Formlabs is proud to introduce the Fuse 1+ 30W Starter Package, an end-to-end solution for industrial selective laser sintering (SLS) 3D printing at an even more affordable price. Now for only 23,899 €, the Fuse 1+ 30W Starter Package includes the Fuse 1+ 30W printer, a Fuse Series Build Chamber, a Fuse Series Powder Cartridge, and the new Fuse Depowdering Kit, an affordable, manual solution for SLS post-processing and powder recycling.

For product designers, educators, and businesses looking to get started with SLS 3D printing, or for current Fuse Series users who’d like an easy, affordable solution for switching between materials, the Fuse Depowdering Kit is a cost-effective and efficient solution. At the Fuse 1+ 30W Starter Package’s accessible price point, businesses and individuals can bring SLS in-house, gain greater control over their means of production, and innovate with a powerful, industrial solution.

Unlock Affordable SLS 3D Printing And Easy Material Changeover With Fuse Depowdering Kit

Watch our product demo for a walkthrough of Fuse Depowdering Kit with Formlabs experts.

Accessible, Industrial Power

When the Fuse Series launched in 2020, it became the first truly affordable solution for industrial SLS 3D printing. End-use industrial-grade parts were finally within reach for businesses of any size, at a footprint and price that meant they could bring it in-house. Fuse Sift offered a complete, contained workflow, making the Fuse ecosystem even easier to integrate into established processes. Though the price point enabled many businesses to get started, and even scale production with fleets of Fuse Series printers, the complete package has still been out of reach for some — until now.

The new Fuse 1+ 30W Starter Package further removes the barrier to accessing powerful SLS workflows. For a tenth of the cost of many traditional powder systems, you can now begin to produce high-fidelity prototypes, end-use parts, manufacturing aids, and tooling with any material in the Formlabs SLS powder library. New business owners, product designers, and anyone looking to gain more control over their means of production now have access to the same professional quality parts offering industrial strength, flexibility, and durability.

