Source-based 3D reconstruction of ancient cities has become an important component for archeologists, (art-)historians, and architects. It is used not only to illustrate the cities, but also to better understand historic events, and present hypothetical visualisations of the past.

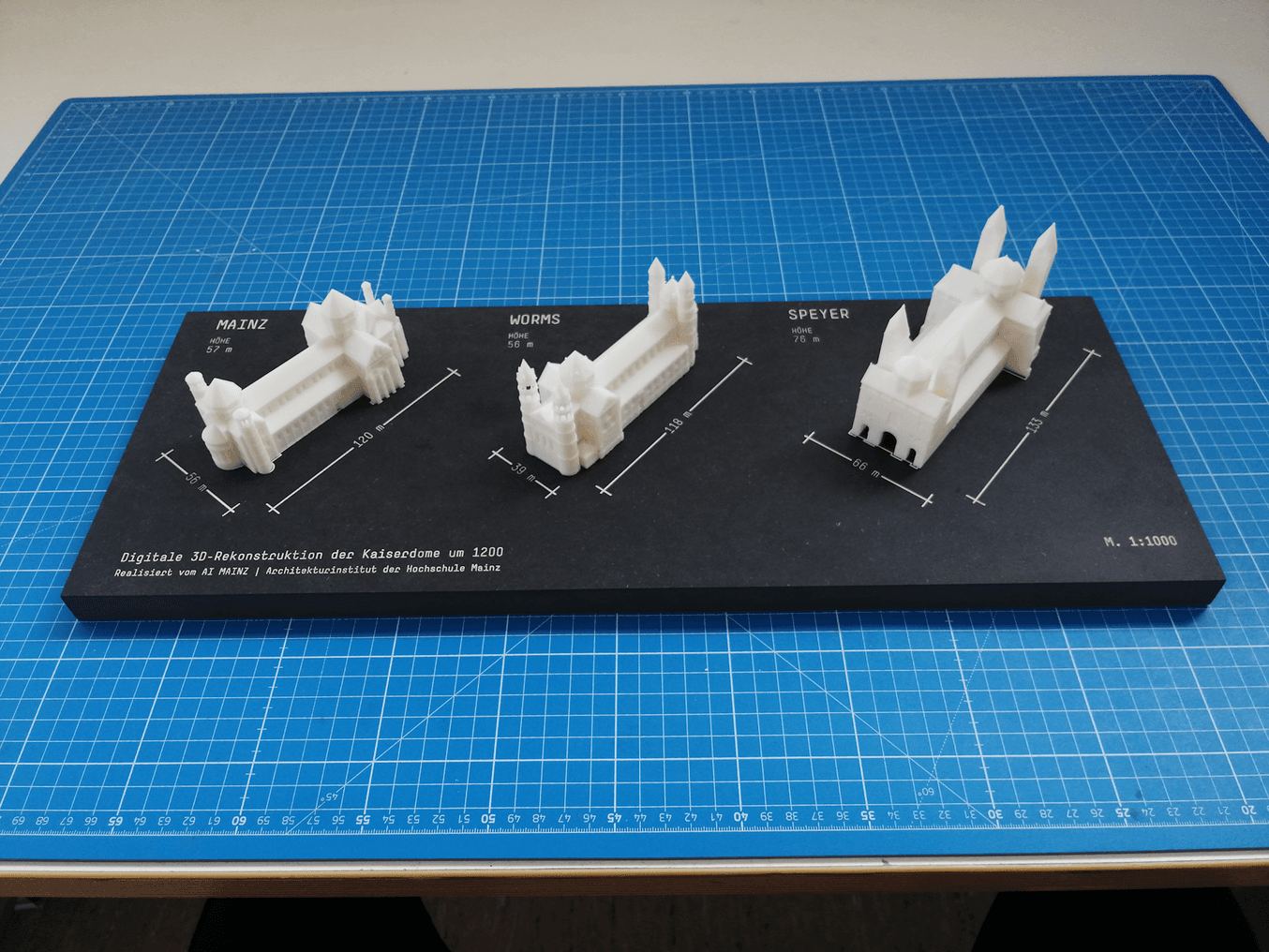

The cities of Worms, Speyer, and Mainz—the so-called SchUM cities—are among the historically valuable cities whose development is of great importance. As one of the most influential communities in the Holy Roman Empire in the High Middle Ages, these cities developed into pillars and the social and cultural centers of imperial power. In order to better understand the medieval world, the Directorate-General of the cultural heritage of Rhineland-Palatinate under the leadership of the former general director Mr. Metz decided to re-create 3D versions of all three cities in cooperation with the Institute of Architecture at the Hochschule Mainz - University of Applied Sciences. The result is an extraordinary exhibition that showcases six large-scale models of the cities, in the years 800 and 1250 AD. The models consist of over 650 parts, all of which were created using stereolithography (SLA) 3D printing technology.

