Creating A Custom Keyboard From Recycled Plastic Using 3D Printed Injection Molds

Juan Ignacio Carmona, a product designer based in Spain, completed his thesis project with the help of a Form 3 stereolithography (SLA) 3D printer and a HoliPress desktop injection molder.

The project involved creating a custom mechanical keyboard for use in combination with the CAD software Blender. Its keycaps are made of recycled plastic parts, using molds printed in Rigid 10K Resin on the Form 3.

Injection Molded Parts in <24 Hours? Low-Volume Injection Molding 101

In this webinar, we'll show you how to use stereolithography (SLA) 3D printed molds in the injection molding process to lower costs, reduce lead times, and bring better products to market.

Using Recycling to Improve Efficiency

Discarded FDM 3D printed ABS parts recycled in this project.

ABS, a thermoplastic derived from petroleum, is one of the most commonly used materials in fused deposition modeling (FDM) 3D printing due to its strength and durability. It is not biodegradable since it is petroleum-based, but being a thermoplastic, it can be recycled if properly separated from other plastics.

ABS is an ideal material for molding and is used to mold common plastic parts, such as LEGO blocks. In its liquid state, it is very malleable and not too adhesive, which allows for great precision and fine details, and prevents it from sticking to the mold. It also cools fast and has little thermal shrinkage, making the molding process quick and simple.

In addition to improving the key aesthetics, using recycled ABS also added a sustainable value to the product, since it reused material that would otherwise have been wasted. Aside from being good for the environment, using recycled plastics can attract consumers who value sustainability and care for the environment.

Los Hacedores, the Madrid-based Formlabs partner that Carmona collaborated with to carry out the project specializes in 3D printing and modeling, and a software they often use is Blender. Free and open source, Blender is one of the best-known and used 3D modeling programs worldwide, but it is also known for being complex to learn due to its wide variety of functions and controls.

For this reason, Los Hacedores’ team has identified the number pad keys used in Blender and colored them based on their purpose to make them easier to use, which has contributed to improving the company's efficiency and effectiveness. The goal of this project was to experiment with injection molding to create a standalone number pad that is compatible with a computer and allows customization, including the assignment of functions to different keys.

