Gavin Stener’s company, 67 Designs, is a manufacturer and product development specialist working with customers in every industry, from large-scale automotive to marine and aviation equipment. Since 2012, 67 Designs has built a reputation for delivering high-quality, American-designed and manufactured products.

Despite 67 Design’s significant commercial success, Stener actually started the business as a way to expand his personal mission: helping to reeducate the manufacturing workforce so traditional skills aren’t lost as skilled workers get older.

“I’m interested in driving the urgent narrative around the need to reindustrialize our nation and make what we need here at home. The people who can help with that knowledge transfer are aging out of the workforce."

Gavin Stener, Owner 67 Designs

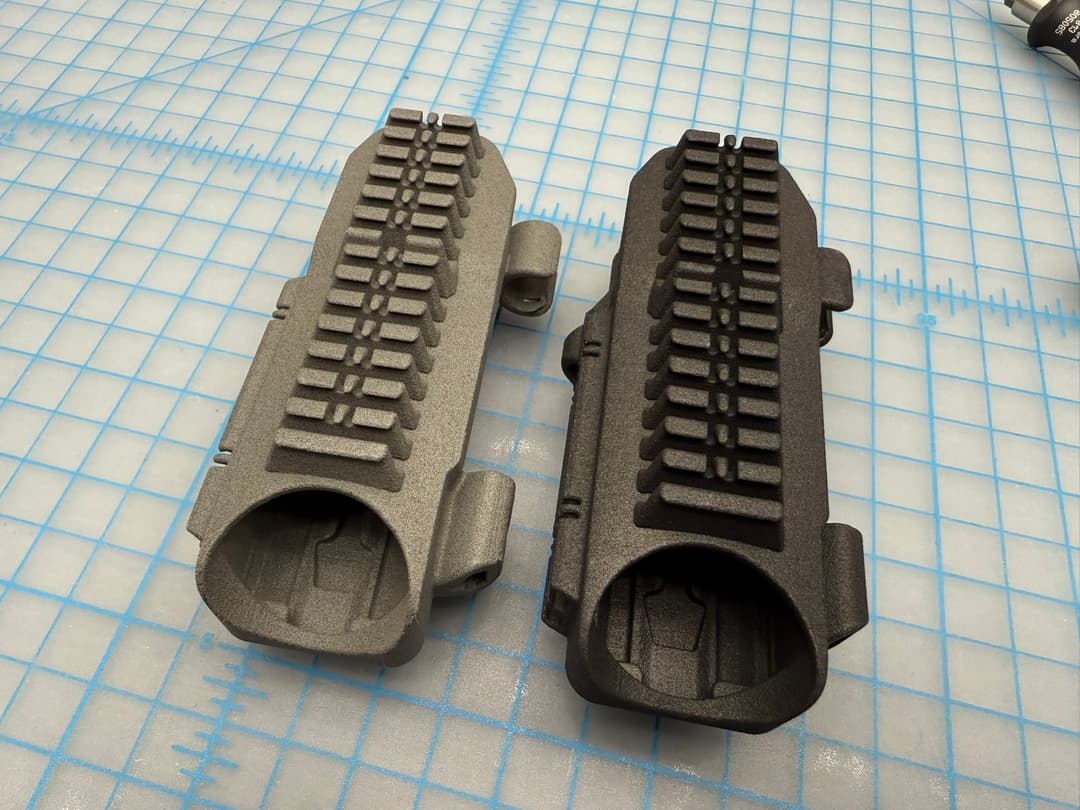

67 Designs is helping bring back ‘Made in the USA.’ These Mini iPad holders, pictured in the Fuse Sift before media blasting, are manufactured as end-use components on the Fuse Series in low volumes.

In-house manufacturing with the Fuse Series ecosystem can make low to medium volumes possible and cost-effective. 67 Designs has several customers ordering runs of hundreds or even thousands of 3D printed parts.

