The marriage of traditional craftsmanship with modern technology has brought about a remarkable transformation in the market for 3D-printed religious idols in India. By leveraging the capabilities of 3D printing, jewellery makers and idol manufacturers can now bring their imaginative designs to life with unprecedented precision and intricacy, surpassing the limitations of traditional fabrication methods. Enabled by this technology, Imaginarium Jewel Tech has redefined the jewellery industry, offering a myriad of possibilities for crafting unique, personalised, and breathtaking pieces that cater to individual preferences and tastes.

As the demand for intricate and customised idols continues to grow, the 3D printing industry stands at the forefront, providing a perfect solution for temples, households, and devotees seeking exquisitely detailed divine figurines. Moreover, the versatility of this technology goes beyond religious idols. It allows for the creation of a wide range of other products used in religious practices, such as intricately designed pooja thalis, accessories like diyas (oil lamps), incense holders, and bells. Additionally, religious artefacts, symbols, prayer beads (Mala), and decors like wall hangings, sculptures, and mandirs (shrines) find their intricate forms through this innovative manufacturing process. Furthermore, 3D printing plays a vital role in the preservation of heritage by creating replica artefacts that showcase cultural richness and significance.

Understanding 3D Printing for the Jewellery Industry

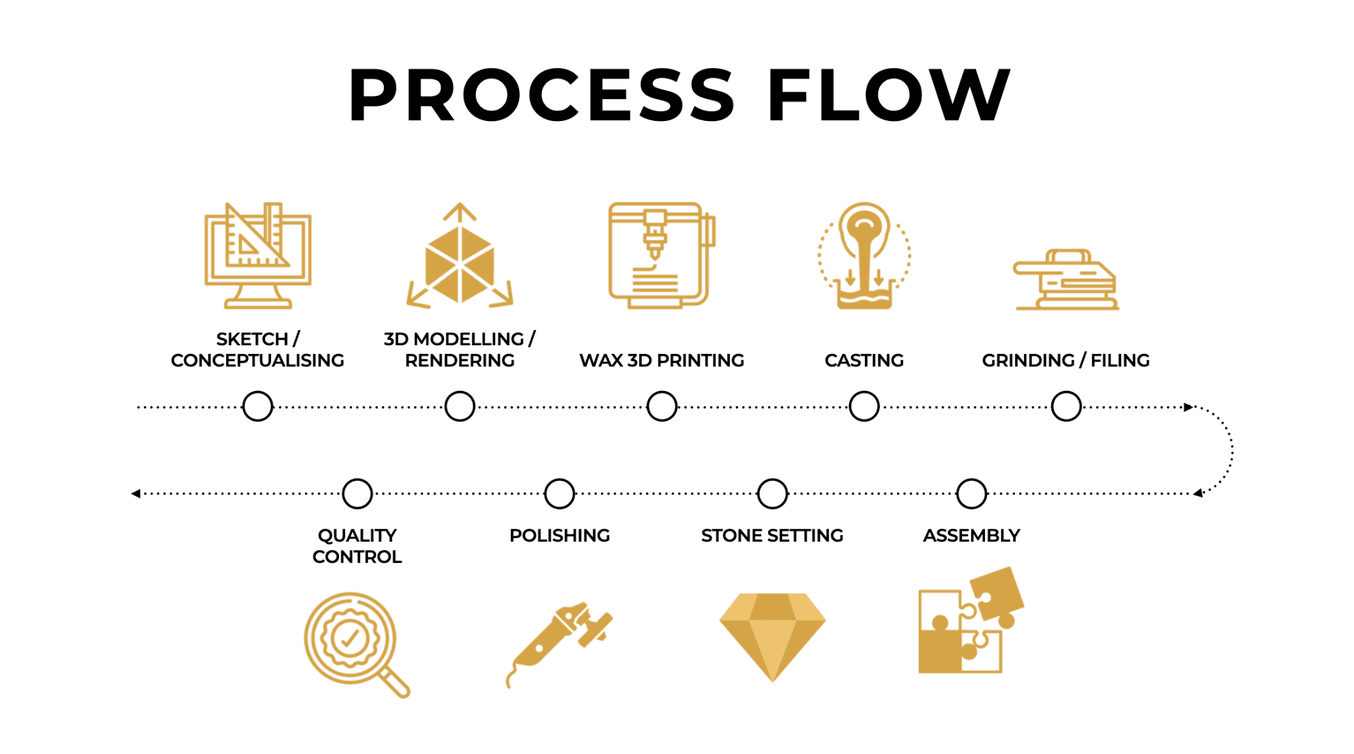

The printing process flow varies based on jewellery processing needs

The process of 3D printing jewellery begins with creating a digital model of the desired design using specialised software. This model serves as a blueprint for the 3D printer to follow and print. Once the digital model is ready, it is sent to the available 3D printer, which works by adding thin layers of material on top of each other to build the desired shape. After the printing process is complete, the jewellery piece may or may not undergo a post-processing phase. If the part is meant for a master, post-processing is usually skipped. Master casting refers to the process of creating a master model or prototype through 3D printing, which is then used to produce multiple copies of the same design through traditional casting techniques, enabling scalability and repeatability.

