선택적 레이저 소결(SLS) 3D 프린트 부품은 우수한 기계적 물성과 비용 효율적인 생산 방식으로 인해 항공 우주 및 안경 설계와 같은 다양한 산업에서 점점 더 많이 사용되고 있습니다. 미적 및 기계적 물성을 더욱 향상시키기 위해 SLS 3D 프린팅 사용자는 종종 염색, 코팅, 도금 또는 도장과 같은 후처리 기술을 사용합니다.

Fuse 시리즈 SLS 3D 프린터에서 Nylon 12 White Powder로 3D 프린트한 염색 파트는 고객이 매력적인 시제품을 제작하고 다양한 색상으로 양산형 파트를 제작할 수 있는 다양한 기회를 열어줍니다.

이 가이드에서는 SLS 3D 프린팅 파트 염색 프로세스를 간략하게 설명하고 이 프로세스가 제공하는 여러 가지 이점을 검토합니다. 전체 염색 워크플로우를 알아보려면 백서를 다운로드하세요.

SLS 3D 프린팅 파트를 염색해야 하는 이유는 무엇입니까?

설계부터 제조 공정까지의 개별 단계에서 SLS 3D 프린트 파트가 점점 더 보편화되고 있습니다. SLS 3D 프린팅 파트는 표면이 다소 거칠기 때문에 평활화, 코팅, 염색 등 후처리 방법도 관심을 모으고 있습니다.

염색은 저렴한 비용으로 SLS 파트에 색을 입혀 기계적 물성은 유지하면서 미관은을 향상할 수 있는 방법입니다. 소량의 컬러 파트부터 팬톤과 일치하는 대량 생산까지, 모든 워크플로에 어울리는 염색 방법이 존재합니다.

저희 팀은 네 가지 인기 있는 염색 방법을 테스트하고 그 결과를 보고서로 작성했습니다. 이 가이드는 개요를 다루므로 전체 결과를 확인하려면 백서를 다운로드하세요.

염색은 브랜드 미학에 어울리는 색상을 맞춤형으로 적용할 수 있어 기능성 프로토타입 제작과 최종 사용 파트 생산 모두에 적합한 공정입니다.

무료 SLS 샘플 파트 요청

Formlabs의 품질을 직접 보고 경험해 보세요. Fuse 1+ 30W로 프린팅한 Nylon 12 White Powder 샘플 파트를 근무지까지 무료로 배송해 드립니다.

Dyeing Equipment

We tested dyeing equipment to assemble the optimal setup for dyeing Nylon 12 White Powder. Below, we outline the hardware, dye mixture, and dye bath parameters that achieved the best results in our testing.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

| 방법 | 크기 | 수량 | 색상 | UV 안정성 | 비용 |

|---|---|---|---|---|---|

| 포트 염색 | ★★ | ★★ | ★★ | 없음 | $50 미만 |

| 초음파 염색 | ★★★ | ★★★ | ★★★ | 없음 | $100 ~ $1000 |

| 압력 염색 | ★★ | ★★ | ★★★★ | 없음 | $100~ $500 |

| Dyemansion DM60 | ★★★★★ | ★★★★★ | ★★★★★ | 있음 | $50,000+ |

The hardware that we recommend for dyeing is the ESVC-28 - Spectrum Thermal Circulator from Winco. This machine is affordable, available from multiple sources, and is easy to set up and use.

US Source: $699.99

EMEA Source: €659.99

APAC Source: $299

The Winco ESVC-28 Spectrum Thermal Circulator is an ideal solution for ultrasonic dyeing.

Any system that is able to reach the necessary temperatures of 80 °C to 90 °C as well as circulate the solution should be adequate for dyeing. We also recommend having stainless steel tongs nearby to assist in removing parts from the dye bath.

There are also industrial solutions available on the market for dyeing SLS parts, like the Dyemansion DM60, that are cost-effective for high volumes of parts and when extremely consistent results are necessary. This product is capable of holding up to 60 L of components per dyeing batch and will automatically inject the dye as well as rinse the parts post-dye.

The DM60 confers a much higher degree of consistency when compared to pot dyeing as well as improved UV stability of the dyes. An additional service offered by Dyemansion is tailored color development. For users with a strict color requirement or who are looking to dye a very high volume of parts (end-use parts, production runs of 1000+ units), using an industrial machine such as the DM60 may be a good choice.

