Eyewear, from reading glasses, to safety goggles, to celebrity-endorsed sunglasses, are the rare example of a product that can be endlessly personalized in terms of both style and functionality. Eyewear manufacturers make adjustments on things as big as material choice or as small as micron-level differences in lens thickness. As resolution, accuracy, material versatility, and finishing processes for 3D printing become more advanced, the technology presents a costeffective method of designing and manufacturing eyewear.

Introducción: La aparición de las gafas impresas en 3D

La adopción de las gafas de uso final impresas en 3D ha crecido mucho en los últimos cinco años, al aprovechar tanto las pequeñas empresas como las grandes marcas las ventajas en cuanto a libertad de diseño, capacidad de producción en lotes pequeños y sostenibilidad que ofrecer la impresión 3D.

La impresión 3D ha penetrado en el sector de las gafas y ha cambiado cómo los diseñadores y los fabricantes piensan en la producción, con fines tan dispares como la protección en el espacio de trabajo, el rendimiento funcional o la moda.

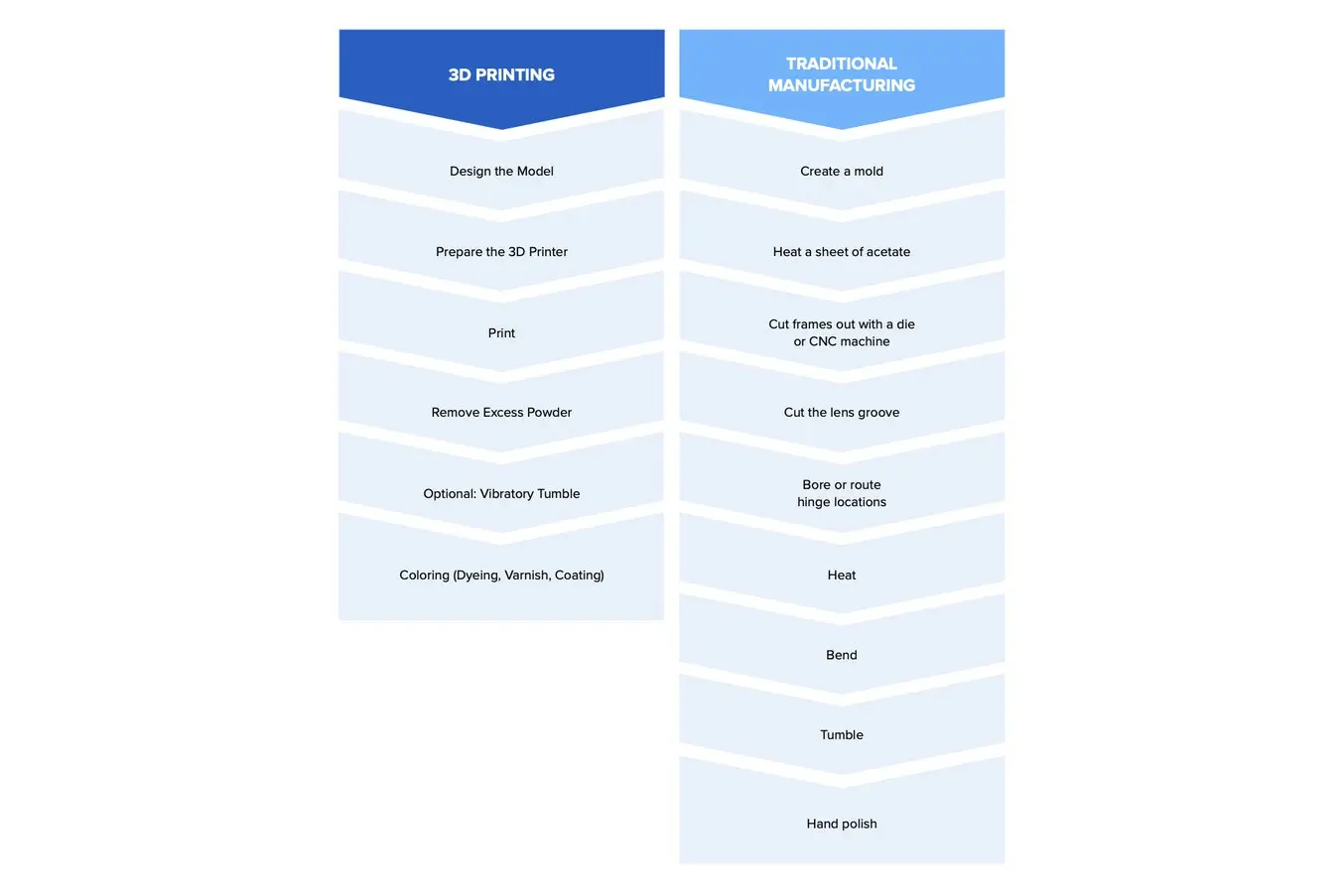

Una de las principales ventajas de la impresión 3D reside en cómo reduce los pasos de montaje durante la fabricación y mantiene al mismo tiempo un alto nivel de uniformidad y calidad en los productos. Algunos fabricantes de gafas afirman que la producción de monturas de acetato puede requerir hasta 60 pasos distintos.

