Foiling, where short surfboards lift above the waves as they’re propelled by a masthead and wings below the surface, adds an entirely new dimension to riding waves.

Foil Drive, a manufacturer of electrified foiling equipment is familiar with the third dimension — they use 3D printing in each step of their design process, and produce close to a thousand end-use parts each week on their large format Form 3L and Fuse Series printers. As foiling has exploded in popularity, 3D printing enables an agile and responsive manufacturing model, keeping high-performance products available and affordable for a customer base that always wants to try something new.

“There are limitless possible set-ups you can try. It’s dynamic; there’s always something to tweak or engineer with a 3D surfing experience,” says Foil Drive founder and CEO Paul Martin. What started as a way for Martin to try out new set-ups developed into a multi-million dollar global business in its second year, and 3D printing has buoyed Foil Drive’s success since the beginning.

Getting Started

Though foiling removes some of the shoulder stress that every surfer endures from constant paddling, it’s still a very physically demanding sport. To generate the speed that can propel you up and out of the water, the rider has to paddle aggressively.

Dealing with an old shoulder injury, Martin saw an opportunity to use his engineering skills to take things to the next level. He designed a small but powerful electric propulsion system that attaches to the masthead and generates enough speed to easily lift boards up and out of the water. “It was the obvious next progression. I’ve been 3D printing for 20 years, so I was able to make some early prototypes that worked. From the get-go, the product started because 3D printing was available to me,” says Martin.

Iterative testing included a lot of time out on the water, and the design started to get attention from other foilers. People began to ask him for propulsion systems of their own, and as Martin began to tinker with different designs, he realized that with a little bit of serious manufacturing attention, he had a real commercial product on his hands.

Foiling is one of the fastest-growing sports in the world, and demand is growing exponentially for customized, next-generation set-ups.

Finding the Right Material for an End-Use Propeller

Weight and size are extremely important in foiling, where momentum is everything. If the components are too big or too heavy, the propeller can’t generate enough speed to lift the system out of the water. Designs needed to go through many iterative stages to strike the perfect balance of power and size, so 3D printing made perfect sense. Martin had access to FDM and low-cost SLA units, and was able to rapidly iterate. “You can micro-manufacture very complicated parts in house without spending massive amounts of money to develop them,” says Martin.

During testing, however, it became apparent that he needed to find a 3D printing solution that provided some stronger mechanical properties. The strain on the propeller blades poses a unique challenge; the blades are spinning at 3000 rpm while plunging in and out of the water, and dealing with the high horsepower and torque generated by an electric motor. Though only weighing about nine grams, the blades needed to be extremely strong to manage all the force. “It is a brutal expectation of a propeller blade, to be able to cope with these forces,” says Martin.