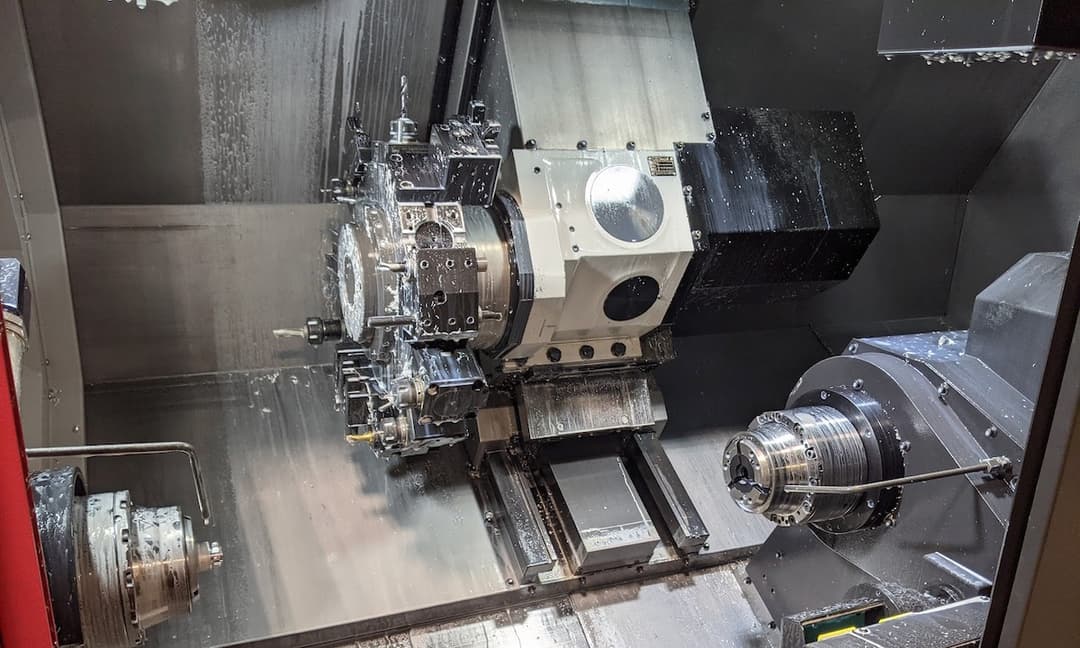

On its commercial side, 67 Designs combines advanced additive manufacturing technologies with more traditional machining, molding, tooling, and fabrication methods. Part of their approach uses the Fuse Series selective laser sintering (SLS) 3D printer for jobs where geometric flexibility, tight timelines, or overall cost make additive manufacturing the better option.

The Fuse Series is also important for Stener’s goal of helping to reeducate the workforce — he sees additive manufacturing as a great stepping stone for students (of all ages) to start making physical products. “Machining, casting, tool making, they’re not going away. But I think additive manufacturing is perfectly suited to the role of inspiring people and making it easy to start working with physical products,” says Stener.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Start To Finish: Drive, Fly, or Float

Post-processing methods like dyeing, coating, or vapor smoothing can make SLS 3D printed parts basically indistinguishable from injection-molded plastics. For replacement parts or aftermarket components in cars and boats, these post-processing techniques add enormous value, without much extra overhead.

SLS 3D printing enables complex geometries that would be difficult to machine or mold. For parts that an OEM has deemed obsolete, ordering a custom-machined or molded option could be several thousand dollars, whereas 3D printing is affordable and fast.

Stener has built his business based on word of mouth. His first automotive customers in 2015 came to him from the vehicle-based adventure world, looking for customization on their off-roading or long-haul vehicles. “Most of the people who are into exploration vehicles are also into flying, or also have a boat, so they keep coming back for new projects,” says Stener.

The high quality of their consumer-grade parts — smaller accessories like phone mounts for an off-roading vehicle — often led individuals to then contact 67 Designs when they needed a product designed for their 9-5 job at a corporation. “We have a lot of enterprises come to us as a result of using our products in consumer environments, or to get involved with us doing custom, short-run work. People who love our products are those who want something different, or they have a unique, specialized application,” says Stener.

That customization aspect makes 3D printing integral in the design process, even if the final product ends up being traditionally made. Stener started out with accessible Replicators, fused deposition modeling (FDM) printers that let him get a sense of what a part would look and feel like in the physical world. “FDM is good for small conformation pieces to review or to prototype. But supports have always been a problem, and when we started in 2012, the only supportless printing technology was a huge, half-million dollar system,” says Stener.

In-house SLS 3D printing makes it possible to shorten your development timeline and bring it all in-house. Here, these Ledge Universal Holder components are about to go through the Fuse Blast.

All packaged up, the Ledge Universal Holders are ready to ship out to end-use customers, and the best part is, the entire workflow was done in-house. They only use the Apple MagSafe Charger versus white-label.

While building 67 Designs' customer base and reputation, Stener stayed on top of the powder bed technology market. In situations where the product needed to get out there, he would outsource end-use quality power parts to service bureaus before spending tens of thousands on tooling for injection molding.

