Jeil M-Tech: Marking the Future of Industrial Printing

Dot peen marking machines are industrial devices used to print text, barcodes, and other markings on products during production, manufacturing, and distribution processes. Jeil MTech specializes in the manufacturing and sales of industrial dot peen marking machines and laser marking machines. The company has supplied and installed its products for industrial sites such as Hyundai Motor Company, Kia Motors, Mobis, WIA, as well as manufacturers of ship and aircraft components.

Jeil MTech has expanded its market reach by selling portable dot markers and desktop laser markers online. Despite fierce competition from low-cost markets in the region. Jeil MTech strives to stand out through its proprietary technology.

Choosing Formlabs Fuse 1+ 30W for Technological Edge:

To highlight their technological strengths, Jeil MTech focused on optimizing their product output process. Traditional injection-molded products incurred high initial mold costs and posed challenges in product modification. Their portable marking machines, initially made from aluminum, needed to be lighter, prompting the integration of 3D printing technology.

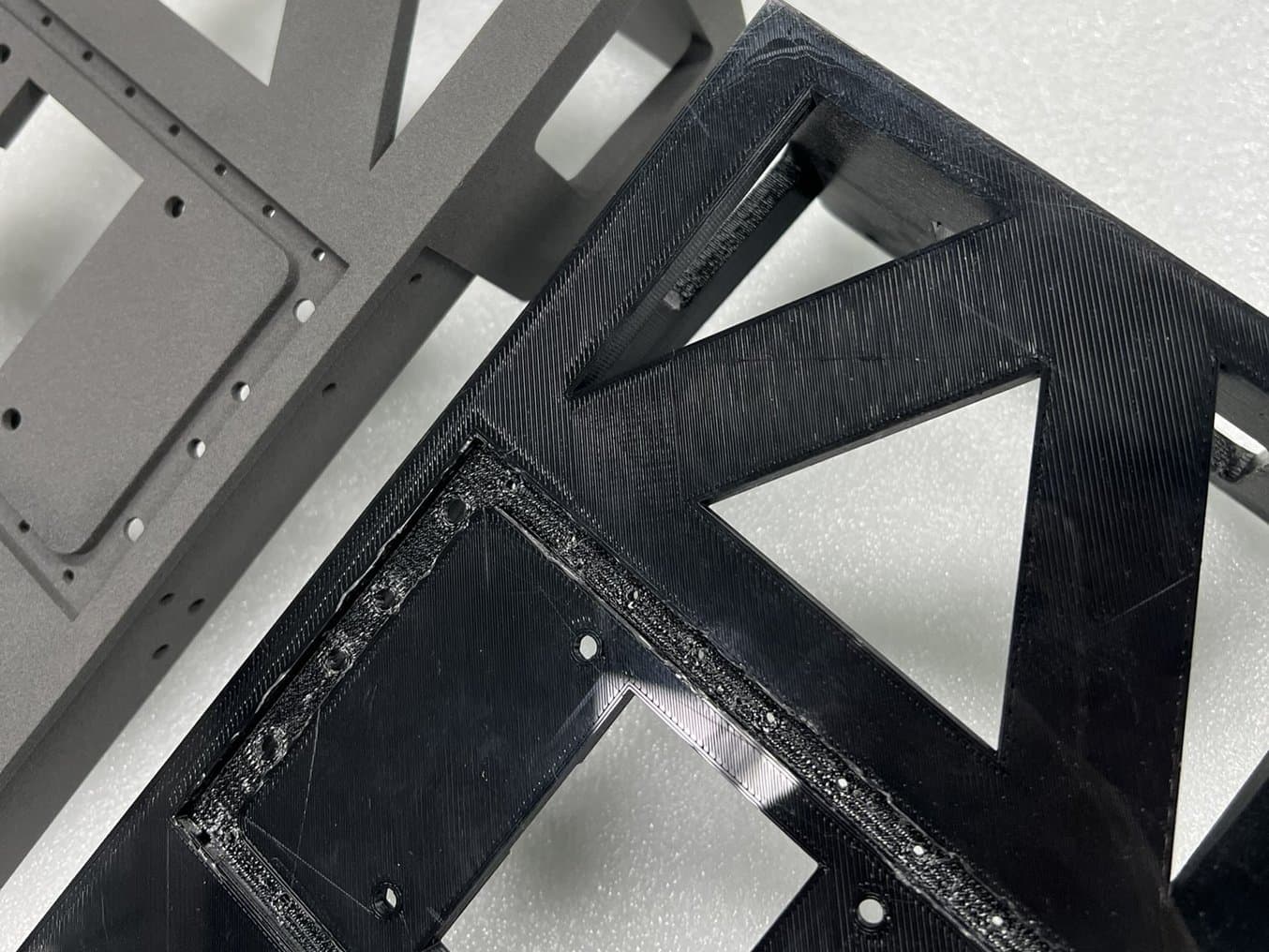

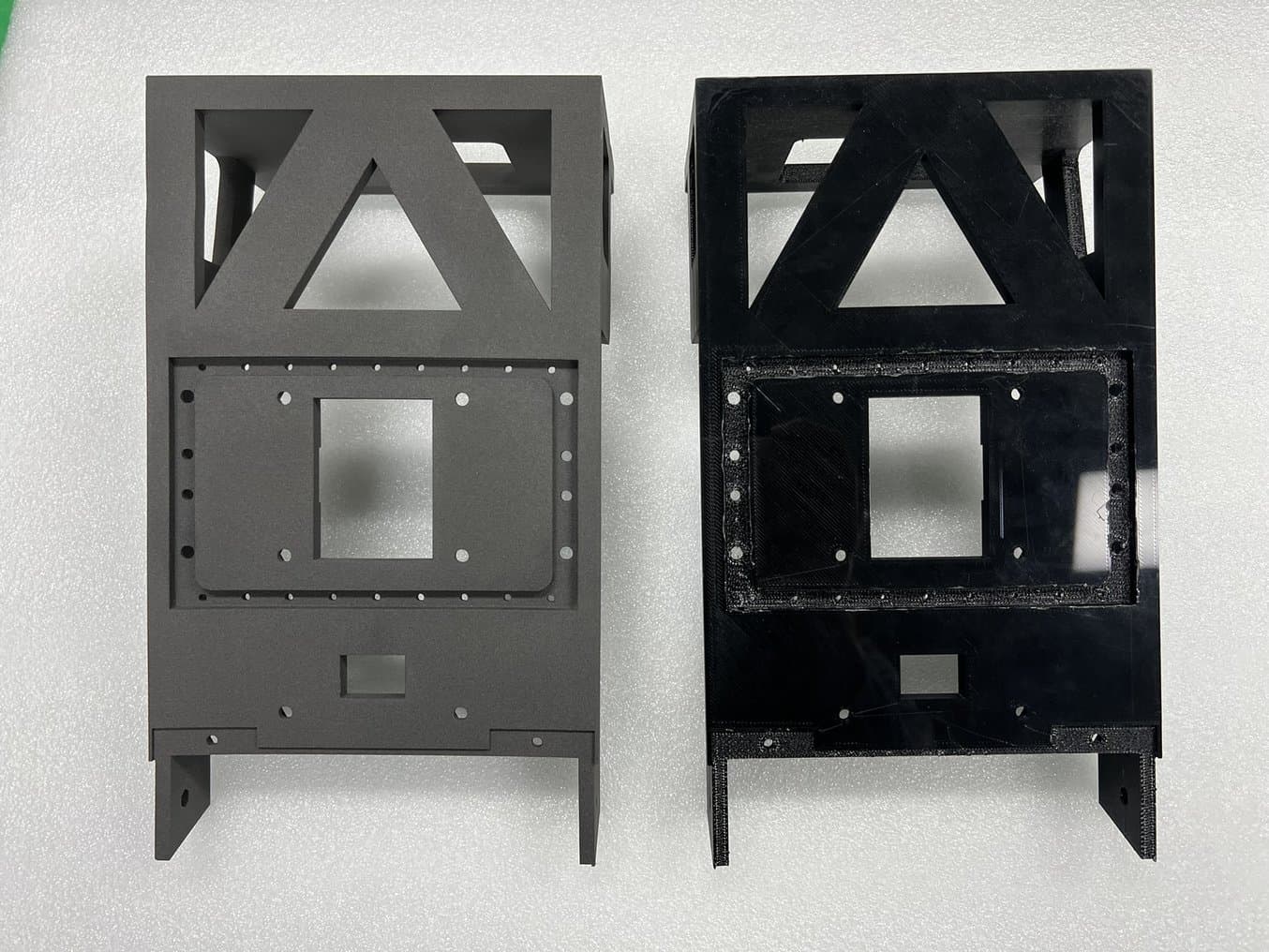

Early attempts with FDM (Fused Deposition Modeling) printers revealed significant drawbacks such as poor durability, visible layer lines, and issues in surface quality and presentability. Products made using FDM printers were prone to damage if dropped, making detailed work challenging.

