Service bureaus are often the best way to analyze trends in manufacturing, and in additive manufacturing especially. As service providers, they are fielding requests across different industries and for a wide range of parts, materials, and processes — and they’re handling more 3D printing volume than most original product manufacturers. Wohlers estimates that 60% of 3D printing output in China comes from contract manufacturers and 3D printing service bureaus.

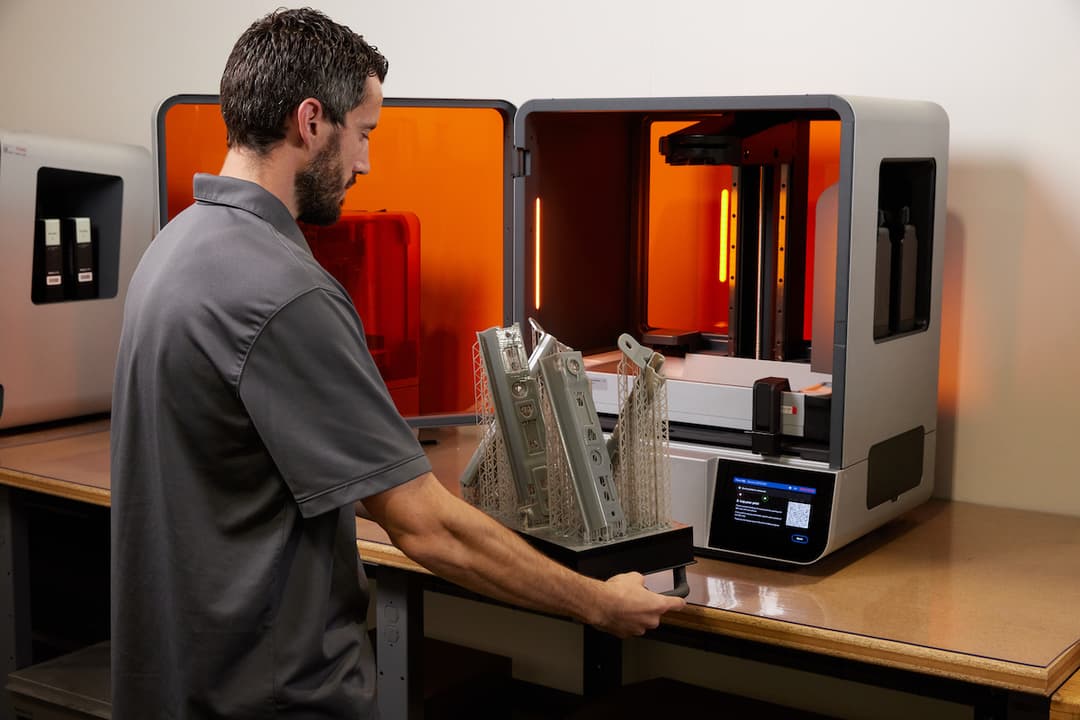

Dongguan YuenCheng Technology (DYT), a service bureau in South China, has seen a gradual shift away from requests for prototypes printed in photopolymers towards a demand for strong, functional, end-use parts, primarily printed on powder bed fusion systems. Dongguan YuenCheng has been able to stay one step ahead of the demand curve by scaling their 3D printing fleet with Formlabs’ accessible Fuse Series selective laser sintering (SLS) printers.

Evaluating Industrial Options

These components require high dimensional accuracy and superior surface finish — after evaluating several powder bed 3D printing options, DYT settled on the Fuse Series because of its ability to consistently and cost-effectively produce parts of this caliber.

