Zerømouse Blade: Producing the Ultimate Gaming Mouse on Form 4 Series 3D Printers

When Ali Sayed set out to make the ultimate gaming mouse, he knew it needed to be ultralight, stiff, grippy, ergonomic, and offer precise control. The result of two years of work, Zerømouse Blade was released in July 2025. Weighing just 21 grams, the shell of the Zerømouse Blade is the lightest and uses the fewest screws of any mouse on the market, and it was prototyped on a Formlabs Form 4 3D printer. When it came time for production, Sayed produced the final shell and scroll wheels on Form 4L in Black Resin, achieving the quality of injection molding in less time and at lower costs than it was taking him to outsource production in nylon.

“I know many people hear ‘3D printing’ and think of it as cheap and low quality, but things are changing. Some of the most expensive machines and products in the world use 3D printed parts.”

Ali Sayed

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Experimentation

Sayed’s project began because the mouse he wanted for gaming didn’t exist. The Zaunkoenig M2K taught him the benefits of fingertip-grip, but, he says, “I wanted it to be wireless and more ergonomic to hold. Nothing like that existed on the market so I set out to make exactly that.”

This fun personal project turned into a mod-kit that allowed users to transplant the internals of their 58 g Razer Viper V2 Pro into a mouse that weighed 29 g. The mod-kit was both prototyped and produced on outsourced HP multijet fusion (MJF) 3D printing with Nylon 12. Prototyping with outsourced 3D printing meant waiting weeks between iterations.

“These prints were always outsourced, which meant that I’d have to wait 1-2 weeks before testing the new version and re-opening CAD. The moment I switched to the Form 4, productivity was in hyper speed. I could do multiple prints and design upgrades in a single day.”

Ali Sayed

The mod-kit was an important precursor to the Blade, revealing breaking points and pressure points that showed Sayed “where to add mass and where I could subtract it without affecting the experience or feel.” But the biggest change to Sayed’s workflow when it came to prototyping the Bade was bringing 3D printing in-house with Form 4.

Sayed acquired a Form 4 for in-house rapid prototyping, shortening iterations to hours rather than weeks while achieving accurate dimensions and a finer surface texture. “Being able to make changes in the morning, have a print done by midday — I mean, it is ridiculous,” says Sayed.

For the Blade, Sayed’s design process was to model changes, with different design branches for different models. “For example with the Blade, the structure that holds the scroll wheel had three completely different designs. Then I would print them all at once and test which design was best.” Adjustments to the design included changing the grip width, the angle of the grips, and the height of the triggers. Some of the final refinements included minute, 0.05 mm adjustments to the thickness, optimizing the feel of a click.

He attempted printing one batch of custom scroll wheels with a Bambu Lab X1 Carbon fused deposition modeling (FDM) 3D printer, but found that the time to print batches as well as the quality of the prints weren’t a match for Form 4.

“You can't print really small, really detailed objects on filament 3D printers. You can only print as small as the nozzle that you’re printing with. On most printers, that’s 0.4 mm. These printers (Bambu Labs X1 Carbons) can go down to 0.2 mm… but even that is not detailed enough.”

Ali Sayed

Printing a single scroll wheel on the Bambu Lab X1 Carbon and Form 4 takes about the same amount of time. But printing 100 scroll wheels takes over three days on the Bambu Lab X1 Carbon, and only 2.5 hours on Form 4.

Time to print scroll wheels

| Time to print | 1 scroll wheel | 100 scroll wheels |

|---|---|---|

| Bambu Lab X1 Carbon | 1 h 9 min | 3 days |

| Formlabs Form 4L | 1 h 18 min | 2 h 30 min |

On FDM 3D printers, speed scales linearly: the more parts you’re printing, the more time it takes. With the masked stereolithography (MSLA) technology of Form 4 Series 3D printers, because the entire layer is exposed at once, there’s a similar print time whether you’re printing one part or a full build platform.

