The Form 4 Ecosystem

Complete Your 3D Printing Experience

Discover how you can improve your productivity, part quality, and workflow, as well as reduce costs and lead time by upgrading to Form 4 from Form 3 or Form 3+.

Improvement

form 4 vs. form 3

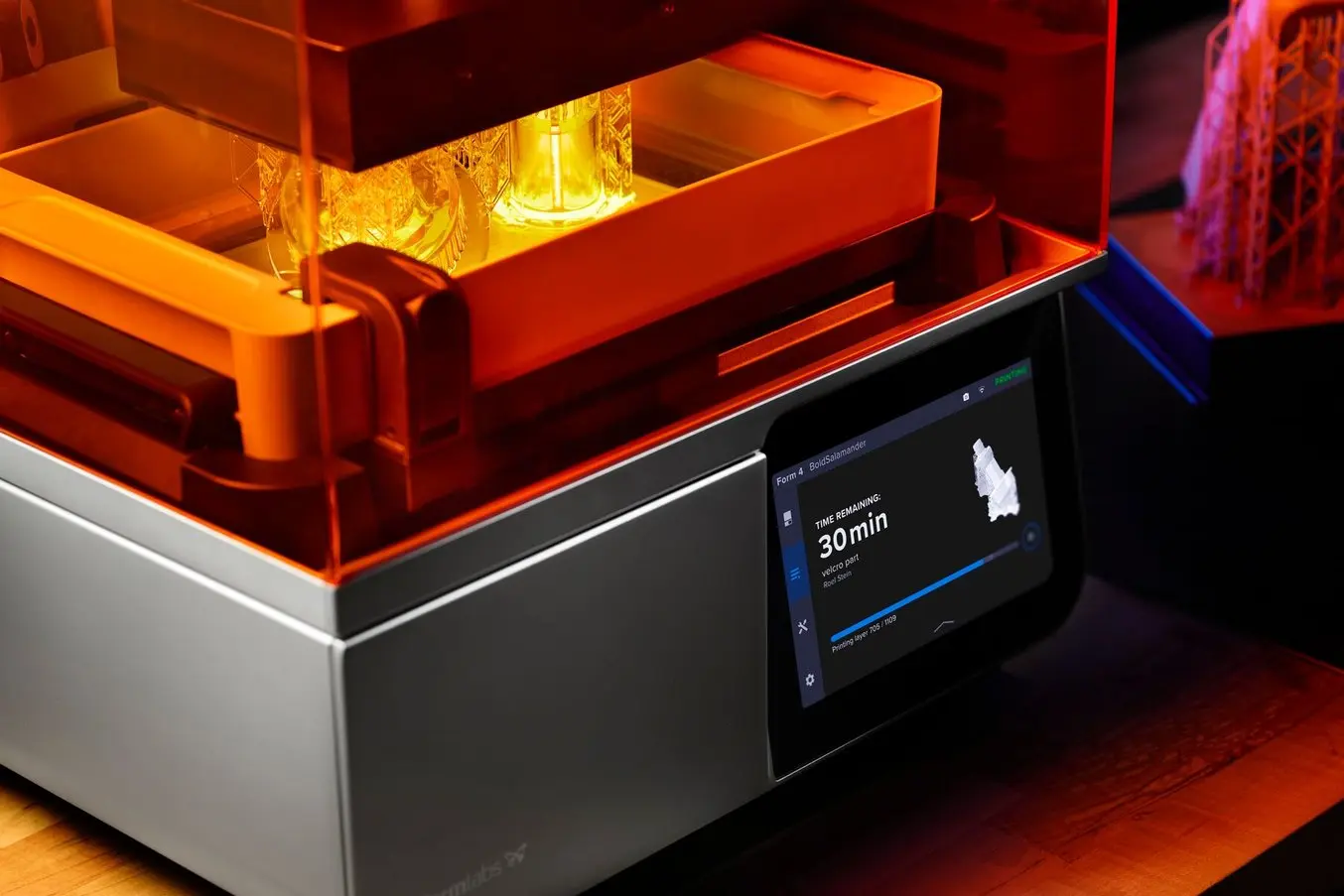

Most prints are completed in under two hours for faster iterations or more efficient production.

“The dramatic increase in print speed for Form 4 has significantly accelerated our fabrication cycle.”

NASA Goddard Space Flight Center, Matt Mullin, Laser Engineer, Laser and Electro-Optics Branch

"I really appreciate the reliability paired with the speed. It's not one or the other, like many other tools. Now I can commit to internal deadlines and feel confident that I can deliver every time."