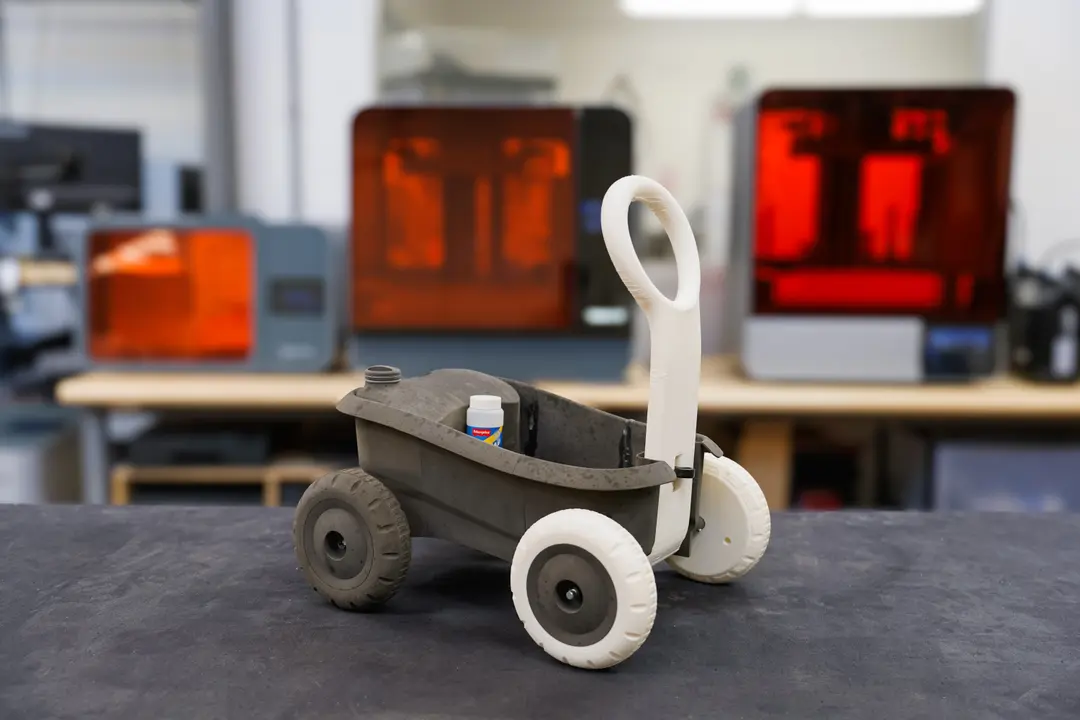

SLS 3D printing enables geometries that injection molding or machining cannot accomplish — these computer mouse shells have complex designs that make them lightweight, and would be nearly impossible to machine.

DYT works primarily with small and medium-sized businesses who are looking for 3D printed parts with versatile material properties, excellent dimensional accuracy and precision, and options for moving to production volumes efficiently.

They began to evaluate options for adding industrial power 3D printing technologies, but had three major concerns with many of the available industrial options:

-

The high up-front cost of large-format industrial options would preclude them from any ramp-up time — they would need to start making a profit on parts immediately to begin to pay off their investment.

-

The high labor cost of experienced powder bed fusion 3D printing operators — most industrial options are complex and require operators to have extensive training and experience.

-

Despite high costs, part consistency and quality were not guaranteed with expensive industrial options.

Alex Wu, the CEO of DYT led an effort to compare each possible option for functional, end-use quality parts. DYT looked at several factors, including dimensional accuracy, tolerances, and the consistency of those results across different machines and materials, as well as the after-sales service that different OEMs provided. When running an analysis on the overall cost-effectiveness of the machines, the Fuse Series SLS 3D printers achieved a complete ROI in half the time that other, higher-priced options did. DYT concluded that the Fuse Series offered a combination of part quality, scalability, and workflow efficiency that the other options couldn’t match.

“Only after fully assessing the return on investment do we gain confidence in gaining a competitive edge in the market. After comparing various SLS equipment from different brands, we found that Formlabs' Fuse 1+ 30W fully meets our needs and addresses our longstanding concerns."

Alex Wu, CEO, YuenCheng Technology Co., Ltd.

Competitive Cost Per Part

DYT customers expect this high level of dimensional accuracy and superior surface finish. The self-supporting nature of SLS technology ensures that post-processing is straightforward and that there are no marks left over from support structures, as there often are with FDM and SLA technologies.

Though up-front cost is often the biggest ticket item when analyzing fabrication technology options, DYT was also concerned with cost per part, and how that would factor into their daily operations and customer relations.

As accessible and scalable systems like the Fuse Series are gaining popularity, more businesses are realizing that SLS 3D printing presents a compelling opportunity for end-use production at certain volumes. For stop-gap printing, early customer validation runs, aftermarket parts that need to be updated regularly, or for mass customization, 3D printing is typically less expensive than ordering an injection molding tool, and almost always delivers parts faster than the tool can be machined.