Rivaling the Qualities of Injection-Molded Parts

“The Blade is the first model where we’ve printed on Formlabs Resin, it’s also our first complete mouse (using the Falcon module from Finalmouse). Most of our customers can’t believe it’s actually 3D printed. The jump in quality and performance from our previous mod-kits is monumental.”

Ali Sayed

When Sayed did his first Zerømouse mod kit two years ago he says, “I would put my Zerømouse next to a Zowie or Logitech and the difference was just painful… I had a long way to go in terms of quality and refinement.”

“Literally from the first print on Form 4, I was blown away by how good it looked,” says Sayed. He printed the shell and scroll wheel in Black Resin, which is a rich, matte black with a surface finish that rivals that of injection molded parts. As Sayed says, “The quality of the part is in a completely different league… almost injection molding.” Unlike parts printed with FDM, or even the outsourced parts he was having printed, the detail and surface quality were finer, the material was stronger, and it allowed for higher resolution prints.

“If you want to print something like a scroll wheel for a mouse, there’s resin 3D printers like Form 4, which take detail and resolution to a completely different level. This would be like if a filament printer had a 0.05 mm nozzle.”

Ali Sayed

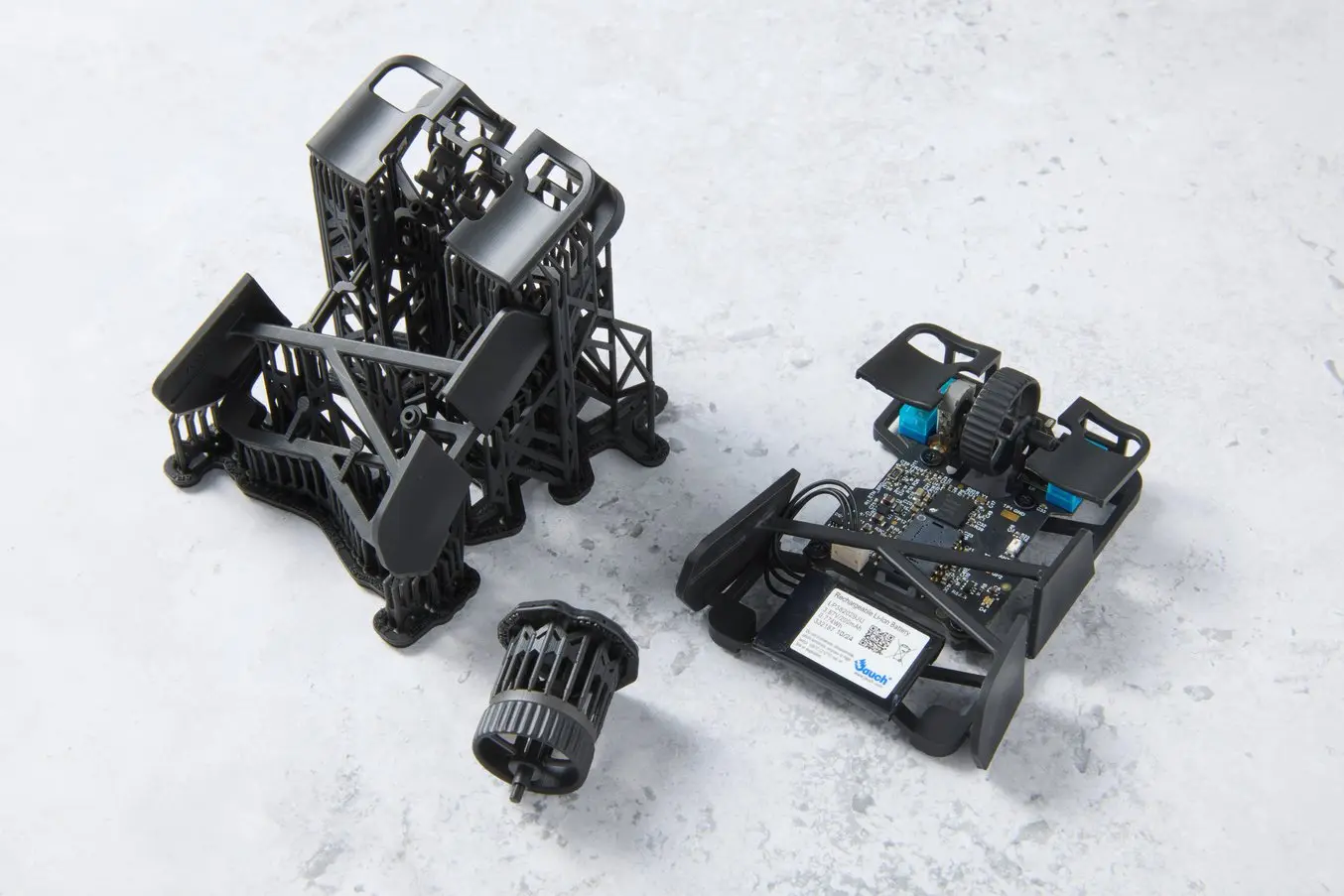

The Zerømouse Blade is printed in a custom support shell to optimize printing and surface finish.

To achieve the finest finishes, Sayed also optimizes print setup to reduce layer lines. While early prototypes are printed with a 50 μm layer height and auto-generated supports, Zerømouse Blade is manufactured with 25 μm layer height and a custom shell support structure so that the points a person will touch when using the Blade don’t have support touchpoints.

