Insights from a Product Designer: Maintaining Productivity and Staying Innovative During Remote Work

As the world adjusts to a new reality, individuals across the globe are looking for ways to maintain productivity while working from home.

For some, the shift in working arrangements may only require a laptop and a strong internet connection, but for those who rely on physical tools and regular in-person client meetings to bring their designs to life, the transition may prove more complex.

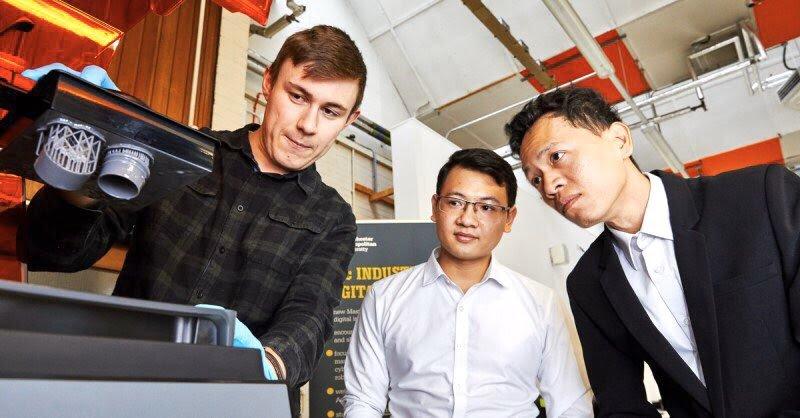

We spoke with Mark Chester (pictured left in the image above), the Innovation Development Manager at Manchester PrintCity, who shared insights on how he’s adapting to this new working environment, and the unexpected efficiency gains he achieved when engineering from home.

Helping Businesses Innovate Faster at PrintCity

PrintCity is a 3D additive and digital manufacturing centre based in Manchester, a city with a rich industrial legacy and the UK’s biggest technology hub outside London. The facility is home to a unique mix of manufacturing experts, designers, engineers, and students from the MSc in Industrial Digitalisation at Manchester Metropolitan University.

Together with additive manufacturing specialist and Formlabs partner, GoPrint3D, the digital manufacturing hub collaborates with businesses, large or small, offering expertise and a wealth of 3D printing technologies and ideation tools for organisations looking to “go digital”.

Describe how you’re working from home during this period, and the technologies and tools you’re currently using to do so?

"At Manchester Print City we have 10 Formlabs printers and a range of other additive manufacturing technologies to use for our design work, with access to a wide range of prototyping materials. My current 3D printing setup at home (pictured below) includes a combination of a Ultimaker S5 fused deposition modeling (FDM) printer, and a Formlabs Form 3 stereolithography (SLA) desktop machine with a Finish Kit and Form Cure post-curing station."

Mark’s current work from home setup, complete with an Ultimaker S5 and a Formlabs, Form 3, desktop 3D printer.

"This enables me to be able to quickly prototype designs using PLA, or Formlabs Draft Resin, before producing a higher quality prototype to send out to customers. Right now we’re conducting all our meetings on Zoom to allow one to one design sessions with clients, providing real-time feedback on their projects."

"Through Fusion 360 we can also share designs remotely through an internet browser, allowing the customer to inspect a 3D model without having to download the software themselves. Furthermore, to comply with regulations all prototypes are now disinfected and sent via post instead of waiting for clients to come across to the facility for collection.”

Why is it so critical for you to continue 3D printing during this challenging time?

"It's imperative for our customers that we continue working during this period. The pandemic provides a fantastic opportunity for businesses to re-evaluate their operations, processes, and products."

Mark Chester, Innovation Development Manager, PrintCity

“Having a 3D printer at home is hugely beneficial to my work as a greater amount of feedback can be gained from a physical 3D model than it can virtually. I tend to find myself 2D printing less and moving into 3D as my clients start to adopt a more digital mindset. Without it, many of my current projects would need to be put on hold as there's only so far I can go in CAD.”

One of Mark’s current projects in partnership with a local high performance helmet manufacturer to reverse engineer and develop components using 3D scan data.

What are your biggest learnings from 3D printing from home over the past month?

“One of the biggest takeaways from working from home is just how easy it can be. The Form 3 took hardly any setup time to continue printing again, meaning many of my projects could continue as scheduled without disruptions."

Mark Chester, Innovation Development Manager, PrintCity

"With many of my clients, I'm finding working from home more productive as there are fewer distractions and I can get feedback quickly. However, it can be difficult to stick to normal working times without traveling in and out of work, so I would advise planning your day or week to ensure that you're not working around the clock."

"Each day I tried to make sure I stop working and head out for a run to get fresh air and exercise. It really helps to clear my head and reflect on what’s happened during the day. Strava Challenges like the April 200km have helped to keep me motivated and focused on a goal, especially when the weather isn’t looking great.”

Some people working from home may be limited by resources, how are you managing to engineer from home sustainably?

“Running out of materials is something which is quite concerning, however, it has made me more selective as a designer around what prototypes I choose to print. At PrintCity, having access to multiple Form 3 machines means I can easily print designs whenever I need, which is a luxury that I don’t have at home. Knowing the tolerances and design guidelines definitely helps to ensure you only have to print once or twice. In addition, selecting the correct printing strategy in conjunction with the geometry I am printing helps me increase efficiency."

"Additionally, we have also started exploring ways in which we can share files digitally through Augmented Reality. Apps such as Sketchfabb and Reality Composer are great examples of simple to use AR tools which can help reduce the amount of 3D prints required. Here you can see how AR can help clients digitally evaluate products in different colours before purchasing online.”

Maintaining Productivity During Work Disruptions

With several 3D printers, teams across multiple locations can collaborate more effectively. By using the same 3D printers and materials, professionals can iterate and produce parts on different machines seamlessly.

Want to learn more about maintaining productivity using your Formlabs 3D printer remotely? Read our Ultimate Guide to Engineering from Home for tips and advice on safely transporting your 3D printer and optimising your workflow in a remote environment.