Alternatively, if the part printed is for end use, it will involve removing any excess support structures or powder residue left from the printing process. The piece may also pass through additional treatments, such as polishing or plating, to achieve the desired finish and appearance.

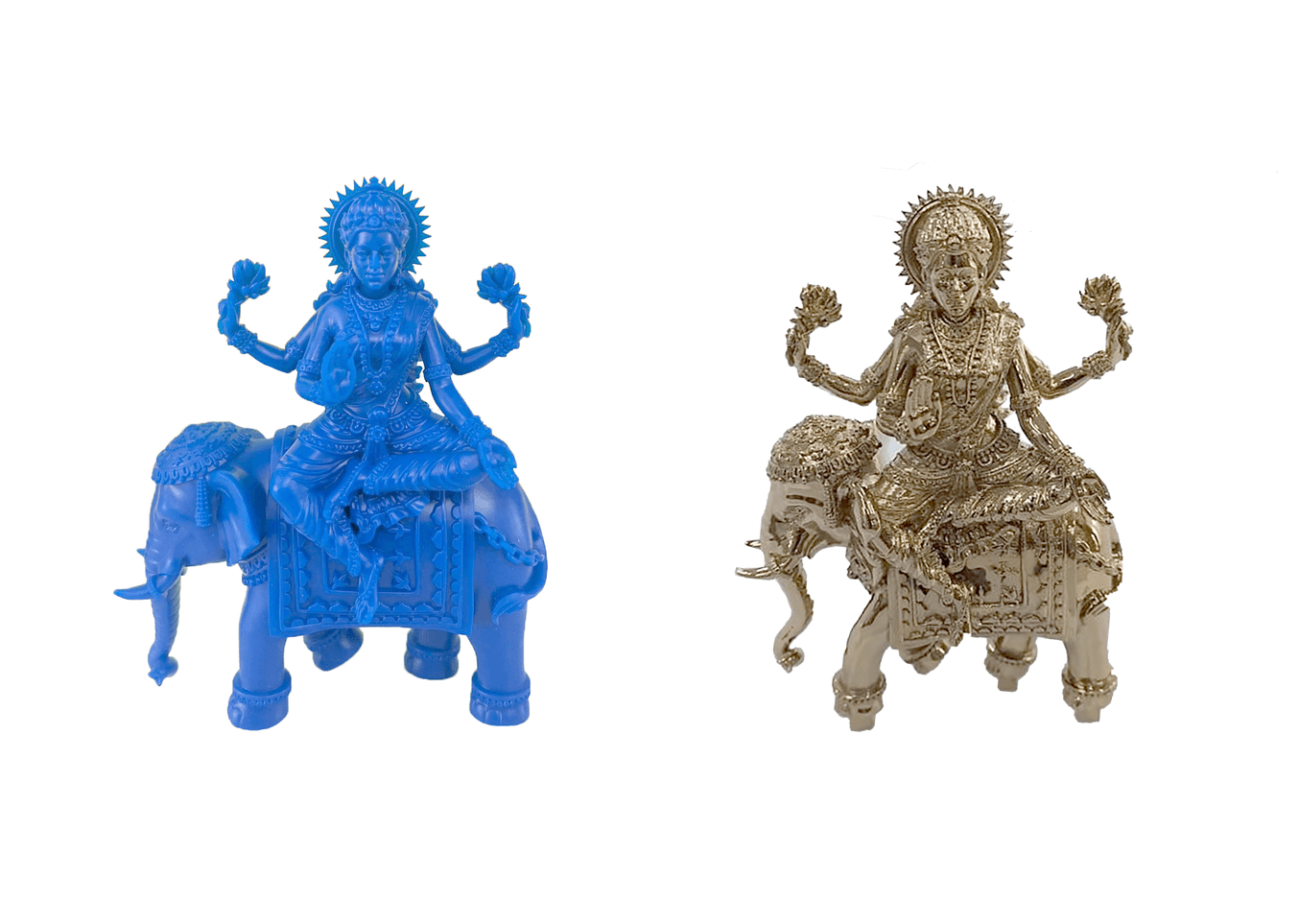

The idol printed in Form 3+ produced a detailed master (left) and the post-processed brass part without compromising on any features. (right)

