FROM PRINTED TO POLISHED IN 15 MINUTES

Fuse Sift + Fuse Blast

The Fuse Workflow

The Fuse ecosystem is enabling fast and affordable SLS 3D printing of industrial-grade parts and reinventing SLS post-processing to go from printed to finished parts in as little as 15 minutes with an efficient, hands-off workflow.

Fast, Automated Post-Processing

Fuse Sift filters, measures, mixes, and stores powder for you, while Fuse Blast delivers 100% hands-off part cleaning and polishing.

Same-Day Turnaround

Fast and Reliable Printing

Easily set up your printer and achieve fast printing thanks to the 30W laser. Print same-day prototypes and enable small series manufacturing of durable end-use parts in under 24 hours.

RECLAIM

5-10 minutes

Convenient, Compact Powder Management

Our all-in-one powder management station combines part extraction, powder recovery, storage, and mixing in a single device. Fuse Sift will dispense and mix used and new powder automatically so you can reduce waste and control your powder supply.

FINISH

10-15 minutes

Fully Automated Part Cleaning And Polishing

Fuse Blast is an advanced automated finishing solution for SLS parts that quickly removes powder and consistently delivers professional parts that are clean to the touch. Deliver a smooth, semi-gloss, and dye-ready surface finish with the polishing option.

Fuse Sift

Compact and efficient powder management station.

Parts are extracted and unsintered powder is collected and sifted to remove debris so it can be reused.

New and used powder are automatically measured, mixed with fresh powder, and stored for the next print.

Fast, Simple

Compact, Enclosed System

A Fuse Sift is equipped with an HEPA filter, as well as a negative air pressure system that keeps powder inside, while enabling open access and easy cleanup.

Fuse Sift Dimensions

Manageable

Low Waste

Fuse Sift efficiently collects unsintered powder and filters out debris so it can be reused in the next print. Competitive material recyclability allows you to use up to 80% used powder.

Powder Recovery

Automatic Powder Mixing

Fuse Sift will dispense, mix, and store used and new powder automatically so you can reduce waste and control your powder supply easily.

Consistent

Nonstop Printing

Reduce downtime by transferring modular build chambers and powder cartridges between the printer and Fuse Sift for a nonstop, cyclical workflow with minimum downtime — even during cooldown.

