By integrating computer science and engineering, robotics shows great promise in the healthcare industry. From disinfecting patient rooms to operating as laboratory assistants, robots can accommodate a wide range of healthcare applications. When it comes to high-stakes medical procedures like surgery, precision is everything. In North America, Medical Related Error accounts for >400,000 deaths every year, making it the 3rd highest source of unnatural death behind cancer and heart disease. How can robotics help?

At Haply Robotics, a Montreal-based company founded in 2018, robots help surgeons finetune surgical procedures. Haply Robotics is building the next generation of physical simulation consoles to empower more than two million surgeons worldwide to perfect over 260 surgical procedures using state-of-the-art virtual and augmented reality technologies. Dubbed the “PlayStation for Surgeons,” the Haply inverse force-feedback console allows surgeons to simulate operations before they perform them, with the goal of decreasing the risk to patients and improving surgery times.

Haply Robotics brought 3D printing in-house for rapid prototyping, deploying FDM, SLA, and SLS 3D printing across their projects. In this post, we learn how Haply Robotics has used various 3D printing technologies, and why they purchased a Fuse 1.

Starting the Collaboration with Developing Ventilators for COVID-19

Felix Desourdy, head of mechanical engineering at Haply Robotics, said that he met Colin Gallacher and Steve Ding co-founders of Haply Robotics, in 2018. “We met at the National Research Council of Canada where we were working on a team doing where we were doing haptic development for medical surgery simulation. We were all fans of the new era of being able to design something and quickly iterate on it and be able to just do prototype after prototype to generate the perfect idea of what we want to do.”

In 2020, the team had a major collaboration with the government of Canada put on hold and decided to put their design and robotics skills to use by entering the CODE LiFE Ventilator Challenge—a call for device firms to design a low-cost, simple, easy-to-use, and easy-to-build ventilator that could serve patients suffering from COVID-19.

More than 2,600 registrations were received, representing over 1,000 teams from 94 countries. The Haply design was selected as the best of these on the balance of simplicity in design and operation, as well as cost of production and ease of training.

“Our experience with the CODE LiFE Ventilator Challenge was incredibly challenging but was one of the most rewarding experiences we have gone through as a team. We were motivated by the disparities between developed and developing nations in access to essential medical technologies like ventilators which have been highlighted by COVID-19. We are incredibly grateful to the organizing committee and specifically to Prof. Reza Farivar, the Montreal General Hospital Foundation, the RI-MUHC, and the McGill Faculty of Engineering for putting together such a meaningful initiative,” said Colin Gallacher, Co-Founder of Haply Robotics.