These larger format solutions take much of the manual labor out of the dyeing process and include programmed settings for different types of parts and colors. However, higher upfront costs mean the return on investment will be faster for those printing very high volumes of parts.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

SLS 3D 프린팅 파트 염색 방법

Formlabs has conducted extensive testing to determine what colors can be achieved with SLS printed parts using accessible, low-cost dyeing techniques. The dye used was RIT ProLine dye, a low-cost, easily accessible powder that contains a mixture of direct, acid, and disperse dyes, and is effective on nylon fibers. Further variables tested include temperature, acidity, saturation of dye, duration of dye time, and detergent additive in the dye solution. Both Nylon 12 Powder and Nylon 12 White Powder parts were tested and the effect of each variable is covered below.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

Temperature and time have a huge impact on the final part color. Based on our tests, higher temperatures lead to a more saturated color in a shorter amount of time.

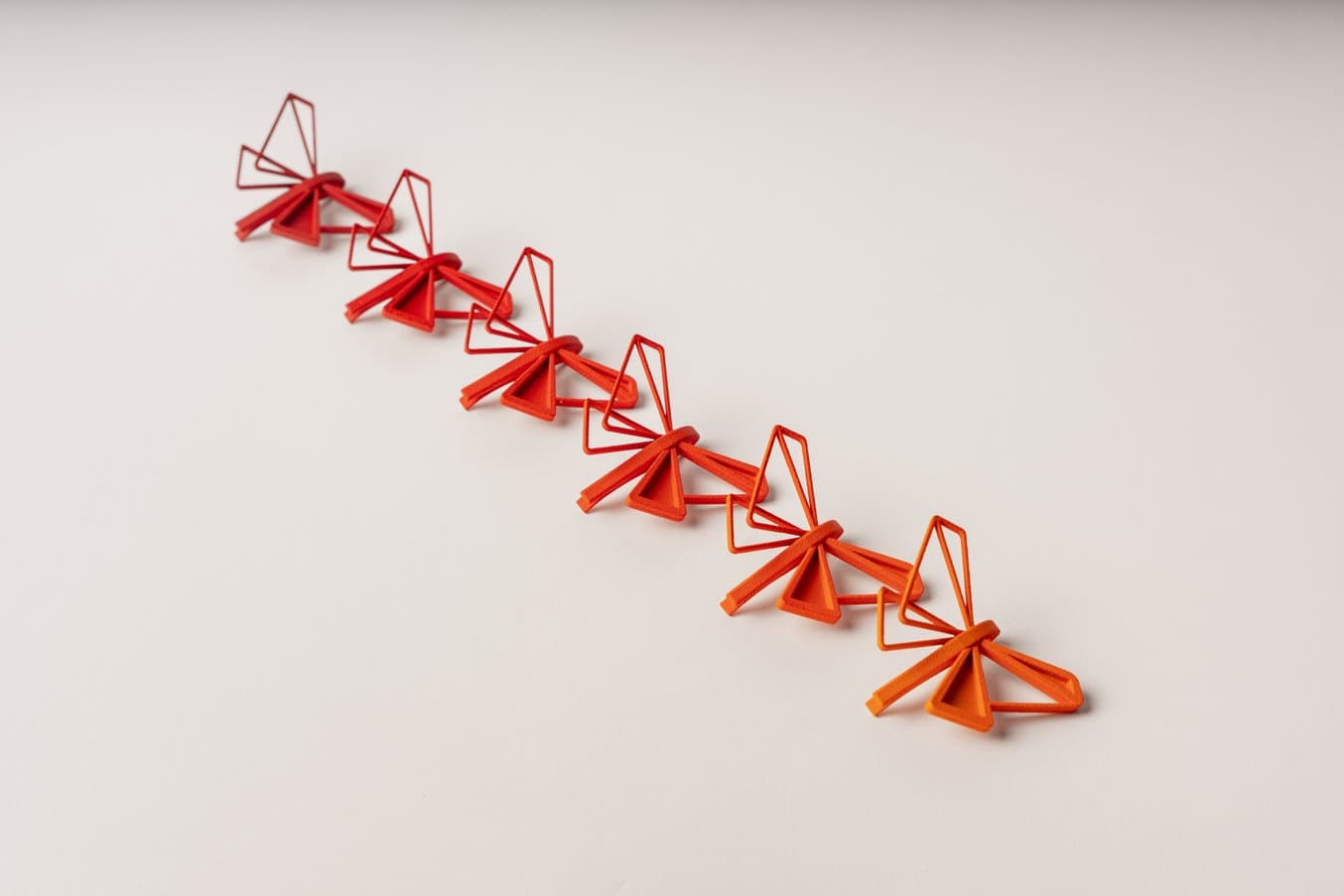

The parts in this image were dyed in the same dye bath, at 90 °C, with parts removed at 3-minute intervals from right to left.

