype designs, fit clients, and produce large batches of ready-to-cast pieces. Digital tools allow for the creation of consistent, sharply detailed pieces without the tediousness and variability of wax carving.

Applications:

Audiology

Hearing specialists and ear mold labs use digital workflows and 3D printing to manufacture higher quality custom ear products more consistently, and at higher volumes, for applications like behind-the-ear hearing aids, hearing protection, and custom earplugs and earbuds.

SLA 3D Printing Materials

SLA 3D printing materials are highly versatile, offering resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics. There are resins formulated specifically for manufacturing concerns like electrostatic discharge or flame retardancy, and resins formulated to mimic the mechanical properties of industry-familiar plastics. Biocompatible resins and skin-safe resins have been introduced to broaden the scope of SLA 3D printing applications, opening up doors in end-use products, medical equipment, 3D printing at the point of care, and medical procedure innovation.

Depending on the formulation and engineering, some resins can be considered pure materials, like true silicone or technical ceramic material.

Formlabs’ materials library of nearly 40 uniquely formulated resins opens up opportunities in applications across every industry. Resins include ESD Resin for manufacturing with electro-static dissipative qualities in electronics manufacturing, to Silicone 40A Resin for creating true silicone gaskets, air and fluid-flow devices, and more. Advanced materials like Alumina 4N Resin — 3D printing’s first accessible, technical ceramic — make possible new applications in aerospace, casting, nuclear waste handling, and more.

3D printing’s ability to create cost-effective parts with complex geometries makes innovation possible, and, with the right material, those innovative ideas can be tested, validated, and put into practice. Formlabs’ materials enable applications like mass-customized consumer goods, surgical tools, dental implants and appliances, manufacturing aids, rapid tooling, and more. Formlabs’ resin 3D printers make accessing these powerful workflows possible.

General Purpose Resins

Formlabs’ General Purpose Resins are formulated for speed and consistency to create parts in a range of applications and industries. From matte greyscale parts for design review prototypes to Clear Resin parts for millifluidics and transparent molds, General Purpose Resins are the workhorses of any materials library. Improvements in formulation and print settings allow new heights to be reached in speed, mechanical properties, and resolution — Fast Model Resin can print at speeds of 100 mm per hour, and Grey Resin V5 has an Ultimate Tensile Strength of 62 MPa.

| Material | Description | Applications |

|---|---|---|

| Fast Model Resin | Print speeds of up to 100 mm/hour | Concept models Review models |

| Clear Resin | The only truly clear material for plastic 3D printing | Parts requiring optical transparency Millifluidics |

| Grey Resin | Polishes to near optical transparency | Concept models Prototypes Fixtures, jigs Masking tools |

| Black Resin | Smooth, matte finish High resolution | Concept models Prototypes Fixtures, jigs Masking tools |

| White Resin | Smooth, matte finish High resolution | Models for painting Concept models Prototypes |

Engineering Resins

Formlabs Engineering Resins have been formulated to answer a specific need in the engineering workflow. These materials are designed to match or exceed the capabilities of industry-familiar materials like ABS or PLA. From rigid materials that can handle the compression in industrial molding applications to softer materials that are excellent at handling friction, Engineering Resins are relied upon in every industry to streamline operations and complete field testing.

| Material | Description | Applications |

|---|---|---|

| Rigid 10K Resin | Highly glass-filled Stiff, precise Withstand significant load | Injection molding Aerodynamic test models Heat-resistant jigs, fixtures |

| Rigid 4000 Resin | Smooth, polished finish Stiff, strong Simulates PEEK’s stiffness | Mounts and brackets Jigs and fixtures Thin-walled parts |

| Tough 1500 Resin | Strong, robust Compression-resistant Impact-resistant | Housing and enclosures Jigs and fixtures Connectors Functional testing prototypes |

| Tough 2000 Resin | Stiff, strong Bend-resistant | Housing and enclosures Jigs and fixtures Connectors Functional testing prototypes |

| Durable Resin | Simulates polypropylene Pliable Impact-resistant Low-friction | Assemblies Belt guides Squeeze prototypes Impact jigs and fixtures Snap-fit parts and flexures |

| Flexible 80A Resin | Rubber-like Soft, flexible | Handles, grips, overmolds Cushioning, dampeners Cartilage, tendon, ligament models |

| Elastic 50A Resin | Soft, flexible Repeated cycles without tearing | Wearables Compressible buttons Stretch enclosures, casings Actuators, end-effectors Soft-tissue anatomy models Special-effects props and models |

| Silicone 40A Resin | True silicone Softest Formlabs material | End-use flexible goods Short-run manufacturing Gaskets, seals Tubing |

Dental and Medical Resins

Formlabs dental and medical resins have been formulated to uphold the highest standards in compliance and safety with medical and dental practice governing bodies. Some resins, such as Precision Model Resin, are designed to deliver fast, precise models for the creation of orthodontic appliances. Others, such as BioMed Durable Resin, have been formulated in adherence to rigorous biocompatibility standards for safety.