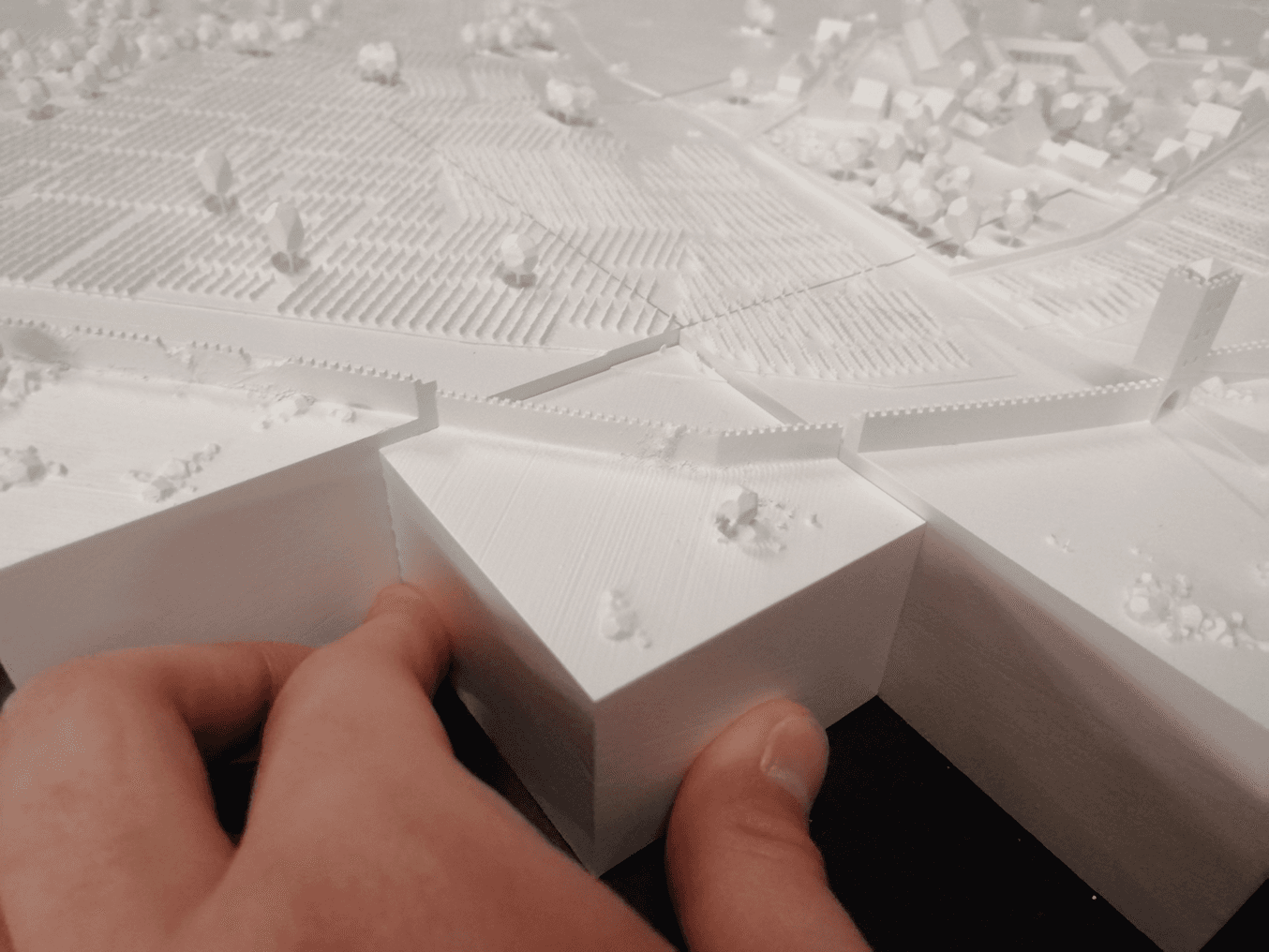

The reconstruction of the three cities in the two different time periods consisted of over 650 segments, which were printed using Formlabs White Resin, each measuring 12x12cm.

The Development of the Imperial Cities on the Rhine River

The Institute of Architecture in Mainz (AI MAINZ) is part of the research facility of the Hochschule Mainz - University of Applied Sciences. As an interdisciplinary institution, AI MAINZ represents the interface between architecture, (art-)history and applied computer science.

This convergence of departments is also shown in their most recent project in which more than 50 people from different departments were involved. The project started in September 2018 with the objective to visualize the development of the three cities—Worms, Speyer, and Mainz—at the beginning of the decline of the Roman Empire in 800 and their subsequent development up to 1250.

