Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. As technology like affordable desktop 3D printing gives more engineers hands-on experience with a variety of polymers, a baseline knowledge of mechanical properties is important for choosing the right material for a given job.

In this post, we’ll walk through the six most essential mechanical properties you should consider when choosing between materials, and in particular, when deciding which Formlabs Engineering Resin is the best fit for your project.

Find the Right Material for Your Application

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Elastic Modulus: How Stiff Is It?

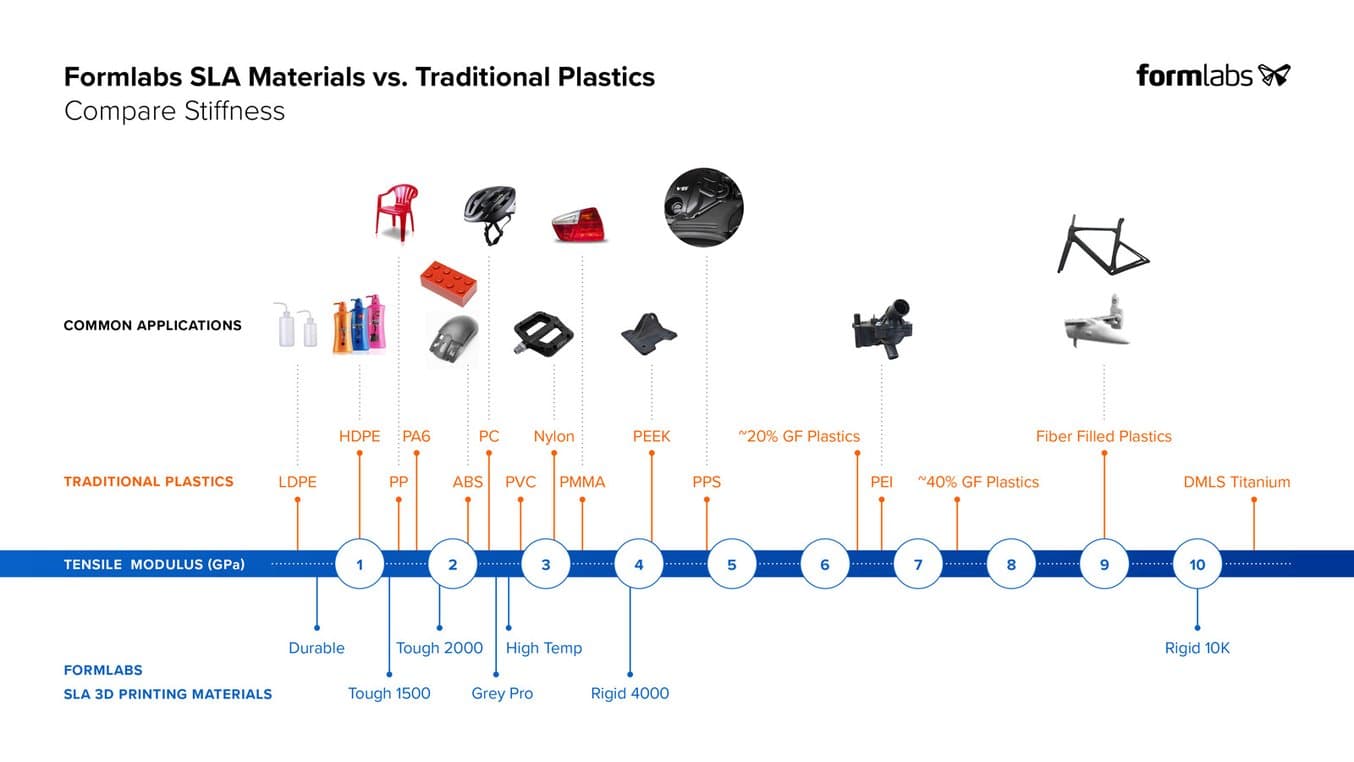

Elastic modulus is a material’s resistance to elastic deformation under stress.

Flexural modulus, the measure most relevant to plastics, is a measure for a material’s stiffness, or tendency to bend. A highly stiff material requires more force to deform compared to a soft material. A high flexural modulus indicates a stiffer material, like a diamond, while a low flexural modulus indicates an elastic material, like a rubber band.

Flexural modulus and tensile modulus (or Young’s modulus) are closely related and typically don’t differ largely. Shear modulus describes a material's response to shear stress, for example, cutting it with dull scissors.