| Material | Description | Applications |

|---|---|---|

| BioMed White Resin | Rigid and opaque white. Approved for long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). | End-use medical devices and device components; patient-specific implant sizing models and molds; cutting and drilling guides; surgical tools and templates; biocompatible molds, jigs, and fixtures; anatomical models that can be used in the OR. |

| BioMed Black Resin | Rigid and matte black. Approved for long-term skin (>30 days) and short-term mucosal membrane contact (<24 hours). | Medical devices and device components; biocompatible molds, jigs, and fixtures; end-use parts requiring patient contact; consumer goods. |

| BioMed Amber Resin | Rigid and semi-transparent. Approved for long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). | End-use medical devices; implant sizing models; cutting and drilling guides. |

| BioMed Clear Resin | Rigid and transparent. Approved for long-term skin (>30 days), breathing gas pathways, and mucosal membrane contact (>30 hours) or short-term bone, tissue, and dentin (<24 hours). | End-use devices, including gas pathway devices; biocompatible prototypes, molds, jigs and fixtures; models for visualization and implant sizing; cell culture and bioprocess devices. |

| BioMed Durable Resin | Impact, shatter, and abrasion resistant. Transparent. Approved for long-term skin (>30 days) and mucosal membrane (>30 hours) or short-term tissue, bone, and dentin contact (<24 hours). | Patient-specific instruments; single-use instruments; end-use devices and components requiring biocompatibility and impact resistance. |

| BioMed Elastic 50A Resin | Soft and silicone-like. Translucent. Approved forlong-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). | Comfortable medical devices requiring long-term skin contact; biocompatible soft tissue models surgeons can reference in the operating room. |

| BioMed Flex 80A Resin | Hard rubber-like. Translucent. Approved for long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). | Flexible biocompatible medical devices and components; medical devices requiring short-term mucosal membrane contact; firm tissue models to assist in surgeries. |

Specialty Resins

Several resins in Formlabs’ materials library have been formulated to fulfill a specific need in customer workflows. From integral but not high-visibility applications like electro-static dissipation to technical materials that haven’t been accessible for 3D printing before, such as true ceramic 3D printing, these resins unlock new applications for 3D printed parts.

| Material | Description | Applications |

|---|---|---|

| Flame Retardant Resin | Self-extinguishing Halogen free UL 94 V-0 certified Favorable FST ratings | Interior aerospace and automotive parts Protective and internal consumer products or medical electronics components Custom jigs, fixtures, and replacement parts |

| Alumina 4N Resin | High-density and high-purity technical ceramic Accessible workflow | High-voltage components Thermal protection Chemical resistance Foundry tools |

| ESD Resin | Static-dissipative | Tooling & fixturing for electronics manufacturing Anti-static prototype and end-use components Custom trays for component handling and storage |

| Castable Resins | Low ash content Easy burnout High resolution | High-fidelity jewelry pieces |

| Polyurethane Resins | Sturdy Accessible customized polyurethane parts | Protective casings, housings, and enclosures Static jigs and fixtures undergoing high stress Sturdy consumer products |

| Color Resin | High resolution Simple workflow | Bright, colorful parts Anatomical models Consumer products prototyping |

Bringing SLA 3D Printing In-House

Many businesses may have first been introduced to resin 3D printers through an outsourced part order, but the proliferation of options in the SLA 3D printing world has made it easier than ever to bring a resin 3D printer in-house.

There is a wide variety of prices and sizes to choose from, and there are high-quality options that are still extremely affordable and have streamlined workflows. With advances made in the speed, cost, and material versatility aspects of resin 3D printing, these machines have become reliable, consistently high-performing tools that can address problems in every type of workflow.

Control Your Supply Chain

3D printing in-house can look different for different types of professionals. Many large businesses, such as Microsoft or Rivian, choose to operate internal service bureaus, where engineers, designers, and manufacturing teams request parts from a centralized lab. Other businesses, especially those that are design and iteration-focused with high degrees of CAD expertise in their workforce, prefer a decentralized approach with a printer on every designer’s desk. Accessible, affordable, desktop-sized machines like Form 4 make these types of workflows possible and can present agile solutions for a changing workforce and office environment.

Whether centralized or decentralized, 3D printing in-house gives employees greater control over their workflows, and reduces costs and uncertainties for the business as a whole.

Scale as Production Needs Increase

Depending on the number of parts and printing volume, investment into a small format 3D printer can break even within months. With small format machines, it’s possible to pay for just as much capacity as a business needs and scale production by adding extra units as demand grows. Using multiple 3D printers also creates the flexibility to print parts in different materials simultaneously.

To make managing multiple resin 3D printers easier, Formlabs customers have access to two software platforms. Dashboard is a free software platform that helps them monitor their printers and streamline management. For added capabilities and advanced management tools, Fleet Control leverages automation to make printer assignment and consumables oversight more efficient.

Reduce Costs

Owning a desktop 3D printer results in significant savings over 3D printing service bureaus and traditional machining, as these alternatives rapidly become expensive with growing demand and production.

| Cost | Lead Time | |

|---|---|---|

| In-House SLA 3D Printing | $9-$28 | 1-5 hours |

| CNC Machining | $45-$340 | 2-3 weeks |

| Outsourced 3D Printing | $51-$137 | 1-3 weeks |

Get Started With In-House SLA 3D Printing

Formlabs offers desktop and benchtop SLA 3D printers that are fast and affordable and deliver high-quality parts with a wide range of material properties. The Formlabs resin 3D printing ecosystem is designed for ease of use and as few touchpoints as possible.

To continue exploring SLA 3D printing, start with feeling the quality of SLA for yourself: request a free sample 3D printed part in your choice of material to be mailed straight to your door.