Together with archeologists and (art-)historians from the Directorate-General of the cultural heritage of Rhineland-Palatinate, archeological excavation, and the remaining structures, the cities were reconstructed digitally in all their details. "We wanted to show the development of every religion in the cities. Every city had a Jewish quarter and a very important roman cathedral by 1250, which were connected to the emperor and city structure," said Igor Bajena, one of the team members responsible for the digital and physical visualization and implementation of the project.

The three cities were divided into squares on a grid. The result is over 650 segments representing two different time periods.

The Essential Attention to Detail With SLA

The decision for the physical visualization also meant that the right printing method had to be selected. Given the demands for detail and accuracy of the segments, SLA 3D printing proved to be the best option. "We compared this to different technologies and we found out that Formlabs technology is way better for us, because details are much more visible and the aesthetics are more fitting to what we need," said Aliyah Mahmood, who, together with Mr. Bajena, was responsible for the physical realization from start to finish. Today, AI MAINZ runs four Form 2 and three Form 3 with which the project was successfully executed.

The AI MAINZ used four Form 2s and three Form 3s SLA 3D printers for the completion of their project.

The reliability of the Form 2 and Form 3 allowed Mahmood and Bajena to 3D print over 650 segments during the course of the project, operating the SLA 3D printers continuously during this process. They were paused only temporarily for cleaning and replacing the resin tanks to ensure that the printers can continue to operate with the highest precision and consistent accuracy. The Formlabs support team assisted them along the way: “Formlabs has really helped us going through this whole process," said Aliyah Mahmood who was in charge of maintaining and operating all seven SLA printers.

Depending on the level of detail and height of the buildings on the segment, one print took between 12 and 24 hours. The respective base of 12cm x 12cm with a height of 0,8 to 0,9 cm was printed first, followed by the architectural details.

How Renzo Piano Building Workshop Creates Architectural Models With 3D Printing

Learn more about how Pritzker Prize winner Renzo Piano and his team use 3D printing to visualize their architectural ideas down to the smallest detail and implement changes within hours.

In total, the combined segments of the models of the three cities in scale 1:1000 have the following dimensions:

- Worms 800 reconstruction: 116,7 cm x 108 cm, height from 0,9 cm to 4,0 cm

- Worms 1250 reconstruction: 116,7 cm x 108 cm, height from 0,9 cm to 7,9 cm

- Speyer 800 reconstruction: 252 cm x 159,8 cm, height from 0,8 cm to 3,3 cm

- Speyer 1250 reconstruction: 252 cm x 159,8 cm, height from 0,8 cm to 8,8 cm

- Mainz 800 reconstruction: 168 cm x 204 cm, height from 0,8 cm to 6,6 cm

- Mainz 1250 reconstruction: 168 cm x 204 cm, height from 0,8 cm to 7,5 cm

The dimensions and the division of the segments are based on the build volume of Form 2 and Form 3.