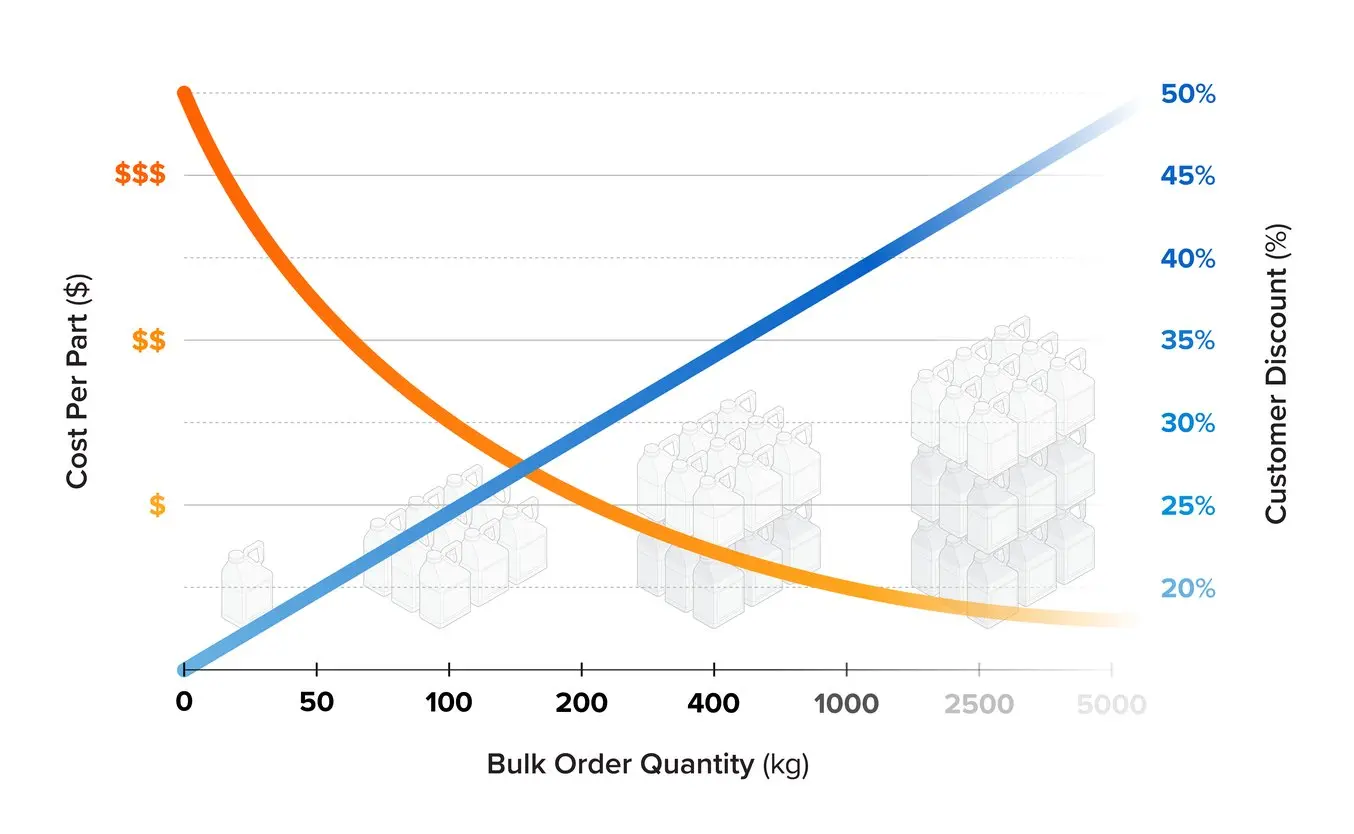

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

The exact point at which injection molding becomes cheaper depends on material choice, geometry and size, surface finish requirements, and more. However, for many manufacturers making nylon, TPU, or polypropylene parts that can nest several at a time into the Fuse Series build chambers, it is often cheaper to produce several thousand parts on the Fuse Series than to order an injection molding tool.

For DYT, they had the additional considerations of the ease and cost-effectiveness of Chinese domestic manufacturers. When comparing parts to those printed on the Fuse Series, they found that though costs were competitive, part quality and dimensional accuracy were far better with the Fuse Series. Being able to consistently produce parts with a 0.1 mm to 0.15 mm tolerance outperformed any domestic powder or powder bed fusion printer they had evaluated.

"We compared parts printed with the Fuse 1+ 30W and found the quality to be as good as that of other equipment costing several times more, while the cost per part is close to that of domestic printers. This has empowered us to win more orders from businesses and partners, offering a competitive edge, better cost-effectiveness, faster next-day delivery flexibility, and greater business operational opportunities."

Alex Wu, CEO, YuenCheng Technology Co., Ltd.

Creating a High-Functioning Fleet With Fuse Series

Higher volumes of parts will only continue to help make the case for scalable SLS 3D printers like the Fuse Series. For stop-gap production, customer validation stages, or more, SLS 3D printing is often the most cost-effective solution.

These prosthetics teaching aids are used in medical schools for education. Large parts like these are still quite cost-effective on the Fuse Series, because they’re typically only needed in lower quantities, with short timelines for delivery.

DYT has plans to scale their SLS fleet up to 20 machines from the three Fuse Series printers they operate now. The feedback they’ve received so far from their current customers ordering Fuse Series SLS parts has made them confident that demand for these products will only continue to grow.

