How Harlequin Is Meeting Tight Deadlines for Hermès, Dior and Louis Vuitton With SLA Printing

Harlequin Design is known around the world for creating jaw-dropping visual merchandising, using 3D printing to create large models, fittings, and tooling. Since their founding in London in 1994, they’ve expanded around the globe with subsidiaries in Milan, New York, Shanghai, and Dubai, designing extraordinary retail experiences for global beauty and fashion brands like Louis Vuitton, Hermes, Marks & Spencer, Macy’s, John Lewis, and many more.

Facing an increasing number of requests from the fast-paced fashion industry, Harlequin needed to find a way to produce dazzling, custom displays on very short timelines. We talked with Mark Garside, Head of Innovation & Product Development, about the advantages of a large printer fleet and how Harlequin leverages it to cut costs, decrease lead time, gain independence from supply chains, and increase flexible production.

Designing Props for the Retail Theater

It’s been almost 30 years since Amazon shipped its first online order, and today anyone can comfortably buy everything they could wish for without leaving the house. Though online retail sales have continued to grow over the last 20 years, the majority of retail revenue still comes from brick-and-mortar stores. Even after the pandemic, 76% of surveyed consumers in France, Germany, and the UK responded that they plan to keep on shopping in stores.

Garside explains this interest in offline retail with the analog experience in what he considers retail theater: “Yes, we could all shop on our phones, but it's like most things digital: a bit boring. People want to be excited. That’s why we are talking about entertainment and the retail theater.”

Consequently Harlequin is acting as a prop designer for those retail theaters, helping stores to convey their message in the most interesting way possible. “A high street store with only a digital screen in its window will never be as interesting as something that’s being refreshed, that's three-dimensional, that’s real,” says Garside.

At least every season, store and window dressings need to be updated with eye-catching new displays. But the lead time for seasonal themes is short, meaning new displays must be created in a very short time.

That’s why Harlequin is constantly challenged to present creative and unique designs in very tight deadlines. “The retail and fashion world is moving very fast. There's a furious amount of work that needs to be done very quickly and sometimes all at once. It's fast design, fast understanding of the project, and fast delivery,” Garside explains.

Finding the Right Tool for High Quality and Large-Scale Custom Projects

For a long time, Harlequin had to rely on external sculptors and model makers to create the unique decorations they are known for. Although their works were matching Harlequin’s quality requirements, the lead times and costs for those external services were a risk for the tight deadlines of its projects.

Harlequin was looking for a faster, more flexible, and less costly solution that they could use in-house. They quickly turned to 3D printing, known for its cost-effective production of single pieces and low-volume series that are typically requested by Harlequin. But starting out with simplistic fused deposition modeling (FDM) printers, they didn’t find the results they were hoping for. “Everyone dabbles with a starter thing like FDM, but I always found it really disappointing. I never saw it stick on the bed. They always bend off or they break. It just feels very, very hobbyist,” Garside remembers.

Especially with larger prints, FDM printing was too slow and unreliable to benefit Harlequin’s business. “My god, you'd wait a week to get something printed with it, and halfway in, it would've broken or something would've happened. It was useless for us.” As Harlequin can’t afford to have problems with printing in already time-critical projects for high-value brands, they needed to part ways with FDM.

