Saving £8,000 and Two Hours of Surgery Time at the UK’s Leading Spinal Unit with 3D Printing

When it comes to the operating table, time is everything. Complex surgical procedures take time to perform and operation length is frequently cited as a major risk factor for postoperative complications. This is where 3D printing fits in.

With access to affordable, precise 3D printing technologies through their partners at Axial3D, specialist surgeons like Andrew Bowey at Newcastle Hospitals NHS Foundation Trust are able to dramatically improve preoperative planning with high-precision, patient-specific anatomical models.

Why is this so important? Research finds that using 3D printed anatomical models in surgery significantly reduces operating time, improving patient care and limiting risk to the individual. Patient-specific anatomical models can also aid surgical simulations, intrateam discussions, conversations around patient consent, and help reduce the associated costs of surgery.

Transforming Preoperative Planning with Patient-Specific Anatomical Models

Back pain is the largest single cause of disability in the UK. According to the NHS, seven in ten people in the UK will suffer from some type of spinal issue in their lifetime, ranging from fractures and curvature of the spine, to degenerative diseases and spinal tumours.

Each patient’s pathology is different and therefore requires a different approach in both diagnosis and treatment. As a result, there is a growing demand for custom and patient-specific medical applications across the globe that can provide clinicians with bespoke treatment solutions.

As a consultant orthopedic spinal surgeon, Mr. Andrew Bowey is responsible for leading the 3D platform within the Royal Victoria Infirmary and Freeman Hospitals based in Newcastle, which are pioneering centres for spinal treatments within the UK. The trust is one of the busiest teaching NHS foundation trusts in the UK with over 1,800 beds and 14,000 staff.

Patient-specific anatomical models can also aid surgical simulations, intrateam discussions, conversations around patient consent, and help reduce the associated costs of surgery.

Wherever possible the team utilise advanced, minimally invasive surgical techniques to minimise discomfort and reduce patient recovery time. By enlisting the expertise of Axial3D, Mr. Bowey and team are able to transmit patient CT and MRI data securely from the ward in Newcastle to the Axial3D HQ in Belfast, Northern Ireland. Within hours of the transfer, the Axial3D team can segment the data and produce tactile 360º models of the patient’s anatomy.

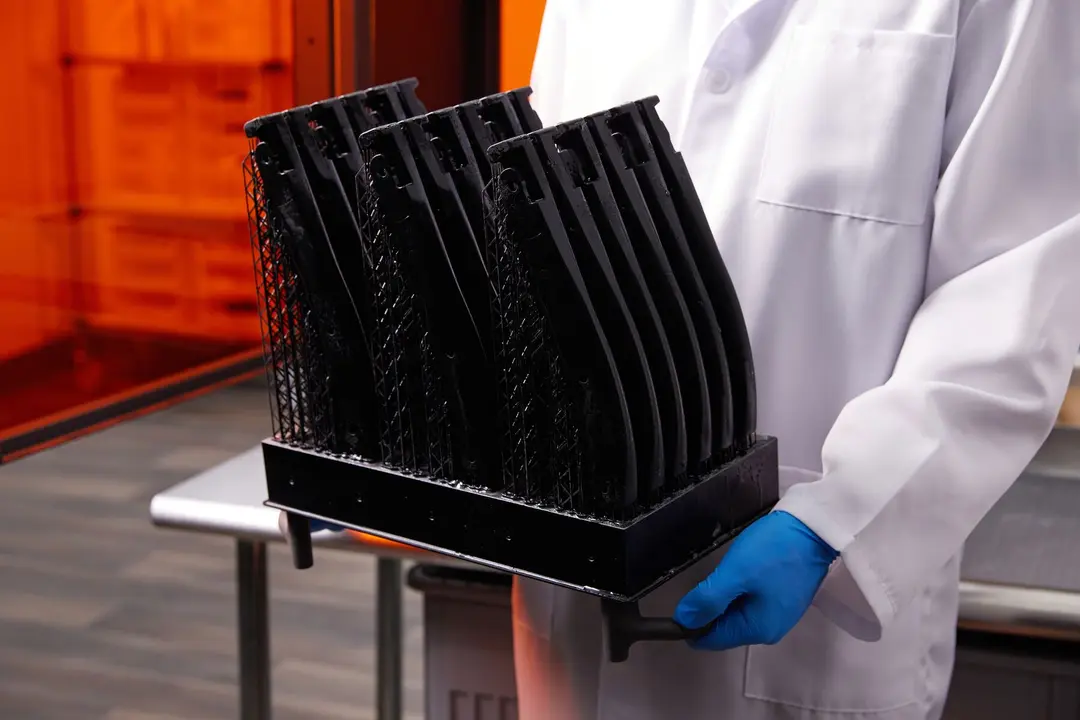

The medical imaging experts at Axial3D then 3D print the models with their Form 3B Desktop SLA printer, and deliver them to the hospital within 48 hours. Once shipped, these models can be used to help with pre-operative planning, conducting surgical simulations, or to help educate and gain consent from the patient.