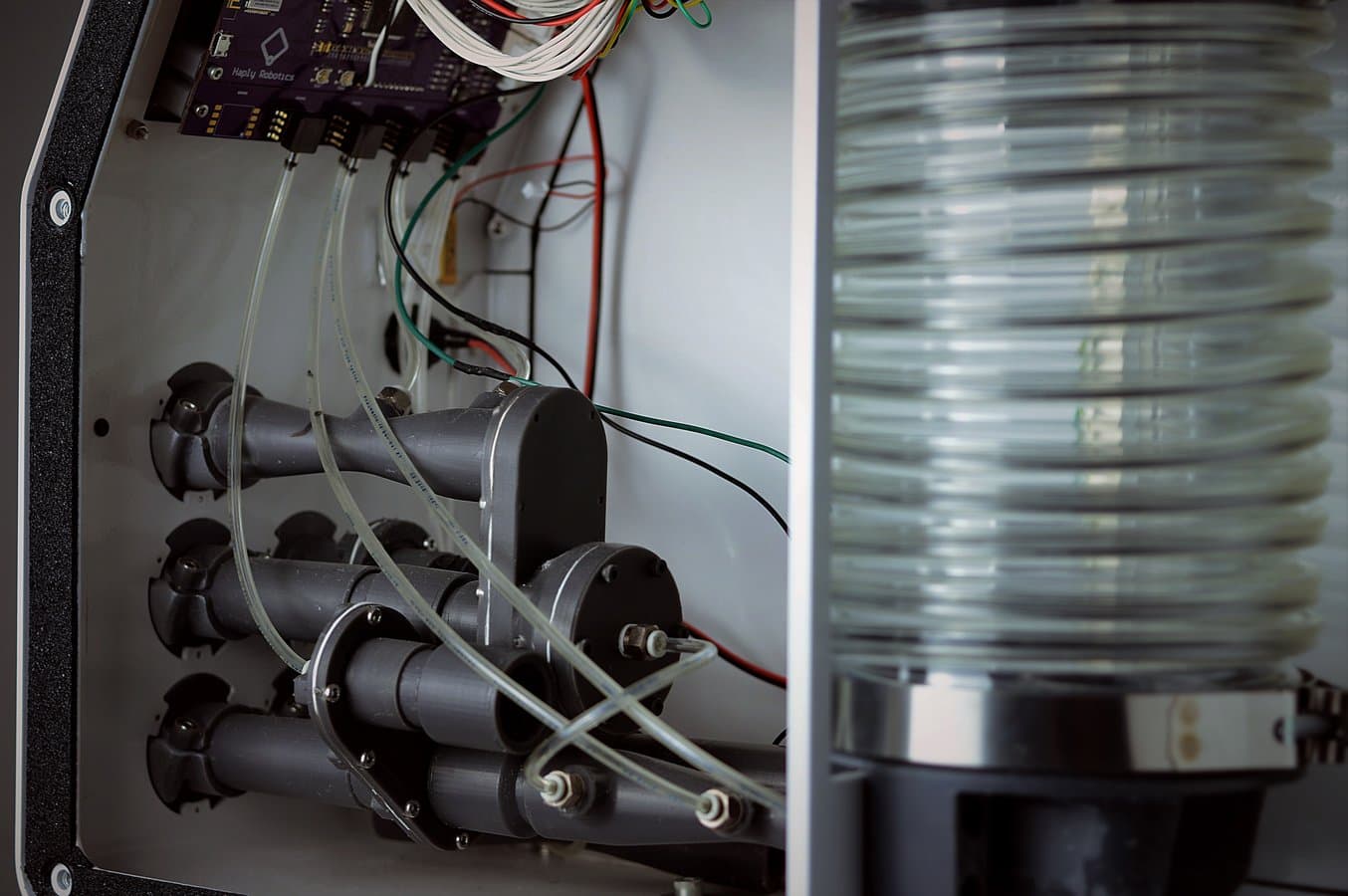

Haply deployed 3D printing to help them develop the ventilator, using the Form 3 and Tough Resin to create internals for the machine. Having in-house 3D printing allowed the team to create final use parts for the inside of the ventilator, quickly turning around a design capable of winning the contest and making ventilation devices more available during the pandemic.

The 3D printed internals of the Haply ventilator.

“Tough Resin was amazing for this project, because it can be sealed. And we could drill into the resin, insert fittings, and it wouldn't leak. It is very similar to ABS,” said Desourdy.

Rapid Prototyping the Perfect Design

Taking the learnings from the COVID-19 ventilator development, the team continued working on their main project: haptic development for medical surgery simulation.

Rapid prototyping is the main reason Haply invested in in-house 3D printing; with desktop printers the team prints multiple iterations of complex parts until they can find the perfect shape. Desourdy pointed to two main reasons for why iteration is key: ergonomics and achieving the correct geometry, saying that, “we are fans of the new-era of design: generate prototypes after prototypes until you find the perfect shape. And everything we are making is a great size for 3D printing.”

Haply has gone through dozens of iterations for their inverse force-feedback console

The team originally invested in FDM printers, due to their low price point and quick printing speeds. These machines originally met the team’s goals for rapid prototyping. However, over time the team wanted to build more looks-like, works-like prototypes that required printing in higher quality. They eventually bought a Form 2, and then a Form 3 for high-resolution printing.

“We're working around the hands of people often, especially in the surgical simulator. You have to be able to just iterate and iterate,” Desourdy said. “We were iterating on having a stiffer device and gaining a little bit more understanding what makes it stiff, without changing the material at first, and having the correct geometry for what you want to do. The way I see it, you iterate towards something that has a better geometry and when we're done, it's easy to change the material to have something stiffer. But to change the geometry, you need to take it a little bit further to be able to do this.”

