Form 4L Redefines Large-Format SLA 3D Printing With Unmatched Speed, Reliability, and Accuracy

Formlabs is proud to announce Form 4L, our next-generation large-format resin 3D printer that takes the speed, accuracy, and reliability of Form 4 to a completely new scale.

Form 4L and its biocompatible version, Form 4BL, are built on the same groundbreaking Low Force Display™ (LFD) technology as Form 4 and Form 4B, but built for delivering parts nearly five times bigger than what is possible on our desktop models.

For human-scale prototypes, truly on-demand manufacturing aids, or consumer-grade end-use products, Form 4L delivers superior quality parts in record times — even full build volumes typically finish in under six hours.

Together with new SLS powders and the opening of the Formlabs ecosystem, Form 4L represents the continuation of Formlabs’ mission to empower our users by building tools that bring their ideas to life, regardless of scale or complexity.

Product Demo: Form 4L

See how Form 4L, our next-generation large-format resin 3D printer, takes the speed, accuracy, and reliability of Form 4 to a completely new scale.

Going Big With Next-Generation Technology

Form 4L makes same-day production of large, highly-detailed parts in versatile materials possible.

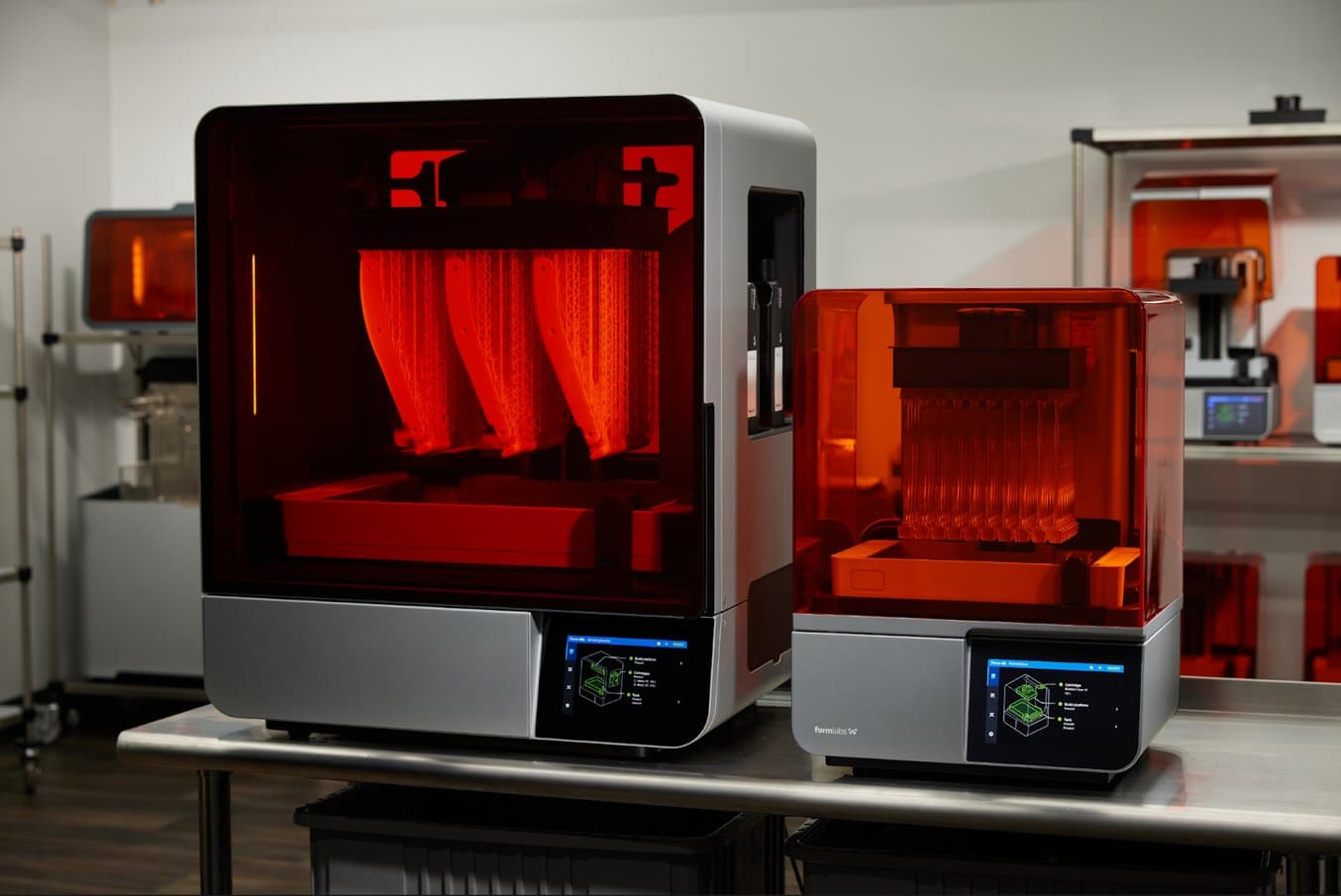

Form 4 established a new paradigm of accessible SLA 3D printing — the next-generation LFD technology enabled faster-than-ever print speeds without compromising on accuracy or reliability. Form 4L takes that same print engine and goes bigger: its build volume is 4.6x larger that of Form 4’s at 35.3 x 19.6 x 35.0 cm (13.9 x 7.7 x 13.8 in), and even 13% larger than its predecessor, Form 3L.

Compared to our previous large-format SLA 3D printers, Form 3L and Form 3BL, Form 4L is faster, more reliable, and easier to operate and maintain. The large-format Form 4L exposes each layer of liquid resin to the powerful Light Processing Unit 4L (LPU 4L) in an instant, compared to the dual laser motion of the Form 3L that had to trace each shape. When printing large parts or multiple smaller parts on the Form 3L, that dual laser process could add hours of print time. For Form 4L, it doesn’t matter how much of the build volume is covered — the light source will cure each layer instantly before moving to the next, resulting in large parts that will finish right after lunch.

Form 3L was the first truly accessible large-format resin 3D printer available, but its slower print process often presented obstacles in iterative workflows. For product designers, engineers, and tooling manufacturers who wanted to leverage the material versatility and print quality of SLA, print times that lasted multiple days slowed things down and led to dead time in the development process.

Form 4L’s blazing fast print times enable these same projects to move ahead without downtime — running large parts or many smaller parts can now be done multiple times a day, so that innovation can move at the same pace as your team.

