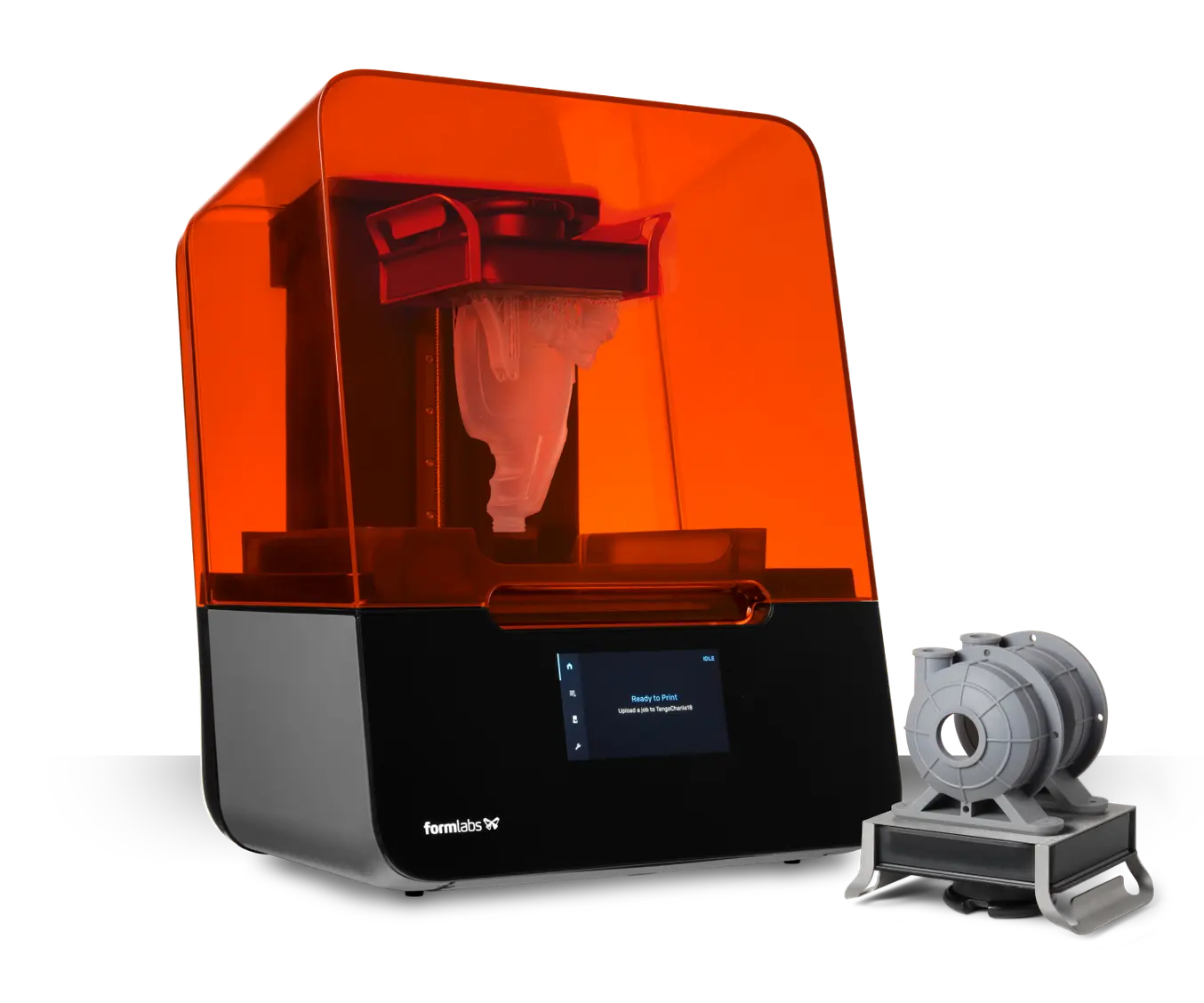

Form 3+

Flawless Parts, Every Time

Trusted by tens of thousands of professionals around the world. Whether you need rugged performance parts or accurate details, the Form 3+ delivers.