“If you’ve ever wondered what 3D printers companies like NASA or Microsoft use, it’s actually these,” says Ali Sayed of Form 4 Series 3D printers. (Image: Ali Sayed)

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Ease of Use

Sayed initially stayed away from resin 3D printers due to the post-processing parts required and their reputation for mess. “Formlabs, though, is different. It’s a premium price for a premium experience.”

Automatic resin dispensing means resin doesn’t need to be poured into the resin tank, for a clean, seamless workflow. Once parts are removed, Form Wash and Form Wash L are easy to use, “there’s no getting your hands dirty or clean up involved whatsoever.” A build platform is put in the wash, the correct preset selected, and the build platform is lowered with the touch of a button. Agitation ensures a thorough wash, after which the build platform is automatically raised from the wash. When it comes to post-curing parts, Sayed says that the presets for Form Cure “are impossible to mess up.”

The automation and workflow ease of the Formlabs ecosystem removes the “mess” people often assume is a part of resin 3D printing. Sayed says, “I’ve yet to find any annoying things or pain points in this workflow. Every step of the user experience with these printers has been obsessed over down to the details.”

“Every interaction you have with these printers is so easy and refined. When your tools are this nice to use, it not only removes the friction of making stuff but makes it thoroughly enjoyable every time you fire them up.”