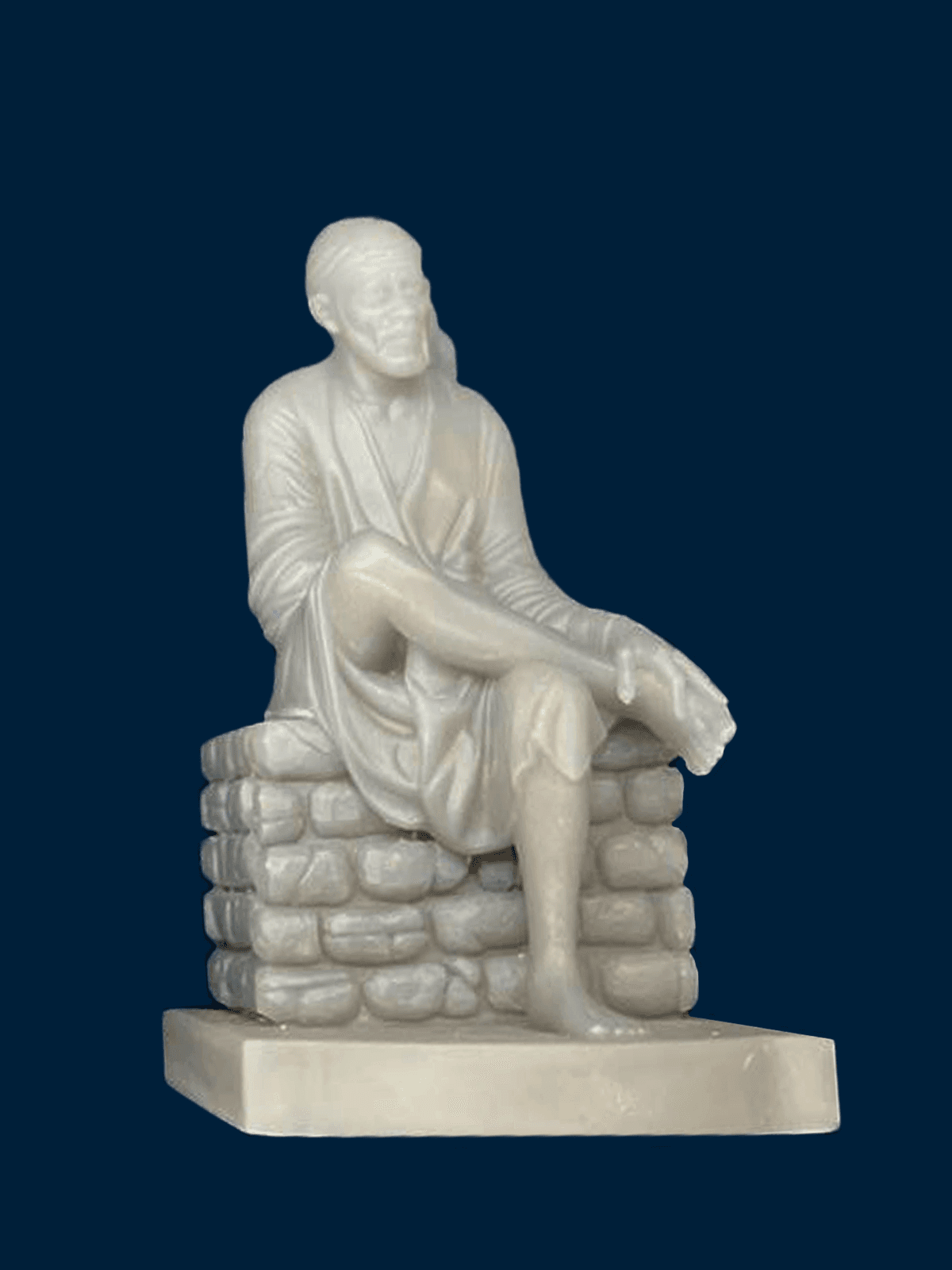

Case 1: Crafting an Intricate Goddess Idol (Murti)

The idol cast in brass was the centrepiece of the ‘Parikar’ setting.

As part of a bigger setting, Imaginarium embarked on the task of producing an intricate goddess idol (murti) using Formlabs’ Castable Wax 40 resin. This particular project involved their onsite Form 3+ machine, which accomplished the printing process in 16 hours.