Robert Mackowiak, Rapid Prototyping Engineer, Hasbro

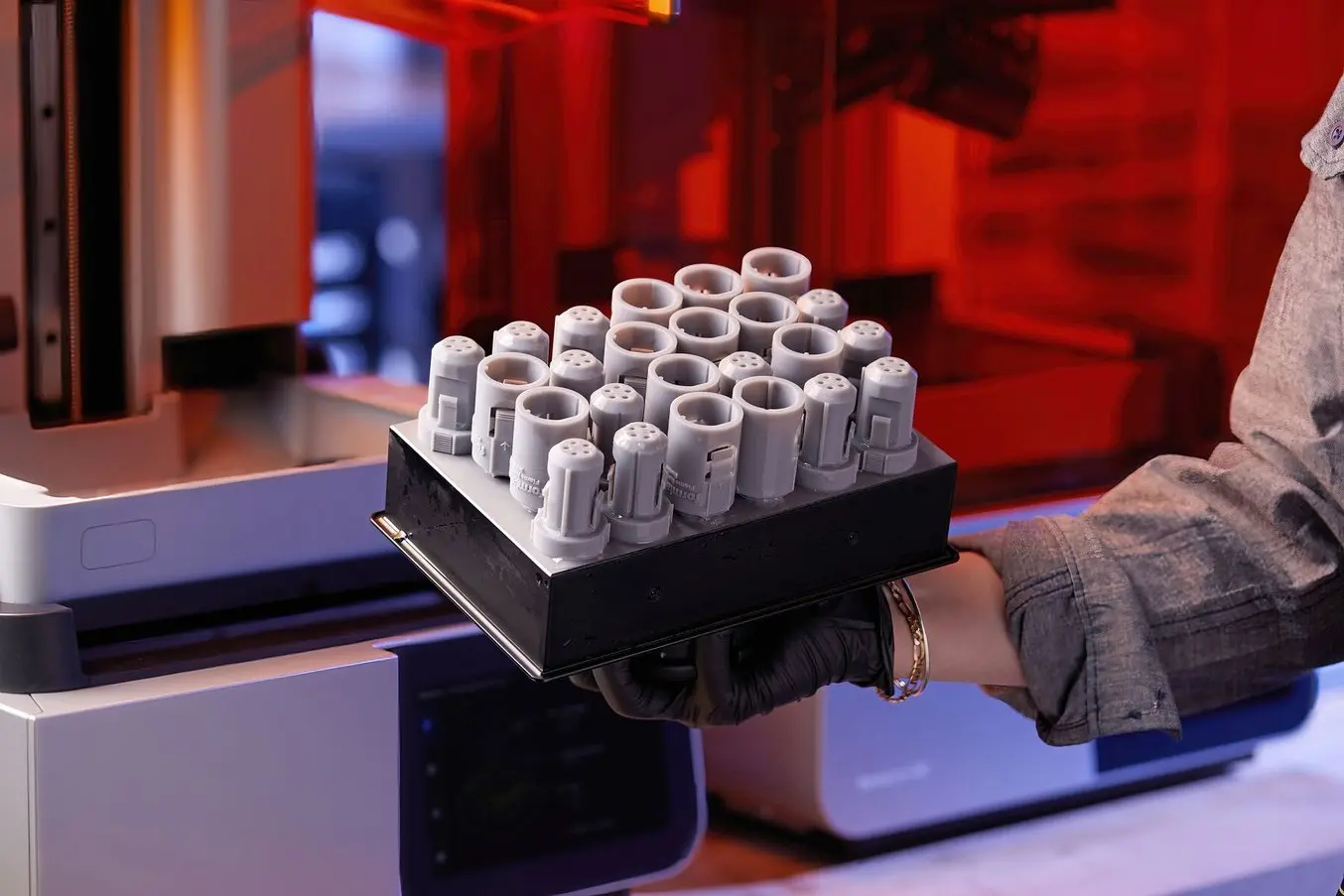

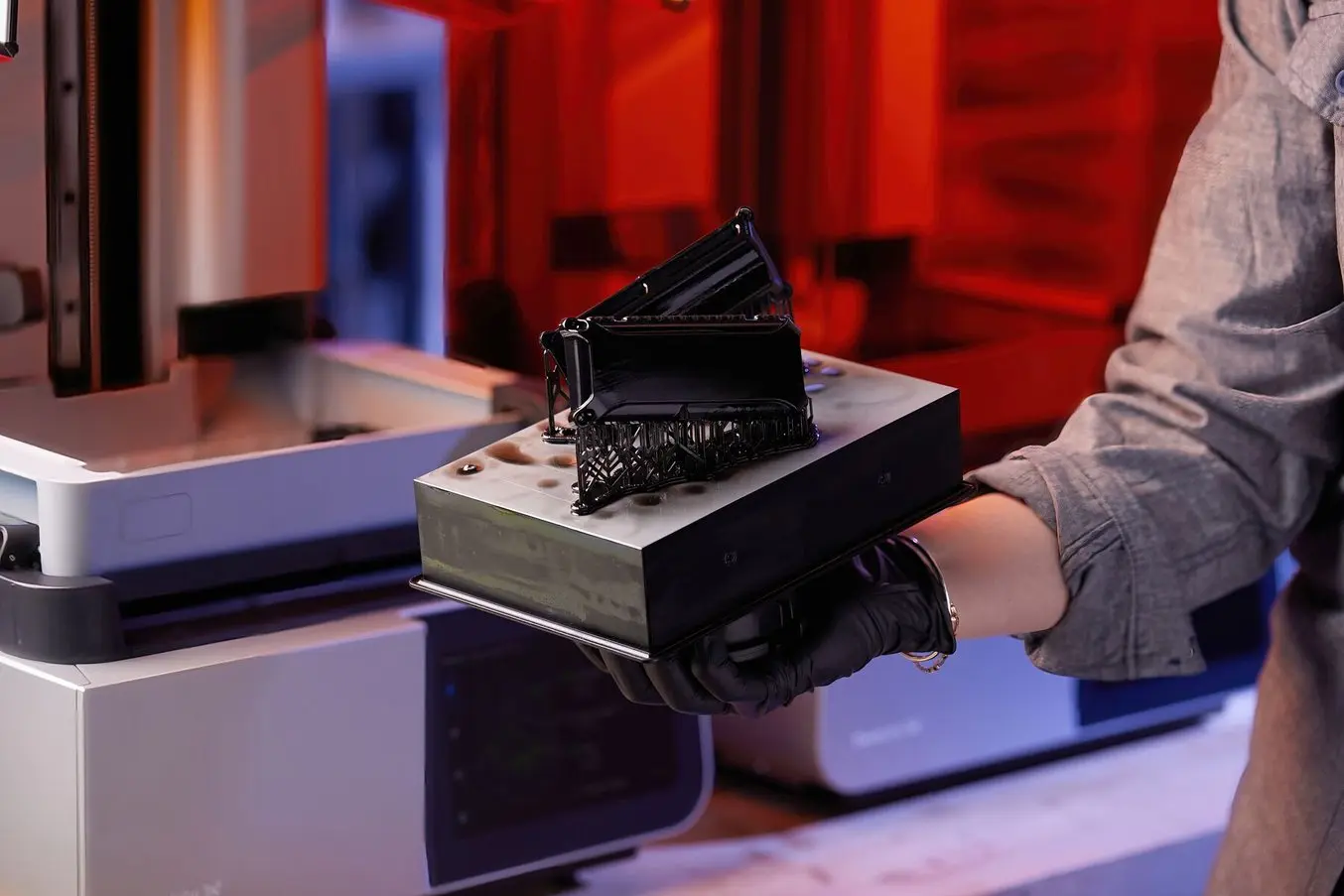

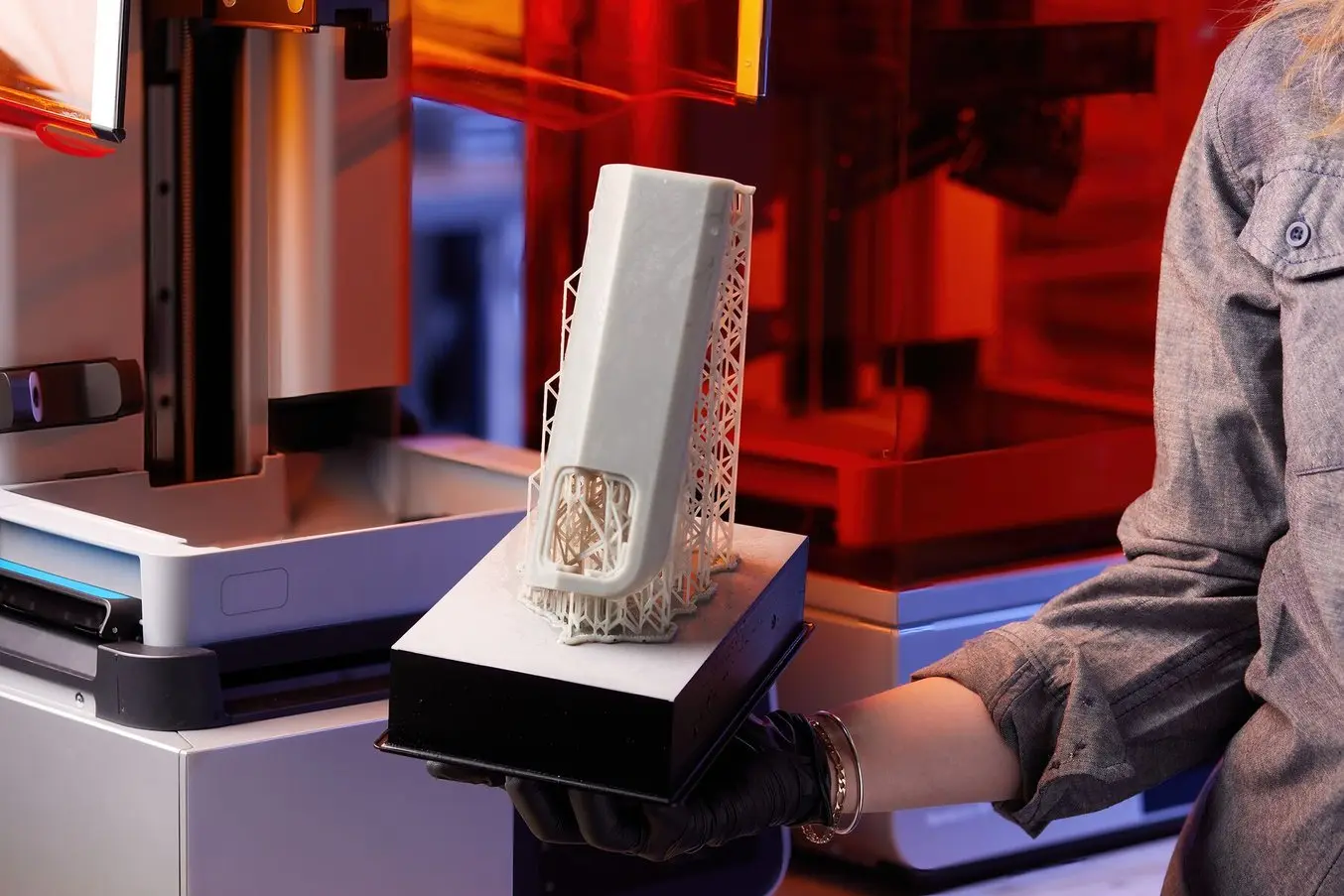

Increase productivity by printing more parts in a single build or optimizing orientation for faster print speed.

Our new General Purpose Resins provide higher performance, richer color, and crisper features – all at a fraction of the price of the Form 3/+ equivalents.

"Form 4's speed and materials versatility enable us to create multiple prototypes and manufacturing aids every day.”

Bruno Alves, Additive Manufacturing Expert and Tooling Specialist, Ford

Improved aesthetics enable presentation-ready parts and end use part production.

Produce parts with the finest and most intricate features.

"Form 4 is our go-to choice for projects needing tight tolerances and engineering-grade materials.”

Mark Honschke, Additive Prototyping Lead, Microsoft

Substantially lower operating costs thanks to cost-effective materials and long-lasting consumables.

Minimize upkeep costs and waste with long-lasting consumables.