Injection Molding Using 3D Printed Molds

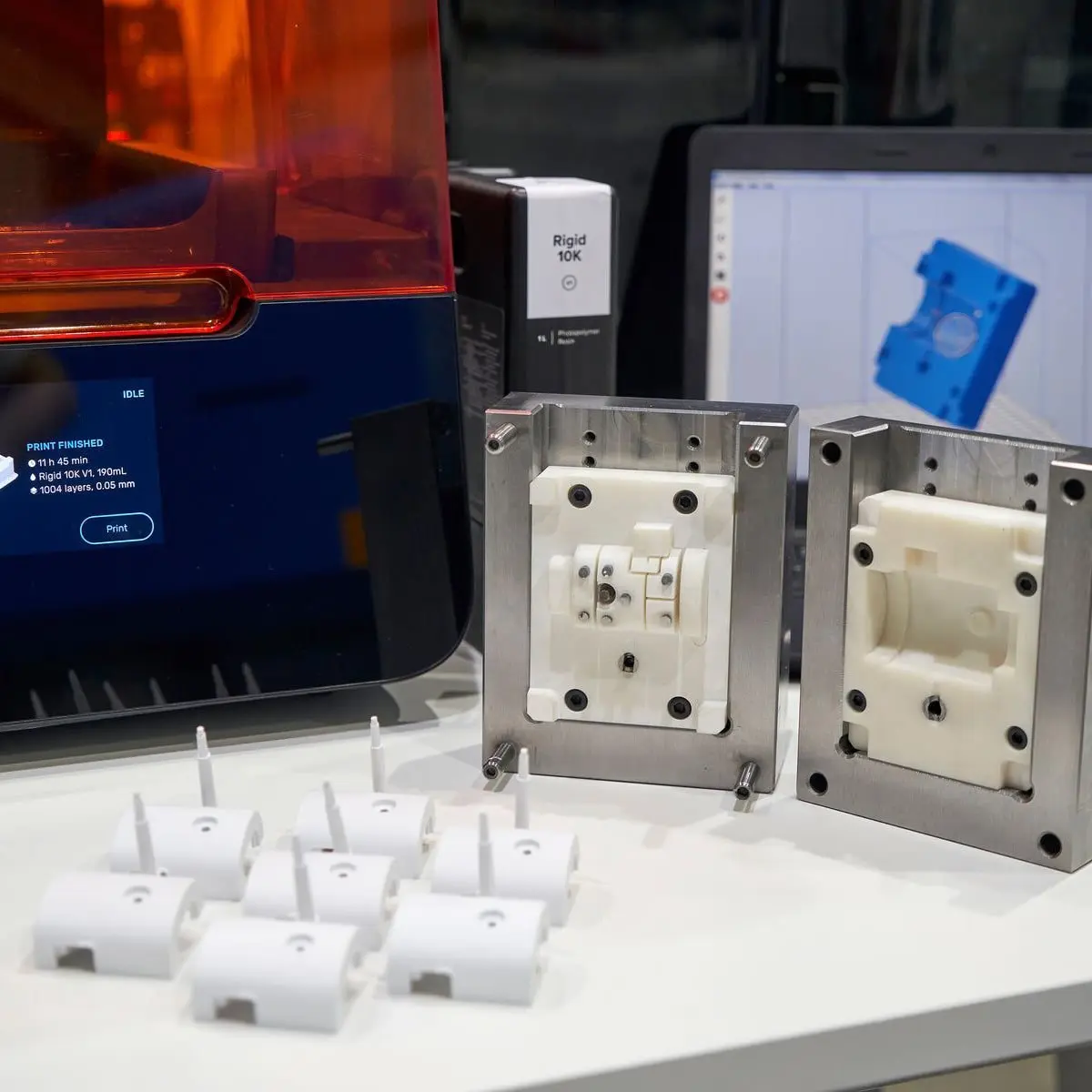

For this project, Carmona used a Form 3 SLA 3D printer and a HoliPress desktop injection molding machine.

The Form 3 is an affordable professional printer with a compact size, that offers a wide range of materials, including advanced engineering ideal for molding. Carmona tried different resins for manufacturing the molds, including Grey Pro Resin, High Temp Resin, and Rigid 10K Resin.

-

Rigid 10K Resin is Formlabs’ recommended material for injection molds as it combines strength, stiffness, and thermal resistance. It is an industrial-grade, highly glass-filled material with an HDT of 218°C @ 0.45 MPa and a tensile modulus of 10,000 MPa.

-

High Temp Resin can also be considered as an alternative to Rigid 10K Resin. This resin has an HDT of 238°C @ 0.45 MPa, the highest among Formlabs resins, allowing it to withstand high molding temperatures. However, prints from High Temp Resin are more brittle than those from Rigid 10K Resin and will break much earlier under pressure.

-

Grey Pro Resin is a third option, only suitable for a small and a low number of parts, such as with desktop injection molding. It should be used when pressures and temperatures are low and the dimensional accuracy of your molded part is less critical. Molds made from Grey Pro Resin will bend before breaking, worsening accuracy over time as the mold is used.

This is summarized in the table below where more stars indicate better performance under that condition.

| CRITERIA | RIGID 10K RESIN | HIGH TEMP RESIN | GREY PRO RESIN |

|---|---|---|---|

| High molding temperature and pressure | ★★★ | ★★★ | ★ |

| High number of cycles | ★★★ | ★ | ★ |

| Thin walls | ★★ | ★★★ | ★ |

| Reduce resin costs | ★ | ★★ | ★★★ |

Low-Volume Rapid Injection Molding With 3D Printed Molds

Download our white paper for guidelines for using 3D printed molds in the injection molding process to lower costs and lead time and see real-life case studies with Braskem, Holimaker, and Novus Applications.

Injection molds printed in Rigid 10K Resin.

HoliPress is an injection molding machine that consists of a tube with resistors to heat and melt the material. A manual or automated piston is then used to inject the material into a mold, making it possible to create more complex shapes than with other technologies.

The finished number pad with recycled keys.

Traditionally, injection molding machines have a high cost and large size as they’re developed for industrial use, but HoliPress has a more accessible size and price for prototyping and low-volume production in house, and is easier to use with its thermal controller and manual piston. Despite not having a high injection capacity (16 cm3 max), this did not end up becoming a problem for the project due to the small size of the parts required.

Try Out Injection Molding In House

The recycled injection molded keys feature unique colors.

“With enough time and dedication, anyone can achieve similar results in their own home without the need for a large facility or factory,” said Carmona.

This project is a good example of displaying the potential of desktop 3D printing and injection molding, as well as showcasing the beauty and uniqueness of products made from recycled materials.

Interested in trying out injection molding with 3D printing? Our white paper provides methods and guidelines for using stereolithography (SLA) 3D printed molds in the injection molding process to lower costs and lead time.