La impresión 3D ofrece una reducción considerable en la complejidad del montaje y el trabajo manual asociado, con el siguiente proceso básico:

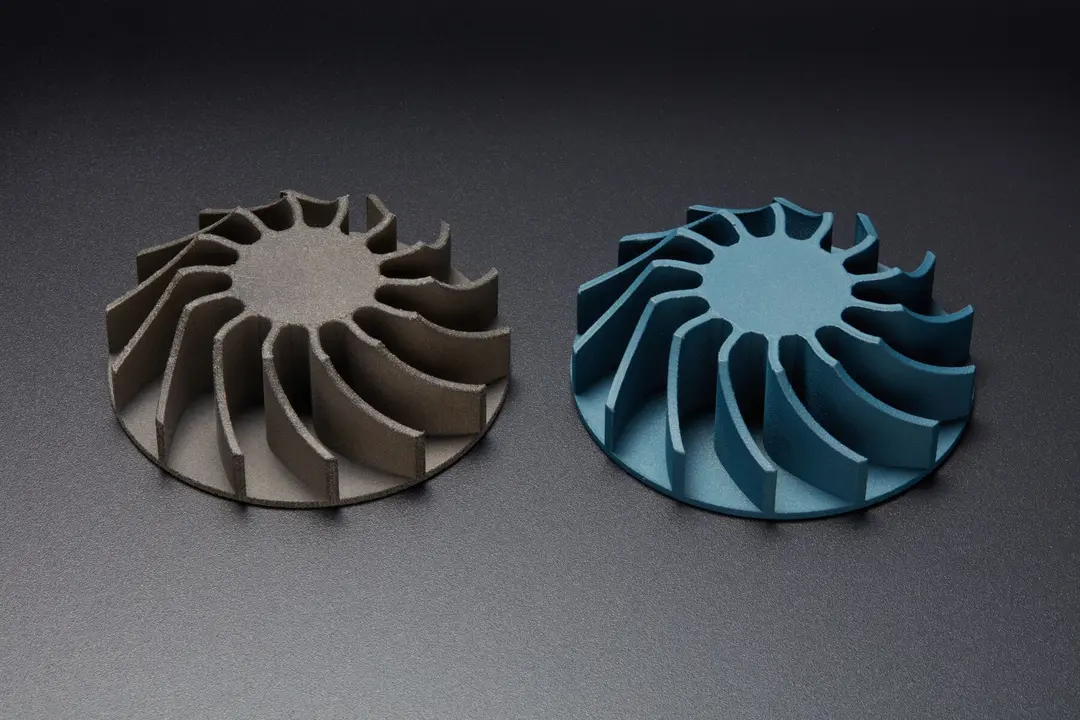

La impresión 3D por sinterizado selectivo por láser (SLS) es la tecnología de fabricación aditiva más común para aplicaciones industriales. Ingenieros y fabricantes de diversos sectores confían en la impresión 3D SLS por su capacidad de generar piezas resistentes y funcionales.

Las impresoras 3D SLS usan un láser de alta potencia para fundir pequeñas partículas de polvo de polímero. El polvo sin fundir sirve como soporte para la pieza durante la impresión y elimina la necesidad de agregar expresamente estructuras de soporte. Esto hace que la impresión por SLS sea ideal para geometrías complejas, como relieves interiores, socavados, paredes delgadas y negativos de piezas. Las piezas producidas mediante SLS tienen excelentes características mecánicas, con una resistencia similar a la de las piezas moldeadas por inyección, de modo que el proceso es ideal para producir gafas impresas en 3D.

Sigue leyendo para saber cómo la impresión 3D puede acelerar tu llegada al mercado, reducir el trabajo manual y eliminar la necesidad de cantidades mínimas para los pedidos de monturas y patillas de gafas.

Value Propositions of 3D Printed Eyewear

Manufacturing Sustainability

Current eyewear frame production is primarily accomplished through injection molding, die cutting, or precision CNC milling, forcing manufacturers to invest in significant mold and equipment costs. Outsourcing production of molds or machined parts can take weeks and cost thousands of dollars. To justify the expense, the manufacturer has to commit to extremely high

quantities of the product which can result in lower profits and high volumes of unsellable stock.

This system is unsustainable both financially and environmentally. 3D printing allows companies to own their manufacturing with no mold investment, lowering the risk of starting a new product line substantially. In-house 3D printing frees manufacturers from high MOQ requirements and commitments to unpopular product designs by enabling the production of small, on-demand batches with no upfront molding costs.

Most pieces of eyewear today are created through injection molding or a subtractive process where acetate is cut into the designated shape. The cutting process takes large sheets of acetate and cuts away the frame shape, leaving all resulting material as waste.

Una montura de acetato tradicional creada mediante un proceso de corte. Fuente: Visio Optical

En cambio, la impresión 3D es un proceso aditivo, en el que las piezas se crea capa a capa a partir de un suministro base de material. Con el ecosistema SLS de Formlabs, el polvo de impresión que no se usa se puede reciclar para reutilizarlo en la siguiente impresión, con lo que apenas se desperdicia material.

Nylon 11 Powder 3D printed frames being extracted from the powder cake in the Fuse Sift.

The small footprint and affordable price point of the Fuse SLS ecosystem allows manufacturers to purchase multiple machines for multiple locations, thus distributing production capacity to regions that are physically close to consumers, and reducing the reliance on overseas production that can be slowed by global supply chain complications. Having distributed production also reduces the negative environmental impact associated with overproduction and shipping.

Libertad de diseño

Unlike other polymer 3D printing technologies, parts produced through SLS 3D printing do not require support structures, as they are supported by the surrounding powder bed. With no support structures, sprues, or restrictions on draft angles and undercuts common in traditional molding or cutting processes, SLS 3D printing offers almost unlimited design freedom, enabling advanced designs that were previously too costly or even impossible to produce.

