Latest News

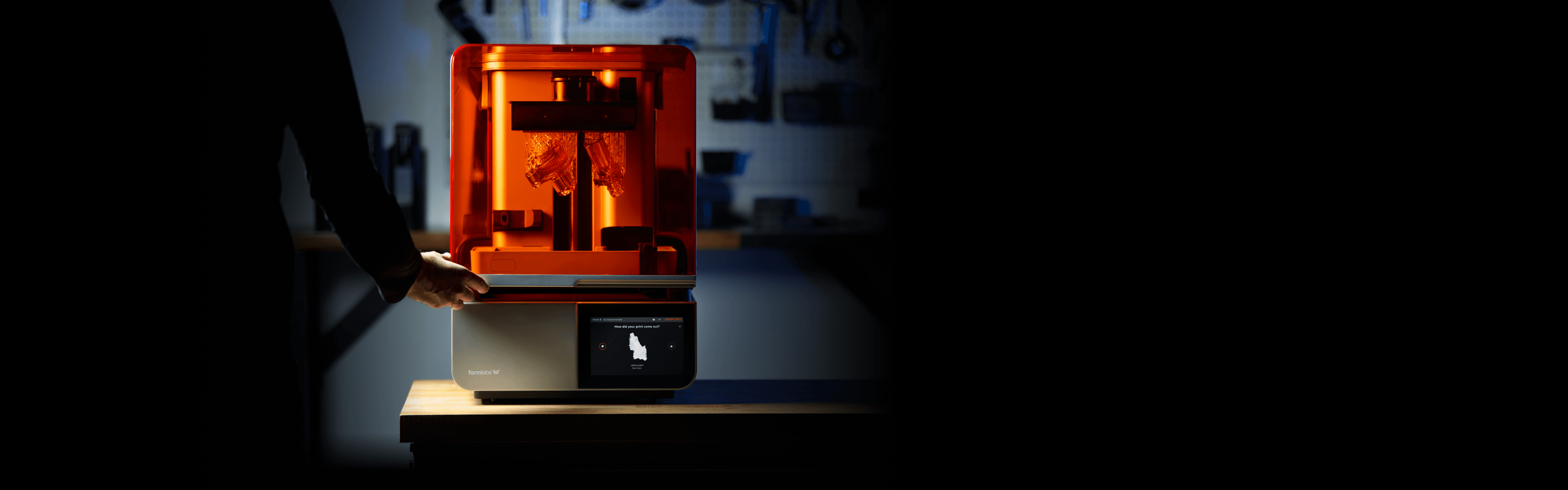

Form 4: Unmatched Speed, Accuracy, and Reliability to Redefine 3D Printing

Form 4 represents the next evolution in SLA 3D printing, built upon years of groundbreaking hardware, software, and materials science innovations. With unprecedented speed, Form 4 delivers the majority of parts in under two hours, in all materials, without ever compromising on dimensional accuracy or surface finish.