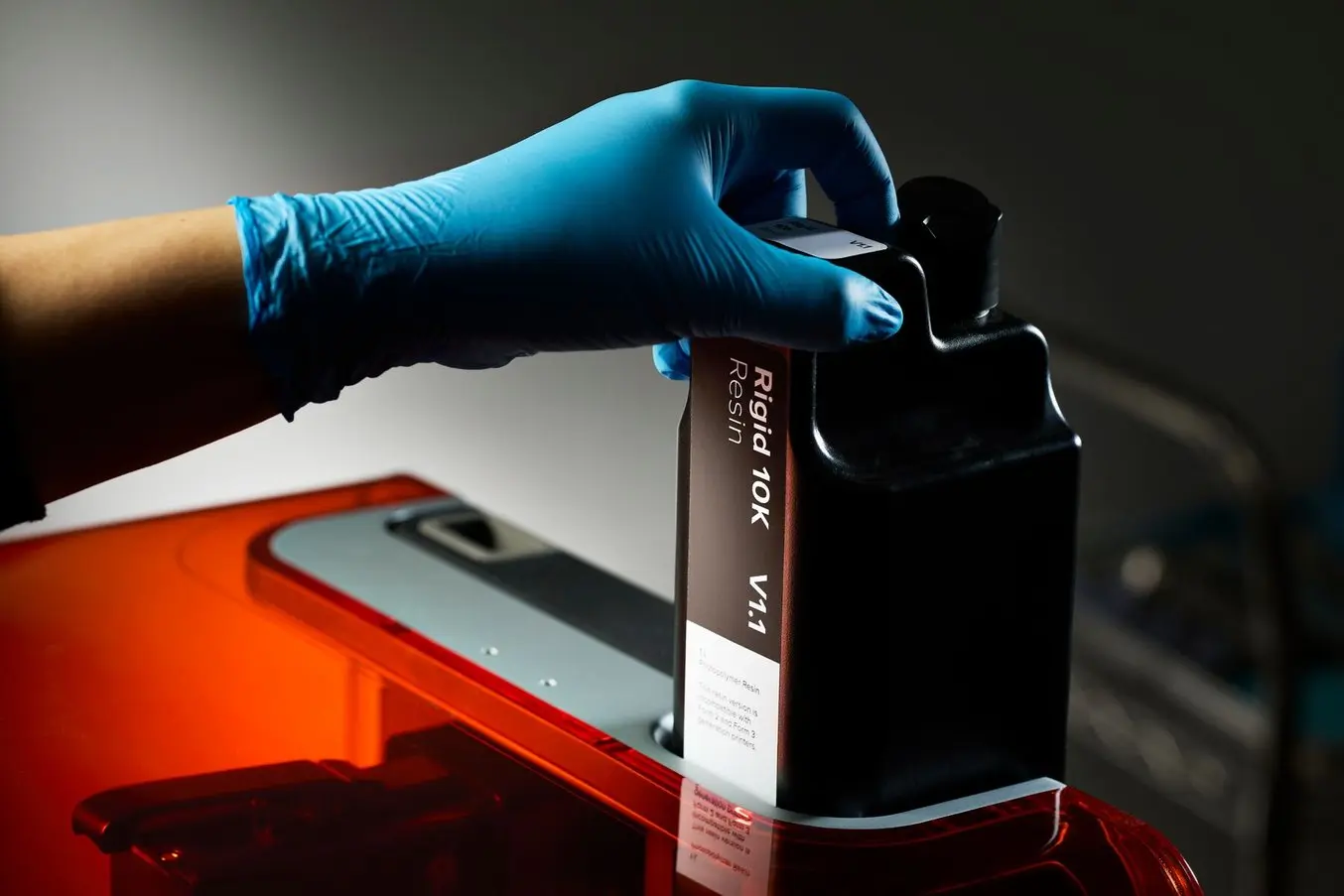

Our next-generation resin cartridge enables hassle-free, efficient, and fast automatic resin dispensing.

Access images and timelapses online to remotely monitor your prints.