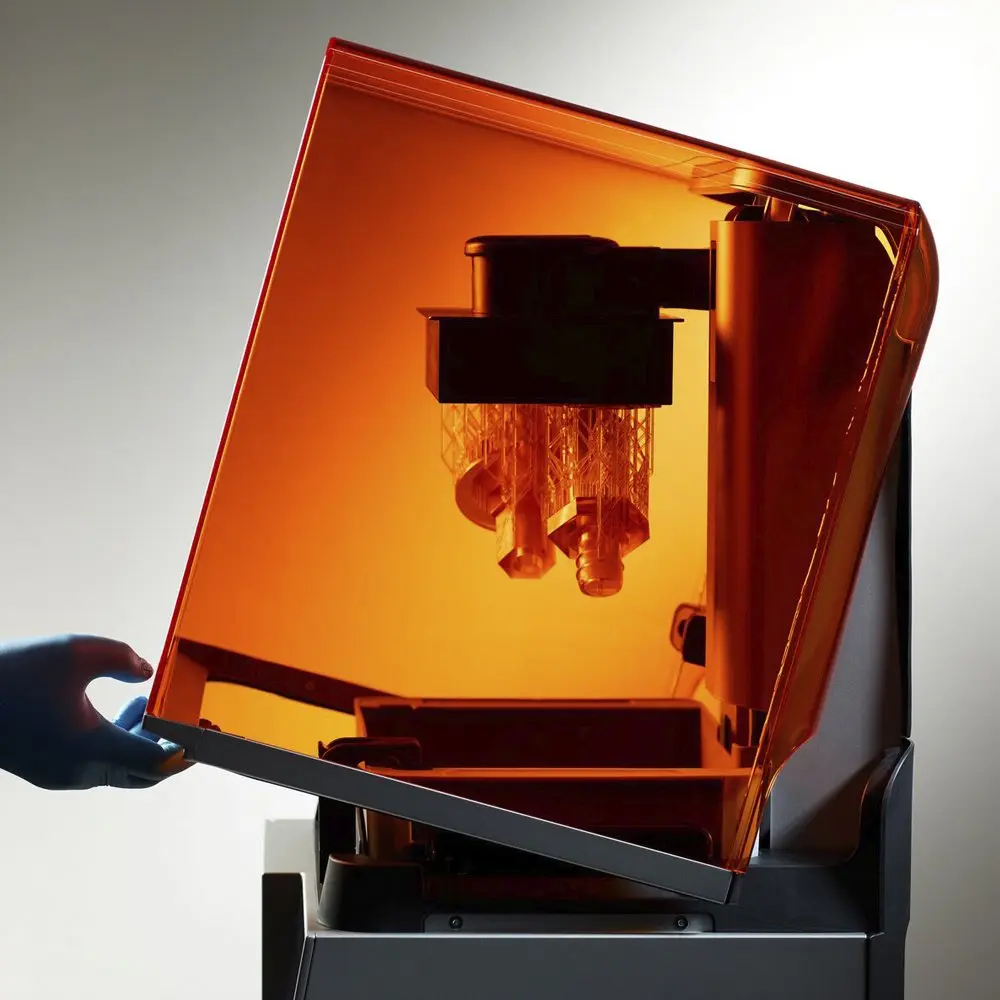

Formlabs quickly stood out to Garside as a better and more reliable solution, fitting Harlequin’s professional needs. “There are a lot of 3D companies that just come and go. Formlabs instantly appealed to me because their printers are also used in the medical industry, so I knew there’s quality and reliability there. You really want a company that you know is going to be around next year, who is going to solve your problem, if you’ve got one.”

With the FDM printer, it never felt like it was helping. It was a hindrance. Whereas with the resin printer, right from the word go, it was useful and it made designs possible that we weren't able to do before.

Mark Garside, Head of Innovation at Harlequin Design

From the beginning, Garside was planning to have a big fleet at his disposal to flexibly react to crunch times and increase the resilience of the production. That’s why he likes how easy it was to scale his printer fleet to seven Form 3Ls, easily managed with free Dashboard software. “We once considered investing in one of those MJF printers, which is way more expensive than the Form 3L. Only one machine would already be about a quarter of a million pounds, for not even a really big build size. If that machine breaks the whole production is blocked. I rather have a lot of printers at my disposal, where you can just press go and you get speed,” Garside explains.

Product Demo: Form 3L Ecosystem

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large-format post-processing machines? In this demo, we showcase end-to-end workflow, including post-processing.

Gaining Speed and Flexibility With In-House 3D Printing

Today Harlequin is using Formlabs 3D printers in a wide variety of use cases to cut production costs and meet the tight deadlines of the hectic retail industry even for the most complex designs.

Skip the Sourcing: Saving Cost and Time With Customized 3D Printed Parts

Harlequin’s schemes are meant to create a flawless illusion of an exciting world pedestrians can’t resist visiting. For this unified look, fittings and fixtures play a critical role.

The big problem? “We don't live in a world with a lot of options on fittings and fixtures anymore. There used to be a lot more available, but even big companies like Häfele don't really hold stock anymore in the same way. They have certain fittings and that's it,” Garside describes. But those one-size-fit-all-solutions rarely matched Harlequin’s high standards and unique designs.

With the stock availability of fittings constantly shrinking, Harlequin is simply printing its own. They independently create solutions like these fittings printed in Tough 2000 Resin that bond rods into plywood.

That’s why Garside is happy to be able to print the parts he needs, whenever he needs them.

3D printing is giving us great flexibility to work with whatever we have at hand. Even for designs made by somebody else, we can tailor our fittings precisely to that object.

Mark Garside, Head of Innovation at Harlequin Design

But this doesn’t mean Harlequin has abandoned mass-produced parts. On the contrary, the flexibility of 3D printing lets them leverage the full potential of cheap stock items and easily upcycle them, saving production costs. “What I love about the 3D printing process is that you've got the option to style something that you wouldn’t be able to use otherwise. Sometimes you want to just utilize the off-the-shelf hardware and now we can dress it up, creating a beautiful skin for it, so we can use it in our windows,” Garside says.