Manufacturing restrictions no longer prevent product designers from creating the most functional, best fitting, and most fashionable designs. 3D printed eyewear enables responsiveness to consumer trends faster than ever before, allowing brands to capture new and emerging market segments.

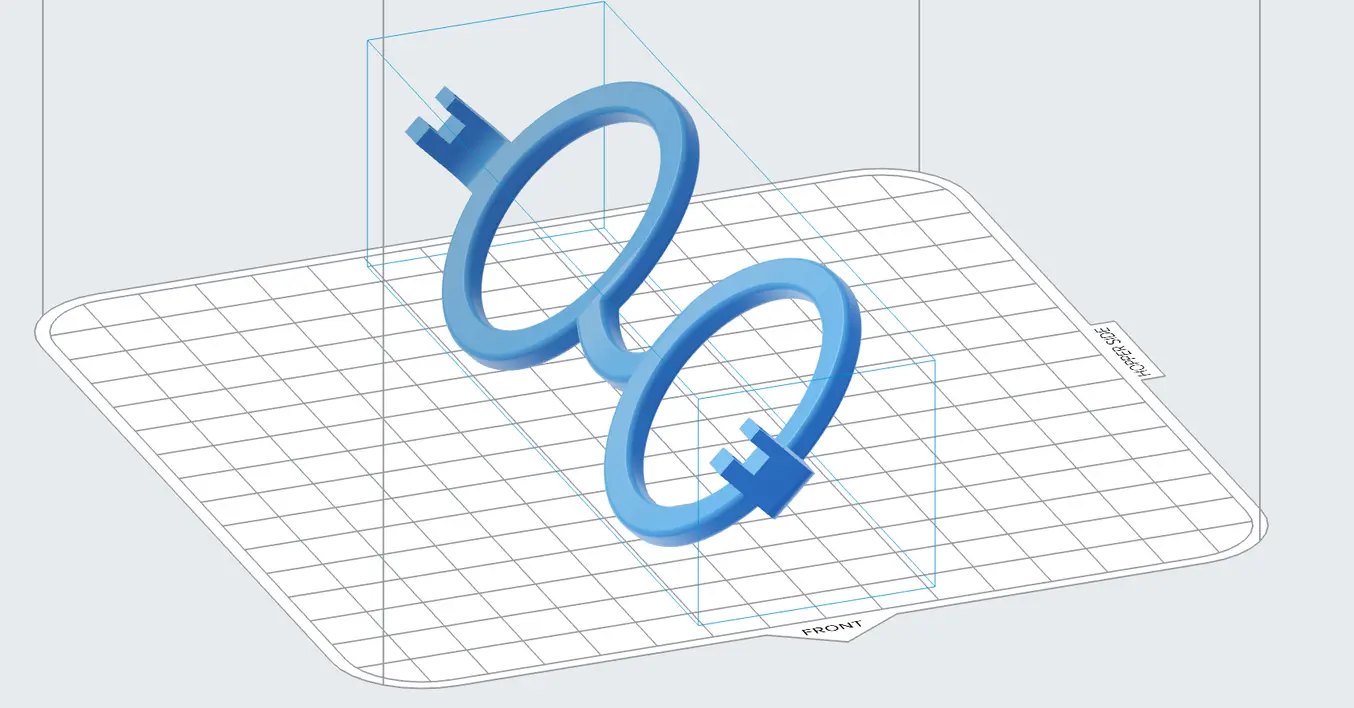

Un diseño complejo de patilla impreso en 3D que sería difícil o imposible de producir de forma eficiente con herramientas tradicionales.

Customization and Personalization

De forma parecida, al no haber requisitos de herramientas o cantidades mínimas de pedidos, la individualización de los productos por fin está a nuestro alcance. De este modo, se pueden tomar decisiones de medidas y diseños que ofrezcan a los clientes un producto completamente único o que se ajuste mejor a ellos.

La impresión 3D ya se está usando para personalizar productos en campos como la ortopedia, las figuras de acción y la audiología, cosechando el mayor éxito posible cuando los consumidores sienten que el producto se ha mejorado para ser más funcional o más atractivo para ellos. Con la gran variedad de edades, grupos étnicos y rasgos faciales que existen hoy en día, los diseñadores de productos se están viendo obligados a apartarse de una mentalidad de talla única y a acercarse al mundo de la personalización.

“With 3D printing, I can do it immediately. If you are familiar with CAD design, you can easily make adjustments to the 3D model, upload it to the software, and print it directly. When it comes to milling, on the other hand, I would always need an individual and expensive tool development to hold the elements in the machine."