Ali Sayed

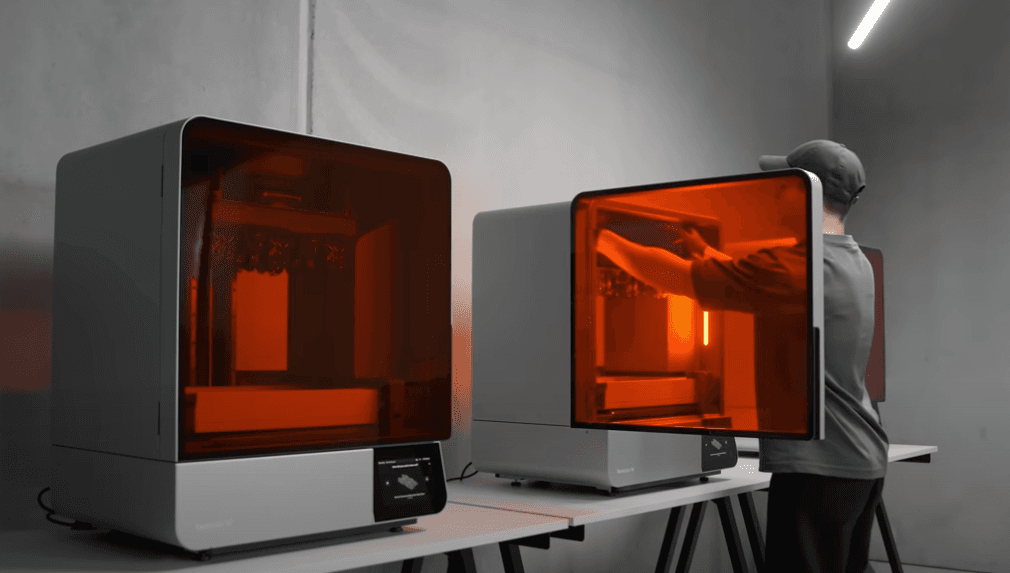

Production With Form 4L

“The Zero Mouse is now printed on Formlabs Form 4Ls, basically the most insane resin printers you can buy without spending enterprise-level money. They are insane machines, especially for production stuff like this, because the workflow is just so amazing.”

Ali Sayed

The initial mod-kits were outsourced, printed in Nylon PA12 on HP MJF 3D printers. The printing method was prone to warping, and “sometimes I would add a little feature, a little detail or cutout, and it just would not hold up with this material — it just either wouldn’t be there or it would be broken.”

Additionally, outsourced order minimums were in quantities of 1,100, meaning Sayed would be locked into a design for a large print run. Sayed says, “The problem is, when you’re ordering that many, you start to notice some problems and inconsistencies.” By producing in-house via 3D printing, Sayed could continue to make changes to the mouse and print only the quantities required, for complete control over inventory.

Prototyping and manufacturing with the same method — in this case, Form 4 Series 3D printers — means the material properties and tolerances of prototypes are the same as the product going to market. Changes are also easier, faster, and less expensive, as expensive tooling for injection molding isn’t needed.

While Form 4 met Sayed’s requirements for print speed and finish, production would require increased throughput. Enter Form 4L. With a 4.6x larger build volume than Form 4, Sayed could increase his throughput while still achieving the speed and surface quality as Form 4 — all while utilizing the same material, technology, and workflows.

Time to print shells

| Quantity | Print time per batch | Print runs per day | Total parts per day | |

|---|---|---|---|---|

| One Form 4L | 15 shells | ~3.5 h | 3-4 | 45-60 |

With two Form 4Ls, Sayed can produce ~100 shells per day, or ~1,000 in 1-2 weeks. As each print batch is only 15 shells, he can still iterate, refining the product as needed.

The Zerømouse Blade

“The Zerømouse is in a completely different league compared to before. Switching to resin, having a proper coating, having a dedicated circuit board with the proper standoff positions and sensor position, everything considered from the beginning — it truly destroys any product or prototype that I’ve made before.”