If a lighter shade is desired, consider reducing the dye solution temperature to 70 °C or lower. At higher temperatures, saturation can occur extremely quickly, leaving very little margin for deviation and potentially resulting in variance of finished parts. There is an increase in part uptake of dye over time but this trend plateaus at 20-25 minutes as the part reaches a saturation point where no more dye can penetrate the surface.

Changing Dye Bath Colors

When changing the colors of a dye bath, first drain the entirety of the current solution and dispose of it according to local regulations and the dye’s safety data sheet (SDS). Alternatively, the dye bath can also be stored in liquid form to be used at a later date, according to local safety regulations.

As a dye solution is heated and cycled, some settling can occur. Due to this, the walls and base of the tank should be wiped down after draining to ensure no cross-contamination of colors occurs. Once these two steps are completed, a rinse with clean water is recommended to make sure any remaining dye in the circulation system is removed.

Only after the machine is cleaned should a new dye solution be prepared. If multiple colors are going to be used frequently, getting multiple circulators to prevent frequent swapping is an option.

Ken Pillonel designed an easy workaround for this step, using large flasks filled with dye solution within the tank, and a rotating magnet on the bottom of them to agitate the liquid. This way, he can use different flasks for each dye color, without waiting for cooling and cleaning. To learn more about his method and this workaround, watch his video, shared at the end of the article.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

색상 및 소재 조합

백색 파트의 색상 염색

색상을 가장 폭넓게 얻으려면 Nylon 12 White Powder를 염색하는 것이 가장 좋습니다. 파스텔을 포함한 모든 밝은 색상과 선명한 색상을 염색할 때는 Nylon 12 White Powder를 사용해야 합니다.

