If you use a stereolithography (SLA) 3D printer, it’s essential to know how to post-cure your resin 3D prints. Post-curing enables parts to reach the highest possible strength and become more stable. However, each resin behaves slightly differently when post-cured, and requires different amounts of time and temperature to arrive at the material’s optimum properties.

Download our guide on post-curing resin prints to learn the basics of post-curing and how post-curing affects each Formlabs resin

Why Should I Cure Resin Prints?

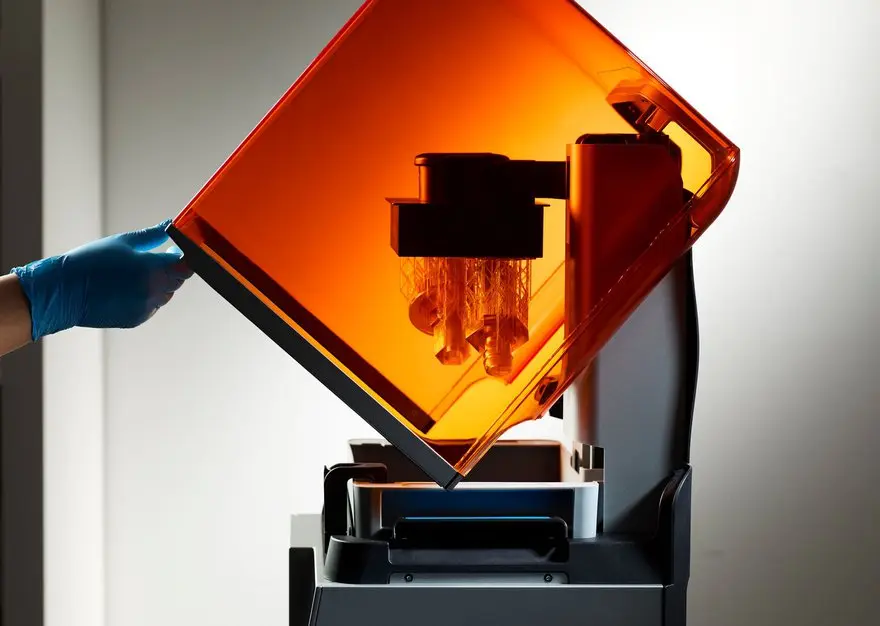

Each Formlabs Resin is formulated with advanced, light-sensitive polymer chemistries. Formlabs stereolithography (SLA) resin 3D printers, such as the Form 3+, Form 3B+, Form 3L, and Form 3BL use 405 nm lasers to cure the liquid resin, producing a highly accurate solid part.

When a resin 3D printed part finishes printing, it remains on the build platform in a “green state.” This means that while parts have reached their final form, polymerization is not yet fully completed and the part has yet to attain maximum mechanical properties. Post-curing with light and heat is key to unlocking this last mile of material properties for SLA 3D prints.

Achieving optimal properties is especially essential when using functional or specialty resins. For biocompatible materials, post-curing is necessary to achieve the safety standards determined by regulatory agencies.

How Long Should I Cure Resin 3D Prints?

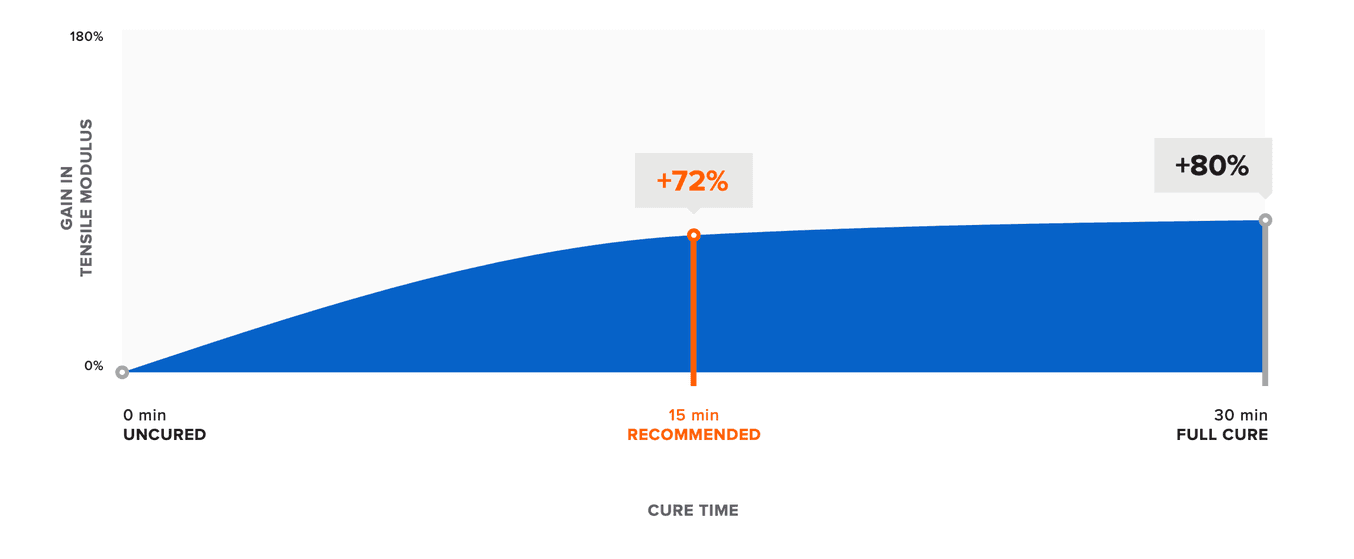

An ideal post-cure setting achieves the properties you need in the most optimized amount of time. For Formlabs Standard Resins (White, Grey, Black, and Clear), this amount may be none at all, or a short 15 minute post-cure. Where strength, rigidity, and temperature resistance are needed, Formlabs Engineering Resins improve with post-cure of up to 120 minutes.