The closed robotic arm.

Prototyping End-Use Parts With the Fuse 1

As Haply Robotics continued to build prototypes for its robotic arm, they brought SLS 3D printing in-house with the Fuse 1. This is because the nylon parts created on the Fuse 1 are closer to the end-product the team is looking for. Previously, they were prototyping with nylon by outsourcing, which came with a host of problems. “With the Fuse 1, it's even a whole new level of prototyping. We get a part in two days instead of five, and I'm going to have something that is in nylon which is closer to an end product. Since the printer is in-house, you get to know the tolerance of the machine and material. The precision of everything is just a lot nicer,” Desourdy said.

The team was able to print a functional button using the Fuse 1.

Desourdy added that outsourcing means less control over the results. “When you send it out, you don't necessarily have the correct orientation or the correct specification for it, and you don't know the printer the agency will have or how well they maintain it, so you don't know the result you're getting,” he said. “I think really just being able to iterate so quickly on these things is the most valuable thing that you can have.”

Another consideration for small, but growing, companies like Haply Robotics is the often tight, physical space of their growing office. Most traditional SLS 3D printers take up a significant amount of space and can often be hard to accommodate. The Fuse 1 offers a relatively compact size, while delivering a high-level of output. “The Fuse is quite nice because it's not that big. It takes more space than a regular desktop 3D printer, but honestly, if you compare it to any industrial machine that is getting into that type of production, it's very small,” Desourdy said. According to him, the team did look into investing in an HP SLS printer, but the large size of the machine was a barrier. He added, “when you start looking at industrial grade machines, the Fuse 1 is small compared to what else is out there.”

Jessica Henry, product owner at Haply, said that 3D printing with the Fuse 1 streamlines and automates their process. Henry said that capturing details, however subtle they may be, is key for 3D printing. “We can change one little detail and it will make the robotic arm run completely smoothly, and we can change even the smallest details with each print,” Henry said. And with the Fuse 1, the team can print multiple parts per print cycle, expanding how many robotic arms can be in production at once. To match this level of output, the team would need to buy multiple FDM machines but still not hit part performance requirements.

Finally, another major benefit of the Fuse 1 over FDM and SLA is the lack of support structures on the parts.

Desourdy said he noticed this right away: “If I design for FDM, I know I need one flat surface for supports, or one surface that will be ugly. Even with a resin printer, one side is going to have to hold the supports. The Fuse 1 has changed how I design the parts, because it prints without supports. In any orientation, the detail is retained.” This change even impacts the design process, with Desourdy adding, “I worry less about the 3D printing process, and I’m more focused on the design, which is what I want to be focused on.”

To further bring their prototypes to life, the team is looking into solutions for dying or painting their post-processed parts.

The robotic arm enclosure, printed in nylon and painted.

SLS 3D Printing vs. Injection Molding: When to Replace Molded Parts With 3D Printing?

This white paper showcases the cost-dynamics for real-life use cases, and presents guidelines for using SLS 3D printing, injection molding, or both.

Learn More About Fuse 1

Though the Fuse 1 is currently being used for prototyping, Haply Robotics has set sights on using the Fuse 1 for end-use parts as well. “From what I saw, it's going to be easy to do for small-batch manufacturing. It's going to be super interesting. There's a portion that is for prototyping. There's a portion that is going to be end-use,” Desourdy said. Henry added, “the product will never go out of date, if you can always add or tweak parts on the machine.”

The Fuse 1 is currently being deployed by a range of manufacturers in healthcare, including companies working on medical devices. Firms such as Partial Hand Solutions and Tension Square are deploying the Fuse 1 to create patient-specific prosthetic solutions and collapsed lung support devices, bringing SLS 3D printing in-house for the first time.

“I’ve always wanted an SLS printer, but they were unattainable at their current price points. The Fuse 1 is perfect for small businesses like Partial Hand Solutions.”

Outsourcing vs. In-House: When Does it Make Sense to Bring SLS 3D Printing In-House?

In this white paper, we evaluate the value proposition of bringing SLS 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau.