Carbon3D M2/L1 vs. Formlabs Form 3+/3L

You Don’t Need to Spend $150,000+ to 3D Print Industrial-Quality Parts in House

Scale prototyping and production as your business grows with the Form 3+ and the Form 3L, affordable, industrial-quality 3D printers.

Compare the Carbon3D M2/L1 vs. Formlabs Form 3+/3L

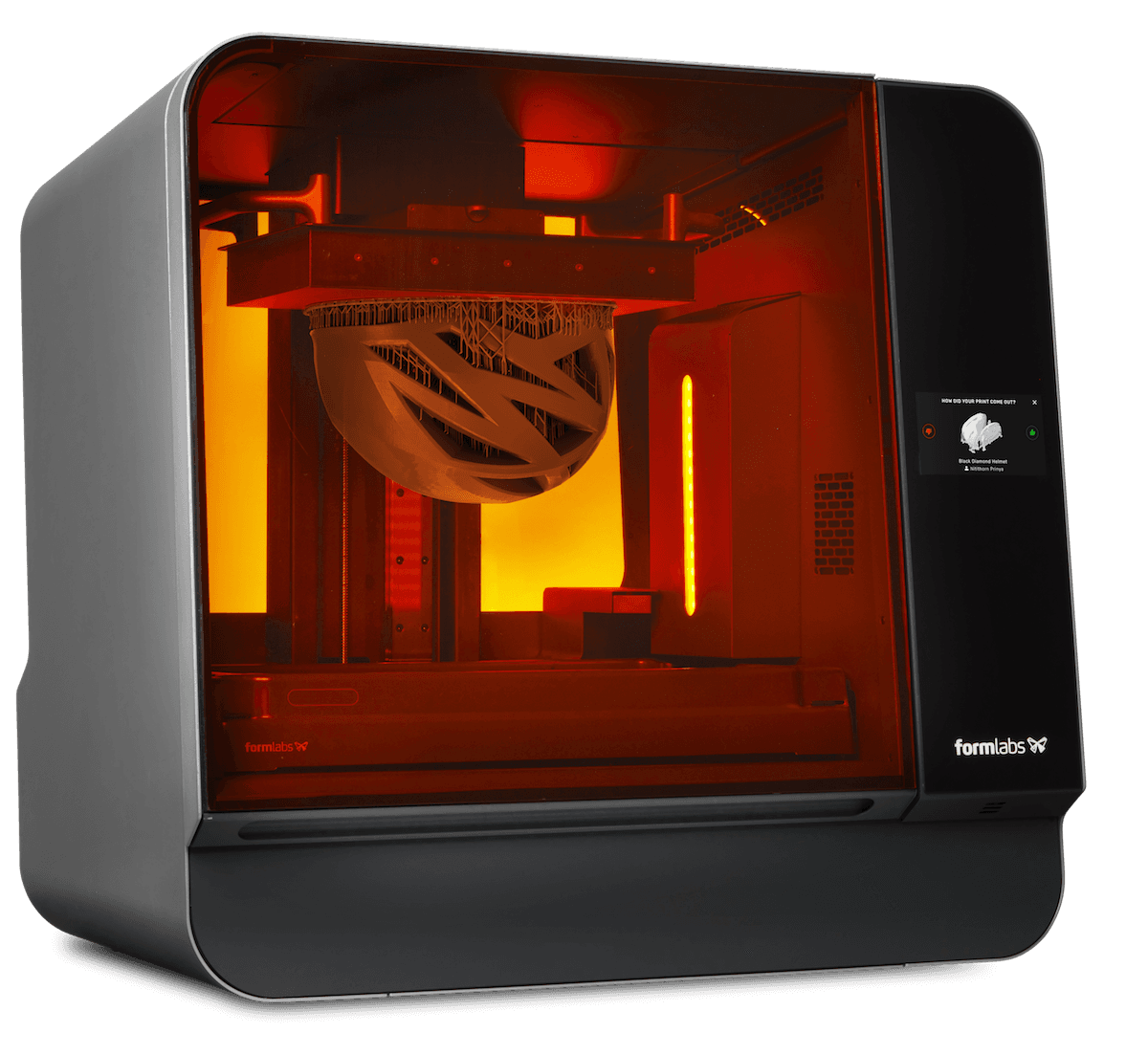

Formlabs

Form 3+/3L

Carbon3D

M2/L1

Starting at $2,499- $8,999

Transparent pricing with no hidden fees. Buy directly from Formlabs via sales or the online store, or locally from a worldwide partner network.

$150,000-$750,000 for 3-years

Complicated and opaque subscription pricing, requires multiple quote requests and negotiation. The M2 system costs $50,000 per year and the L1 $250,000 per year, both with a minimum 3-year contract, which even excludes the accessories required for post-processing.

Low Force Stereolithography (LFS)™

LFS is the next phase in SLA 3D printing, that delivers incredible surface quality and print accuracy, meeting the demands on today’s market for scalable, reliable, industrial-quality 3D printing.

Digital Light Synthesis

(DLS)™

DLS 3D printers work similarly to other resin 3D printing processes like SLA or DLP, but use an oxygen permeable window that can speed up the process for certain geometries like lattices.