The Castable Wax 40 resin, a photopolymer resin by Formlabs, delivered the exceptional quality required for high-precision masters. It exhibited characteristics such as high dimensional accuracy, a smooth surface finish, and low ash content upon burnout. Additionally, its low viscosity and low shrinkage ensured the successful printing of delicate and intricate designs at resolutions as fine as 25-50 microns.

The goddess idol, now cast in wax resin, underwent post-processing to attain the desired brass finish. It became part of a traditional ‘Parikar’ piece, an altar based on Jainism where multiple religious deities are placed and worshipped. The successful integration of Formlabs’ SLA 3D Printing technology in this project demonstrated its capability to handle intricate and complex designs for religious artefacts.

The Easiest Workflow on the Market with Castable Wax 40 Resin

In this webinar, discover how you can get the most out of our high-performing casting material, from design to post-processing.

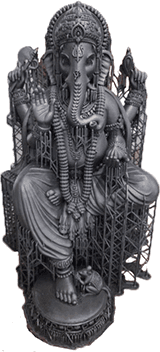

Case 2: 3D Printing a 12-inch Ganesha Idol

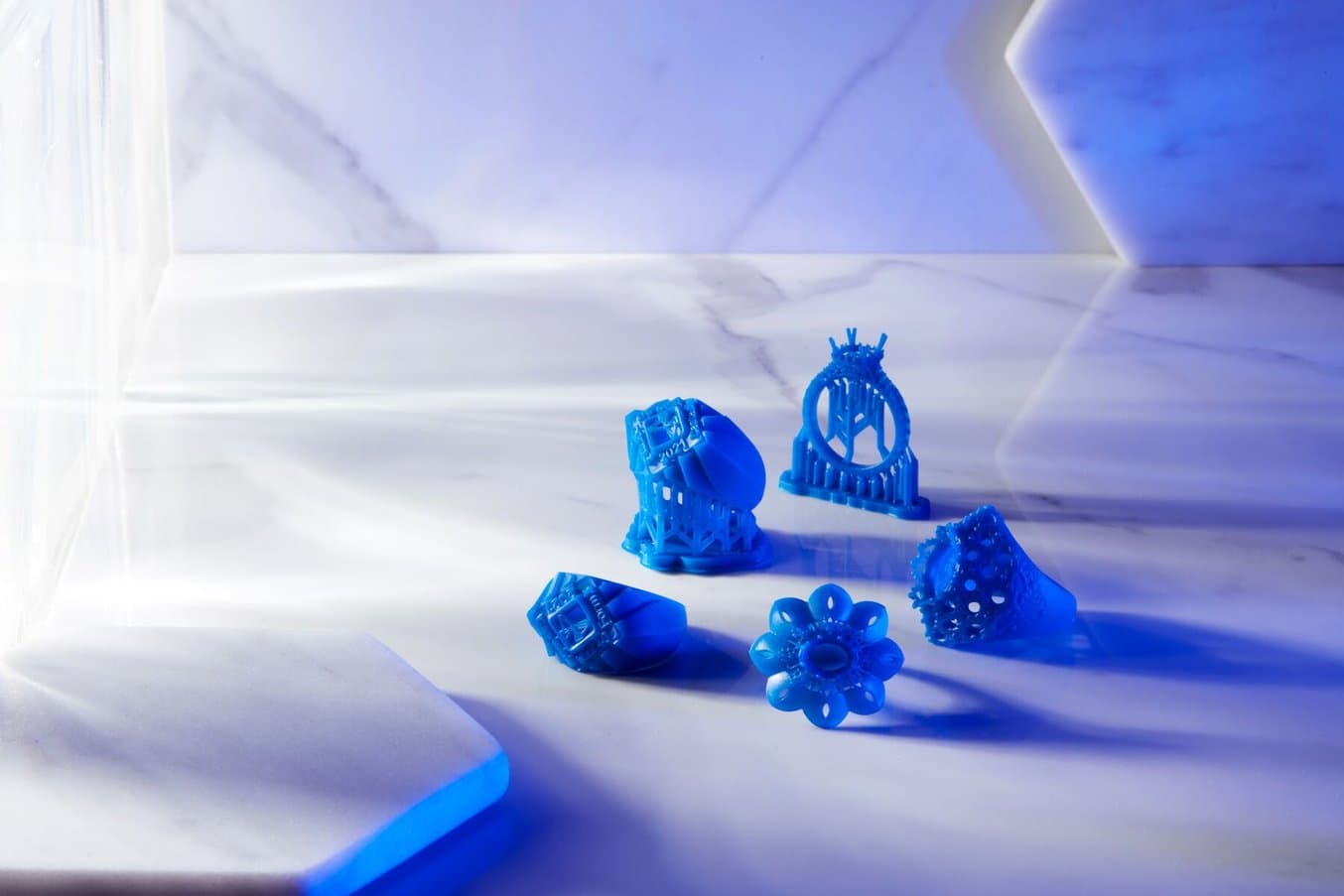

Another avenue in 3D jewellery printing is end-use parts that are produced without the need for additional casting or manufacturing steps. End-use parts can be made from various materials, including precious metals like gold, silver, and platinum, as well as other materials like resin or ceramic.

