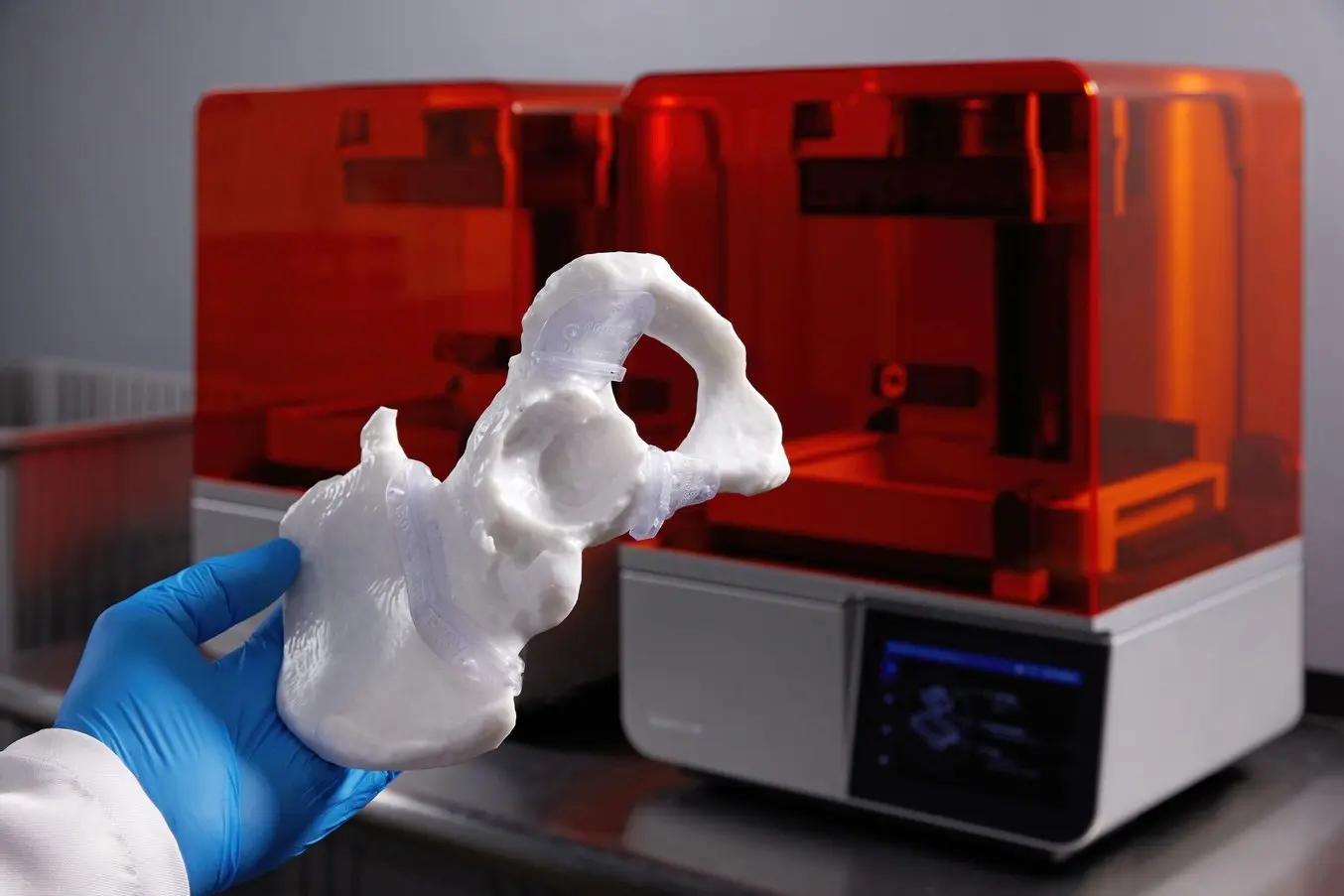

Trusted 3D Printing Solutions for Cutting Edge Healthcare

Every medical facility should have access to the latest tools to improve care and provide the best patient experience. Get started now or expand your in-house production with Formlabs, a proven, cutting-edge partner in medical 3D printing.