Fuse Depowdering Kit: The Key to Affordable, Industrial SLS 3D Printing

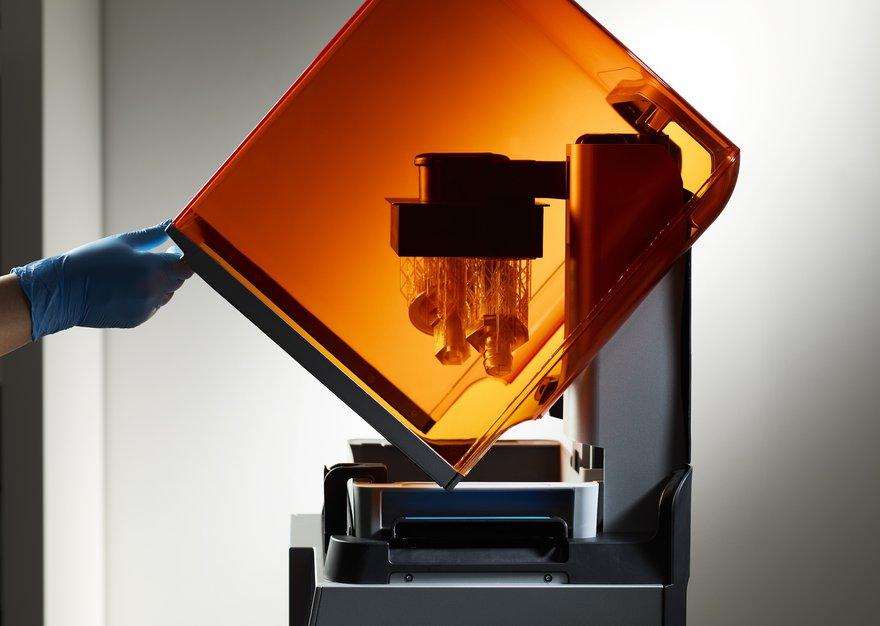

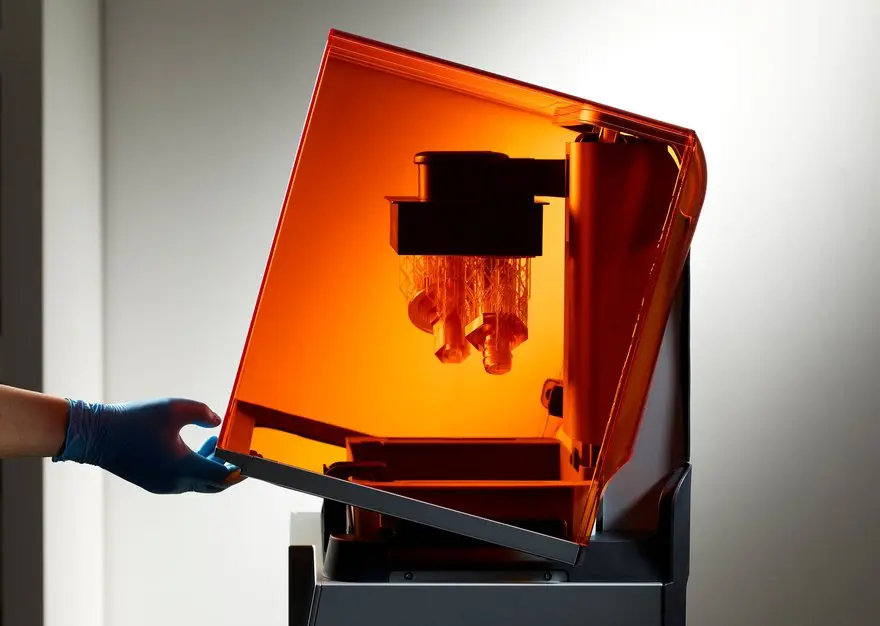

For anyone looking to get started with SLS 3D printing, the Fuse 1+ 30W Starter Package is an affordable option with the same professional results as the automated Fuse Sift workflow. The key is Fuse Depowdering Kit, a custom-designed package of manual tools for powder removal, recovery, and recycling.

1. Powder Removal

2. Recovery

3. Recycling

Though Fuse Sift has enabled many customers to scale up their SLS production to thousands of parts a month, many users don’t need to print at those volumes, and a manual solution can fit their workflow easily. Fuse Depowdering Kit makes it easy to remove unsintered powder in a contained area, then sieve, weigh, and mix that unsintered powder using custom-made tools into new powder cartridges. The process and tools are consistent, reliable, and easy to use, and users can still reach the same low cost per part as with the Fuse Sift, for marginally more hands-on work.

Expanding Materials and Applications for Current SLS Users

Formlabs has focused on expanding the SLS materials library, providing turnkey solutions for our customers’ unique applications. We know that materials are the key to unlocking new applications in which high-performance mechanical properties are most important.

The Fuse 1+ 30W Starter Package and Fuse Depowdering Kit remove the barriers to trying new materials, or operate with multi-material capability. There’s no need to make a choice and stay with one material or another — switching between materials is now faster and easier, optimizing workflows and improving products’ performance.

Switching materials on a Fuse Series printer and Fuse Sift takes around four hours, which is already substantially faster than the same exercise on traditional powder bed fusion 3D printing solutions. With the Fuse Depowdering Kit, switching to a new material is now possible in under two hours.

Switching Materials on SLS 3D Printers

| Fuse Series SLS 3D Printer + Fuse Sift | 4 hours |

|---|---|

| Fuse Series SLS 3D Printer + Fuse Depowdering Kit | 2 hours |

| Traditional SLS or MJF Powder Bed Fusion 3D Printers | 1 day or not possible |

Solutions at Any Size, Scaling With SLS

Traditional manufacturing processes, like injection molding, are cost-effective and efficient — they’re great for large scale manufacturers to continue mass-producing products. For innovators, disruptors, and any new business looking to improve or progress, new methods are necessary. The Fuse Series empowered those looking to change things, and with the Fuse Depowdering Kit and Fuse Starter Package now even more affordable, innovators can create high quality parts that can measure up to any end-use standard.

To learn more about the Fuse Starter Package and Fuse Depowdering Kit, watch the product demo webinar or contact our SLS 3D printing experts directly.