Marcus Marienfeld, Eyewear Designer and Manufacturer

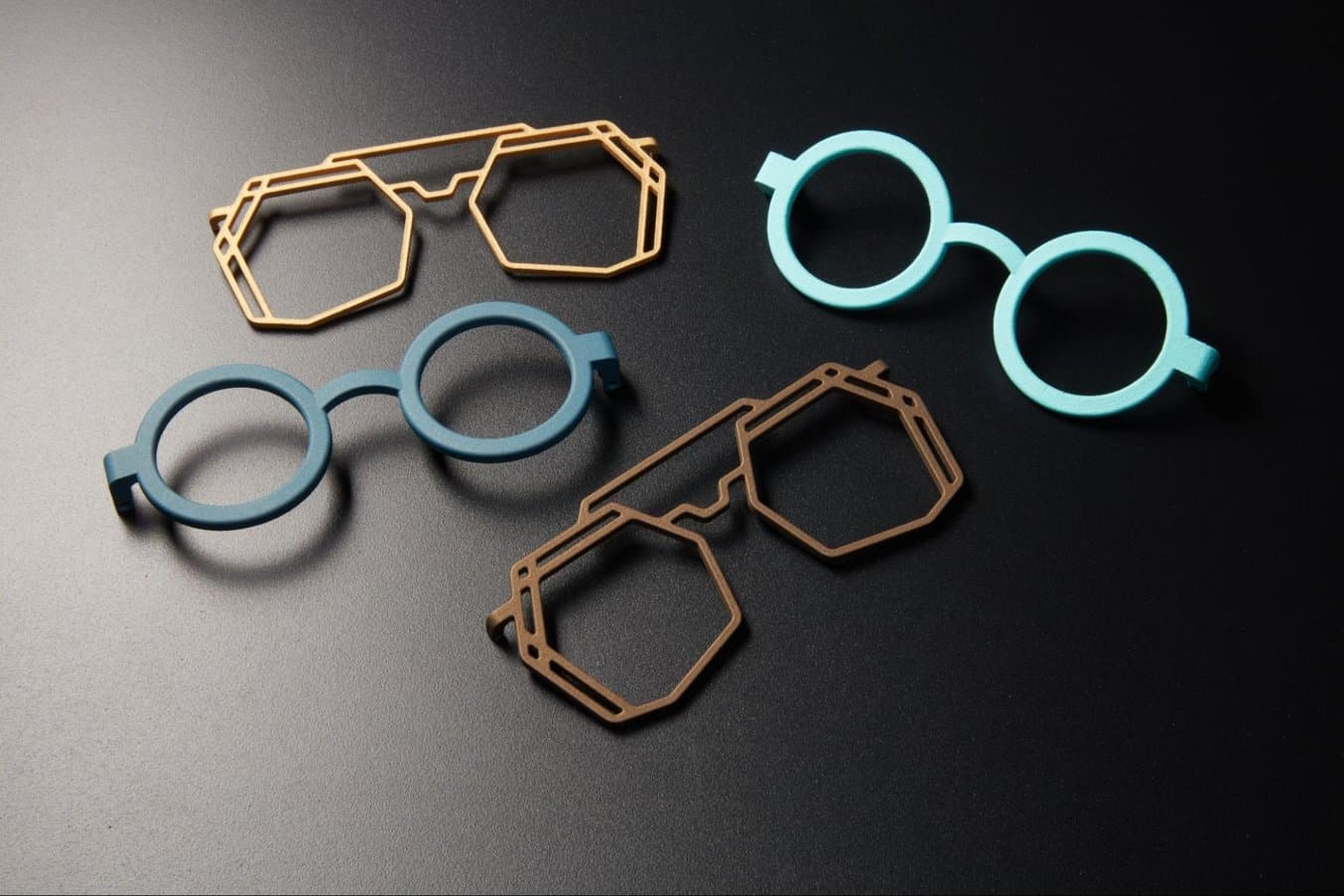

El fabricante de gafas suizo Marcus Marienfeld utiliza la impresora 3D SLS Fuse 1+ 30W para producir gafas impresas en 3D de uso final, como las que se ven arriba.

Cómo fabricar gafas impresas en 3D

Diseño

Crear gafas de uso final con la impresión 3D plantea ventajas y desafíos únicos. En este apartado, trataremos la textura de las piezas, las opciones de bisagras, el diseño de geometrías no moldeables y la personalización.

3D printed in Nylon 12 Powder, these frames are dyed black and maroon in a water bath.

Textura

Additively manufactured parts are formed layer by layer, meaning that some surfaces may have visible layer lines. Layer lines can be mitigated through part orientation optimization, part design, and additional post-processing to smoothen the surface. Adding embossed or debossed texture to the surface of frames and temples is a well-known strategy to mask layer lines on end-use 3D printed goods. Formlabs recommends a minimum 0.35 mm high emboss and 0.15 mm deep deboss to ensure sufficient masking of any layer lines. Finally, part layer lines can be used as a tool to increase grip and friction, preventing slippage on the face.

Opciones de bisagras

3D printed eyewear hinges can be achieved in four main ways:

- Traditional screws

- Heat set inserts

- Snap-fit

- Print-in-place hinges

Hinge threads can be added to the design of 3D printed parts, but traditional eyewear screw threads are typically too small to resolve consistently. Stick to thread sizes of at least ¼”–20 (imperial) or M6 (metric) or larger.

Eyewear assembled with a printed thread and metal screw.

Nylon 11 Powder, Nylon 12 Powder, and Nylon 12 White Powder allow for the use of heat-set inserts and tapped threads, which can be longer lasting and more durable than other options. Read the step-by-step guide here.

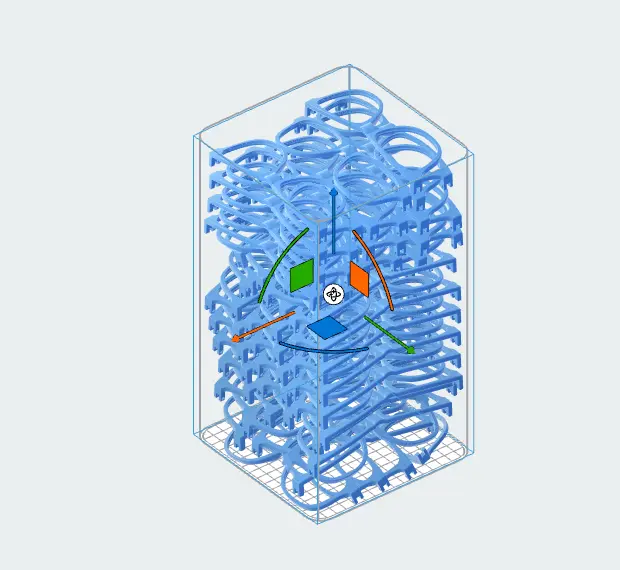

Lastly, due to the lack of support structures, SLS 3D printing enables the use of print-in-place geometries. Frames can be designed and printed with temples already attached, with no further assembly required. Formlabs recommends 0.3 mm of clearance on features less than 20 mm2, and 0.6 mm of clearance on features greater than 20 mm2. Read the entire SLS design guide here.