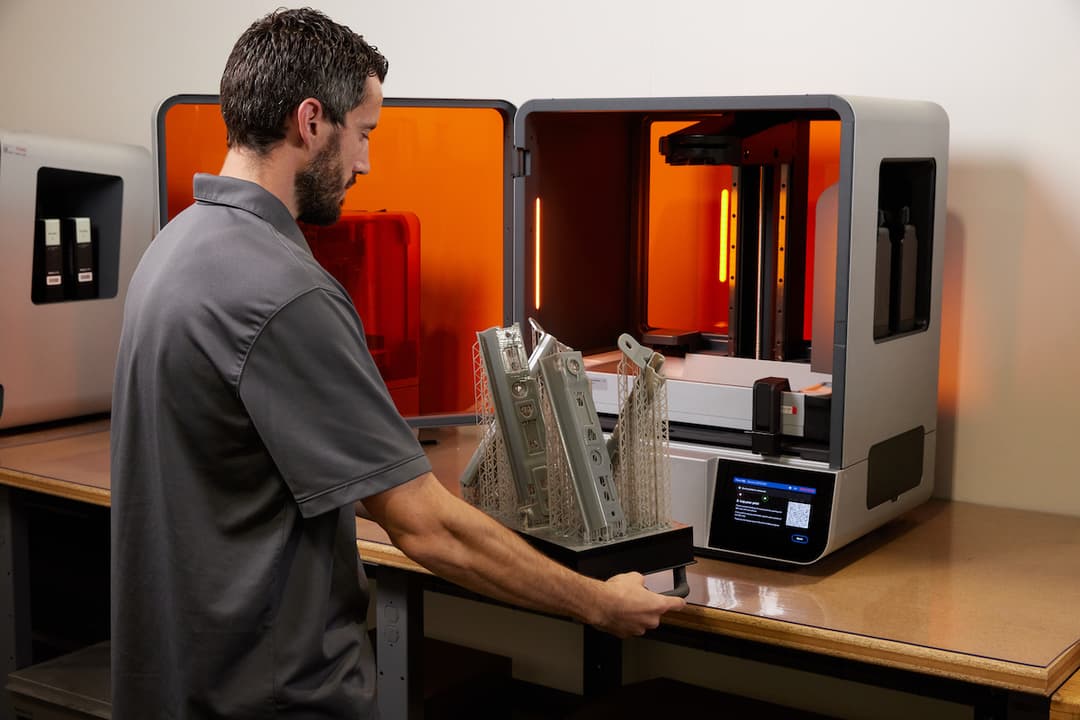

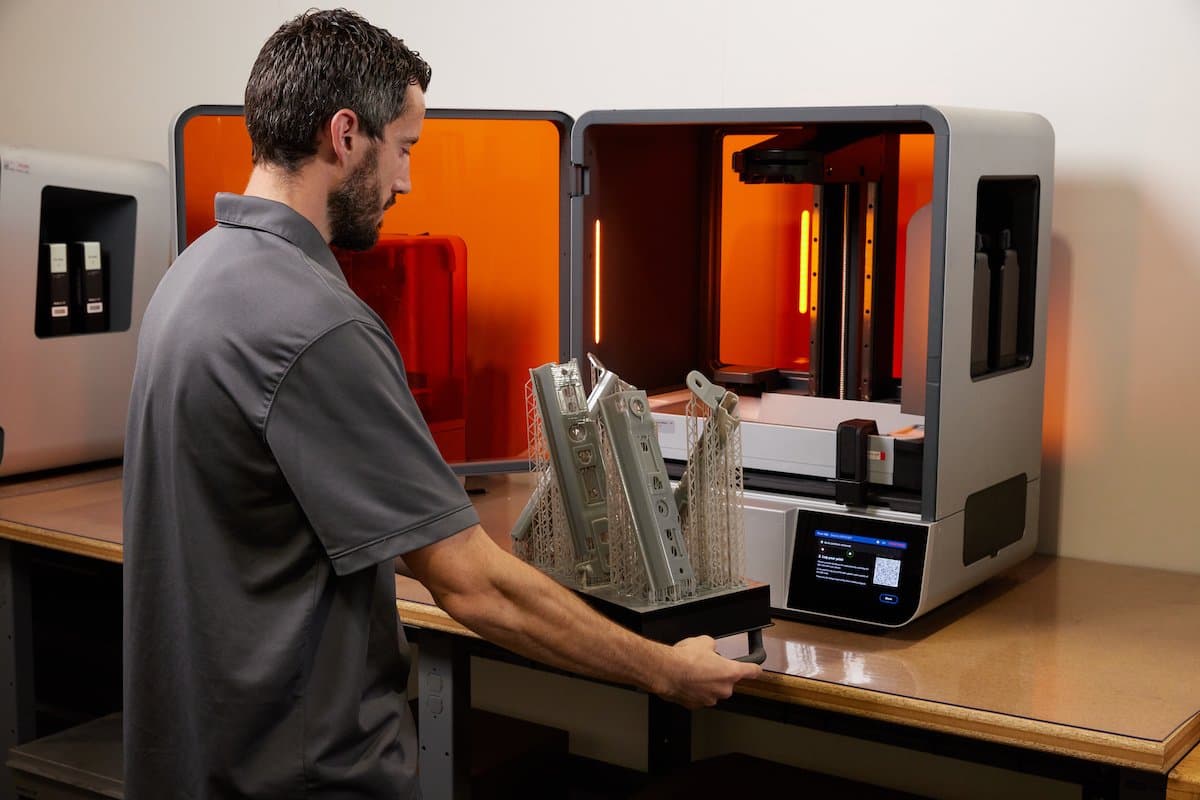

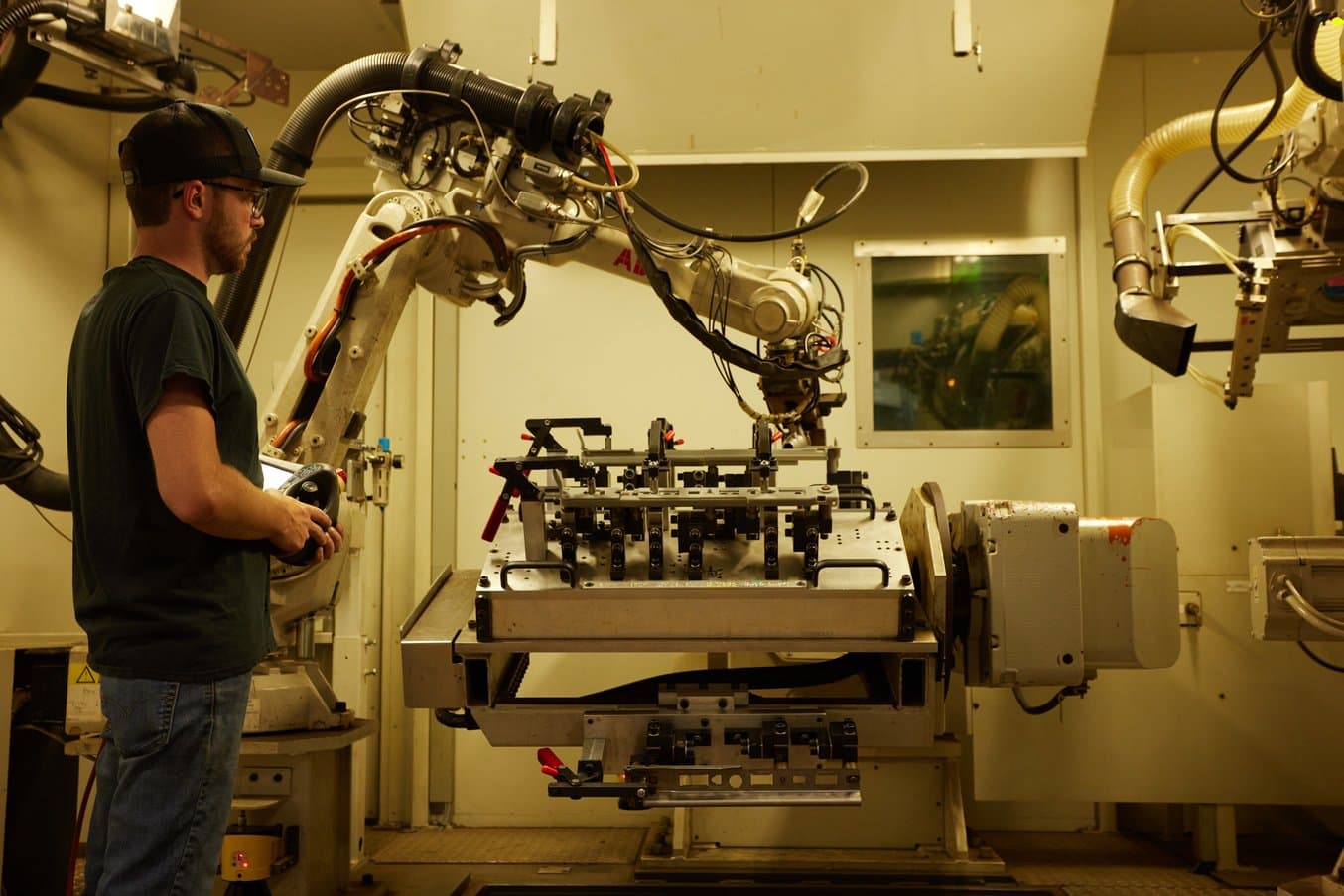

Form 4L Delivers Same-Day Robotic Welding Fixtures at Brose

Brose North America’s Jeremy MacMillan removes a robotic welding fit fixture that he printed in multiple pieces in just under four hours. The part immediately went from the wash and post-cure to the welding department, which used it to set up a new welding program for creating car seat frames.

At Brose, one of the five largest family-owned automotive suppliers in the world, additive manufacturing plays an important role in both design and end-use manufacturing. At their Brose North America location, 3D printing is used for creating high fidelity prototypes in high volumes, on-demand jigs and fixtures, and even hundreds of thousands of end-use automotive components printed in SLS for their OEM partners like BMW.

At Brose North America, the welding department frequently shifts between projects, and each time the welding robot transitions to a new product line, it must be preprogrammed to accommodate the specific parameters of the new project.

Programming a welding robot using metal end-use parts is expensive, and they are very often not available at the time the weld station is ready to teach the equipment. 3D printing offers a fast and inexpensive solution, but it comes with specific demands: the size of these seat rails requires a large-format 3D printer capable of quickly producing highly accurate parts with good dimensional accuracy and the strength to be fixed onto a welding fixture.

This seat part was printed on Form 4L in Fast Model Resin, washed, cured, and assembled onto the robotic welding machine in under three hours. This allows the team to teach the robot movements quickly.

Fit fixtures like these help the welding team transition quickly and efficiently between product lines. They’re highly accurate, affordable, and endlessly replicable in case one needs changes or replacement.