Ecosystem

Additional Specs

Key Components of the Print Engine

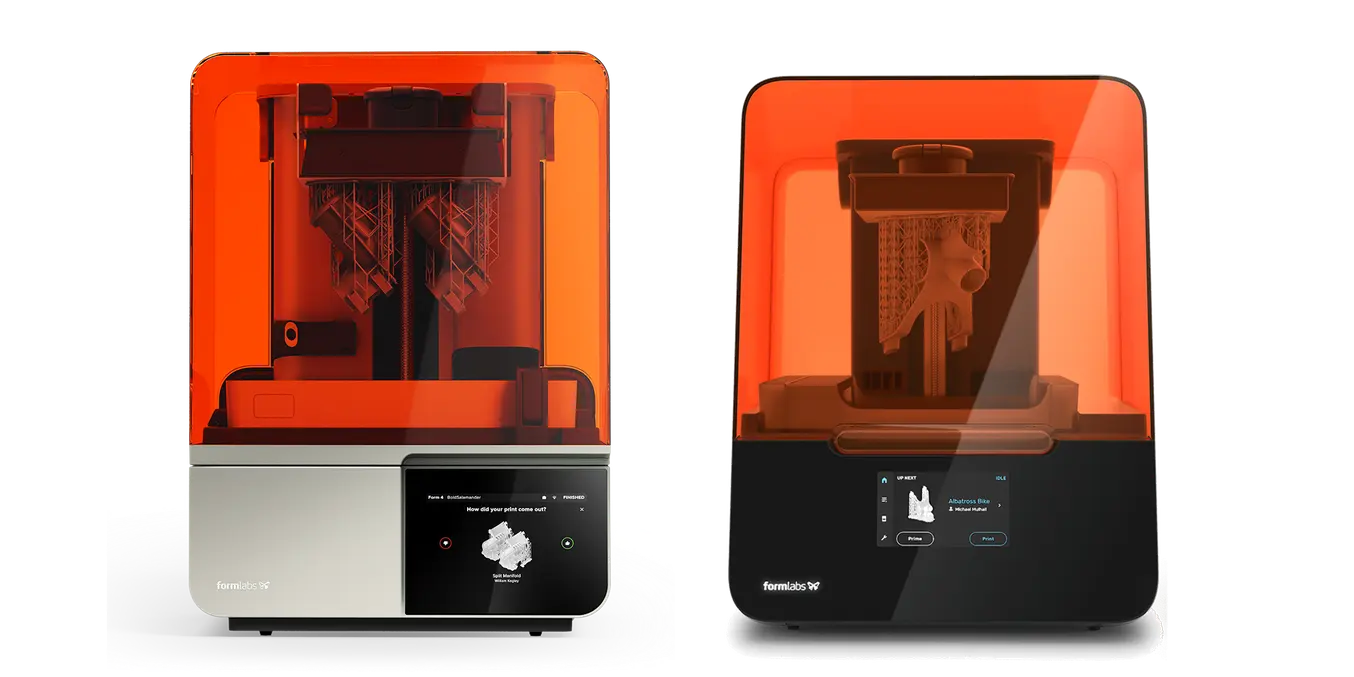

Form 4

Technology

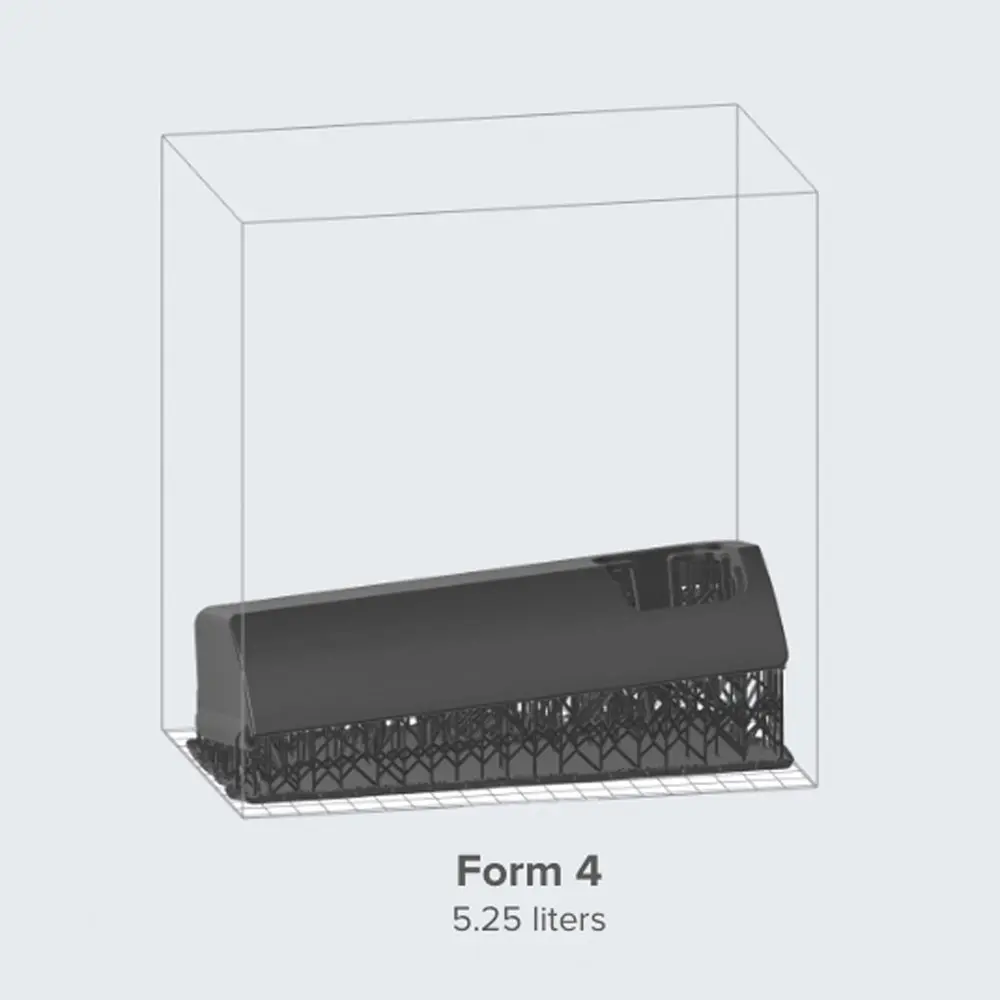

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

5.25 liters

23 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

If you print once a day, you will save $5,000 with Form 4 in just two years.

