In 2022, Black Raisins, a Singapore-based startup offering manufacturing solutions through an innovative e-commerce style platform, integrated the Formlabs’ Fuse 1+ 30W selective laser sintering (SLS) printer into their workflow. The addition of powerful, industrial-grade SLS 3D printing marked a pivotal turning point in the company's production journey. The deployment of the Fuse 1+ 30W led to impressive growth for the startup within its very first month. It also resulted in a shortened timeline from research and development to the final tangible product.

Genesis of Black Raisins: A Vision Amidst Uncertainty

Emerging from the global disturbance caused by the COVID-19 pandemic, Black Raisins was founded in Singapore by young entrepreneurs Ska Masron, Joe, and Adnan Ahmad in 2021. Their startup embarked on a mission to establish an e-commerce platform specializing in additive manufacturing, encompassing both fused deposition modeling (FDM) and stereolithography (SLA) printing technologies. The company's initial focus revolved around crafting 3D-printed molds for confectioners and bakers, offering a diverse range of cookie cutters, cake molds, and chocolate molds.

Black Raisins established a robust online presence with a wide array of products listed on their website. Soon, they recognized the need for tailored solutions in today's fast-paced industries and decided to offer customized product creation services. Clients can submit their unique ideas, and Black Raisins' skilled team will transform these concepts into prototypes or fully realized end products. The company also expanded its horizons to cater to the engineering industry, providing specialized industrial parts. This adaptability allows them to serve a broad spectrum of clients, from individual consumers seeking bespoke items to businesses requiring precision-engineered components.

SLS for End-Use Production

3D printing for end-use production is not only possible, it's more affordable, agile, and scalable than ever with the Fuse SLS Ecosystem. Visit our SLS for Production page to compare production methods, learn about bulk powder pricing, and see production in action for 15 different manufacturers currently using the Fuse Series.

Journey with Formlabs: A Pathway to Excellence

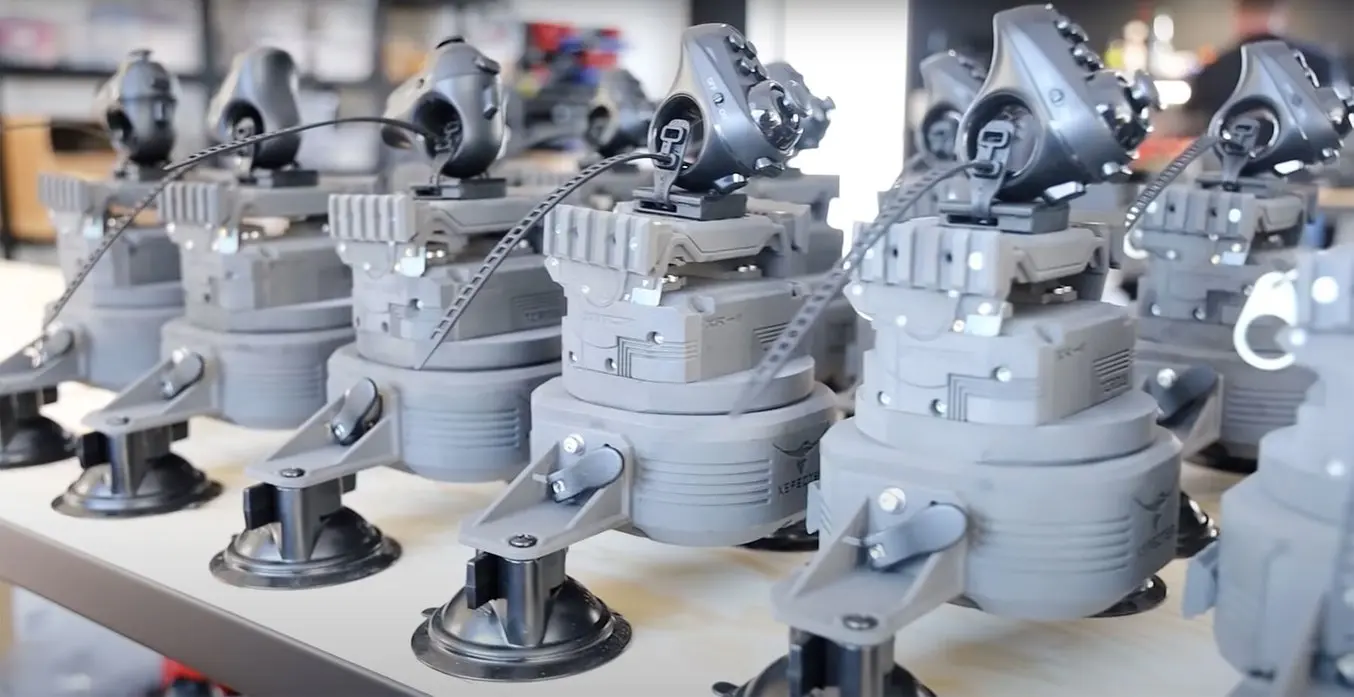

The Fuse 1+ 30W printer and Fuse Sift post-processing unit seamlessly integrate into Black Raisin's facility, optimizing space and workflow efficiency.