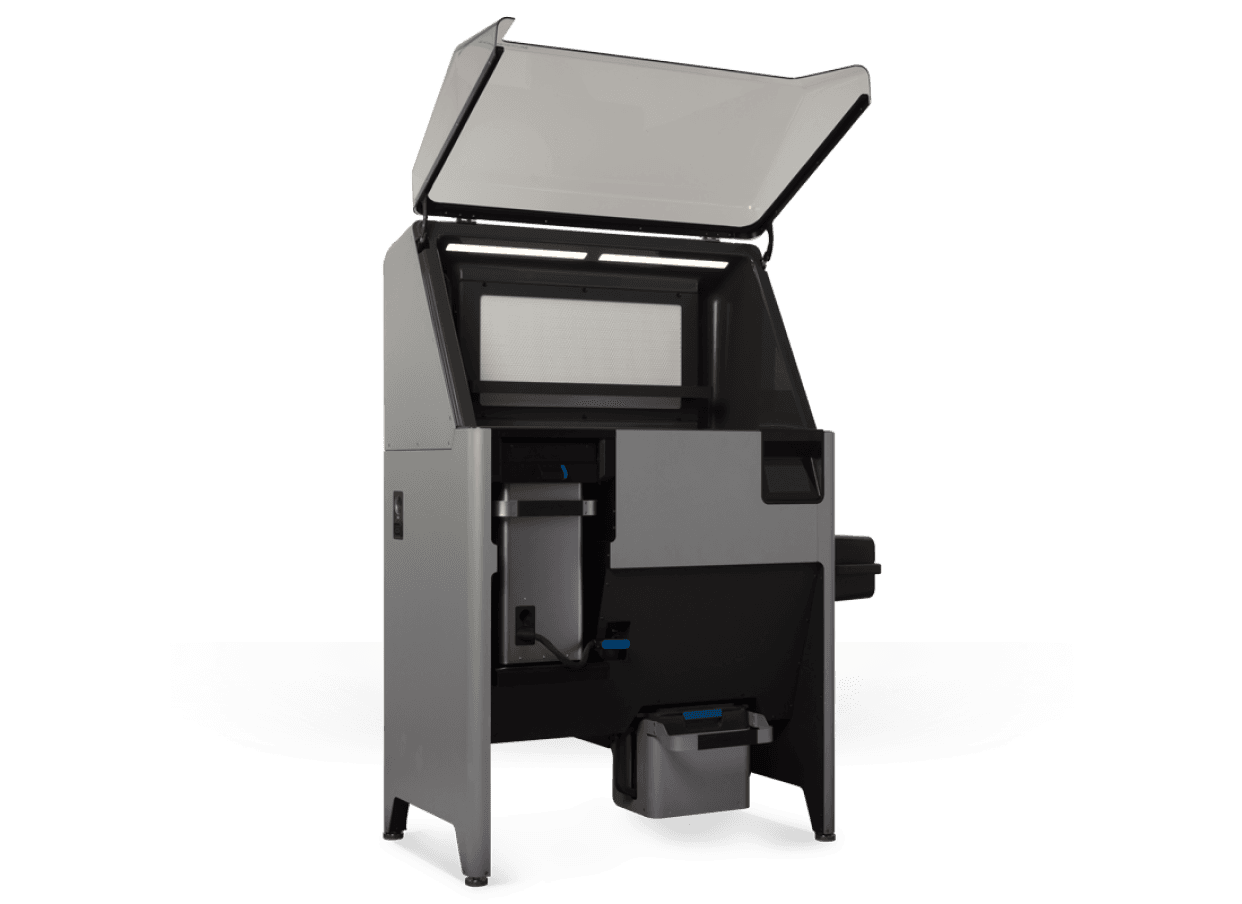

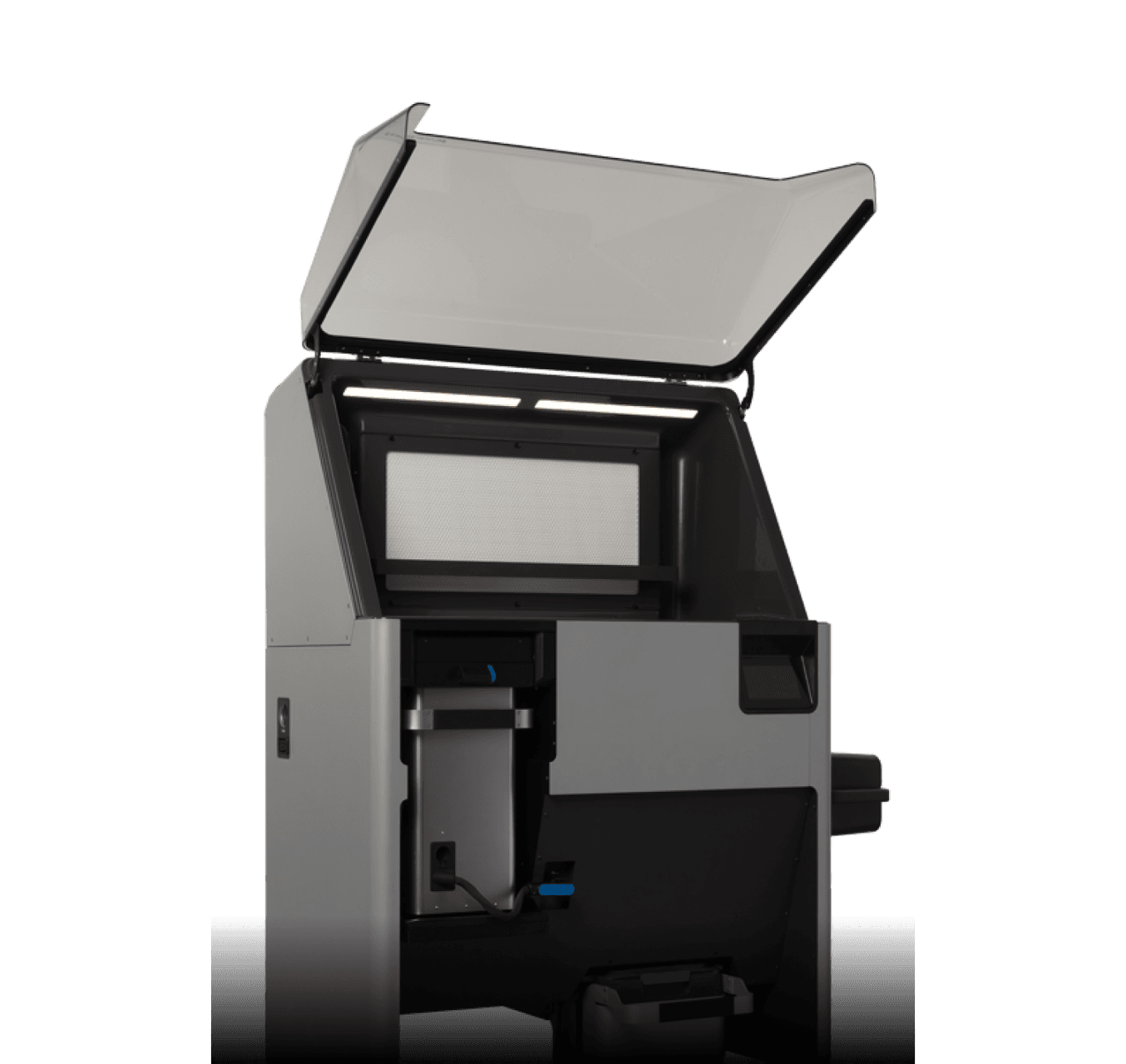

Fuse Blast

Fully automated cleaning and polishing solution.

Choose between automatic or manual cleaning to deliver professional parts that are clean to the touch.

The polishing function allows you to take it to another level with customer-ready parts that exhibit a smooth, semi-gloss surface finish.

Fast, Simple

Automated Cleaning

The best option to effortlessly clean parts with Fuse Blast. The 100% hands-off post-processing cleans a full build volume of parts in as little as 10 minutes with pre-programmed routines that take out the guesswork.

Manageable

Versatile Manual Modes

Switch between automatic, manual-assisted, or handheld modes to ensure thorough cleaning for any part size or geometry.

Powder Recovery

Consumer-Grade Parts

Deliver clean-to-the-touch parts thanks to the in-line ionizer that prevents dust and media from re-settling on your parts, or go the extra mile with the polishing function* for a smooth, semi-gloss, and dye-ready surface finish.

*Optional add-on, available early 2024.

Consistent

Saving Time and Costs

Minimize overhead costs thanks to the waste separation system that reduces media saturation and extends media life by four to eight times, while reducing time spent extracting parts on Fuse Sift by 80%.

Fuse Depowdering Kit

Affordable Depowdering Solution for Low-Volume Production and Multiple Materials

Perfect for low-volume users, this all-in-one manual post-processing kit for SLS is an alternative to Fuse Sift that enables you to easily clean parts and recover and mix the used powder to prepare for the next print, all at an affordable price point. The Fuse Depowdering Kit also enables you to seamlessly switch between materials on Fuse Series printers without requiring you to clean Fuse Sift.

A New Wave of Independent Manufacturing Starts Now

Rethink product development and take control of your own manufacturing. Configure your Fuse Series setup today.