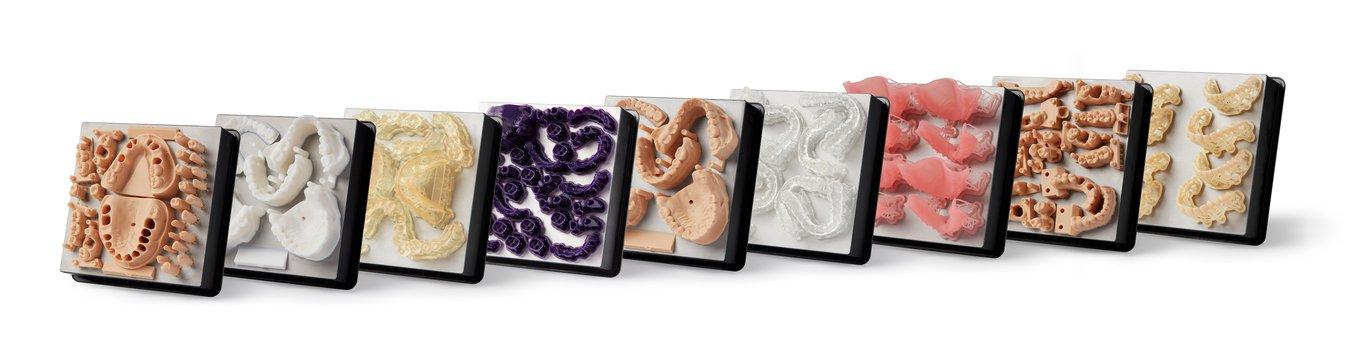

Herstellung von Hawley-Retainern auf 3D-gedruckten Modellen

Serienfertigung kieferorthopädischer Modelle für Draht-Retainer

Hawley-Retainer können digital auf einem 3D-gedruckten Modell gefertigt werden. Dadurch wird die Effizienz gesteigert und die Produktionszeit gesenkt. Jetzt kann jedes Dentallabor und jede Zahnarztpraxis diese Dienstleistung mit geringem Investitionsaufwand anbieten und im Unternehmen Retainer herstellen.

1. Scannen

Erfassen Sie die Patientenanatomie mit einem Intraoralscanner oder scannen Sie ein physisches Modell oder einen Abdruck mit einem Desktop-Scanner.

2. Design

Importieren Sie Scans in Ihre CAD-Dentalsoftware für virtuelle Entwürfe Ihrer Behandlungen oder senden Sie die Scans direkt zur Druckvorbereitung.

3. 3D-Druck

Bereiten Sie die 3D-Modelle mit der PreForm-Software für den 3D-Druck vor, bevor Sie sie an den Formlabs-Drucker senden.

4. Vorbereitung

Spülen und trocknen Sie gedruckte Teile mit dem Form Wash und härten Sie sie mit dem Form Cure nach.

Der Workflow zur Herstellung von Hawley-Retainern auf 3D-gedruckten Modellen

5. Auftragen des Trennmediums

Das Trennmedium verhindert, dass sich das gedruckte Modell während der PMMA-Polymerisierung an den Retainer aus Acrylglas bindet.

6. Herstellen des Drahtgerüsts

Verwenden Sie eine Drahtzange, um den Drahtbogen zu formen und passen Sie ihn an das Gebiss des Patienten an.

7. Auftragen von Acrylglas

Tragen Sie Acrylglas mit den selben Techniken auf, die Sie auch bei traditionellen Steinmodellen verwenden würden.

8. Nachbearbeitung

Glätten Sie alle Oberflächen und tragen Sie eine Wachsschicht auf, um ein glänzendes Finish zu erzielen.

Schnelle und kosteneffektive Produktion

Der 3D-Druck von Modellen muss effizient, schnell und zuverlässig sein. Mit dem Form 3B können Sie große Modelle über Nacht und kleinere Modelle tagsüber drucken, um Arbeitszeit einzusparen und die produzierte Menge zu maximieren. Mit steigenden Anforderungen können Sie die Produktion leicht steigern, ohne Zehntausende Euro für jedes weitere Gerät aufwenden zu müssen.

