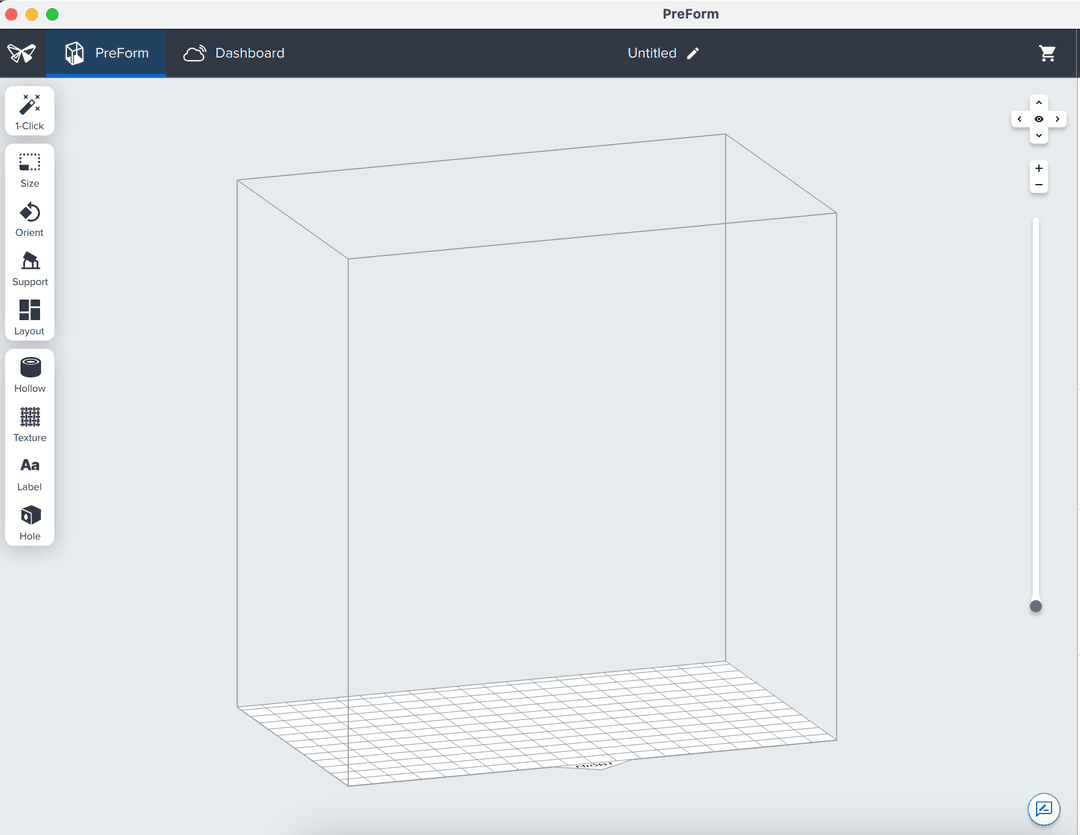

Formlabs’ new software update, PreForm’s Speed Optimized Beta v5.2 setting, dramatically improves print outcomes for parts printed on the Fuse Series with Nylon 12 Powder while maintaining the increased speed of previous versions.

For Formlabs’ selective laser sintering (SLS) customers, both part reliability and speed are crucial to success, but we know that for many, improvements in speed seemed to come with a less reliable surface finish or part performance. After exhaustive testing, the new Speed Optimized Beta setting v5.2 has been developed to maintain the increased print speeds while reducing any degradation in accuracy across the Z-axis. Formlabs SLS customers vary widely in how they prioritize speed, accuracy, throughput, and surface finish. This new beta setting offers the improved speed some customers have prioritized with Speed Optimized Beta setting v5.1, while improving the quality and accuracy of their parts.

Improved Accuracy and Reduced Z-Axis Warpage

These parts have been printed on the Fuse 1+ 30W and oriented vertically, with their greatest length along the Z-axis. When the parts are placed flat on the table and pressed down on the ‘bottom’ ends, their ‘top’ edges lift up, demonstrating how much the part has warped along the Z-axis. The part on the left used v5.1 and the part on the right used Speed Optimized Beta v5.2. The part on the right shows a marked improvement in warpage along the Z-axis.

Since a previous speed increase setting was released, customers taking advantage of faster print speeds have reported occurrences of warping in parts along the Z-axis. With the new speed setting, warping is reduced by more than 50%. To reduce warpage, our team altered the Z-scaling factor — meaning that the way PreForm scales your parts to account for the SLS printing process has changed slightly. However, the new maximum part size in the Z-axis is 294.1 mm, only 1.4mm shorter than previous versions.

Surface Dimpling - Unchanged

The rate of dimpling on parts printed with Speed Optimized Beta v5.2 is comparable to that of Speed v5.1, with no significant differences. However, parts printed with Speed Optimized Beta v5.2 settings are more prone to exhibit dimpling on the surface compared to parts printed with Default v4.1 settings.

Dimpling occurs when the top surface of a printed part caves slightly in. If this defect is severe enough, it manifests across several layers as a puncture and is called pitting.