Harlequin is reducing production costs for unique designs like this spray can, combining cost-effective stock items (metal tube) with customized 3D printed parts (top and valve).

The flexibility of 3D printing is also saving Harlequin valuable time they would otherwise spend searching for parts which might not even exist. “Whatever it is you want to source, you’ve got to find it first. With 3D printing we can either skip that process entirely or cut it down to a minimum, as we can take a part that’s close to what we want and adapt it,“ Garside explains. This enables Harlequin to execute designs no matter what parts are available, increasing their credibility with high-value clients.

Custom Manufacturing and Low Volume Production with 3D Printed End-Use Parts

Watch this webinar to learn how to achieve custom manufacturing and low volume production of end-use parts quickly and cost-effectively with 3D printing.

Exploring New Design Possibilities: The Strength, Complexity, and Accuracy of 3D Printing

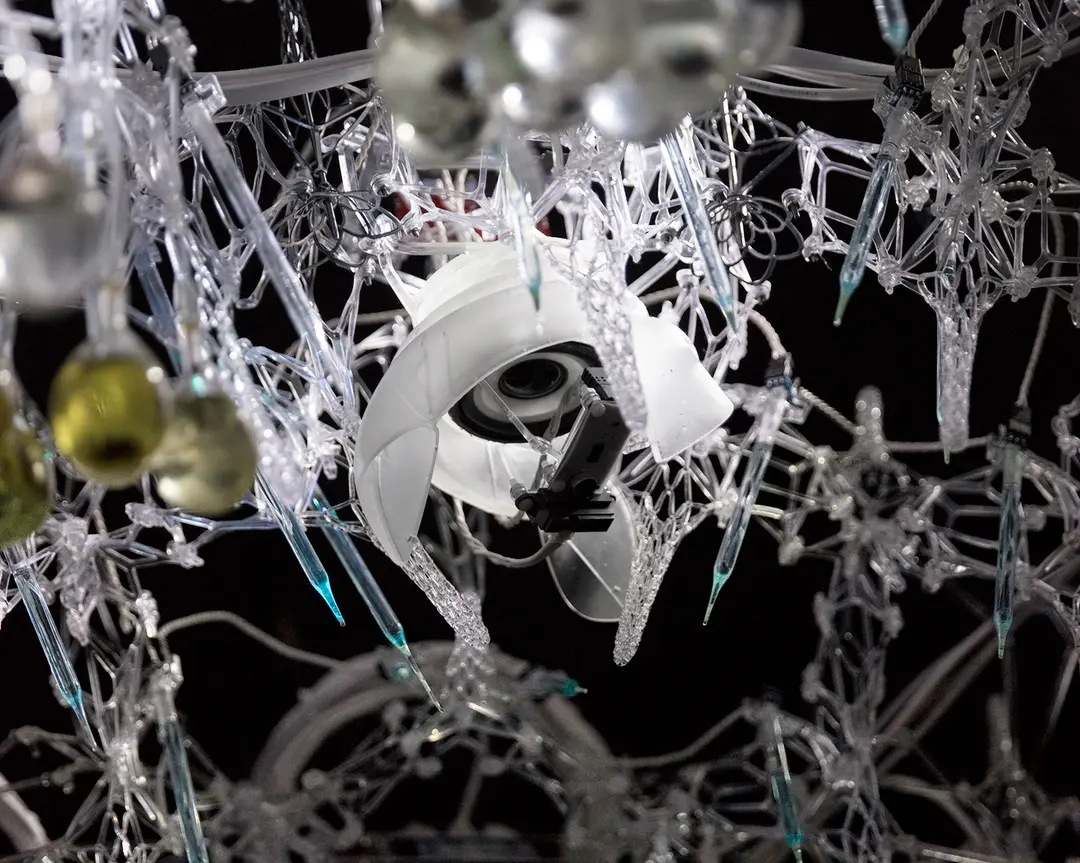

SLA 3D printing is known for its great freedom of design and high level of detail, which Harlequin leverages for geometrically complex and highly customized transition pieces. With 3D printing, Harlequin can create extraordinary displays that were once unthinkable, too cumbersome, or too expensive to execute. “3D printing is very useful for creating smooth transitions between objects. We can easily print pieces that are quite complex, and would request way too much manual sculpting otherwise,” Garside explains.