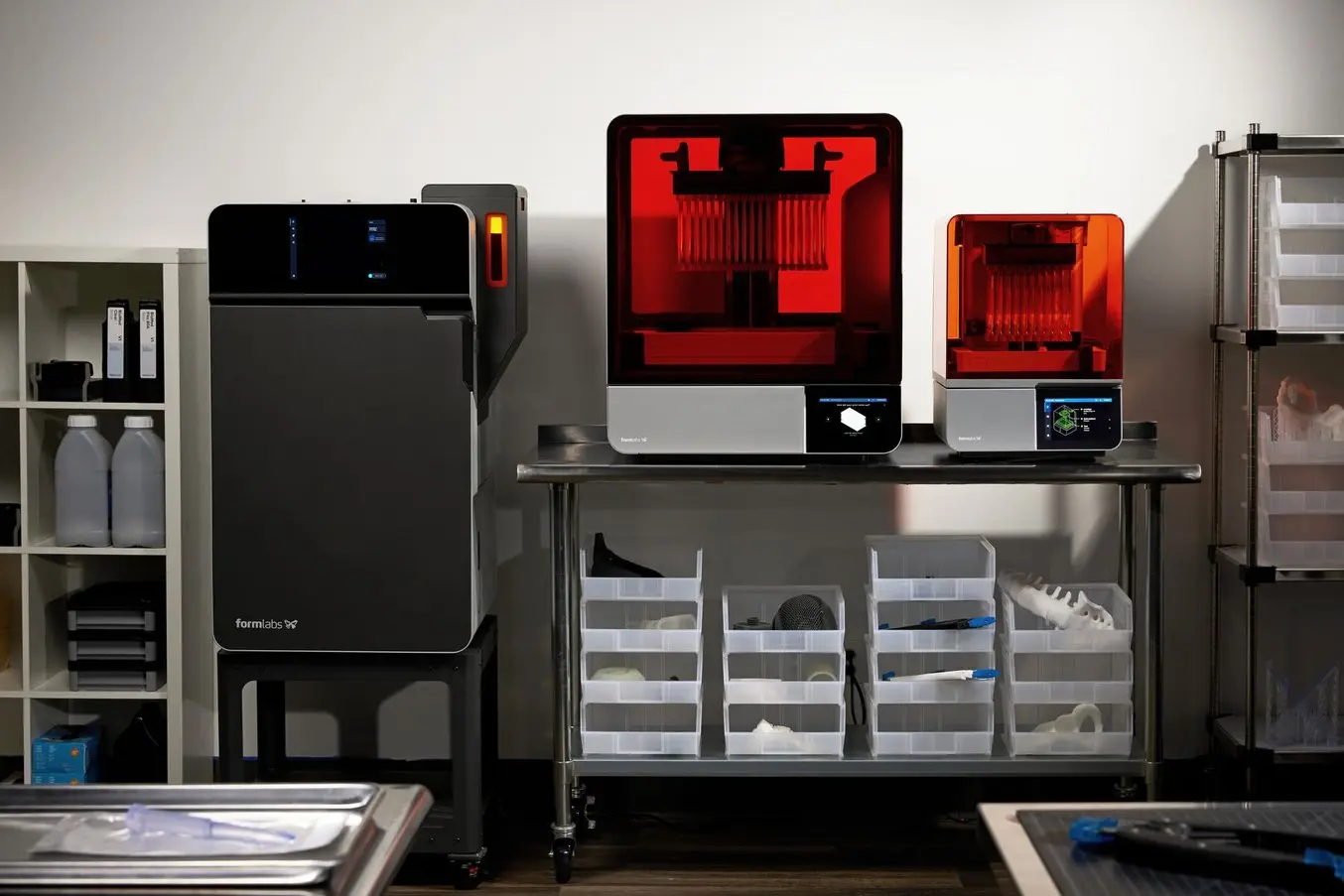

A Full Suite of 3D Printing Solutions

Form 4B

Industry-leading print speeds enable high-throughput production capabilities.

Precise, accurate prints across the build platform.

99% reliability with unmatched print success.

Form 4BL

Same-day turnaround for large prints.

Produce parts with exceptional tolerances and quality, rivaling injection molding.

Achieve high-throughput production with more parts per build and fewer user interactions.

Fuse 1+ 30W

Automated ecosystem for streamlined, end-to-end workflows with fewer touchpoints.

Unlock a broad range of industry-standard materials including nylon, polypropylene, and TPU.

Customer-ready parts in under a day.

Medical Service Plan

Your business needs a 3D printing solution you can rely on for nonstop production. Behind our Medical Service Plan is a dedicated team of certified medical 3D printing specialists who know exactly how to support your healthcare facility.

High-Performance Materials

Access 45+ Formlabs materials, including 25+ biocompatible resins for healthcare, supported by an ISO 13485 and EU MDR-certified Quality Management System in our FDA-registered facility, or experiment with any 405 nm photopolymer or 1064 nm powder using Open Material Mode.

Formlabs Software

Formlabs software solutions help you work more efficiently. Prepare your 3D models for printing with a few clicks, manage a single printer or an entire fleet from the cloud, and automate and optimize your workflow.