| Indikation | Kapazität auf dem Form 3B |

|---|---|

| Kieferorthopädische Modelle mit Gaumen | Bis zu 7 Modelle pro Druck in ~5 h |

3D-Druck von Modellen für Hawley-Retainer mit 3D-Druckern von Formlabs

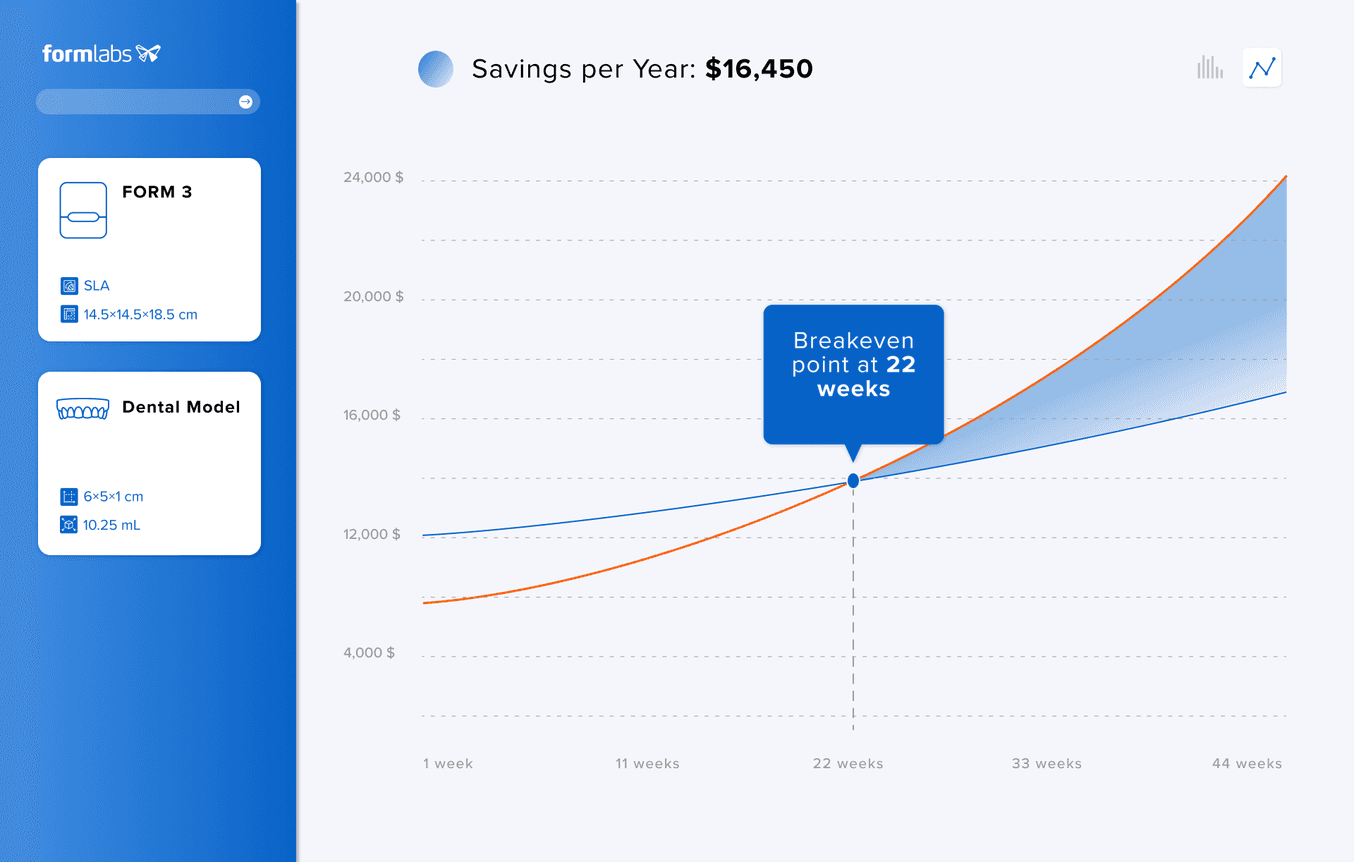

Geringe Kosten und schnelle Rentabilität

Bevor Sie eine neue Technologie für Ihre Zahnarztpraxis oder Ihr Dentallabor anschaffen, müssen Sie die finanziellen Aspekte genau kalkulieren. Der Druck von kieferorthopädischen Modellen auf dem Form 2 ist günstig und erfordert weniger Arbeit als bei anderen 3D-Druckern.

| Kosten | Durckkosten auf dem Form 3B |

|---|---|

| Kieferorthopädische Modelle mit Gaumen | 2,50-3,50€ pro Modell |

Das berichten unsere Kunden über die Arbeit mit 3D-Druckern von Formlabs

„Der Form 2 ist sehr zuverlässig; wir nennen ihn unser Arbeitspferd. Wir können uns darauf verlassen, dass, wenn wir abends nach Hause gehen, am nächsten Morgen alles gedruckt ist. Es gibt keine Ausfälle, alles ist da. Darum können wir unser Geschäft um die Drucker aufbauen.” – Sean Thompson, Adv.Prosth/Adv.Orth./DIP.PS.(dist) M.P.T. M.M.U./L.O.T.A., Gründer und Director von Ashford Orthodontics