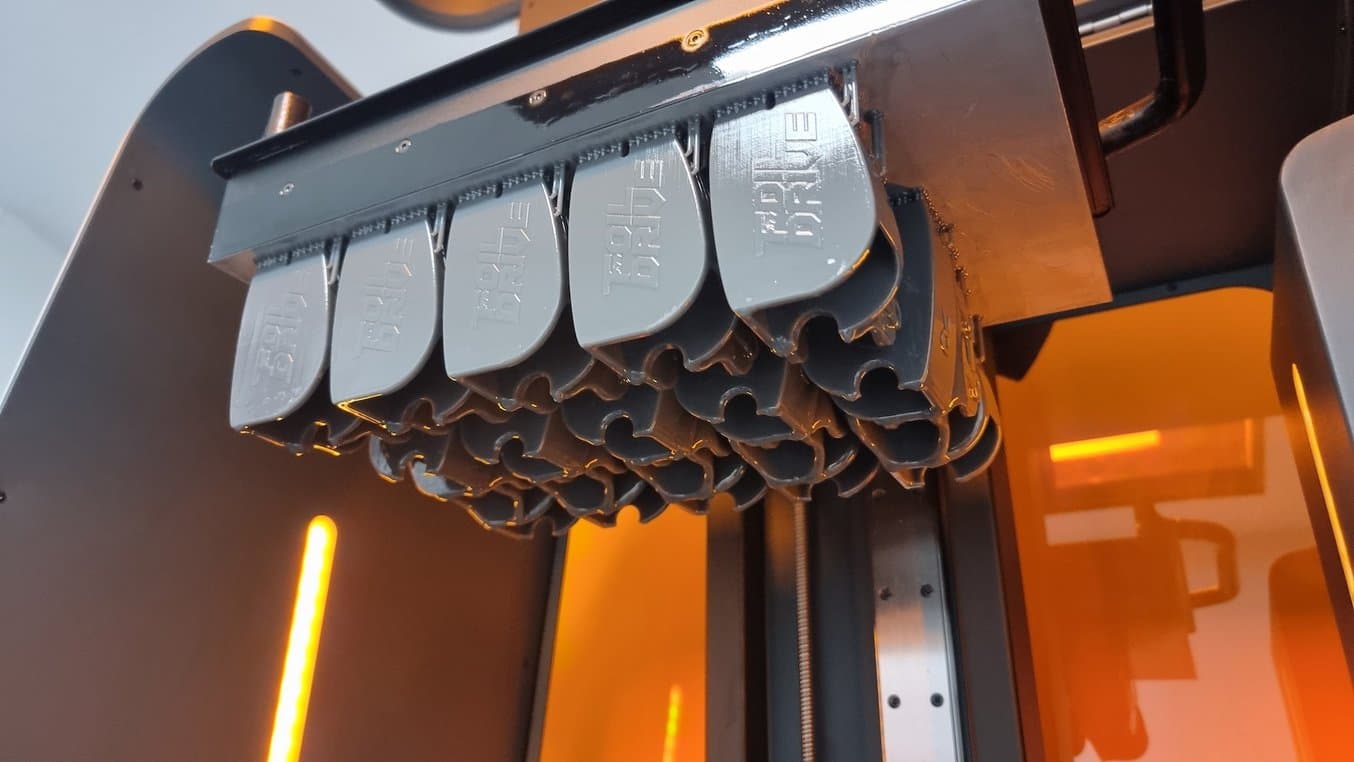

The final design of the propeller blades, printed on the Form 3L in Rigid 4000 Resin.

Tooling for a metal blade would cost tens of thousands of dollars, and limit his ability to change the design later on. “I need to manufacture these tiny propellers in low quantities, at a price point that makes selling these even possible. There’s no way to do that unless you’re 3D printing them,” says Martin.

After trying out a few different resin 3D printers, Martin ran into issues getting consistent material batches that had reliable material properties. Consistency pays off for a small business like Foil Drive — a bad batch of material would cause part failures in the water, and end someone’s ride. Martin covers all his products with an iron-clad warranty, but the service and shipment of replacement parts was costing him more than the cost of goods. “Having these parts break was not an option going forward.” Finally he was able to test out his design using glass-filled Rigid 4000 Resin on a Form 3+ SLA printer, and worked with Melbourne-based supplier Thinglab to test out parts and eventually purchase multiple machines.

It wasn’t until we tried the Rigid 4000 Resin that it all worked. It allowed us to make thousands of them and send them all over the world for people to use as an end-use propeller blade.

Paul Martin, Founder and CEO, Foil Drive

No More Broken Brackets

The Foil Drive team had been using larger, inexpensive resin printers for parts other than the propellers, like the controller brackets. After producing and shipping them all over the world, some customers started over-tightening the brackets and breaking them. Martin decided to start production with the Form 3L and Tough 2000 Resin that could handle the clamping motion of the brackets and repeated use. “From that point onward, we never had one failure — it paid for itself. You get what you pay for, and with the Form 3L, we can set the machine and just let it run,” says Martin.

Tough 2000 Resin provides strength and durability, even after months in ocean water and repeated clamping and unclamping.

That Form 3L showed the advantages of reliability and advanced mechanical properties, but as customer orders started pouring in, the Foil Drive started to think even bigger. To produce higher quantities and experiment with new geometries, all while maintaining the agility that 3D printing enables, they needed something with industrial power. Powerful, in-house SLS was the answer.

We got to the point where we were selling a lot of systems, and we also wanted to design some different shapes without supports — the Fuse allowed us to make more parts in higher quantities with lower material costs.

Paul Martin, Founder and CEO, Foil Drive

SLS for End-Use Production

3D printing for end-use production is not only possible, it's more affordable, agile, and scalable than ever with the Fuse SLS Ecosystem. Visit our SLS for Production page to compare production methods, learn about bulk powder pricing, and see production in action for 15 different manufacturers currently using the Fuse Series.

Harnessing Power for Flexibility and Speed

Once they set the Fuse Series up, it was off to the races — the team started with 100 parts a week, and then 200, and now, with a second Fuse 1+ 30W printer, about 650 Nylon 12 Powder parts each week. Foil Drive has been able to match production to the growth of their customer base as the sport continues to explode in popularity. “The Fuse printers really introduced volume and scalability. They run 24 hours a day, seven days a week,” says Martin.

Paul Martin (right) and his team run the Fuse Series SLS printers 24 hours a day, seven days a week to keep up with the high demand for his electric foiling systems.

At that kind of volume, many manufacturers would start to think about moving to traditionally molded components for a lower cost per part, but Martin saw the benefits of a vertically integrated workflow during the supply chain issues of the past few years. During a severe silicon chip shortage, Foil Drive had to change suppliers, and the component that held the chip no longer fit correctly. If they had been using mass-molded components like some of their competitors, there would have been enormous waste. Instead, Martin was able to pivot quickly, redesign, and completely avoid any wasted components.

For us it was a trivial thing, to change a few things, send to PreForm, print, and have revised bits the next day that perfectly fit the new chip,” says Martin. “Being vertically integrated gave us total control — we were able to tack at a moment’s notice.