Formlabs developed an in-house post-cure study to identify optimized settings for each individual Formlabs Resin. Using the ASTM method, our materials scientists tested a variety of mechanical properties at various temperatures for each material.

Material properties, such as modulus, are improved by post-curing printed parts. Each type of Formlabs resin requires unique post-cure settings. Please refer to the official Formlabs data sheets with ASTM testing for more information.

Find all up-to-date recommended post-cure settings for Form Cure or Form Cure L on our website. Material data sheets with specific mechanical properties after the recommended post-cure are available for download on our website.

Post-Cure Hardware

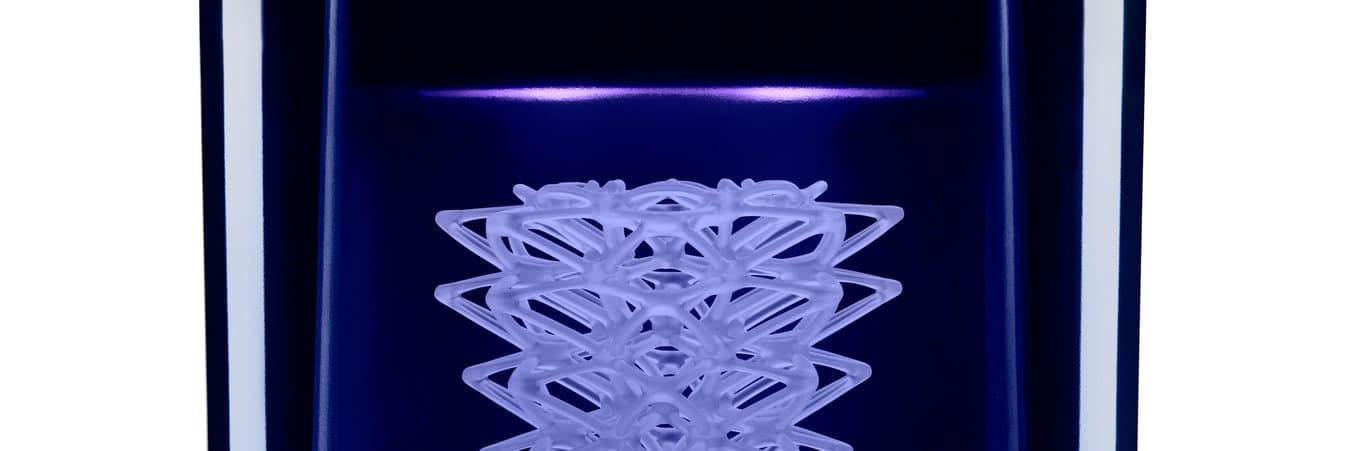

Many methods for post-curing exist, from curing simply with light (natural sunlight, UV nail salons, UV curing stations, DIY UV cure boxes, etc.) to using both light and heat. Heat accelerates the process and enables even more complete bond formation, resulting in increases in material properties impossible to achieve with light alone.

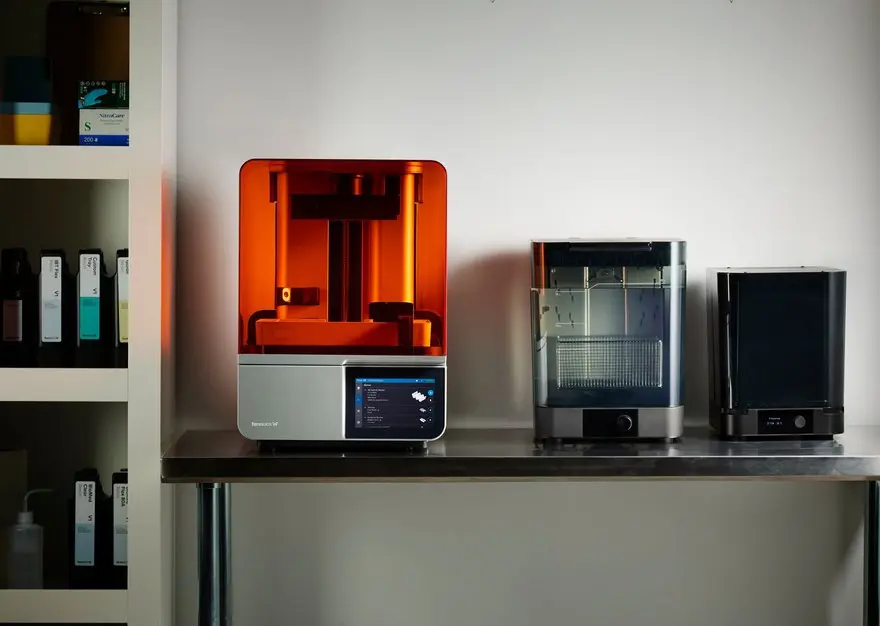

Form Cure and Form Cure L, the two post-curing solutions from Formlabs for desktop and large-format SLA professional 3D printers, are designed to post-cure parts printed in Formlabs Resins with speed and consistency. With Form Cure and Form Cure L, SLA 3D printed parts can be post-cured at precisely the correct wavelength, at different temperatures, and for varying lengths of time.

Get Started With Curing SLA Resin 3D Prints

Use Formlabs Post-Curing Guide to understand how post-curing affects the key properties of each Formlabs Resin, and determine the optimum post-curing plan for your application.

Download the guide to learn:

- How post-curing affects the key properties of each Formlabs material

- Optimum post-curing recommendations for material-specific applications

- Strategies for avoiding common post-curing issues