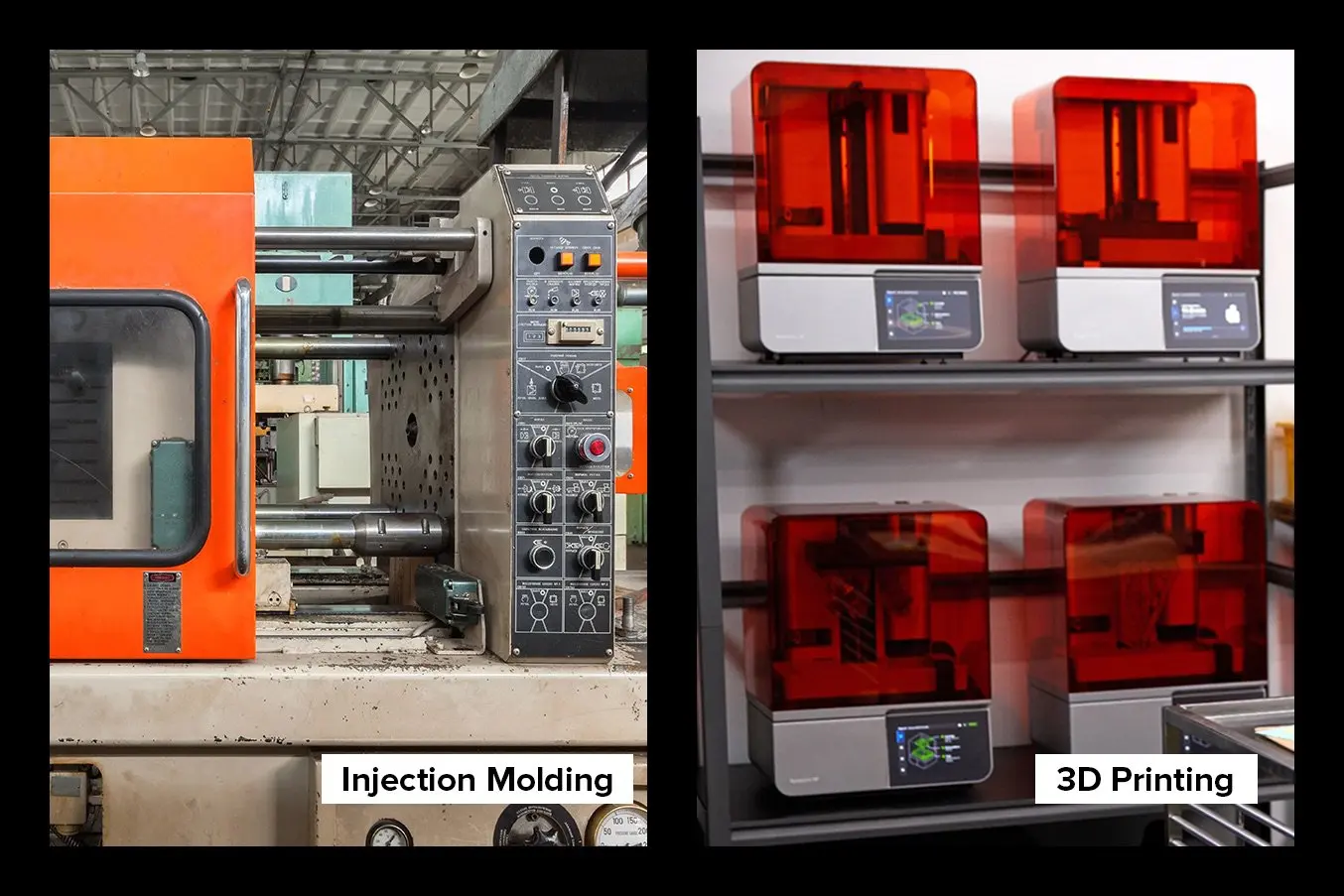

Form 4 Beats Injection Molding Machine in Speed and Quality

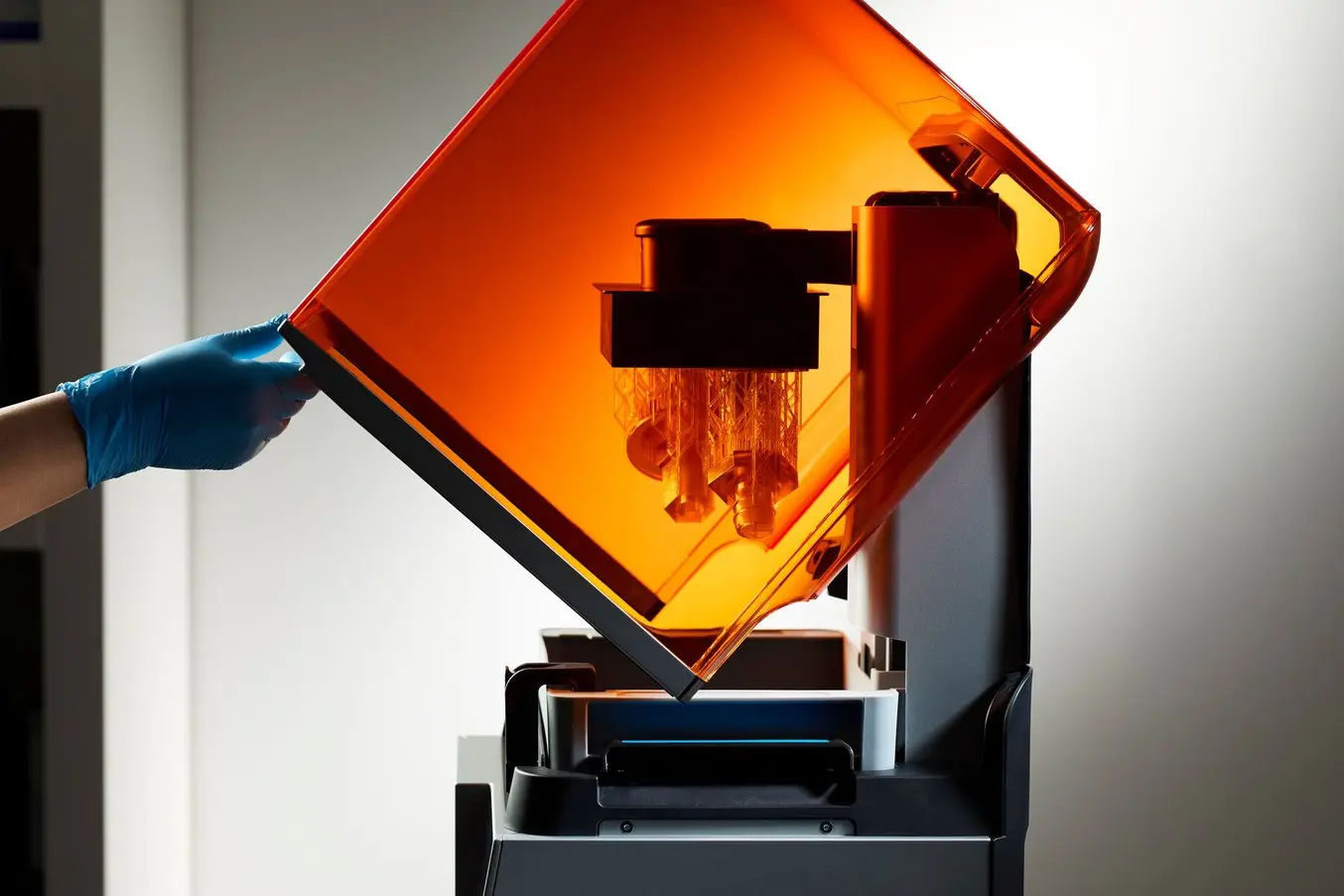

SLA 3D Printers

Our Form Series SLA 3D printers quickly delivers incredible surface quality and print accuracy with the widest range of materials, meeting the demands of today’s market for scalable, reliable, industrial-quality 3D printing.

SLS 3D Printers

The Fuse Series are the first benchtop industrial SLS 3D printers that offer high quality end-use parts in a compact footprint. The complete, simplified workflow delivers high throughput at a fraction of the cost of traditional industrial SLS systems.

Make Anything With Formlabs 3D Printers

Turn your ideas into high-fidelity prototypes that look and work like final products within a day and bring better products to market faster.

Turn your ideas into high-fidelity prototypes that look and work like final products within a day and bring better products to market faster.