Geometrías no moldeables

Patillas de Nylon 11 Powder diseñadas con opciones de celosías en el software nTopology.

Eyewear frames and temples printed on the Fuse 1+ 30W printer, designed and manufactured by Alvaro Planchart.

La impresión 3D ha permitido a los diseñadores geometrías no moldeables y no troquelables para sus diseños de gafas, sobre todo en las aplicaciones de moda más vanguardistas. Las geometrías no moldeables, como las patillas de la imagen de arriba, pueden abrir la puerta a nuevos niveles de expresión de los usuarios o pueden hacer posible que los componentes se aligeren hasta el extremo para aumentar la comodidad.

Impresión 3D

Impresora 3D para gafas

The Fuse Series SLS ecosystem offers an accessible and scalable production solution for eyewear, due to its reliable hardware, industrial grade materials, and intuitive user interface. The sections below will cover tips and tricks specific to producing eyewear with SLS 3D printing.

The Fuse Series SLS ecosystem is comprised of the Fuse 1+ 30W printer, Fuse Sift powder recovery station, and automated Fuse Blast media blasting and polishing solution.

Solicita una pieza de muestra gratuita de SLS

Experimenta la calidad de Formlabs de primera mano. Te enviaremos una pieza de muestra gratuita de SLS impresa con la Fuse 1+ 30W a tu oficina.

Materiales para imprimir en 3D monturas de gafas

The Fuse Series offers three material candidates sufficient for eyewear production: Nylon 11 Powder, Nylon 12 Powder, and Nylon 12 White Powder. These three materials are thermoplastics, just like acetate, meaning that opticians can heat the frames and temples to better fit the face after printing.

When comparing functional performance against acetate, TR90, and polycarbonate, all three SLS materials are extremely comparable, with Nylon 11 Powder being preferred by some customers due to its superior elongation at break and sustainability benefits.

| Cellulose Acetate | Grilamid TR90** | Nylon 11 Powder | Nylon 12 Powder | Nylon 12 White Powder | |

|---|---|---|---|---|---|

| Resistencia a la rotura por tracción | 30 MPa | 60 MPa | 49 MPa | 50 MPa | 47 MPa |

| Módulo de tracción | 1700 MPa | 1500 MPa | 1600 MPa | 1850 MPa | 1950 MPa |

| Alargamiento de rotura | 30 % | 50 % | 40 % | 11 % | 8 % |

| Resistencia a la flexión | 40 MPa | N/A | 55 MPa | 66 MPa | 56 MPa |

En pruebas funcionales en condiciones reales, el Nylon 11 Powder ha demostrado tener una ductilidad y una resistencia al impacto impresionantes:

Additional environmental and material properties should be considered when creating a long- lasting, sustainable product that will be exposed to the elements.

| Acetato de celulosa* | Grilamid TR90** | Nylon 11 Powder | Nylon 12 Powder | Nylon 12 White Powder | |

|---|---|---|---|---|---|

| ISO 10993-10:2010/(R)2014, Tests for Irritation and Skin Safety | Not an irritant | Not an irritant | Not an irritant | Not an irritant | Not an irritant |

| Bio-Based Content | >50% bio-based | N/A | 100% bio-based | N/A | N/A |

| Densidad | 1.3 g/cm3 | 1.0 g/cm3 | 1.0 g/cm3 | 0.99 g/cm3 | 0.95 g/cm³ |

| Water Absorption | 2.3% | 3% | 0.07% | 0.66% | 1.40% |

| Solvent Compatibility, Salt Water (3 .5% NaCL), 24-HR Weight Gain | N/A | N/A | 0.1% | 0.2% | 0.1% |

| Heat Deflection Temperature (HDT) @ 0 .45MPa | 75°C/170°F | 100°C/212°F | 182°C/360°F | 171°C/340°F | 177°C/350°F |

| Flammability, UL 94 Section 7 | N/A | HB | HB | HB | HB |

*Source: https://www.makeitfrom.com/material-properties/High-Plasticizer-CA

**Source: https://www.picoplast.nl/uploads/bab8c3f16780cb5b51b67be4baece673Grilamid%20TR90%20LX%20-%20MDS%20-%20EN.pdf

Acabado de la superficie

Surface finish is highly dependent on model design, and different orientations will yield varying surface finishes. Formlabs has conducted extensive part orientation testing, finding that a 45-degree frame print orientation in Nylon 11 Powder, Nylon 12 Powder, and Nylon 12 White Powder results in the most optimal aesthetic surface finish on an example round frame design. Whichever side of the part is facing towards the bottom of the build chamber will have a slightly smoother surface finish.