For a long time, the designers of Harlequin had to find a perfect balance when it came to the thickness of those transitional pieces or fixtures. On one hand, every added inch would increase the stability needed to hold pieces in place. On the other, it makes purely structural parts observable. The mechanical properties of Tough 2000 Resin make it possible to decrease the thickness of supporting structures, making them less visible without compromising on strength.

Introduction to 3D Printing With Desktop Stereolithography (SLA)

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Making the deadline: Rapid Delivery With Form 3L 3D Printer Fleets

Garside’s colleagues receive urgent requests daily due to the ever-changing trends in retail and fashion. Ever since building their in-house printer fleet, they can meet these demands, easily printing overnight. “Everything comes and goes quickly and I never know what will happen tomorrow. But with 3D printing, we have got the flexibility to respond as quickly.”

Before 3D printing, Harlequin would have had to wait for external poly sculpting or printing services, which would take up to weeks to deliver results. Today they are fully independent and printing critical parts within a day, securing the success of high-value projects. “I've had situations where mistakes happened and we've needed to create, for example, fittings on the day of delivery. We didn’t have time to shop those parts or source them, but we managed to print them,” Garside says.

The availability of a large printer fleet has already saved projects. Garside vividly remembers one project for Louis Vuitton, for which he needed to prepare a crucial part within 24 hours. “It would've been a week at least to get this part sent by an external sculptor. We would've missed the deadline. It's an example of something where it wouldn't have been possible to deliver this before. But the fact that we used the fast Draft Resin and we've got the number of printers we've got, I was able to hit the ground running and get [Louis Vuitton] something printed out for the next day.”

Getting complex parts sculpted externally used to take Harlequin weeks, making it impossible to meet short term requests. Today they print detailed models, like this bag for Louis Vuitton, overnight.

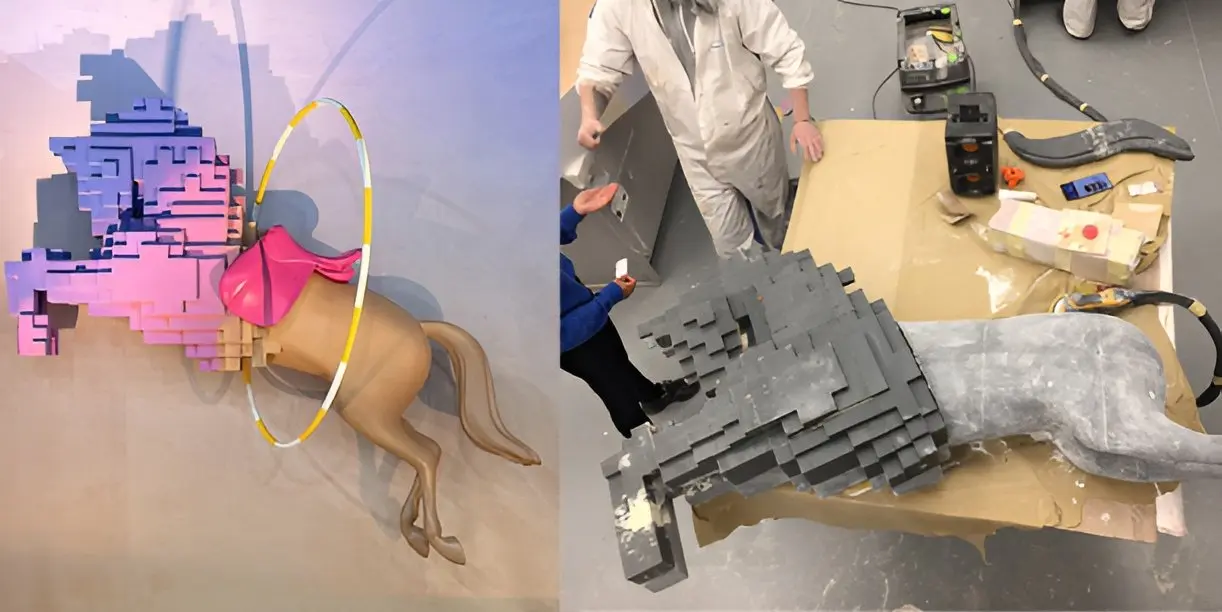

If you want to catch the customers' eye, you sometimes simply need to be big, bold, and colorful. That's why Harlequin designed a pixelated horse, which would never have jumped into the real world without the help of 3D printing. Garside remembers the challenge: “The horse was almost life-size, and we didn’t have a lot of time.” Their typical approach of sculpting would have been way too expensive and time-consuming.