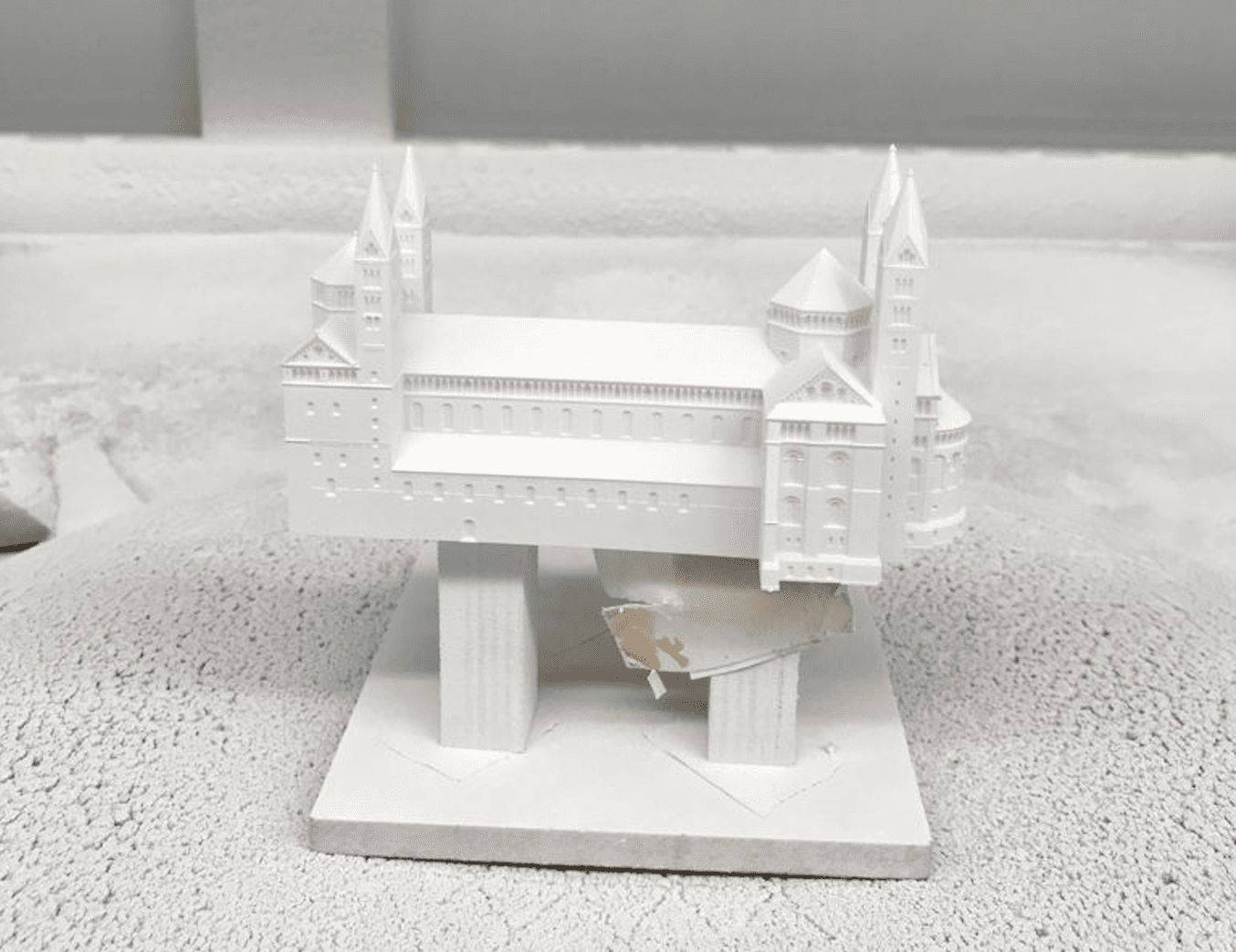

Among the objectives of the project was the visualization of roman cathedrals around 1250, which were connected to the respective emperors as well as the structure of the city.

The architectural standards, as well as the level of detail required, facilitated Mahmood’s and Bajena’s decision to use Formlabs White Resin. With its neutral color, high detail fidelity and matte surface finish, it offers ideal conditions without extensive post-processing. "White Resin is much better because we can show the details better and the segments are more smooth. You already have a presentable model right out of the printer," said Mahmood.

Request a Free Sample Part

You want to experience the quality of our White Resin yourself? Request a free sample now and we will send you a White Resin SLA-printed architectural model to your office.

Mahmood relied on Formlabs White Resin to ensure presentable models right out of the printers as well as a high level of detail which the project required. The details can be seen especially well in the displayed roman cathedral from Speyer in the period of 1250.

The Workflow for Creating Scale Models

After the 3D printed parts were removed from the printer, each segment underwent a routinized process that required, a great deal of sensitivity:

-

Washing

To remove excess resin and prepare the segments for further processing, each segment was first washed in an isopropyl alcohol (IPA) bath in the Formlabs Form Wash.

-

Removing Support Structures

After the segment was removed from the building platform, the support structures were removed in two steps. First, the finer structures on and inside the buildings were carefully removed using the flush cutter and tweezers from the finishing kit. Here special attention had to be paid to segments with small details and openings such as the cathedrals in order not to break anything. In the second step, the coarse structures below the segment were removed and made even.

-

Sanding

To remove any marks from the support structures and to make details more visible, each part was then sanded and defined by hand. Care had to be taken not to sand too much in order to create a visually smooth transition of the individual segments.

-

Painting

As a final finish, each segment was sprayed with two coats of white paint using a spray gun. This enhanced the surfaces of the segments and highlights especially small details.

Due to the fine structures and details of each segment, the post-processing became very time consuming. Breaking or damaging buildings or sanding too much automatically meant reprinting the segment and losing valuable time.

Post Processing and Finishing SLA Parts

Learn more about the different methods and ways of finishing your SLA 3D-printed parts.

From the 3D Printer to the Mainz State Museum

After two years, 650 segments and over 22,000 hours of work, Worms, Speyer, and Mainz were put together in a final step in their respective two time periods.

Visitors can view and compare the historical development, physical reconstruction, and printing of the medieval cities in the newly opened Digital Urban History Lab. The hybrid lab was realized as an integral part of the state exhibition "The emperors and the pillars of their power - from Charlemagne to Frederick Barbarossa" by theTime-Based Media Degree Program at Design School and the Institute of Architecture at Hochschule Mainz - University of Applied Sciences as well as the General Directorate of Cultural Heritage Rheinland-Palatinate

Learn more about how you can successfully scale architectural models in our white paper.

*The project was made possible by the financial support of the Directorate-General of the cultural heritage of Rhineland-Palatinate, the Federal Government Commissioner for Culture and The Media, Sparkasse Rhein-Nahe as well as J. Molitor Immobilien GmbH.