Accurate, repeatable prints with a smooth surface finish

25-200 microns Z resolution

25 micron XY resolution

Accurate, repeatable prints with more visible layers

100 micron Z resolution

75 micron XY resolution on the M2

160 micron XY resolution on the L1

Form 3+:

14.5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

Form 3L:

33.5 × 20 × 30 cm

13.2 × 7.9 × 11.8 in

Carbon3D M2:

18.9 x 11.8 x 32.6 cm

7.4 x 4.6 x 12.8 in

Carbon3D L1:

40 x 25 x 46 cm

15.7 x 9.8 x 18.1 in

30+ functional resins

A wide range of materials for prototyping and production from soft silicone-like to flexible, tough, durable, and rigid varieties. Specialty materials for high-temperature applications and castable patterns. A wide variety of dental resins, including biocompatible materials.

20+ functional resins

A wide range of materials for prototyping and production from soft silicone-like to flexible, tough, durable, and rigid varieties. Specialty materials for high-temperature applications and castable patterns. A wide variety of dental resins, including biocompatible materials.

Plug and print

Contact-free delivery and online or in-person training for the entire team. Easy workflow empowers anyone at your company to use the system independently after less than one hour of training.

Complex

Setup and training with on-site installation required. The more complex workflow and the steeper learning curve means that the system requires a skilled technician in-house to operate and maintain.

Free and easy to use

Formlabs' free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine as needed. Try it now. You can also use the online Dashboard to manage printers, materials, and teams.

Free

Carbon3D’s print preparation software is included in the printer subscription and offers a similar range of basic and advanced features and online fleet management.

Pro Service

Premier support service with fast response time, customized training, replacement printer, and extended warranty—all for an affordable price.

Included

Installation and training, as well as phone and email support are included in the subscription.

Formlabs adapted the SLA technology to the desktop in 2011 and has since become the market leader, selling more than 70,000 printers as of today.

Carbon3D primarily offers industrial 3D printers that are limited to large companies and service bureaus due to their high price.

Do you have more questions about the differences between these solutions?

Request a Free Sample 3D Print

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

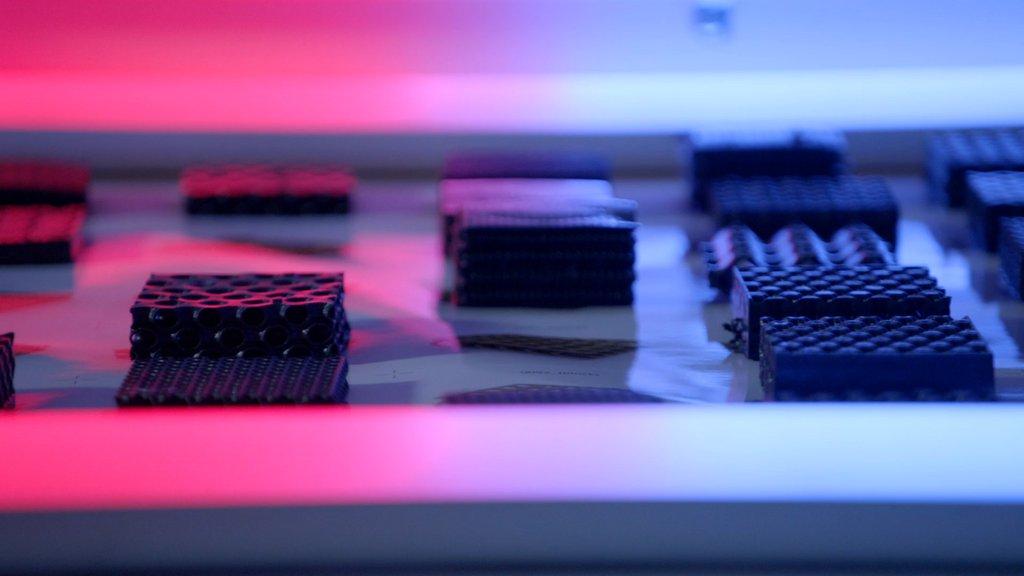

Build an Entire Factory for the Price of a Single Carbon3D Printer

Buy a massive fleet of 60 Form 3+s for the price of a single 3-year subscription to a Carbon3D M2 or 83 Form 3Ls for the price of a single Carbon3D L1 to scale your throughput, be able to print different materials simultaneously, and have peace of mind to avoid downtime.

The Freedom to Design and Manufacture High-Performance Custom Products

Formlabs Factory Solutions is 3D printing reimagined to build the factory of the future for demanding industrial applications. Build your factory the way you want it with intuitive tools, transparent pricing, and proven processes. Learn how Formlabs’ Factory Solutions team armed New Balance with the completely new 3D printing material and production system they needed to launch TripleCell.

Form 3+ and Form 3L: Product Deep Dive

In these product demo webinars, our printing experts will walk you through the step-by-step workflow for using Formlabs 3D printers.

High Quality Parts, Fast, Affordably

Reduce costs, iterate faster, and bring better experiences to market with our advanced 3D printing materials designed to deliver beautiful final parts for a wide range of applications.

Form 3+

Draft Resin

$3

42 minutes

70,000,000 Parts Printed With Formlabs Technology