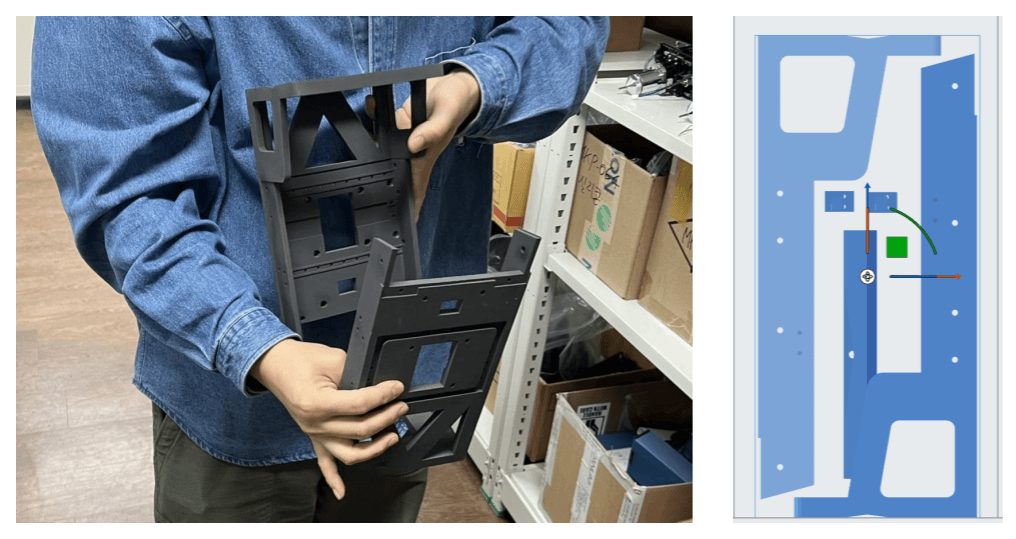

While exploring alternative 3D printing methods, Jeil MTech discovered Formlabs' SLS (Selective Laser Sintering) 3D printers at the 2023 KINTEX exhibition. After testing sample prints, they decided to invest in the Fuse 1+ 30W printer.

SLS 3D printer Fuse 1+ 30W (right) and SLS post-processing equipment Fuse Sift (left) installed in a Jeil MTech's 3D printing room.

The Advantages of Fuse 1+ 30W

The Fuse 1+ 30W offers the flexibility to make frequent product modifications, leading to higher-quality and visually appealing results. Unlike FDM-printed parts, which often suffered from durability issues and rough finishes, SLS-printed parts were robust and had a superior surface quality. Additionally, the SLS printer's lack of support structures simplified post-processing and enabled faster production times. While aluminum machining took 3-4 weeks and FDM printing required 2.5 days per part, the Fuse 1+ 30W could produce two parts in just 1.5 days.

Efficient and Rapid 3D Printing

With the Fuse 1+ 30W, Jeil MTech could print two parts in 15 hours, allowing for efficient overnight production. This significantly reduced the overall production timeline, enabling the creation of eight parts per week. The printer's build volume (165 × 165 × 300 mm) comfortably accommodated Jeil MTech's components (154 x 108 x 270 mm), facilitating the production of multiple parts in one print cycle.

Durable Material

Jeil MTech used Nylon 12 Powder for its parts, which offered exceptional durability and precise detailing. This material was lightweight and strong, reducing the weight of their portable marking machine by 600 grams compared to its aluminum counterpart. The enhanced durability and portability of the Nylon 12 parts made them ideal for practical use.

Superior Finish

The surface quality and finishing of the printed parts with the Fuse 1+ 30W was significantly higher than those produced with FDM printers. With FDM-type 3D printers, once printing is complete, supports must be manually removed or dug out using tools. This process often damages the surface of the printed part and leaves scratches on areas where supports have been removed. In contrast, the absence of support structures in SLS printing eliminated surface damage and ensured a clean finish. The superior final product quality exemplifies the strengths of the Fuse 1+ 30W.

Technical Manager of Jeil MTech

"Traditional injection-molded products were slow and heavy, and FDM 3D printing posed issues with durability and finish quality. With Formlabs, we solved weight and durability problems and accelerated part production."

Looking Ahead

Jeil MTech's experience with the Formlabs Fuse 1+ 30W showcases the transformative potential of advanced 3D printing technology in industrial applications. By leveraging SLS printing, Jeil M-Tech has achieved enhanced product quality, reduced production times, and improved overall efficiency, setting a new standard in the marking machine industry. Jeil MTech plans to use Formlabs 3D printers for various marking machine applications, including laser markers. Formlabs is committed to supporting Jeil MTech in developing a diverse range of marking machines.

This user story was provided by Formlabs’ authorized partner, AM Korea.