“Spinal procedures can be extremely complex and no two procedures are the same. Anatomical models help surgeons like myself in explaining the associated risks of a procedure, which is important for gaining informed consent especially when complications could put them at risk of paralysis.”

—Mr. Andrew Bowey, Spinal Surgeon, Newcastle upon Tyne Hospitals

Historically, this workflow would involve sending MRI or CT data to a lab and waiting several weeks to receive a model. Within this time, the patient could be facing severe pain. Mr. Bowey explains that this model would often be representative of the entire scan, rather than the precise area that is under investigation - increasing materials costs and analysis time.

“As a clinician, I don’t have the time or the software to segment the medical images. Knowing the experts at Axial3D understand what surgeons need and can segment accordingly so we’re left with an accurate depiction of the patient’s pathology is of huge benefit to our team.”

—Mr. Andrew Bowey, Spinal Surgeon, Newcastle upon Tyne Hospitals

Saving £8,000 and Reducing Surgery Time by Two Hours

Mr. Andrew Bowey and team were recently presented with a patient with a neural tube defect in the form of Spina Bifida and a severe kyphotic deformity, a spinal disorder in which an excessive outward curve of the spine results in an abnormal rounding of the upper back.

The increasing deformity and the inability for the patient to sit or sleep comfortably caused huge day-to-day pain for the patient. Having access to the 3D printed model helped with pre-operative planning, as it allowed Mr. Bowey to assess the possibility of conducting a shortening osteotomy which helps reduce the spinal cord tension without causing direct neural damage. It also gave the team enhanced insight into which pedicles were viable for screw positioning, and how best to conduct the surgery.

“Surgeons are very tactile people and holding anatomical models in their hands as planning and simulation tools, aids a more precise surgical experience with fewer complications.”

—Mr.Andrew Bowey, Spinal Surgeon at Newcastle Hospitals

The 3D printed model also enabled the clinical team to consult with the patient and their family to manage expectations and to fully demonstrate any associated risks. By conducting a full surgical simulation before the operation, Mr. Bowey was able to save over 120 minutes of time during a complex surgical procedure, equating to around £8,000 GBP of the hospital’s funds. In addition, the process also contributed to reduced blood loss and better communication with the surgical team throughout the procedure.

“The Orthopaedic and Spinal team at Newcastle Hospitals have an international reputation for their ground-breaking work on complex conditions. We are excited to be working closely with the team to assist in making medical 3D printing routine practice within the Trust, to ultimately help improve the quality of patient care across the region.”

—Daniel Crawford, CSO and Founder at Axial3D

Technology that Scales: Expanding 3D Printing Facilities Within the NHS

Formlabs and Axial3D’s joint mission to increase accessibility to 3D printing for medical professionals doesn’t stop there. To support the growing demand for patient-specific 3D printed models, Axial3D is currently working with Newcastle Hospitals to develop a full on-site 3D printing facility. This training facility will give clinicians around-the-clock access to Formlabs 3D printing technology with dedicated support provided by Axial3D.

“3D printing has become an essential part of pre-operative planning in complex spinal cases. In Newcastle, we’re excited to now roll 3D printing out across the trust. The benefits in other areas, such as trauma, are clear to see.”

—Mr.Andrew Bowey, Spinal Surgeon at Newcastle Hospitals

The Newcastle upon Tyne Hospitals NHS Foundation Trust is one of the busiest teaching NHS foundation trusts in the UK with over 1,800 beds and 14,000 staff.

The Trust, one of the top 10% best performing Trusts in the UK, will host a printer onsite at the Royal Victoria Infirmary for day-to-day use, while excess prints can sent to Axial3D’s head office using Formlabs remote start feature, and shipped to the requesting clinician, meaning the Trust can effortlessly scale its offering to address evolving patient needs.

Formlabs' 3D printing systems have been used and discussed in various research projects in the scientific, medical, and dental communities. Find out more about medical applications of 3D printing, or request a free 3D printed sample to evaluate the quality of Formlabs technology firsthand.

Learn More About 3D Printing Applications in Healthcare

Original Research: Medical 3D Printing Cost-Savings in Orthopedic and Maxillofacial Surgery: Cost Analysis of Operating Room Time Saved with 3D Printed Anatomic Models and Surgical Guides

Request a Free Sample Part

See and feel the quality of SLA 3D printing firsthand. We’ll ship a free 3D printed sample part to your office.

Request a Free Sample Part