Ali Sayed

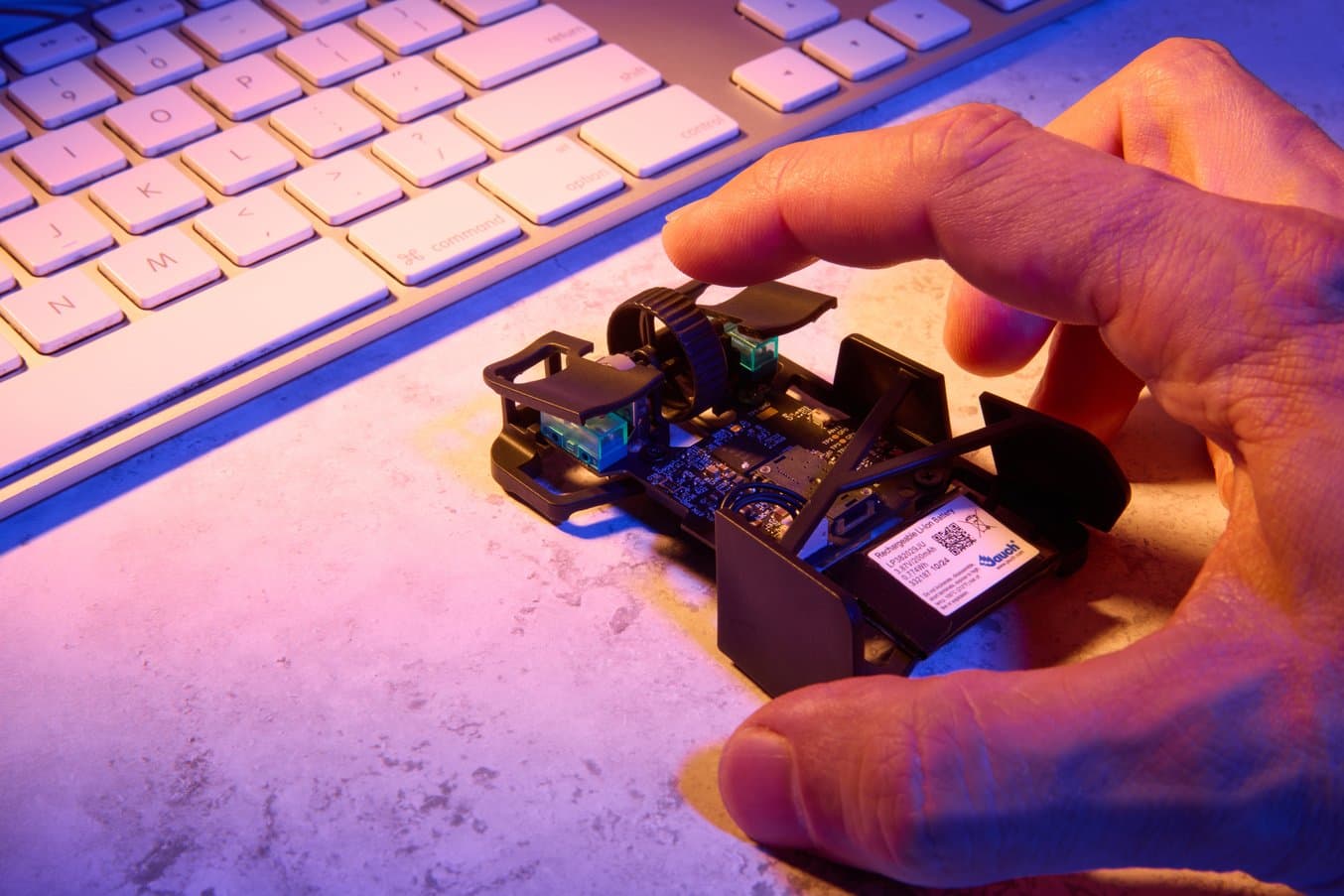

After the mouse is printed and post-processed, it’s coated in a UV-resistant, ultra-matte spray to enhance grippiness, before the electronic components are added.

The initial production run of the 21 gram Zerømouse Blade sold out in two minutes. The shell and scroll wheel were manufactured on Form 4L.

“Even if I had committed my Zerømouse to injection molding, at the end of the day it would be a heavier and weaker product and I would still at least have one Form 4 for prototyping because the amount of prototyping and iterating that I’ve been doing lately on this machine – there's almost no price that you can put on that kind of development speed.”

Ali Sayed

The first run of the Zerømouse Blade sold out in two minutes. Once orders were fulfilled, Sayed faced his next two challenges: how to make the Zerømouse tougher without compromising on weight, and how to scale throughput to meet the demand for his product. Learn how he solved for both in part two of this story, “Making the Zerømouse Blade “Indestructible” With Tough 2000 Resin and Form 4L.”

“I feel immense joy when, every day, I can work towards being better at something and I see the improvement. And, for the past two years, that has been the Zerømouse.”

Ali Sayed

To start printing, explore Form 4 Series 3D printers or contact sales to learn more. To evaluate the quality of parts for yourself, request a free sample part.