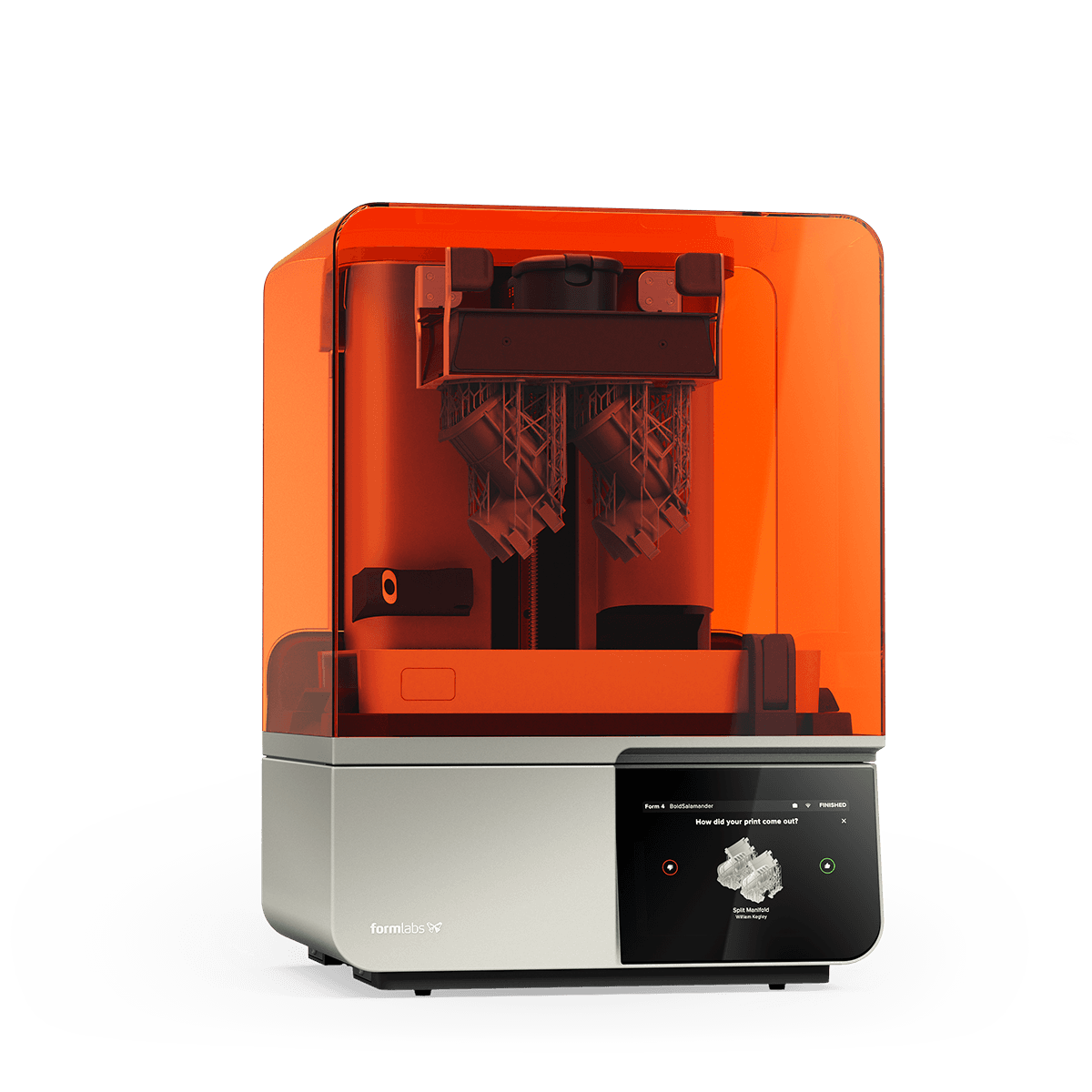

Form 3+ is now succeeded by Form 4, our next-generation MSLA 3D printer, which improves upon its foundation in every possible way.

The Next Generation of Industrial 3D Printing

Form 4 is powered by our Low Force Display™ (LFD) Print Engine, setting the new industry standard for blazing-fast speed, unmatched reliability and accuracy, and the widest range of performance 3D printing materials.

24/7 Reliability, At Your Service

Form 3+ offers industry-leading technology and support so you can spend less time troubleshooting and more time printing.

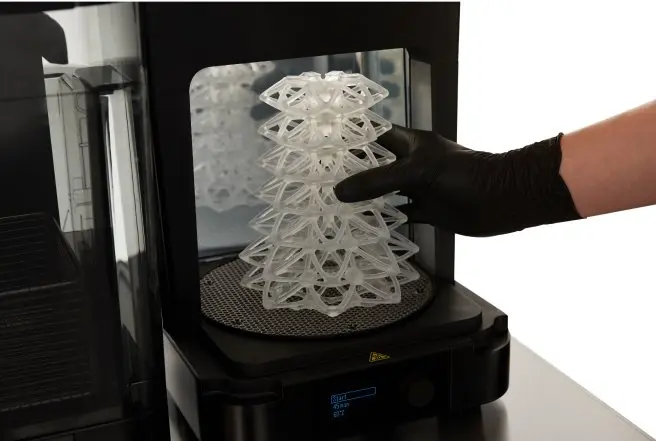

The Parts You Want, Every Time

Best-in-class printer reliability and accuracy means your parts come out right the first time.