“Using SLS was a no-brainer. There’s only one way to get a product accepted by the wider market and that’s to get things out there. My vision is that anything short of a 10,000 part order, don’t cut metal to make a tool. You’ve got to go fast, innovate fast,” says Stener.

Staying with Shapeways for years, Stener watched the Fuse Series enter the market and considered its production-ready capability from afar. “We wanted to make sure our SLS printer was production-ready, that it could hold tolerances and maintain fidelity. When we were sure the Fuse was up to it, we moved forward,” says Stener.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Benefits of the Fuse Series for a Small American Manufacturer

Since bringing the first Fuse 1+ 30W printer in-house, Stener has added more printers. “I believe in redundancy. If we have a printer down, production doesn’t have to stop. There’s a much greater risk in one $500,000 machine than in five $100,000 machines,” says Stener.

The Fuse Series has enabled 67 Designs to keep production running at all times, working on higher volume orders for customers and corporate partnerships, all while manufacturing their own designs, like their best-selling phone mount for off-road vehicles.

Having an agile workflow enables 67 Designs to produce products that outperform competitors on every level. This Ledge Universal Holder includes an Apple MagSafe Charger.

By maintaining consistent batch sizes across multiple build chambers, the team optimizes every cycle and streamlines their post-print operations. “Our team knows what to expect, and efficiency becomes second nature,” says Stener.

“Accessible SLS gives people a lot more options. And end-use SLS parts help get additively made parts in the minds of the consumer; they set the stage for delivering products in the market where people said we couldn’t,” says Stener. Getting products out there isn’t the whole story, however. To break the perception of 3D printing as a prototyping-only tool, SLS 3D printed end-use products have to be well-made.

“You have to be disciplined about it and have a production mindset. We made our own Fuse calibration tool, and go back in regularly to make sure it stays on track. Small companies still need to have a big corporation mindset when it comes to production quality. And that discipline comes from traditional engineering,” says Stener.

Another axiom of 67 Designs is that additive and traditional manufacturing are not interchangeable. Stener is still the main designer for nearly every product 67 Designs produces — theirs and their customers. When the end-product needs to have the strength of a cast or machined metal, he designs for subtractive — even if the prototypes will be 3D printed. If the application doesn’t require that strength, but might benefit from lightweight, generative design and organic structures, or if there are only 100-5,000 small plastic parts needed, he might design specifically for additive manufacturing. “I don’t ask an AM part to be an injection molded plastic. They’re two different animals and I don’t see them as interchangeable,” says Stener.

Though 67 Designs' team can manufacture products using traditional as well as additive parts, there is one advantage to 3D printing that they’ve found more and more appealing for some of their customers: the protection of intellectual property. “With some offshore manufacturing, customers worry about their products being copied and ideas stolen. One way to take advantage of additive manufacturing is to design features that can’t be replicated by traditional tooling,” says Stener.

iPad Mini Holder

SLS 3D printed consumer products not only match molded plastics in function for parts like these, but they also dramatically reduce waste. As consumers everywhere feel the pain of forced obsolescence and diminishing access to resources that enable the ‘right to repair,’ SLS 3D printing can provide an affordable alternative. “When Apple inevitably changes their devices (and they always do), we don’t panic. We don’t liquidate mountains of obsolete inventory or absorb devastating write-offs. We simply iterate — fast — and move forward,” says Stener. The design and manufacturing workflow from 67 Designs eliminates:

- Production waste from excessive packaging

- Carbon emissions from transoceanic shipping

- The environmental toll of trucking products from the Port of Long Beach to Dallas

“The Fuse gives us something invaluable: control. We manage production cycles with precision and optimize every build to match real demand. The build chamber hits a sweet spot — perfectly sized for compact batches of our holders while giving us the flexibility to integrate other SKUs seamlessly. It’s efficient without being rigid, scalable without being wasteful.”

Gavin Stener, Owner 67 Designs

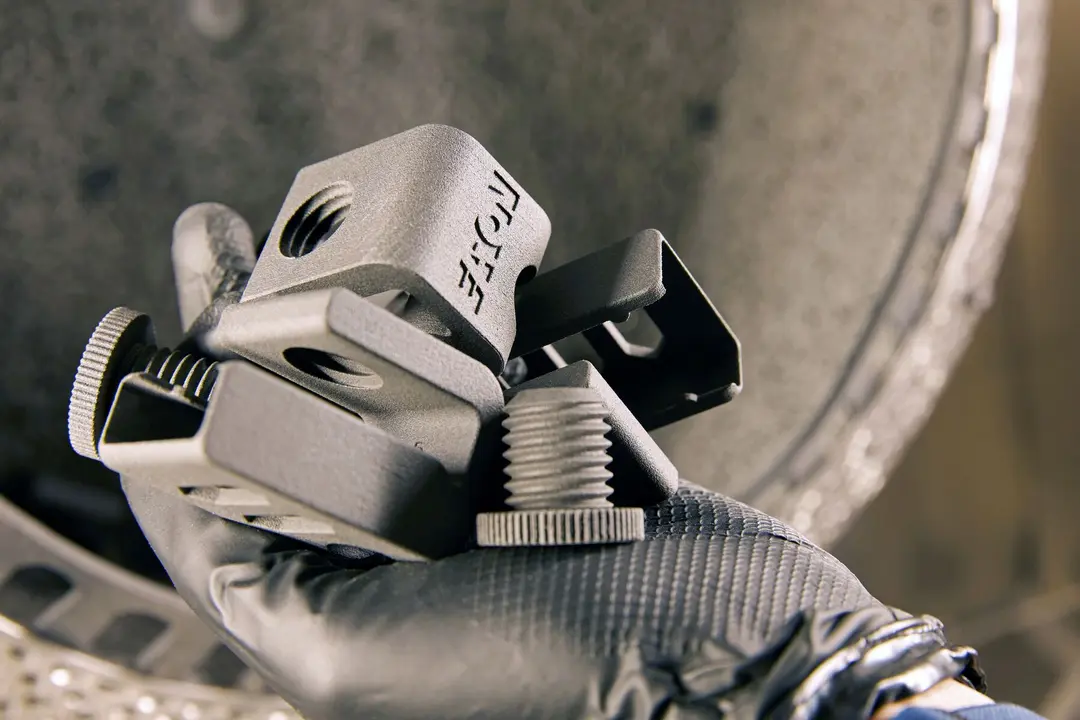

Pitot Tube for Aircraft

A pitot tube is a device used to calculate fluid flow speed by measuring pressure inside the tube and out. On aircraft, the pitot tube is crucial for measuring airspeed. Pitot covers are needed to keep insects out of the tube on the ground and are typically made from fabric. These fabric covers can easily blown off, letting wasps and other insects potentially crawl into the tubes to build nests — a major safety concern for the next flight. 67 Designs worked on a plastic pitot tube cover that was easy to install, easy to remove, yet stayed on snugly at all other times.

“The Fuse allows us to create custom pitot tubes in ways that cannot be easily tooled for injection molding and have a very definite and deliberate shape. The Fuse gives us the flexibility to make these well and mix in with longer run and higher volume SKUs.”

Gavin Stener, Owner 67 Designs

Ledge Universal Holder

One of 67 Designs' most popular products, the Ledge Universal Holder, incorporates an AppleMag Safe Charger and custom, adaptable hardware built on the Fuse 1+ 30W. The Holder likely has the lowest carbon footprint of any comparable product on the market, and its main components are manufactured on the Fuse 1+ 30W. 67 Designs originally decided to go with additive manufacturing for this part because the traditional tooling route would have locked them into one design. For a product that needs to adapt and change as the OEM makes changes, injection molding wouldn’t be economically viable.

“If we had chosen injection molding, the product wouldn’t be cost-effective and we’d be locked into expensive overseas tooling — often manufactured in China at significant cost — with a two to three month development timeline,” says Stener.

Distributed Intelligence

The accessibility of the Fuse Series — both the size and the cost — makes it possible to build an agile manufacturing workflow around the technology, so small businesses can become end-use manufacturers without sinking huge amounts of money into traditional manufacturing processes and tools.

67 Designs isn’t trying to replace traditional manufacturing with 3D printing, but they’re experts at finding situations where additively produced parts can complement or improve on existing workflows.

With the recent federal focus and support on reestablishing a domestic manufacturing network, businesses can look to 67 Designs as an example of what it means to "produce local and consumer local," as Stener puts it. The efforts of his business go beyond just domestically producing parts with 3D printers — they extend to workforce development and education. “Beyond the products themselves, we’re investing in people. We’re training a new generation of manufacturers in advanced manufacturing skills, setting them up for rewarding careers at a time when US companies are expanding domestic production,” says Stener.

To learn more about 67 Designs, visit their website. To test the end-use capabilities of SLS 3D printed parts for yourself, request a free SLS 3D printed sample from Formlabs.