75,000+ layers with any Formlabs material.

Approximately 190 prints using average height model (39 mm tall), any resin, and 100µm layer height.

5-10x faster tank filling

63% less waste

30% less shelf space

2592 x 1944 resolution (5MP)

Remote monitoring, print history, and print timelapses

Can be easily disabled, covered, or removed

Test

form 4 vs. form 3

27.3 cm

10.7 in

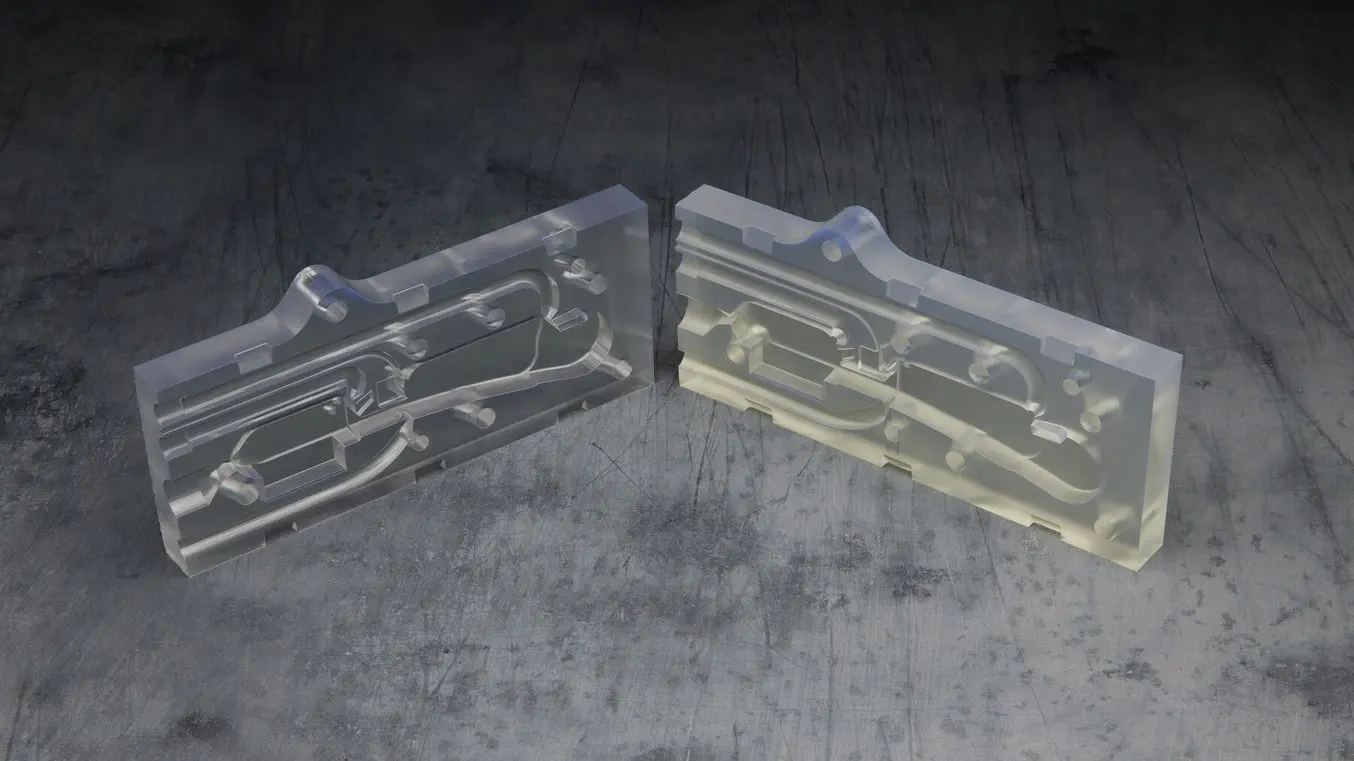

1-30 mm features: ±0.15% (lower limit: ±0.02 mm)

31-80 mm features: ±0.2% (lower limit: ±0.06 mm)

81-150 mm features: ±0.3% (lower limit: ±0.15 mm)

Average: 40 mm/hour across all materials

Range: 15-100 mm/hour depending on the material

100 mm/hour

3.9 in/hour

18.3 kg

40.4 lb

40.7 × 47.8 × 84.4 cm

16.0 × 18.8 × 33.2 in

Form 3/+

Technology

14.5 × 14.5 × 19.3 cm

5.7 × 5.7 × 7.6 in

4.05 liters

27 industry-leading Formlabs materials, or third-party materials using Open Material Mode.