Precise and accurate printing on Form 3L makes it easy for Harlequin to assemble smaller parts into life-size models.

For big projects like this 2.5 meters long horse Garside loves the extended build size of the Form 3L, which makes it possible to print pieces up to 33.5 × 20 × 30 cm. While industrial printers capable of printing at this scale can be very expensive, it’s possible to purchase a fleet of Form 3Ls for the same price. “The ability to simply print different bits simultaneously meant that we could do something far, far, far quicker than anybody else we would be sending it to,” Garside says. “Those bits get glued or fixed together, sanded, finished, painted, done. It’s incredibly quick and easy.”

In the end, Harlequin saved more than two weeks of lead time by leveraging the printing capacity of their in-house fleet and assembling the parts.

For the low price of the Form 3L, it’s crazy not to go with that. Just the fact that you could have a build volume that size, for only a fraction of the 250 000 pounds you need to pay for a HP machine, is remarkable.

Mark Garside, Head of Innovation at Harlequin Design

How to 3D Print Models Larger than Your 3D Printer’s Build Volume

When determining what’s possible with a desktop 3D printer, think beyond the build volume. Splitting a model into smaller parts that can be combined after printing is a great solution for 3D printing large objects that don’t fit on a build platform.

Harlequin is not only leveraging the compound build volume of their printer fleet to quickly create large pieces, but also large amounts of small pieces. To promote their recently opened workshop in New York they printed hundreds of hotdogs with their name on them. Just before the planned start of the campaign, they realized that the dots of the letter I were missing. Thanks to their Form 3L fleet it took Garside less than an hour to print all the missing pieces.

Printing a large series of pieces is no problem for Harlequin thanks to the large build volume of their Form 3Ls.

Producing Parts at Volume: 3D Printed Tools, Jigs, and Manufacturing Aids

In addition to printing models and fixtures, Harlequin uses its printer fleet to print tooling and jigs. The great flexibility of 3D printing and Formlabs’ material library lets Harlequin leverage the advantages of additive manufacturing to optimize the tools in their workshop.

For their decorations, Harlequin often needs a larger series of individual pieces in a short amount of time. One of the processes they use to create such parts is vacuum forming, which uses a tool to quickly and cost-effectively produce large quantities of thin-walled thermoplastic parts.

Preparing forming tools with machining has not only been very expensive but also a time-consuming process, impossible to use in cases with very tight deadlines. “If I’d have vacuum forming tools made in aluminum or machined by a toolmaker, the cost would be insane. We would sometimes wait two weeks each time a tool needed a small adaptation,” Garside says.

Today Garside and his colleagues use the heat-resistant Rigid 10K Resin to quickly iterate tools for vacuum forming. “Rigid 10K [Resin] is perfect, when you need really fine details and absolutely accurate stuff.” With this, they reduce waiting times, saving production costs and making the best use of every task's best-fitting machine.

Just with the last vacuum forming project, we saved thousands of pounds by printing the tools in-house. We were able to make the changes we wanted and we were able to do it very quickly. It’s simply about finding the most intelligent tool for the job.

Mark Garside, Head of Innovation at Harlequin Design

The high resistance against heat of Rigid 10K Resin makes it a great material for printing tools for thermoforming or vacuum forming.

Garside is happy about the great independence Harlequin gained from 3D printing, letting them flexibly solve problems in almost no time. Whenever his team needs pieces, he is now convinced that they will quickly find a way to prepare those, whether it’s a jig, tool, model, or anything else.

3D Print Jigs and Fixtures to Boost Manufacturing Efficiency

Learn how to quickly 3D print strong, long-lasting tools for machining, assembly and inspection. A Formlabs application engineer will guide you through the workflow, share recommendations and delve into real-life examples from innovative companies.

Steady Growth With 3D Printing

Facing fluctuations in the retail and fashion industries, the key to the company’s success is production speed and flexibility, meeting the tight project deadlines and the high quality standards of brands like Hermes, Louis Vuitton, and Dior.

Thanks to 3D printing, Harlequin is creating even the most complex designs faster than ever before, finishing more projects with even higher profit rates. That’s why Garside couldn’t be happier that he invested in a fleet of Form 3Ls as an industrial solution for high quality on-demand production.

If we didn't have the [Form] 3Ls it would feel like a giant leap backwards, because we need to rely on external sculpting which takes far, far longer. We’re saving ourselves a whole load of money by the fact that we print in-house now, because we would be paying somebody else's markup if we were giving it to anyone else. Very quickly before long, that's the cost of the machine that we saved.

Mark Garside, Head of Innovation at Harlequin Design