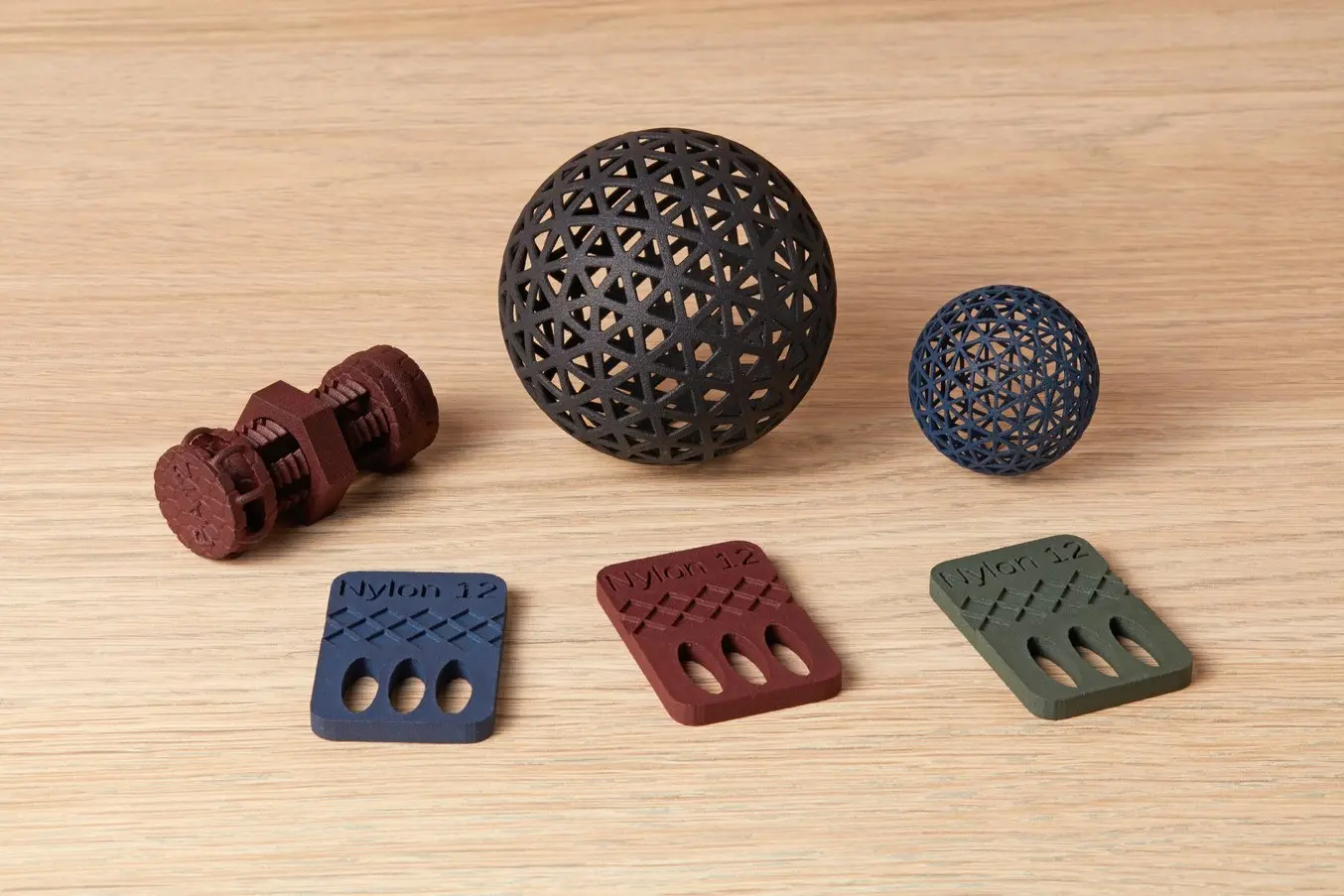

초음파 염색 스테이션에서 염색한 Nylon 12 White Powder로 3D 프린팅한 파트.

회색 파트의 색상 염색

백서에 설명된 프로세스는 Nylon 12 Powder 파트를 성공적으로 염색하는 데 사용되었습니다. 그러나 Nylon 12 Powder로 프린팅한 파트는 짙은 회색이기 때문에 더 어두운 색조만 염색할 수 있으며, 색상이 더 차분한 경우가 많습니다.

짙은 회색의 Nylon 12 Powder 파트를 더 어두운 색조로 염색했습니다.

파트를 검은색으로 염색하기

검은색이 최종 색상인 경우 Formlabs의 표준 Nylon 12 Powder와 Rit ProLine Black을 사용하도록 권장합니다. 이 소재는 바탕색이 더 어둡기 때문에 검은색으로 더 일관성 있게 전환됩니다.

Nylon 12 Powder로 제작된 파트를 검은색으로 염색할 수 있지만 권장하지 않습니다. 기질이 가벼워지면 Nylon 12 Powder의 초기 어두운 상태의 염색에 비해 어두운 색상을 염색하기가 더 어려워집니다.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

비용

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

인건비

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

파트 형상

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

비용

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

인건비

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

파트 형상

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

파트 형상

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Dyeing is ideal for both functional prototyping and end-use production of parts with custom colors to match brand aesthetics.

SLS 나일론 파트 염색: 켄 필로넬의 실험

인기 유튜브 채널 Exploring the Simulation의 설립자이자 엔지니어인 켄 필로넬은 Fuse 시리즈 SLS 에코시스템으로 '1인 플라스틱 공장'을 만들었습니다. 필로넬은 처리 역량을 확충하려고 두 번째 Fuse 1+ 30W 프린터, Fuse Sift, Fuse Blast를 추가한 후, 최종 사용 Airpod 충전 케이스를 염색된 Nylon 12 White Powder로 제조할 수 있게 되었습니다. 최종 사용 파트를 위한 SLS 3D 프린팅, 질소 워크플로 설정, 정밀하고 반복 가능한 고품질 염색 워크플로를 달성하는 방법에 대한 심층적인 논의는 아래 필로넬의 동영상을 시청하세요.

SLS 3D 프린팅 파트 염색 시작하기

초음파 염색과 같은 경제적인 워크플로를 사용할 수 있으므로 SLS 파트를 염색하면 쉽고 간편하게 파트의 미관을 향상시킬 수 있습니다.

쉽게 구할 수 있는 하드웨어와 염료 소모품을 사용하여 Nylon 12 White P owder 및 Nylon 12 Powder 파트를 염색하면 원하는 색조와 관계없이 완성된 파트에 비용효율적이고 효과적인 방법으로 색을 입힐 수 있습니다. 이 프로세스는 최소한의 노동력으로 복잡한 형상을 효과적으로 착색하는 기존 코팅의 대안이 될 수 있습니다.

SLS 3D 프린팅 나일론 파트를 염색해야 하는 응용 분야를 찾고 있다면 담당자에게 문의하여 Fuse 에코시스템과 나일론 파트 염색을 자세히 알아보세요.

SLS 3D 프린팅 또는 SLS 3D 프린팅 파트 염색에 대해 자세히 알아보려면 당사 팀에 문의해 주세요. 전체 테스트 결과와 단계별 워크플로를 확인하려면 백서를 다운로드하세요.