The Brose team opened their newly arrived Form 4L large-format SLA 3D printer on a Tuesday morning. The setup took just 30 minutes, and soon they were printing large welding setup parts using Fast Model Resin. The parts, divided into four pieces, nearly filled the entire build volume. Despite its size, the Form 4L printed it in under two hours, and after a quick wash and post-cure, the fixture was mounted on the welding robot just 45 minutes later.

These parts mimic the design of car seat rails that are welded to create a seat frame assembly. Form 4L’s larger build volume means the Brose team can print these in only a few pieces to assemble in order to accurately program the welding machine.

Once the welding robot has the correct parameters, it can quickly and efficiently weld hundreds or thousands of seat rails and get them ready for seat frame assembly.

“The new Formlabs 4L allows us to print large parts fast. For example, we use Form 4L to print setup parts for our weld cell in just hours instead of overnight. This allows the Brose welding experts to program the robot prior to the metal stamping components arriving. With the new Fast Model Resin, we receive the detail required and the rigidity needed in a faster time than ever before.”

Matthias Schulz, Manager, Seat Prototyping, Brose North America

Brose is used to working under tight timelines — some OEM partners request parts to be delivered within just 24 hours of ordering. The speed and quality of Form 4L’s prints make it a crucial tool that the Brose additive team can rely on to meet these demanding deadlines. To learn more about Brose’s 3D printing initiatives, read the full story or watch their webinar on-demand.

Large-Format Parts In Hours, Not Days

For anyone who relies on a 3D printer in their day-to-day work, large prints usually mean a slow-down in productivity. To check the design of a helmet prototype, you need to see it on someone’s head, to check the fit of an e-bike battery enclosure, you need to clip it onto the bike frame. If you’re printing these in multiple pieces, carving foam, or getting these machined, the difference in look and feel can slow down your iterative process — while your deadline keeps getting closer.

With Form 4L’s powerful print engine and industry-leading material library, you’ll get human-scale parts in just a few hours with materials that look and feel like injection molded plastics. For large manufacturers of end-use products, prototypes need to be made in higher volumes for functional testing and consumer testing phases before locking in a design and ordering tooling makes sense. Form 4L’s size and speed mean that these higher volumes of prototypes can be done in-house, without having to outsource to a 3D printing service bureau, a machine shop, or an injection molder.

Access to high-speed, large-format 3D printing opens doors for businesses to complete more rounds of testing and more consumer feedback rounds, ultimately leading to better-researched, tested, and validated products.

Print Speed Comparison: Radio Flyer Seat Prototype

| Form 4L | Form 3L | Large-Format FDM 3D Printer | |

|---|---|---|---|

| Print Time | 2 hr 37 min | 21 hr 6 min | 42 hr 3 min |

Compared printers and printing parameters:

- Form 4, Fast Model Resin, 200 microns layer height

- Form 3L, Draft Resin, 200 microns layer height

- Ultimaker S7, PLA, 100 microns layer height, 20% infill density

Bringing Higher Volumes In-House At Microsoft’s Advanced Prototyping Lab

Microsoft has been at the top of the tech manufacturing hierarchy for decades, and their Advanced Prototyping Lab (APL) offers a dizzying display of nearly every fabrication method imaginable. The APL fulfills orders from the entire Microsoft ecosystem, including Xbox, Surface tablets, and more.

A colleague recently requested a tablet enclosure that was larger than the build volume of the lab’s Form 4 printers and needed to be done fast. “This is a build we couldn’t do before Form 4L, the turnaround time would have taken too long, and 3D printing wouldn’t be an option. It would have slowed down the iterative process,” says Mark Honschke, head of Prototyping at the APL. The 3D printing team put the prototypes on Form 4L and delivered the parts that same afternoon. “At four hours, it’s a game changer if we can get it,” says Honschke.

But print time isn’t the full story — it’s the pre-process and post-process time that can also have an impact on a team’s productivity and efficiency. Form 4L has simplified the workflow for resin 3D printing for the APL, shortening both prep work and finishing work to help them get parts from concept to delivery even faster.

The Form 4L build volume makes breaking pieces in half a thing of the past, and given the team an option for quick parts during the day as well as higher volumes overnight. In post-processing, smaller touchpoint tips for the supports have shortened the time it takes to get parts finished.

