Located in New York City’s Flatiron design district, Iliad specializes in luxury antiques and bespoke furniture inspired by early 20th-century design—Biedermeier, Art Deco, and Art Moderne. Filled with artwork and furniture masterpieces, Iliad looks more like a fine art gallery than an interior design studio. Co-founders David Charette and Andrea Zemel launched the company in 2001 to revive a lineage of furniture design techniques that have been nearly lost in the United States. Their team resurrects bygone interiors using the forward-thinking technology of 3D printing.

For Iliad’s bespoke furniture, the team set out to revive the distinctive knobs and handles of 20th-century design. At first, an Iliad artisan had to craft each piece by carving wood or molding clay before going through the casting process. Now, 3D printing has made their workflow more efficient. Andrea explains, “The Form 1+ has become an essential part of our creative process.”

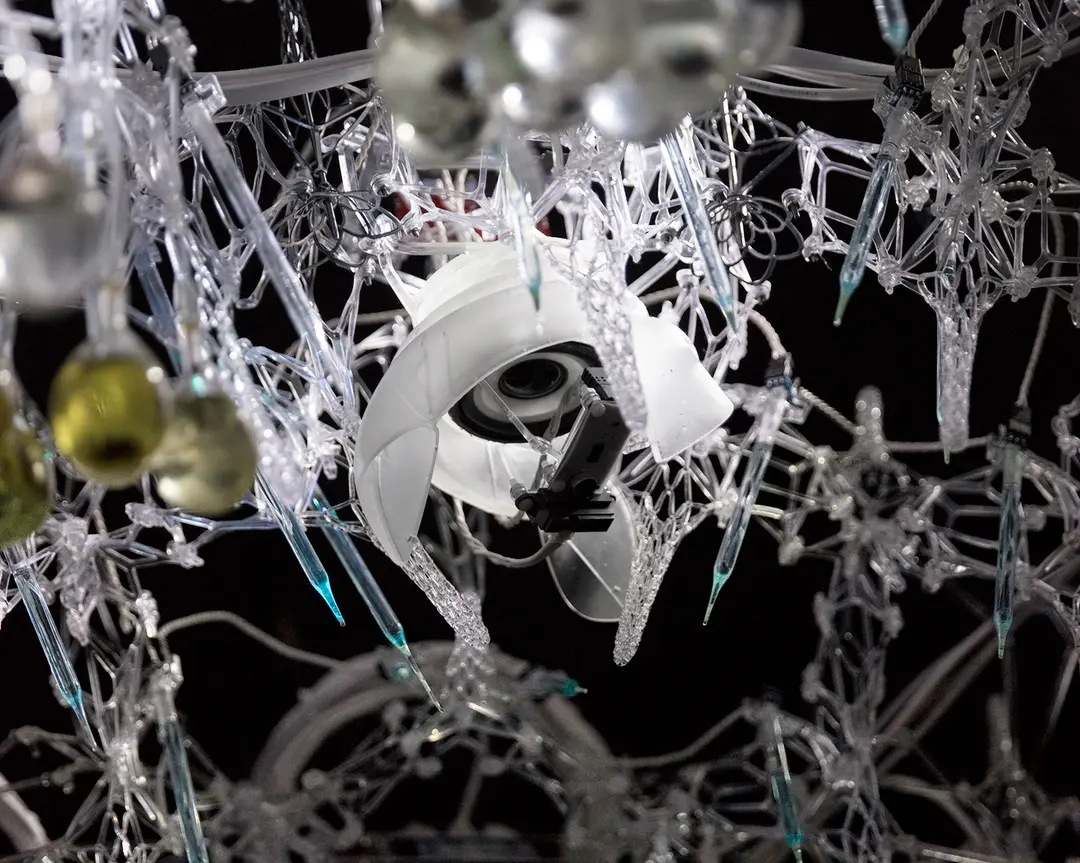

For each bespoke piece, a designer first sketches an idea by hand, continuing a long tradition of furniture-making that begins and ends in the artist’s hands. They reproduce this sketch digitally and use the Form 1+ to print a highly detailed model. Lastly, they cast the piece in brass and rework the metal fixture, bringing out the piece’s intricate features. Because the creative process has remained in-house, the Iliad team can produce hardware quickly. Based on client feedback, the design can be easily changed and reprinted in just a few hours. This efficient process allows them to focus more time and energy on perfecting their designs by hand.

“The Form 1+ has become an essential part of our creative process.”

Recently, the team started using the printer to prototype actual furniture designs. This gives the client the ability to visualize the custom piece before production, improving the ideation process and the client-designer relationship. Andrea explains, “The Form 1+ has been an excellent tool to help our clients visualize our designs as actual three-dimensional objects. It’s an amazing tool not just for me but for my client.”

“The Form 1+ has been an excellent tool to help our clients visualize our designs as actual three-dimensional objects. It’s an amazing tool not just for me but for my client.”

Iliad’s luxury furniture attracts clientele and art collectors across the world. The team has collaborated with renowned designers, including architect Robert A.M. Stern. “Our business has evolved a great deal from our early days relying on old-world techniques,” Andrea says. “Cutting-edge technologies have greatly enhanced our capabilities to design and innovate new furniture forms.” The Iliad team looks forward to many more years of innovation, using new technology to bring past interiors into the present.