Picture of the Semmelweis 3D Centre team (from left to right): Dr. Szabolcs Lányi, Dr. Daniel Palkovics, Gabriella Sódar, Dr. Imre J. Barabás, Dr. Dániel Végh Ph.D.

Lab space and equipment are often in high demand at universities around the world. The scope and staffing of a research project may expand over time, while allocated space does not. Research departments often have to fight for space, and high-cost equipment is kept under lock and key to prevent damage by untrained users. Even within departments, there can be tension between researchers, instructors, and students. Though across a university there might be many advanced technologies represented, that tension leads to the siloing of resources and technical knowledge.

At Semmelweis University in Budapest, a group of researchers, practitioners, and instructors have collaborated to break this cycle. Together, these experts created the Semmelweis 3D Centre (SE3D) to support the Faculties of Medicine, Dentistry, and Pharmacology at the university. We spoke with Dr. Dániel Végh, a practicing prosthodontist who works with SE3D, to learn about how the center was established and has grown to serve so many different groups within their university.

Guide to 3D Printing In Education

In this guide, we’ll discuss the benefits of 3D printing in education, from improved student collaboration to workforce development and empowered creativity.

Can you describe the 3D Centre project at Semmelweis University?

The Semmelweis 3D Centre (SE3D) center is a facility for 3D printing technology at Semmelweis University. Our group’s mission is to promote 3D printing technology and build community among those using 3D technology at our university. The SE3D center was founded by Dr. Imre J. Barabás and Dr. Daniel Palkovics, and was supported by Prof. Dr. Béla Merkely, Rector of the Semmelweis University.

Both the medical and dental fields use 3D technology in day-to-day patient treatment, and both have ongoing innovative research. The SE3D Centre offers a cooperation platform for these researchers and clinicians. Our vision is to find new ways to address old and new medical issues through frontier experiments.

Why did you choose Formlabs SLA 3D printers to be part of the 3D Centre?

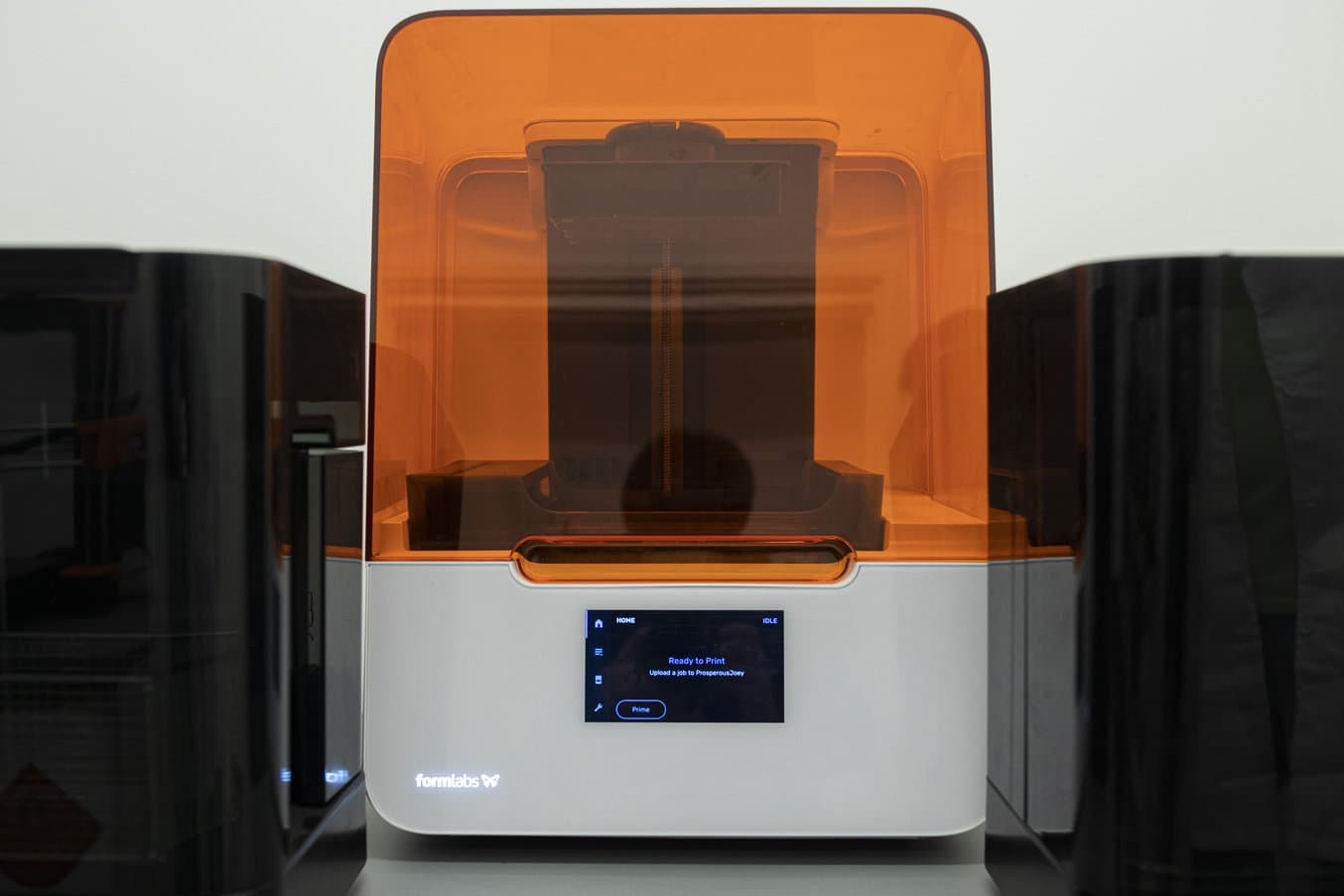

Formlabs is a well-respected company in the 3D printing field. The Form 3B, installed at our centre, delivers high-end parts in a user-friendly, compact package.

The partners working with Formlabs are impressive. We liked that Formlabs is partnered with companies like Materialise, Digital Smile Design, and 3Shape. Additionally, Form 3B is an optimal choice for an average dentist willing to try digital additive technology in patient care. For example, in Hungary, dental offices can apply for government support to develop their businesses and support digitalization. Dentists and dental laboratories are already using these grants to invest in 3D printing because they can save money in the long term, create consistent results, and even consider same-day manufacturing.

And, although it is not related to our discipline, the company’s Hungarian roots and the fact that they have a research center and company location in Budapest add to the charm of using the Formlabs 3D printer.

According to Dr. Végh, Form 3B "delivers high-end parts in a user-friendly, compact package."

How many 3D printers do you have today at the Centre?

There are nine 3D printers in the SE3D Center, and we have 3 Form 3B printers at the Semmelweis University, and this number is growing. Besides the Formlabs 3B SLA printers, we use FDM printers to create anatomic models and for education purposes. Our plans include the purchase of other 3D printers from Formlabs soon. Fuse 1 is very promising; we are advocating for this investment.

What other equipment does the 3D Centre have besides 3D printers?

SE3D has access to 3D intraoral scanners, virtual reality headsets, 3D modeling software, simulators, and more. Because the Centre is integrated into Semmelweis University, we have access to all the equipment owned by the Faculty of Dentistry. We also have partnerships with other technical institutes that can do CAD modeling, reverse engineering, mechanical and fluidic simulations, and even virtual reality.

Our students learn digital techniques with a variety of intraoral scanners, including 3Shape TRIOS, Planmeca Emerald S, and Medit 500.

How will 3D printing be used in education at the university?

Both the dentistry and general medicine faculties have introduced new undergraduate courses specializing in digital technology: Basics of Digital Medicine and Basics of Digital Dentistry. In addition to lectures from the most renowned educators in Hungary, students will plan the treatment of a patient from scan to treatment.

The curriculum is divided into two parts. The first part consists of classroom instruction, teaching the theory and fundamentals of imaging technologies, segmentation, 3D modeling, and 3D printing. The second part is division-specific and hands-on, where students encounter several different anonymized patient cases. This work will take place in the Centre, where students have centralized access to the high-tech equipment used to do this work.

Semmelweis University teaches digital technology that enables techniques like easy visualization of cases and guided surgery, models for which are pictured here.

Why is it essential that students have access to these technologies?

3D printing is becoming standard in the fields of medicine and dentistry. The majority of dental practices and clinics use some sort of digital technology in their everyday work. To prepare students to deliver excellent care to their future patients, universities need to equip their students with hands-on experiences with technology and practical training.

3D printing is still a relatively new learning and teaching tool for medical education. In the general medicine division, patient-specific models with anatomical fidelity made from imaging datasets can significantly improve a new generation of surgeons’ knowledge and skills. This fidelity has allowed students to view and understand gross pathology and structural relationships before surgical intervention. Improved understanding through visualization has, in turn, allowed surgical teams to plan interventions more accurately and guide margins of resection, model appropriate implant dimensions and sometimes create the implant itself using 3D printing technology.

It is unquestionably essential to incorporate the possibilities offered by 3D technology in modern 21st-century medical and dental education.

The 2022 3D Printing Applications Report

What other disciplines could benefit from 3D printing instruction at the university level?

To get inspired, read the 2022 3D Printing Applications Report to see what industry leaders say.