Within a year of its conception, Black Raisins saw a surge in demand for innovative molds. Ska and his team decided to expand their production capacity by integrating a CNC machine and SLS 3D printing into their workflow.

In 2022, Black Raisins was introduced to Formlabs' Fuse 1+ 30W SLS printer through the Singapore-based distributor, Eye-2-Eye Communications Pte. Ltd. According to Ska, “After exploring our options for SLS printers, we found that Formlabs’ Fuse 1+ 30W was the most suitable for our needs. Fuse 1+ 30W took care of it all – our need for speed while enhancing our output.” The fusion of the machine's precision with the array of compatible materials elevated Black Raisins' capabilities, enabling them to explore new dimensions of design intricacy and geometric freedom.

"The machine is excellent, reasonably priced, and a fantastic addition for companies like ours. However, what I appreciate most about Formlabs is the ecosystem that comes with becoming a part of the Formlabs family. They offer a wide range of materials to meet our project requirements, their support system is outstanding, and the abundance of educational resources they provide, including onboarding guides, webinars, and general technical support, is extremely valuable.”

Ska Masron, Black Raisins Co-Founder

Black Raisin has effectively utilized Nylon 12 Powder in the Fuse 1+ system, successfully producing multiple intricate parts. Furthermore, the benchtop industrial SLS 3D printer has a streamlined workflow that allows Black Raisin to produce high-quality parts daily. It fits perfectly within their workspace and budget. Additionally, the printer is durable and user-friendly, making it easy for them to create moulds for Mini 4WD racing cars and jigs using aluminium and other materials.

Transformative Growth: From Acquisition to Success

These parts, crafted with Nylon PA 12, ensure consistent precision in tracking foam darts through the dark, demanding repeatability, accuracy, and a finely-tuned threading solution for optimal performance.

The acquisition of Formlabs' Fuse 1+ 30W proved to be a catalyst for Black Raisins' growth trajectory. With the ability to exercise granular control over production output, the startup witnessed a remarkable 60% growth within the first month of deploying the Fuse 1+ 30W. Furthermore, the efficiency gains were evident not only in numbers but also in the shortened timeline from research and development to the final tangible product.

Ska explains, "We have always been focused on designs and used to outsource the fabrication requirements to vendors. We would design the product, test it, check the tolerances, and then send the files for fabrication. In most cases, we would receive the end product with some defects, and the time-consuming follow-ups would begin, eroding our margins. We wanted to gain control over the entire production process, which led us to the purchase of the Formlabs SLS printer."

From the day Black Raisin acquired the machine, they noticed a significant improvement in delivery time and the quality of output. "We once received an inquiry from a liquor company to create a prototype for a bottle. Since they shared the design and we had materials ready, we were able to deliver the bottle prototype the very next day. This not only boosted our confidence but also pleasantly surprised the customer with both the product's quality and the speedy delivery," shared Ska.

From left to right: Fresh out of the oven, After post-processing, Ready for final production - showcasing the progressive stages of parts manufactured using Nylon 12 powder.

Advancing Post-Processing Techniques: Cerakote as a Game Changer

Left: Parts right out of Fuse1+ 30W, Right: Parts after using Advanced Post-processing technique - Cerakote

Beyond the utilization of Formlabs' state-of-the-art printing technology, Black Raisins has established a reputation for its advanced post-processing techniques. Notably, they have mastered the art of Cerakote application, a technique that involves spraying a polymer infused with ceramic additives directly onto parts. This process requires meticulous preparation, including media blasting with specialized media and thorough cleaning with wax and grease removers to ensure a contaminant-free surface.

Cerakote offers both air-cure and oven-cure formulations, delivering exceptional durability and aesthetic appeal. “While the Cerakote application may initially seem daunting, we have successfully navigated the process by taking advantage of the webinars and whitepapers provided by Formlabs. Additionally, the information available on the Formlabs website proved to be very helpful. These factors greatly contributed to our ability to achieve the desired aesthetics and tactile qualities for our final products," Ska stated.

Cerakote's chemical resistance, mechanical strength, and wide range of color possibilities allow Black Raisins to create durable and customized products. Black Raisins' ability to achieve specific color patterns, tolerances, and material properties has significantly contributed to their growth within the toy and entertainment sector.

A Glimpse into the Future: Formlabs and Black Raisins

As Black Raisins continue to flourish in the e-commerce space, they recognize that embracing cutting-edge technologies is essential for staying ahead in a dynamic market. Looking ahead, Black Raisins envisions an expansion of their product portfolio, reaching new heights of diversity and intricacy. By tapping into Formlabs’ extensive range of materials specifically designed for the Fuse 1+ 30W, they anticipate unlocking even more possibilities for their designs.

“We may add more SLS machines from Formlabs and experiment with many materials and post-processing techniques in the future,” said Ska.

The shared vision of bringing design and manufacturing closer together while maintaining a strong focus on sustainability underscores the deep-rooted alignment between Black Raisins’ aspirations and Formlabs’ innovative offerings.