Imaginarium produced a 12-inch Ganesha idol using Formlabs' Form 3L printer. The process took just 40 hours of print time, and the layer thickness was an impressive 100 microns. For this project, Formlabs' standard engineering black resin was used, highlighting intricate details with its matte finish, making it ready to use right off the printer. The engineering black resin proved to be an apt material, especially for presentation pieces and display models. Form 3L allowed a meticulous precision of 0.35mm to ensure that even the minutest feature of the Ganesha idol was accurately printed.

These 1-foot idols and smaller figures, made with Formlabs' precise 3D printing, stood out at Imaginarium's gallery and jewellery shows for their beauty and detail.

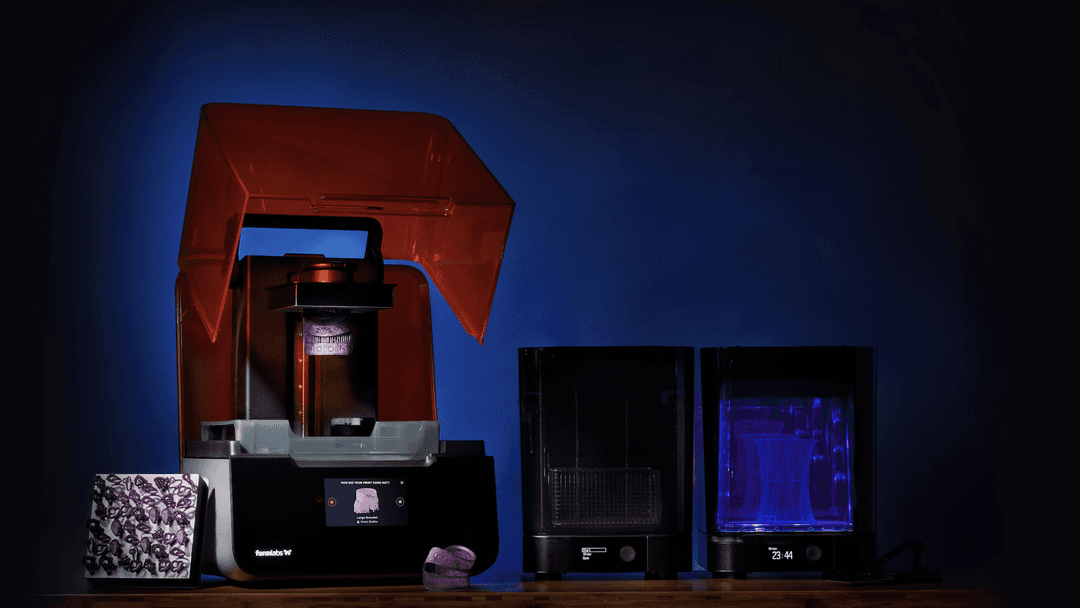

Imaginarium's partnership with Formlabs extends beyond just accessing their high-quality printers. Their integrated software, PreForm, works with STL or OBJ files and displays the ideal layout, orientation, and support for successful printing. This seamless workflow enables them to print without specialized training, and an integrated dashboard allows for remote monitoring and same-day turnaround in creating 3D-printed jewellery and figurines.

"We have witnessed a paradigm shift in religious idol and jewellery manufacturing since incorporating Formlabs' 3D printers. The precision, scalability, versatility of materials and customer support offered have elevated our craft to new heights, empowering us to deliver exquisite pieces. This technology allows us to celebrate the essence of divinity while embracing modernity and design freedom."

Kamlesh Parekh, Director at Imaginarium Jewel Tech

The fusion of technology and tradition is revolutionizing craftsmanship in the religious idol and jewellery industry. With Formlabs' 3D printing and Imaginarium's visionary guidance, intricate, personalized pieces now resonate with spiritual and aesthetic values. Advanced materials and affordable in-house 3D printers are changing how designers work, bringing industrial quality to the desktop. This innovative approach in the Indian 3D printing market promises to mesmerize the world with cultural reverence, crafting divinity with technology.