The APC often fulfills requests for proof of concept (POC) assembled builds that range from Xbox to Surface tablets to headsets and more. But because the components aren’t manufactured at the same time, 3D printing has to step in. “They might get the circuit boards one week, but not the midframes for another three weeks. And we need to figure out, ‘Oh the circuit board is half a millimeter too thick, so now we can’t close this case cover,’ so when we do these builds, it’s not onesies, twosies, it’s 50 to 100 builds,” says Honschke.

A recent POC request came in for Xbox midframes, quantity 50, because there were some issues with outsourcing some of the internal components. “I said, ‘Yes we can supply your 50 parts, but we can’t clean them up.’ But with Form 4L, it wasn’t actually much of an issue because the supports were so much easier to remove. And we were able to do three full builds in three days instead of a week and a half. So Form 4L already paid for itself in that build alone,” says Honschke.

Together, Form 4 and Form 4L have opened up a new opportunity for the APC — if they can get these high-quality parts at such high speeds, they’ll be able to provide more services in-house for large POC builds. “Xbox does one to two POC builds each year, Surface does two to three, and if we can provide that service in-house, A) it’s better security-wise, and B) if we’re faster we can find issues faster. I think there’s a good business opportunity for Form 4 and Form 4L, I think it will prove out that it would make sense to bring staff in just to run them,’ says Honschke.

Improved Workflow: Reliability and Ease of Use

Whether you’re using 3D printing to hit a design deadline, or delivering end-use products for consumers, you need to be able to rely on your tools to consistently perform at a high level. Our large-format resin 3D printing process has been completely reengineered from the ground up, so now you can produce large-scale parts just as reliably as on Form 4.

This simplified print engine, with only one, powerful Light Processing Unit 4L, not only makes Form 4L much faster than a laser-powered resin 3D printer that has to rely on multiple lasers to increase build volume, but the fewer moving parts make the printer easier to maintain and less prone to errors.

Along with the straightforward curing process, high-quality consumables mean your parts come out as intended, every time, and run for much longer without needing replacement. Form 4L’s consumables should make life easier, not harder — both the Form 4L Resin Tank and Light Processing Unit have been torture tested for longevity. The Form 4L ecosystem’s simplified, advanced design leaves much less room for error, so you don’t have to calibrate over time or keep an eye on your machine during the print.

Because the print process isn’t just about the hardware, Formlabs’ material engineering team has printed hundreds of parts in each material, at each setting, to validate the results and print parameters. Regardless of material changes, your part quality, surface finish, support removal, and mechanical performance will remain the same.

The prototyping and production processes should be about how a part performs — how a helmet protects the skull or how a brake lever responds to pressure — not about how the 3D printer performs to get you that part. After years of engineering, research, and listening to our large-format SLA customers, we’re excited to deliver a printer that takes the guesswork out of print success, so you can spend your time on what’s important.