For the highest flexural modulus among Formlabs materials, choose Rigid Resin. Other materials with high stiffness include Standard Resin and Grey Pro Resin. Tough Resin has a relatively low modulus compared to other Formlabs resins.

Elongation: Will It Bend and Stretch?

Elongation is a material’s resistance to breaking when stretched.

Elongation tells you how much a material can stretch without breaking or forming cracks. Stiff materials, such as brittle-hard plastics, typically feature a low elongation at break, while some soft, elastic materials can stretch several times their own length before breaking. High elongation is important parts for packaging that needs to bend, for example, a toothpaste tube.

Ductile materials, for example, most rubbers, have a high elongation, while brittle materials like glasses and ceramics tend to have very low elongation because they do not plastically deform.

For the highest elongation among Formlabs materials, choose Durable Resin or Tough Resin.

Impact Strength (Toughness): Can It Absorb Shock?

Impact strength is a material’s ability to absorb shock and impact energy without breaking.

Impact strength, sometimes referred to as toughness, refers to a material’s ability to respond to sudden impacts. A material with high toughness, like polycarbonate or nylon, can absorb energy and plastically deform before it fractures. In simpler terms, a material with high impact strength can be dropped on the floor without breaking. When looking at material properties, toughness is defined by the area under the stress-strain curve.

“Toughness” or impact strength isn’t synonymous with stiffness, but it requires a balance of strength and ductility. More compliant materials can rate highly when it comes to absorbing sudden shock.

For the highest impact strength among Formlabs materials, choose Durable Resin. Other materials with high impact strength include Tough Resin and Grey Pro Resin.

Tensile Strength: Will It Break Under Tension?

Tensile strength is a material’s resistance to breaking under tension.

A material with a high tensile strength resists breakage under tension, or being pulled apart. Ultimate tensile strength indicates the maximum stress that a material can withstand while being stretched or pulled before breaking. Materials with high tensile strength include carbon, glass, and steel.

Once this maximum stress is reached, brittle materials break very sharply, without plastic deformation, while more ductile materials experience some plastic deformation before fracture.

Today, 3D printing has progressed such that it is able to deliver tensile strength comparable to traditional injection-molded plastics like polypropylene and ABS.

For the highest tensile strength among Formlabs materials, choose Rigid Resin. Other materials with high tensile strength include Standard Resin, Grey Pro Resin, and Tough Resin.

Heat Deflection Temperature: Does It Tolerate Heat?

Heat deflection temperature (HDT) is the temperature at which a material deforms under a specified load.

Heat deflection temperature (HDT) indicates whether a material is suitable for high temperature applications, and is expressed as the temperature (measured in °C) at which a sample deforms under a specified load (measured in MPa).

A high HDT is desirable for enclosures and mounts for heating elements, as well as components that come into contact with hot liquids or gases, such as tooling for injection molds, fluidic connectors, valves, and nozzles.

For the highest heat deflection temperature (HDT) among Formlabs materials, choose High Temp Resin. Other materials with high HDT include Rigid Resin.

Creep: Will It Deform Under Long-Term Stress?

Creep is a material’s tendency to move slowly or deform permanently under mechanical stresses.

Creep is the tendency of a material to deform slowly over a long period of time under stress. A material with high creep is more likely to deform than a material with low creep. Creep differs from other material properties in that it is measured over a longer period of time. Creep depends on time, stress, and temperature.

Choosing a material with low creep is important for parts that need to withstand high stress or temperatures and hold their shape over time, for example, for parts that will bear weight or parts need to perform a repeated function, such as a turbine blade.

For the lowest creep among Formlabs materials, choose Rigid Resin or Grey Pro Resin.