We Help You Succeed From The Start

Get up and running right away with personalized onboarding remotely or onsite.

Service With A Human Touch

Expert service, whenever you need it. When required, we come to you for implementation, training, optimization, and repairs.

Advanced Materials for Industrial-Quality Parts

Bring your parts to life with the most comprehensive library of high-performance materials on the market, designed to deliver industrial-grade parts that are up to any challenge.

30+ Validated Materials, Ready To Be Put To The Test

Each Formlabs material comes with optimized print settings to guarantee industry-leading print success and reliability, as well as standout mechanical, thermal, or biocompatible properties.

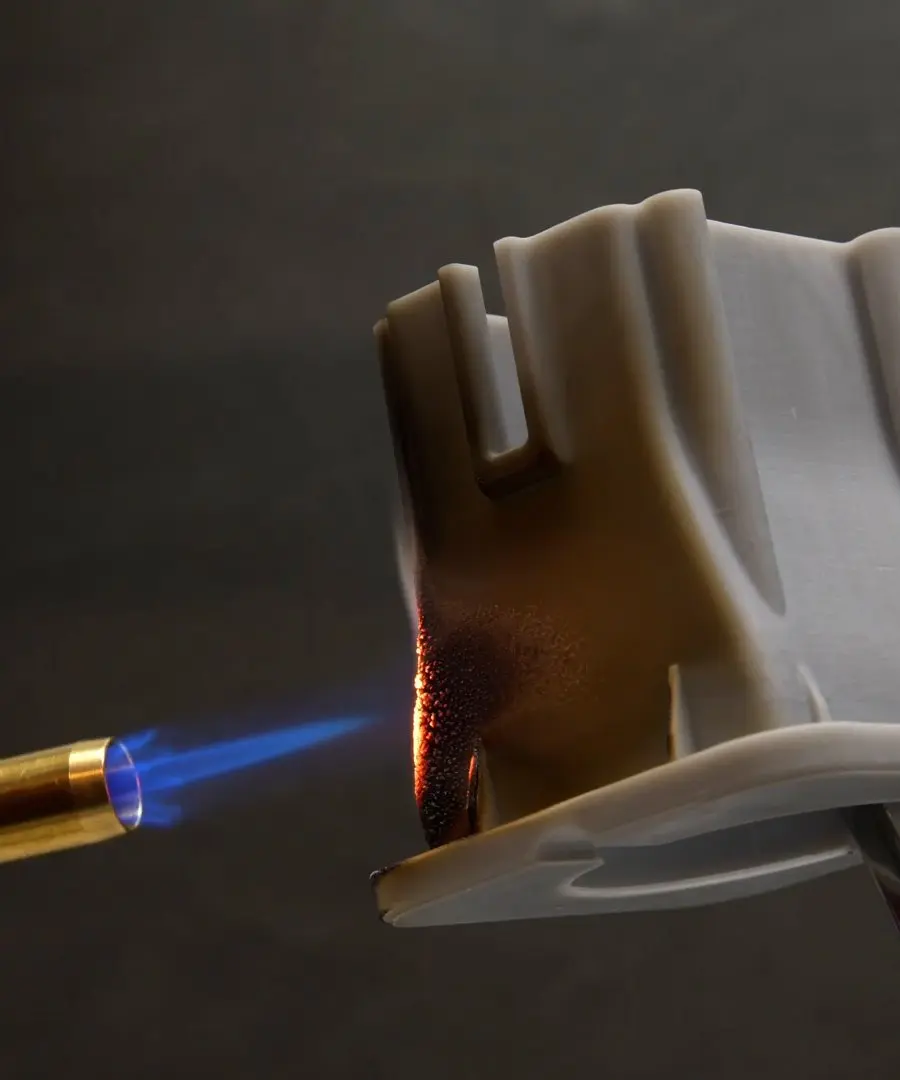

Boundary-Breaking Photopolymers

Specialized materials offer UV stability, flame retardancy, ESD resistance, glass-filled rigidity, biocompatibility, and more.

Total Freedom With Open Platform

Enhance your printer’s versatility with certified third-party materials, customizable print settings, or the ability to print with any unvalidated 405 nm photopolymer resin (optional, paid license).

An Easier, More Efficient Workflow

Go from design to finished part in fewer steps than ever with the streamlined, end-to-end Form 3+ ecosystem.