This forward-looking approach was part of the reasons they chose to scale with the Fuse Series, rather than another industrial option. While larger format powder bed 3D printers often have larger build volumes that can nest more individual parts within them, they often require four or five times the footprint and infrastructure that the Fuse Series printers do.

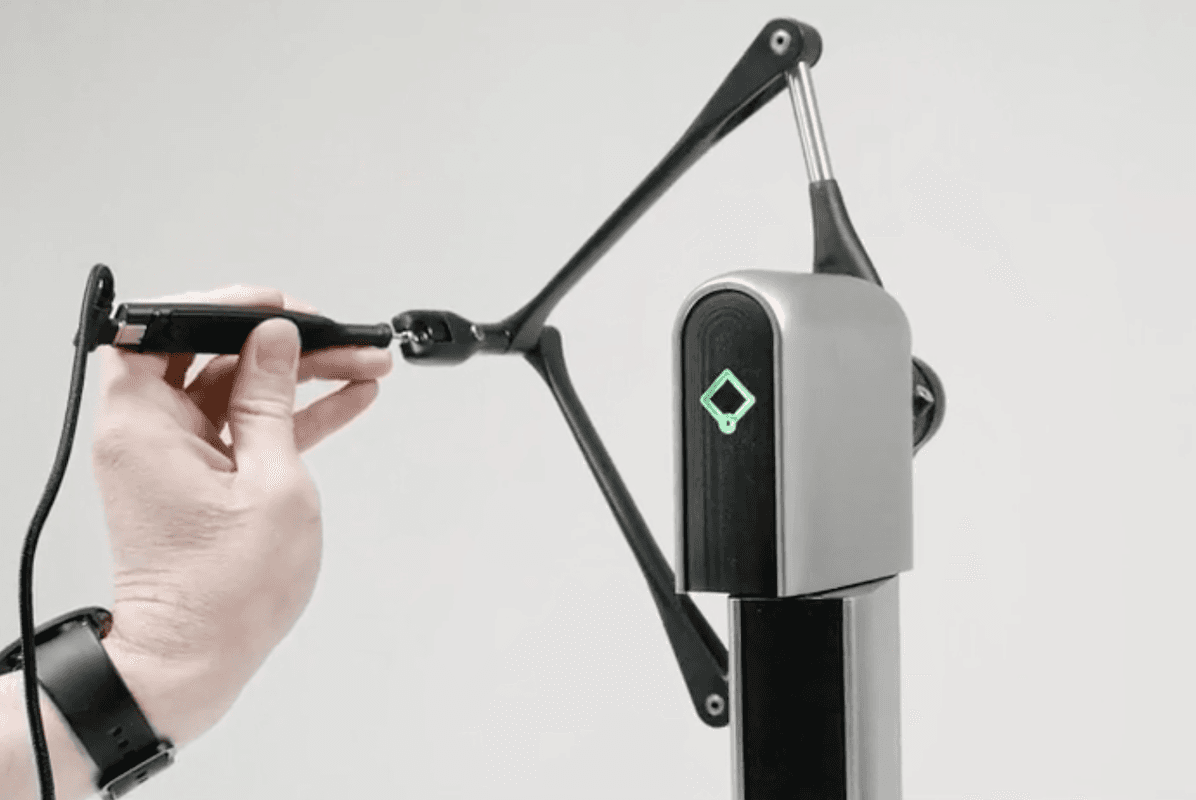

Webinar On-Demand: How to Scale SLS 3D Printing: Optimizing the Production Workflow at Haply Robotics

Haply has effectively scaled their SLS workflow, finding ways to optimize their print process and post-processing solutions in order to maintain consistency and performance, even at production volumes.

What you will learn:

- How to scale SLS 3D printing from prototyping to production

- How to optimize the SLS workflow for consistency

- How to evaluate fabrication technologies for production feasibility

- How to analyze SLS cost per part

Wu and the DYT team knew that they needed a solution that could comfortably scale, so that they could add printers as their demand and customer base grew. Having a fleet of SLS 3D printers differentiates them from their competition because it enables them to offer multiple materials and increases their flexibility and ability to meet tight deadlines. Operating a fleet gives them access to more of the Formlabs SLS Powders library, without requiring them to switch over printers or post-processing machines like the Fuse Sift.

“A 200 square meter studio can operate over 20 Fuse 1+ 30W units, allowing for the flexible use of various materials without the need for nitrogen generators, activation equipment, large sandblasting machines, high-powered air conditioning, manual packing, manual powder mixing, or manual polishing... All we need is a 200 square meter office, which is very appealing.”

Alex Wu, CEO, YuenCheng Technology Co., Ltd.

To learn more about scaling production with the Fuse Series, visit our resources page. To test out the material properties for yourself, request a free sample.