85 µm laser spot size, 25 µm XY resolution

250-800 hours of printing and/or 10-35 weeks exposed to resin, depending on the material.

Approximately 70 prints using Grey Resin V4 and average print time (11 hours) or approximately 20 prints using Tough 2000 Resin and average print time (11 hours).

Original resin cartridge

No camera

Test

form 4 vs. form 3

22.4 cm

8.8 in

Not measured

Average: 11 mm/hour across all materials

Range: 4-17 mm/hour depending on the material

31 mm/hour

1.2 in/hour

17.5 kg

38.5 lbs

40.5 × 53 × 78 cm

15.9 × 20.9 × 30.7 in

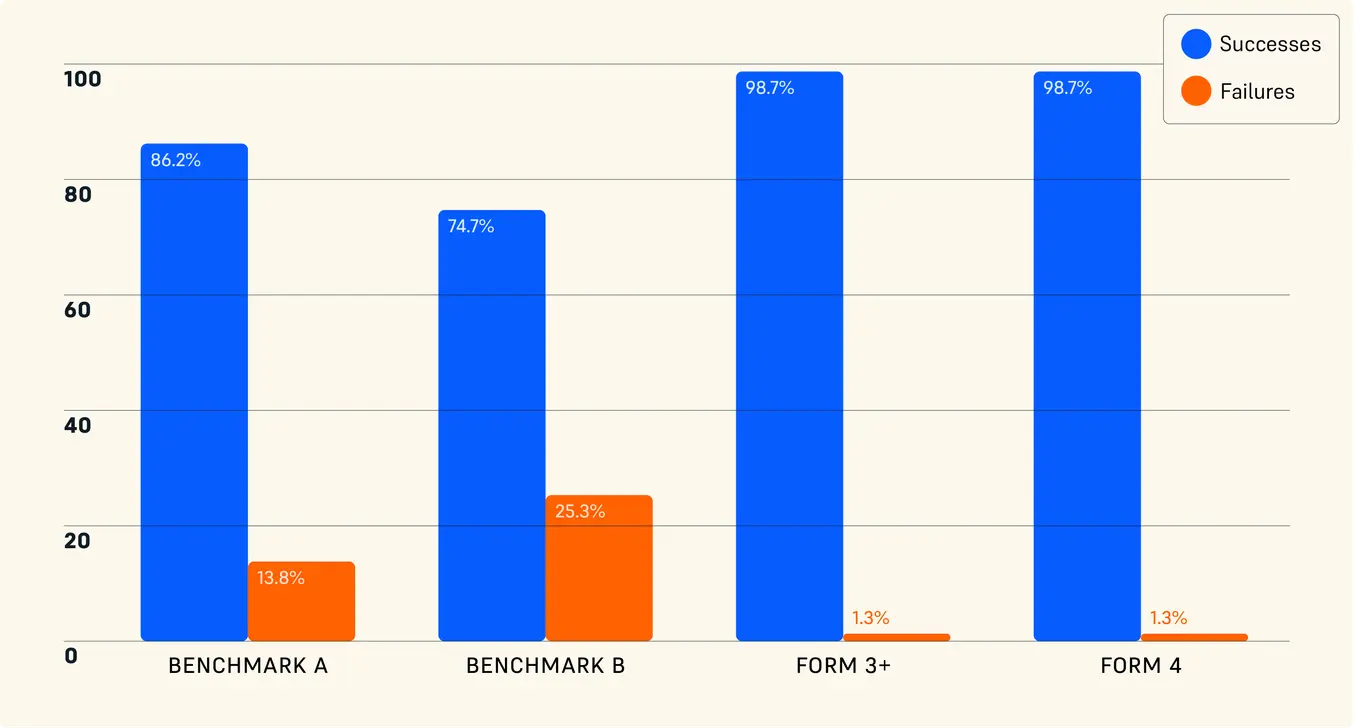

Form 4 achieved stellar results in a series of comprehensive performance tests conducted by an independent third-party lab to evaluate the success rate and repeatability of parts produced on different SLA 3D printers.

The Form 4 Ecosystem

Complete Your 3D Printing Experience