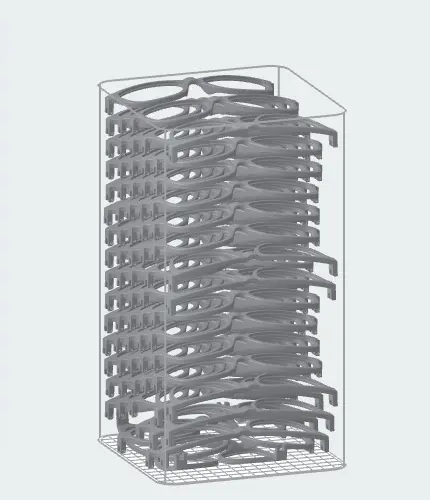

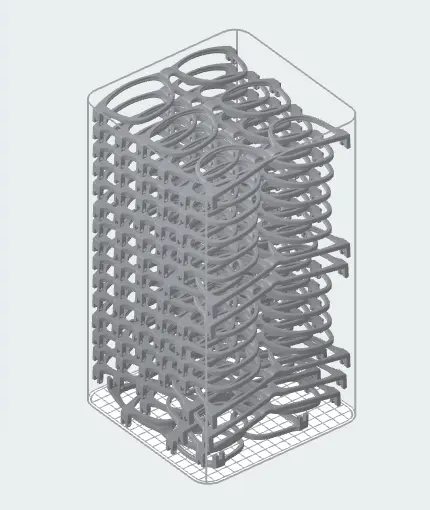

Formlabs has found that printing eyewear frames at a 45° angle to the bottom of the build chamber helps ensure the smoothest, most even surface finish.

Capacidad del volumen de impresión

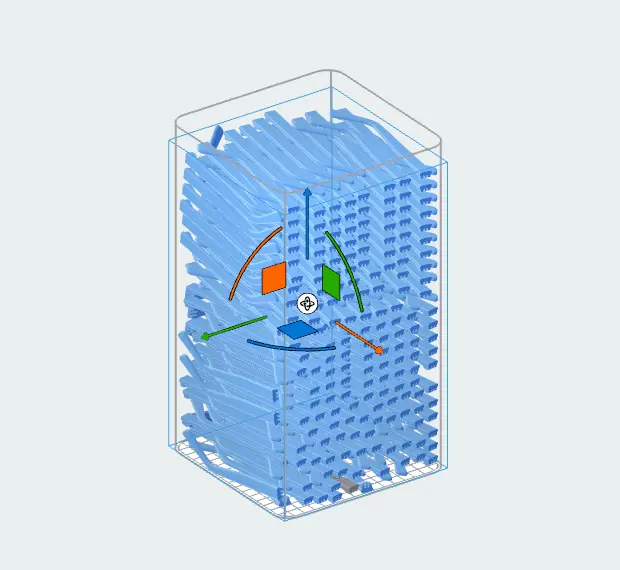

When oriented at a 45-degree angle, 77 example frames can fit in the Fuse 1+ 30W build chamber. This scenario offers a 11% pack density and a build time of just 11 hours when using Nylon 12 Powder as of March 2023. Formlabs is continually improving print settings. To recieve an analysis of your own files to determine cost, print time, and ROI, contact our team.

77 eyewear frames packed in PreForm, Formlabs' print preparation software, which can automatically pack files for optimal print density and print time.

PreForm can also calculate material cost, including both sintered powder and the unsintered powder surrounding the parts, to use in total powder cost analysis.

| Nylon 12 Powder | Nylon 11 Powder | |

|---|---|---|

| Número de piezas por impresión | 77 | 60* |

| Densidad de compactación** | 10 % | 11 % |

| Tiempo de impresión | 11 h | 22 h 30 m |

| Max Yearly Production | 36,960*** | 14,000*** |

*The number of parts was reduced to achieve a print time of sub-24 hours, resulting in a higher production throughput. Nylon 11 is also capable of printing 77 frames at one time, but with a >24 hour print time.

** Read more about pack density and refresh rate here.

***Assuming one print per day, five days per week, for 48 weeks a year. A second build chamber is required to quickly change over and start new prints.

Finishing Options

The natural aesthetic finish of both Nylon 11 Powder and Nylon 12 Powder is an opaque gray color with a surface finish rougher than that of polished acetate. Nylon 12 White Powder has a similar rougher surface finish, with a blue-ish white color. To achieve a finish more similar to that of traditional acetate or TR90 eyewear, a variety of finishing options should be considered.

Frames printed in PA11, from left to right: raw off the printer; vibratory tumbled; vapor smoothed; dyed black; dyed blue; white Cerakote.

Preparación de la superficie de la pieza

Del mismo modo que las monturas de acetato tradicionales a menudo se voltean con gránulos de madera, las monturas impresas en 3D se benefician mucho de pasar unas horas en un tambor vibratorio. Cuando se usan gránulos de cerámica con un lubricante, Formlabs ha observado una reducción del 80 % de la rugosidad de la superficie, que crea un tacto liso. Formlabs utiliza el tambor vibratorio 300 DB de Mr. Deburr, una opción económica y fácil de usar.

| Tiempo | Nylon 11 Powder Surface Roughness Reduction | Nylon 12 Powder Surface Roughness Reduction | |

|---|---|---|---|

| Ceramic* | 8 h | 80,87 % | 82,43 % |

| Organic** | 24 h | 80.53% | 82.77% |

*Ceramic angle cut triangle shapes, with side dimensions of ¼ inch with Kramco 1010 finishing compound

**Walnut Shell Grit 14/30 Mesh Medium

Monturas impresas con PA11. Sometida a volteo vibratorio (abajo), revestida con Cerakote (al centro a la izquierda), alisada con vapor (al centro a la derecha), revestida con Cerakote (arriba).

Parts being tumbled in walnut media to smoothen the surface.