Hassle-Free Materials Management

Seamlessly switch between a wide range of materials in seconds with our spill-free, swappable cartridge system.

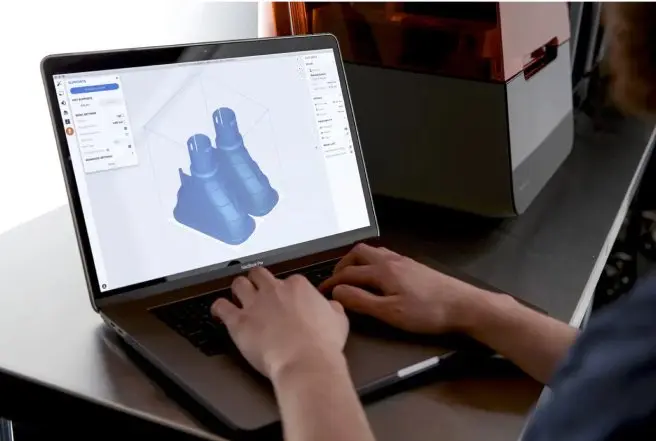

Intuitive Software

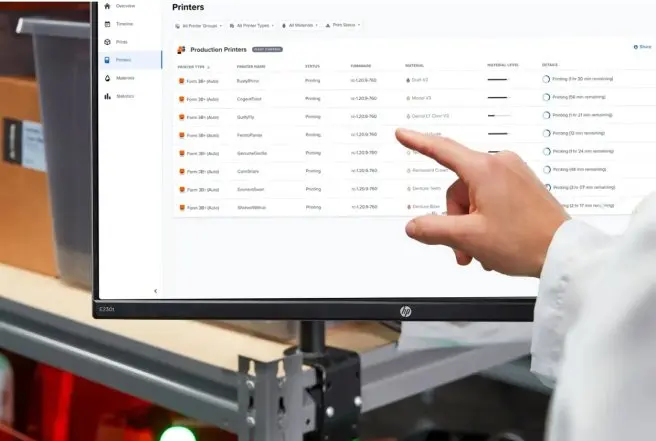

Prepare parts in PreForm with just a few clicks and manage printers, consumables, and teams through your online Dashboard.

Powerful Automation Tools

Minimize cost per part and unlock 24/7 production with the Formlabs Automation Ecosystem.

Pre-Production Validation

Tough 1500 ResinForge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

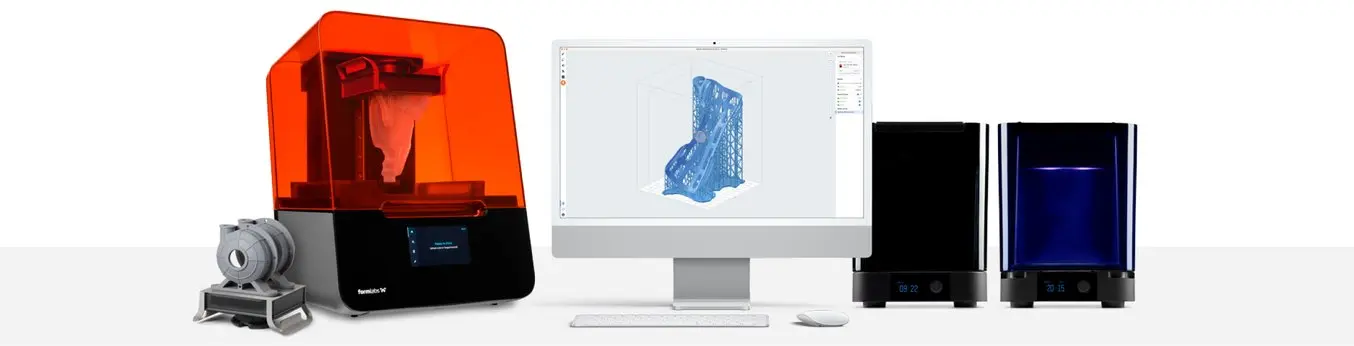

Form 3+ Ecosystem At A Glance

Get more done in a day with the Form 3 Series ecosystem, where every step was designed to save you time.

Materials

Print Preparation Software

3D Printer

Accessories

Post-Processing

Print Monitoring Software

Make Anything At Scale

With Formlabs Automation Ecosystem

Reach new levels of productivity with a fully-automated Form 3+ printer fleet you can operate from anywhere, at any time. Unlock 24/7 production with the Formlabs Automation Ecosystem: Form Auto, Fleet Control, and Resin Pumping System.

100,000,000 Parts Printed With Formlabs Technology