A Multifaceted Approach

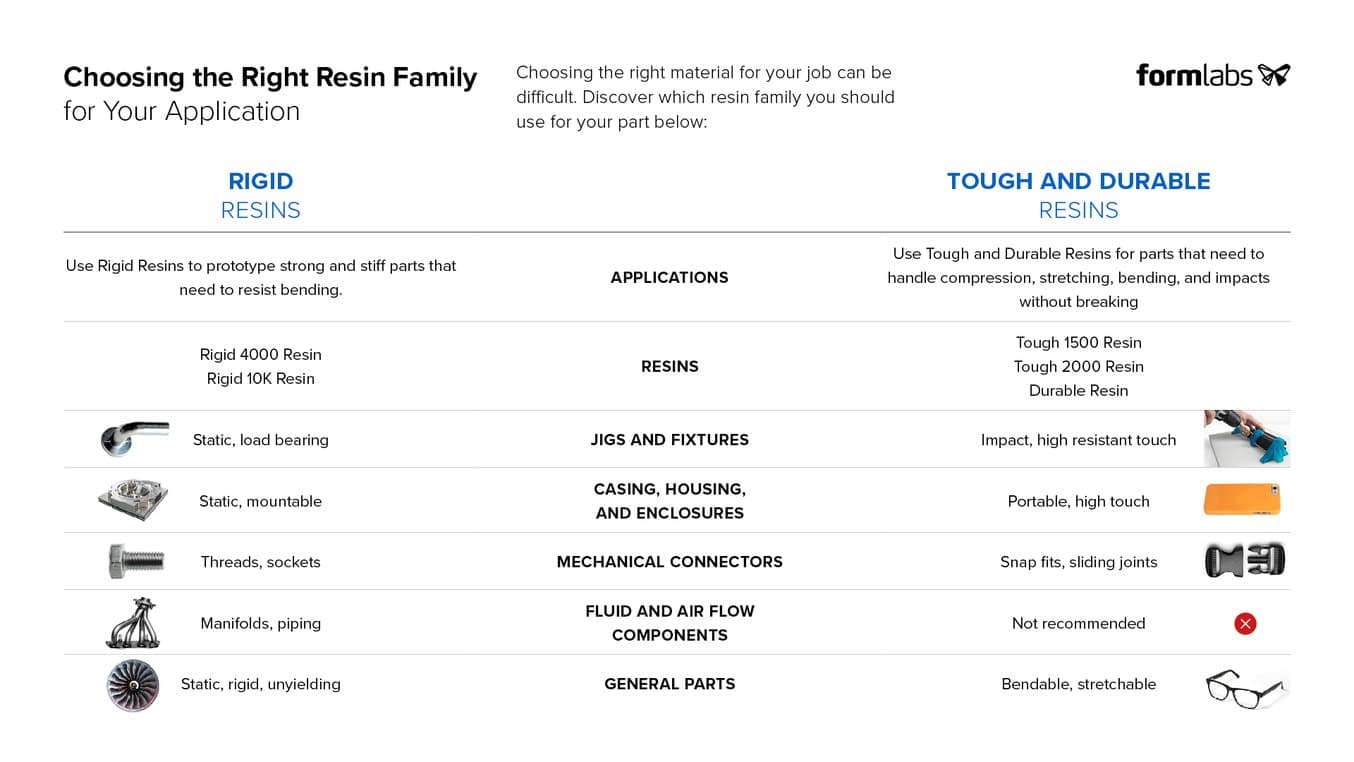

In practical reality, plastic part designers don’t often find themselves optimizing parts for a single property; instead, they make decisions that balance multiple properties at once, based on experience, computer simulations, and other reference points.

You can develop your knowledge of different materials and what they’re good for by referencing guides like this one, but practical experience is just as important. Try different materials and see how they work. Look into what materials everyday objects you use are made of and consider the mechanical properties of those materials. Which properties are these parts taking into consideration for the way they’ll be used?

A few practical examples using Formlabs Engineering Resins:

Consumer packaging for items like household cleaners or shampoo needs to have high enough elongation to bend in a user’s hands and return to its original form, balanced with enough impact strength to survive being dropped. For this prototype, we chose Durable Resin.

A bracket (for instance, on a stand for a computer monitor) requires high flexural modulus, or stiffness. It’s also important to choose a material with low creep so that the part will continue to do its job over time without slowly deforming. For these requirements, Grey Pro Resin is a great choice.

A fan requires thin, strong features. Rigid Resin’s high modulus doesn’t just mean parts will stay sturdy after printing – high green modulus, or modulus before post-curing, means it’s possible to print very thin parts with precision and a lower chance of failure. High impact strength, high heat deflection temperature, and low creep mean this prototype will withstand the elements over time.

Further Reading

We wrote an in-depth guide covering a wider variety of chemical, optical, mechanical, thermal, and electrical characteristics of materials, for those who want to go deeper than this overview.

If you’re interested in furthering your knowledge of materials, these books are a good starting point:

- Materials Selection in Mechanical Design by Michael B. Ashby

- Materials for Design by Chris Lefteri

- Plastic Part Design for Injection Molding by Robert A. Malloy