Paul Martin, Founder and CEO, Foil Drive

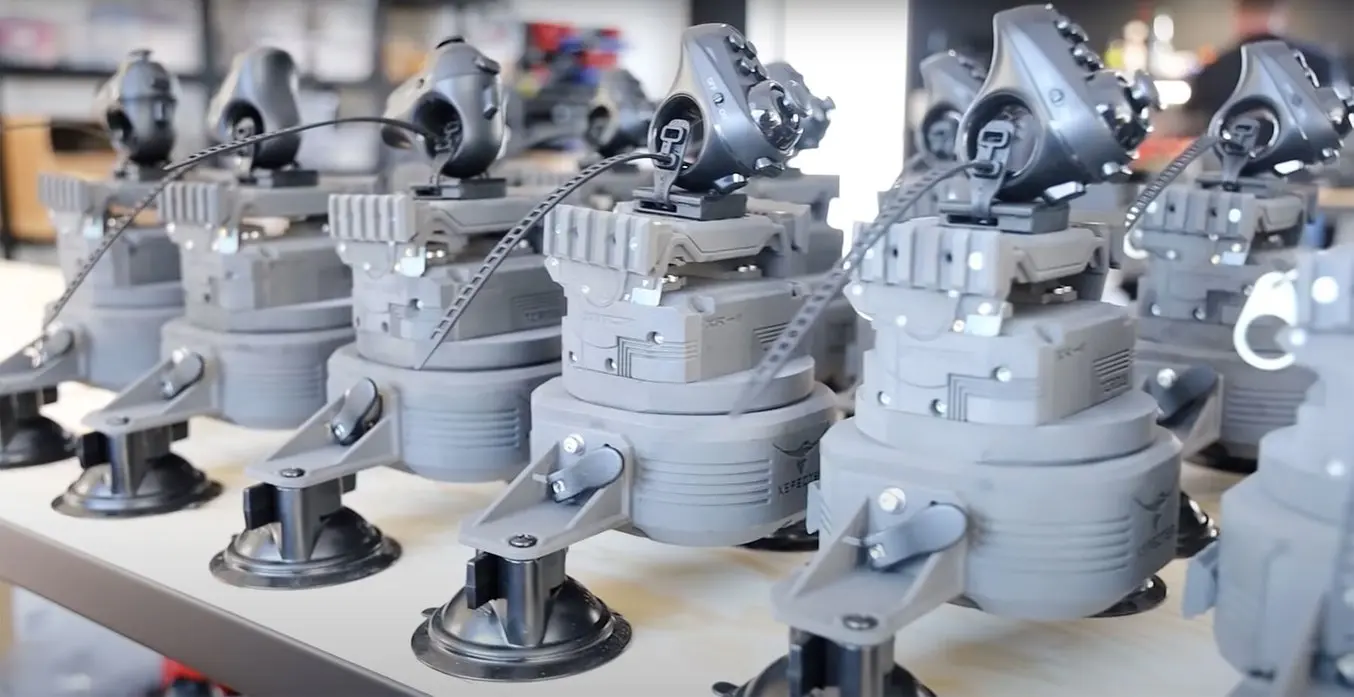

Foil Drive uses the Fuse Series SLS technology to print multiple end-use components for their boards.

The folding propeller assembly uses the strength and machineability of Nylon 12 Powder to create a rugged part.

Production Volumes With Fuse Series and Form 3L

| Printer/Material | Parts Per Print | Parts Per Month | Considerations: | |

|---|---|---|---|---|

| Folding Propeller Assembly | Fuse 1+ 30W in Nylon 12 Powder | ~60 | ~200 assemblies | Able to thread screws into this, slight flexion, production capacity, durability, rugged, end-use ability |

| Impeller Blade | Form 3L in Rigid 4000 Resin | 84 | ~300-350 | Strength, iterative capability, rigidity, withstand underwater pressure at 3000 rpms, sharp/thin edges |

| Bracket | Form 3L in Tough 2000 Resin | 15 | ~200 | |

Generating Momentum

Success in foiling is all about momentum — you need speed to get up and out of the water just like you need speed to bring a new product to market. 3D printing can enable both. The strength of materials like Rigid 4000 Resin or Nylon 12 Powder makes producing durable end-use machinery easy. And by enabling agile production, the Form 3+, Form 3L, and Fuse Series printers have helped Foil Drive grow a multi-million dollar business in only three years.

An electrical motor pod in Nylon 12 Powder printed on the Fuse Series (top) and in Tough 1500 Resin (bottom).

The motor pods can be customized to fit on a wide range of masts from different brands, even those with a tapered construction, like this one from Armstrong.

“With our products, there are so many elements that are counterintuitive to traditional manufacturing: the volumes we need, the shapes, sizes, and geometries, the variations, the fact that not a single item we needed was off the shelf. But when you have this technology, all those issues dissolve away.

Paul Martin, Founder and CEO, Foil Drive

The Formlabs SLA and SLS printers open up new methods of production, whether that means vertically integrating your supply chain to improve manufacturing agility, or creating an entirely new product by dissolving the obstacles of traditional tooling. To learn more about production with Formlabs printers, contact a specialist today.