Print Speed - Unchanged

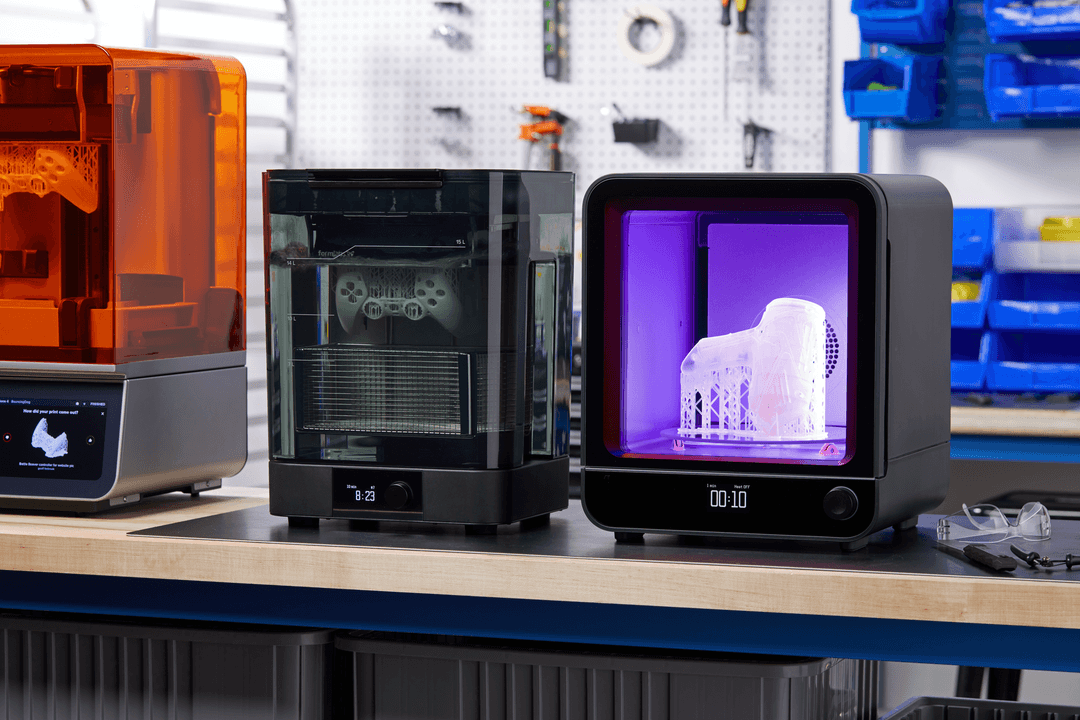

The Speed Optimized Beta v5.2 settings maintain the same fast, efficient print speeds introduced by v5.1. For customers who value productivity and throughput, or fast one-time prints needed for quick iteration, any Speed Optimized setting can improve your workflow. The Speed Optimized Beta v5.2 setting will maintain that speed, while improving part quality. Build chambers can be removed from the Fuse Series printer and a new print started sooner than with V4.2 settings, leading to more parts per day than was previously possible.

Print Cooldown - Increased

While printing and lasing times remain unchanged, Formlabs recommends a slightly longer cooldown period for optimal results. A 30% longer cooldown time is recommended from previous Speed Optimized v5.1 settings. This is 2x the cooldown time of Default settings v4.1. This cooldown can occur outside the Fuse Series printer, enabling the use of additional build chambers to start new prints without delay.

Due to the increased efficiency of Speed Optimized Beta v5.2 settings, the powder cake will remain noticeably hotter after the same out-of-printer cooling duration compared to Speed Optimized v5.1 and Default v4.1 settings. This is a result of the faster printing speeds that make this such a highly efficient print setting. Customers should take extra caution when unpacking parts, and refer to published print cooldown times in PreForm as a helpful guide for when builds can be unpacked. Premature unpacking can cause parts to warp.

Surface Armor Removal

The process of removing unsintered powder and semi-sintered Surface Armor from parts printed using Speed Optimized Beta v5.2 settings vs. previous speed settings may differ slightly. Because bed temperate control impacts to what degree Surface Armor is sintered, you should complete the bed temperature turning process on your Fuse Series printer before starting a project.

Choose the Best Fuse Series Print Setting For Your Needs

| Legacy (2.2) | Default (4.1) | Speed Optimized (5.1) | Speed Optimized (5.2) | |

|---|---|---|---|---|

| Dimpling (Bed Temp) | Best | Good | Fair | Fair |

| Z Direction Warp | Good | Fair | Fair | Best |

| Fine Feature Res | Fair | Best | Good | Good |

| Z Accuracy | Good | Fair | Fair | Best |

| Birchbark (Bed Temp) | Good | Fair | Good | Best |

| Time Between Prints (From Start to Removal of Build Chamber) | Good | Good | Best | Best |

| Time to Part (From Start to Cooldown Complete) | Good | Good | Best | Fair |

Fast Print Speeds With Improved Accuracy and Tolerances

PreForm’s Speed Optimized Beta setting v5.2 demonstrates Formlabs’ commitment to continuous improvement in every facet of our customers’ experience. Offering multiple settings allows our customers to tailor their workflow to their particular needs, yet offers the guarantee that each setting has been exhaustively tested and engineered for performance.

This new update answers customer feedback to improve the overall quality of your production, whether you’re printing single tall parts or stacking small ones, reducing their variance throughout the Z-axis improves consistency.

To update PreForm with this new setting, visit our page. To read the support article on using Speed Optimized Beta settings, visit our services website.