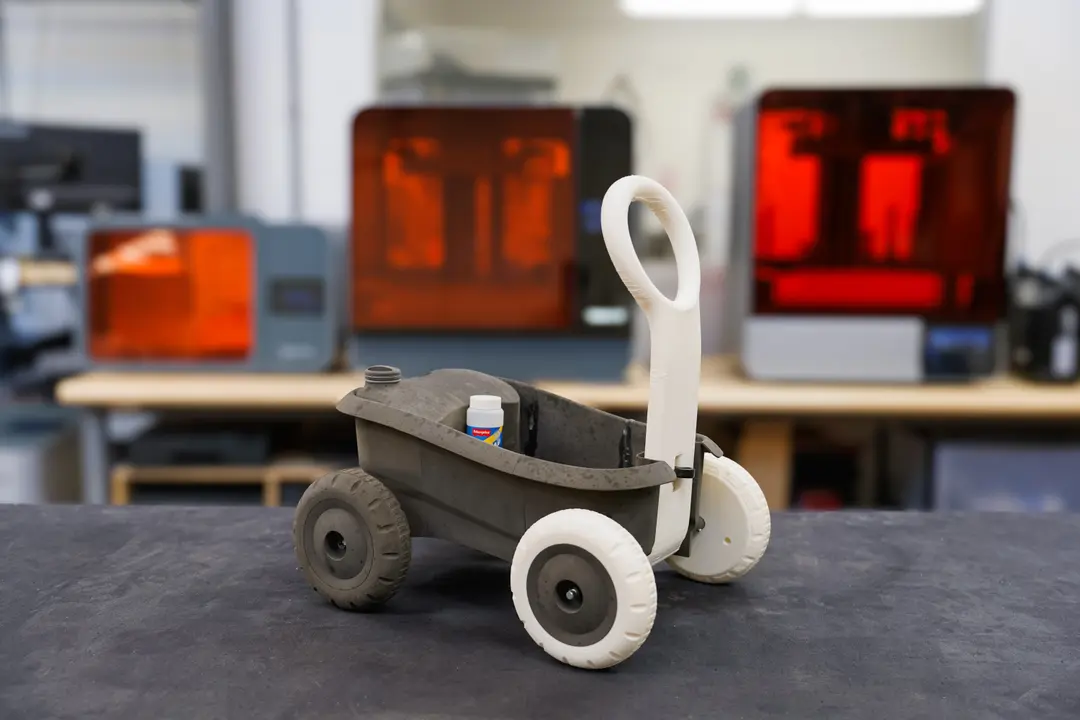

Bringing Back Requests for SLA at Radio Flyer

The original SLS printed prototype (left), SLA 3D printed and painted Roadshow Prototype (center) and final Production Bubble Buddy Walker Wagon.

Trusted and loved by families for over 100 years, Radio Flyer is the maker of the iconic Original Little Red Wagon®, which was inducted into the National Toy Hall of Fame. They have stayed at the forefront of popular culture and the top of every child’s Christmas list as the world’s leading producer of ride-on toys including wagons, scooters, tricycles, go-karts, electric bikes, and other innovative products that help families imagine all the places they’ll go.

3D printing is a big part of Radio Flyer’s development process, and design engineer Agostino LoBello runs a lab that includes two Formlabs Fuse Series selective laser sintering (SLS) 3D printers, Form 3L and Form 4L large-format SLA printers, as well as FDM and PolyJet printers. Before adding Form 4L to their fleet, LoBello wasn’t getting many requests for SLA prints — the design and engineering teams preferred SLS parts from the Fuse Series. After only a few weeks of printing with Form 4L, however, LoBello noticed more requests for same-day parts were coming through for the large-format SLA printer.

“I think Form 4L has closed the gap a lot. We hadn’t been using SLA a lot before this because of print reliability and dimensional accuracy. But now, I distinctly notice people asking for Form 4L prints because it has been so much better in terms of accuracy, and also just how fast we can get them,” says LoBello.

The majority of parts that go through the SLA workflow are what Radio Flyer calls ‘roadshow models.’ These parts get sanded, painted, and then finished to create an injection-molding quality surface finish before they’re sent to photo shoots for e-commerce sites like Target, Wal-Mart, and Amazon. “The vendors get them for a review before they take products on board, so they need to be basically indistinguishable from production parts. For something like that, we do it on SLA,” says LoBello.

The ‘vendor-ready’ parts are only a small subset of what comes through LoBello’s request box; The rest of his requests were typically sent to the Fuse — until Form 4L.

“The speed has been the big difference maker, but also it’s been more dimensionally accurate. Right now, we’re successfully printing a box the full size of the build volume – when we tried to print that size on Form 3L, the box and its lid wouldn’t match up. Before Form 4L we would rather CNC it on our router or piece it together with SLS.”

Agostino LoBello, Product Design Engineer, Radio Flyer

Form 4L has given LoBello more room to accept requests from around the design and engineering teams — the printers still run nonstop, but with faster print speeds, they’re getting more done. To learn more about Radio Flyer and Form 4L, read the full story.

Going Big, Going Fast, But Staying On Track

Form 4L has enabled customers like Microsoft, Radio Flyer, Brose, and more to quickly produce high-fidelity, large, human-scale parts, increasing their iterative speed and helping them hit important deadlines.

Form 4L is a tool made to remove some of the unknowns in the design and engineering process; will this get done in time for design review, can I fit in one more change, is it worth going to tooling for the surface finish?

With Form 4L, you can almost always make your meeting, add an extra feature, or try something new. The part quality that Formlabs SLA customers rely on hasn’t changed, and the material versatility of the Formlabs ecosystem just gets a wider (and taller) platform. All the qualities that make SLA 3D printing great, are here. The fastest and most accessible, affordable, and easy-to-use large-format resin 3D printer in the world improves your productivity and takes the worries out of exporting parts out of the design software and into reality.

To start large-format resin 3D printing at blazing speeds, order Form 4L today. To discuss the printer and your unique workflow needs with an expert, contact our sales team.

Not sure which 3D printing solution fits your business best? Book a 1:1 consultation to compare options, evaluate ROI, try out test prints, and more.