Opciones de coloreado

Dye can still penetrate the darker grey colors of Nylon 12 Powder and Nylon 11 Powder, but the results can become a bit muted and dark.

A simple and cost-effective option for part coloring is to utilize a water bath dye system. Parts are submerged in a heated water bath with a color dye that penetrates all surfaces of the part, permanently altering the color of the part. Though the grey powders (Nylon 11 Powder and Nylon 12 Powder) can be dyed, printing in Nylon 12 White Powder is the best way to ensure you can achieve a range of vibrant colors.

There are industrial options for dyeing SLS 3D printed parts, like machines from Dyemansion. These can cost tens of thousands of dollars, however, and for small-batch production or prototyping, may not make sense. To learn more about using an inexpensive and effective dyeing method for Nylon 12 White Powder end-use parts, watch our webinar with engineer and product designer Ken Pillonel.

Formlabs also utilizes Cerakote coating to both improve the mechanical properties of the part and enable a wide variety of colorways. Cerakote is a thin-film ceramic coating that ranges in thickness from 0.00635 mm to 0.0254 mm and does not require a primer. Once applied, SLS 3D printed parts can expect an improvement in chemical and scratch resistance. Cerakote can also be used to achieve a glossy surface finish, with colors ranging from pastels to metallics and everything in between. Additionally, once coated, parts can be laserimaged to achieve interesting patterns or to carry information, such as logos or serialization. Cerakote can also be used to achieve a glossy finish, through their customizable gloss curing schedules.

Monturas impresas con el Nylon 11 Powder y recubiertas con Cerakote Serie H.

Hydro dipping is also achievable with SLS 3D printed parts. Similarly, varnishing and pad printing processes are compatible with SLS technology. Lastly, vapor smoothing is a process to chemically seal and smooth the surface of SLS 3D prints. Vapor smoothing offers an injection molded-like surface with greatly improved surface roughness, as well as resistance to moisture and bacteria growth, while enabling glossy surface finishes. Formlabs utilizes Additive Manufacturing Technologies (AMT) to vapor smooth eyewear components. Additionally, parts can be dyed in a water bath before or after vapor smoothing, thus sealing in the new part color with additional glossiness.

Vapor smoothed eyewear frames.

Try It Yourself

While Formlabs has explored and developed many finishing options to improve the surface finish of SLS 3D printed parts, there are still many more avenues not yet explored. Many customers have had success with ordering a free custom sample part of their eyewear and then applying their own proprietary finishing techniques (different tumbling media, varnishing, coatings, etc) to achieve unique aesthetics. Contact our sales team to order a free sample of your own design, or order a standard Nylon 11 Powder, Nylon 12 Powder, or Nylon 12 White Powder sample part on which to try confidential or proprietary finishing techniques.

Más usos para la impresión 3D en el sector de las gafas

In addition to its production capabilities, the versatility of the Fuse 1+ 30W system allows for other applications to drive value in the eyewear industry.

Prototipado

Both the Fuse Series and the Form Series system can be used to prototype eyewear to test for dimensionality, fit, and overall design. Choose nylon materials on the Fuse 1+ 30W system to create functional prototypes that can be worn and tested for long periods of time. Choose the Form 4 or Form 4L system to create aesthetic prototypes that demonstrate looks-like designs with translucency similar to acetate and polycarbonate. SLA printed prototypes can be worn for weeks at a time, but are not suitable for long-term wear unless applied with a UV-blocking coating.

Plastinax uses the Form Series SLA printer to produce looks-like prototypes for semi-translucent materials.

Ensayos con usuarios

Utilize the Fuse 1+ 30W to create eyewear that can be tested and evaluated during lifetime and user testing to quickly gain feedback and iterate on dimensions and design.

Plastinax designs their custom eyewear frames in Fusion 360 and then prints them directly on the Fuse 1+ 30W SLS 3D printer.

Nylon 12 Powder frames designed and printed by Plastinax.

Gafas inteligentes

Con la impresión 3D, la complejidad del diseño no es costosa. Añadir bastidores para componentes electrónicos o los complejos conjuntos de piezas necesarios para los dispositivos de tecnología ponible no supone un esfuerzo para la impresora 3D. Considera usar la impresión 3D SLS cuando crees carcasas complicadas para gafas inteligentes que en otro caso serían difíciles de fabricar con moldes de inyección costosos de múltiples piezas.

Sujeciones con guía y fijaciones

Due to their high impact resistance, Nylon 12 Powder, Nylon 12 White Powder, and Nylon 11 Powder are well-suited for custom jigs and fixtures. Formlabs nylon powders are strong enough to bend some metals used in traditional frames and temples, such as titanium, with pressures of more than 90 kg.

SLS 3D printed Nylon 11 Powder press tool screwed into a toggle press.

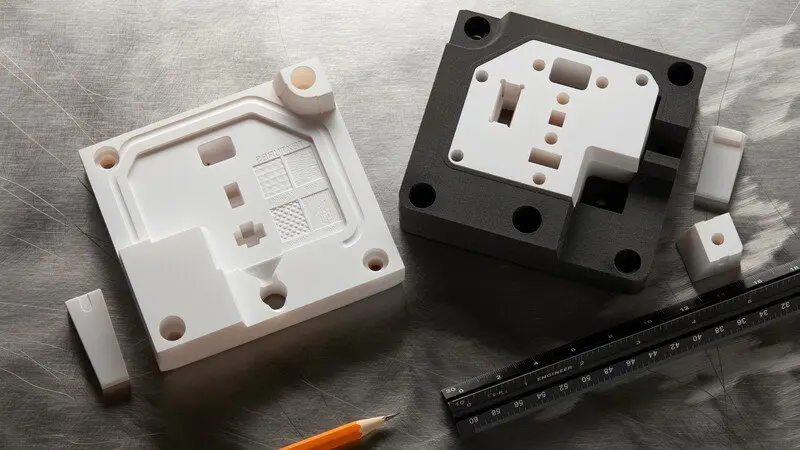

Moldeo por inyección y moldeo en vacío en series cortas

Due to their high impact resistance, Nylon 12 Powder, Nylon 12 White Powder, and Nylon 11 Powder are well-suited for custom jigs and fixtures. Formlabs nylon powders are strong enough to bend some metals used in traditional frames and temples, such as titanium, with pressures of more than 90 kg.

SLS 3D printed Nylon 11 Powder press tool screwed into a toggle press.

3D printed molds for vacuum forming packaging made with Rigid 10K Resin.

Building a Business Case

A New Wave of Independent Manufacturing

Owning a business or creating a new product line enabled by 3D printing is becoming more obtainable and cost-effective by the day. A single Fuse 1+ 30W 3D printer can enable a production run of 19,000+ frames per year or 50,000+ temples per year on an unoptimized five-day production schedule.

| Nylon 12 Powder Frames* | Cost Per Part** | |

|---|---|---|

| 1 Fuse 1+ 30W | 36,960 | $1.27 |

| 5 Fuse 1+ 30W | 184,800 | Contact for Pricing |

| 10 Fuse 1+ 30W | 369,600 | Contact for Pricing |

| Nylon 12 Powder Temples* | Cost Per Part** | |

|---|---|---|

| 1 Fuse 1+ 30W | 87,840 | $0.29 |

| 5 Fuse 1+ 30W | 439,200 | Contact for Pricing |

| 10 Fuse 1+ 30W | 878,400 | Contact for Pricing |

* Assuming a five day workweek with five prints per week, for 48 weeks a year.

**Material cost set at $69/kg, a 30% discount, typical for customers printing in this quantity.

These temples (both left and right) are ideal for printing efficiently, with a pack density of 31%, ensuring that all unsintered powder can be recycled into the next build, reducing cost per part significantly.

These eyewear frames don't pack as densely as the temples, leading to a slightly worse refresh rate and a higher cost per part. However, just one printer can still produce nearly 20,000 frames every year cost-effectively.

Opción 1: Asume el control de tu propia producción

The most efficient and cost-effective way to produce 3D printed eyewear is to own the production equipment. This entails purchasing a Fuse Series SLS ecosystem. The benefits of vertically integrated 3D printing production include achieving faster ROI, tighter control over quality, agility to alter design and move from prototyping to production on the same machine, and the ability to utilize the ecosystem for other purposes, such as creating jigs and fixtures.

Designed to be as accessible as possible, the Fuse Series SLS ecosystem is extremely plug-and-play, with most users learning how to operate the equipment in a matter of hours. Similarly, the ecosystem has minimal facility requirements, allowing for quick installation and easy scalability as demand grows. It’s also important to note that a new Fuse Sift or Fuse Blast are not required with every additional Fuse 1+ 30W printer. Most customers keep a ratio of 4:1, printers to post-processing stations. The cost to incorporate a full Formlabs SLS printing ecosystem, including a Fuse 1+ 30W, a Fuse Sift post-processing unit, Fuse Blast media blaster, two build chambers, two cartridges, 20 kg of Nylon 12 Material, and two years of expert customer support is $64,190.

With the Fuse Series, it's easy and efficient to scale up as demand grows.

Opción 2: Externaliza el trabajo a una empresa de servicios

The most efficient and cost-effective way to produce 3D printed eyewear is to own the production equipment. This entails purchasing a Fuse Series SLS ecosystem. The benefits of vertically integrated 3D printing production include achieving faster ROI, tighter control over quality, agility to alter design and move from prototyping to production on the same machine, and the ability to utilize the ecosystem for other purposes, such as creating jigs and fixtures.

Designed to be as accessible as possible, the Fuse Series SLS ecosystem is extremely plug-and-play, with most users learning how to operate the equipment in a matter of hours. Similarly, the ecosystem has minimal facility requirements, allowing for quick installation and easy scalability as demand grows. It’s also important to note that a new Fuse Sift or Fuse Blast are not required with every additional Fuse 1+ 30W printer. Most customers keep a ratio of 4:1, printers to post-processing stations. The cost to incorporate a full Formlabs SLS printing ecosystem, including a Fuse 1+ 30W, a Fuse Sift post-processing unit, Fuse Blast media blaster, two build chambers, two cartridges, 20 kg of Nylon 12 Material, and two years of expert customer support is $64,190.

Service bureaus can be good options for initial tests and proof of concept.

Get Started With 3D Printed Glasses and Eyewear

Eyewear presents an exciting application for SLS 3D printing. Eyewear manufacturers make adjustments on things as big as material choice or as small as micron-level differences in lens thickness. As resolution, accuracy, material versatility, and finishing processes for 3D printing become more advanced, the technology presents a costeffective method of designing and manufacturing eyewear. With the Fuse Series SLS ecosystem, eyewear designers and manufacturers have an option to prototype faster than ever and produce end-use products without outsourcing or using a tooling manufacturer. SLS 3D printing can help businesses bring the entire design to production workflow under one roof, reducing costs and increasing efficiency.

To learn more about the Fuse Series, visit our website. To test one of our nylon powders for yourself, request a free SLS 3D printed sample.