For maritime industries that operate on — or under — the water, like fishing, aquaculture, or offshore wind farms, everything gets complicated. Supply chain issues, repairs, maintenance, and daily operations are made more challenging by the ever-changing, often inhospitable environment.

As 3D printing makes the fabrication of complex, customized waterproof parts possible, the applications are nearly endless. Waterproof 3D printed parts are being used as end-use engine components, research tools, propeller blades, deep-sea diving equipment components, and more. New ideas are everywhere, but successful products still require the right design process, extensive testing, and powerful tools to make them viable in the harsh environment beneath the surface.

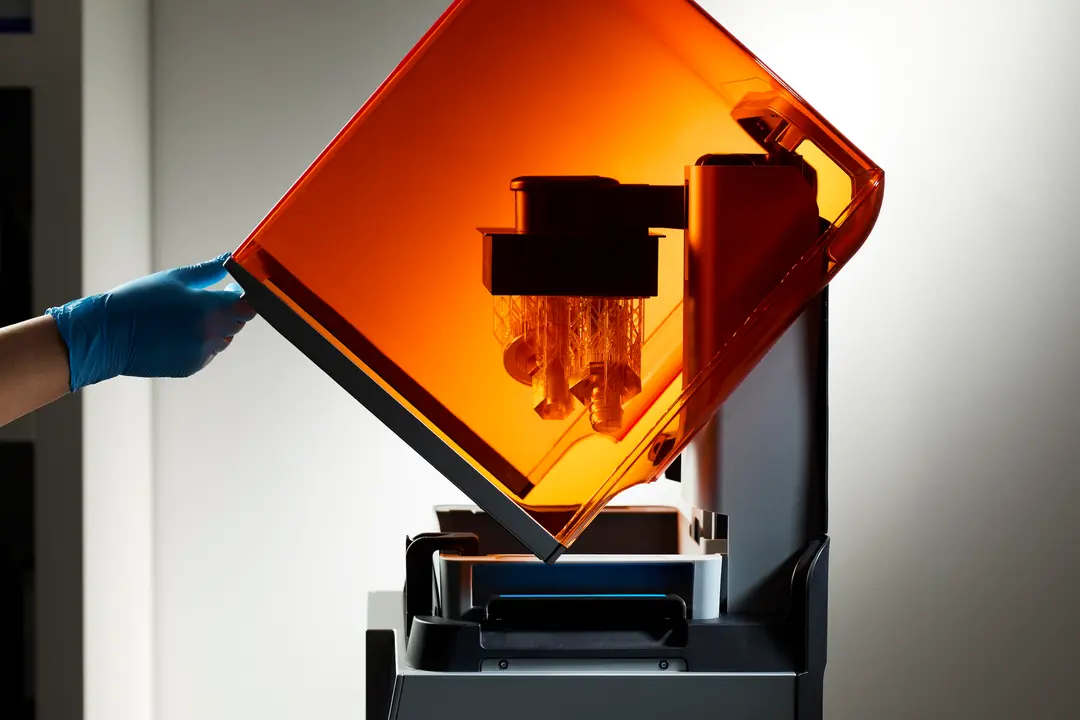

Southern Ocean Subsea (SoSub), an underwater robotics designer and manufacturer, has spent years developing robotics tools for underwater operations. Working with Formlabs partner ThingLab, SoSub leverages a Form 3 and four Form 3L printers to create complex robotics systems.

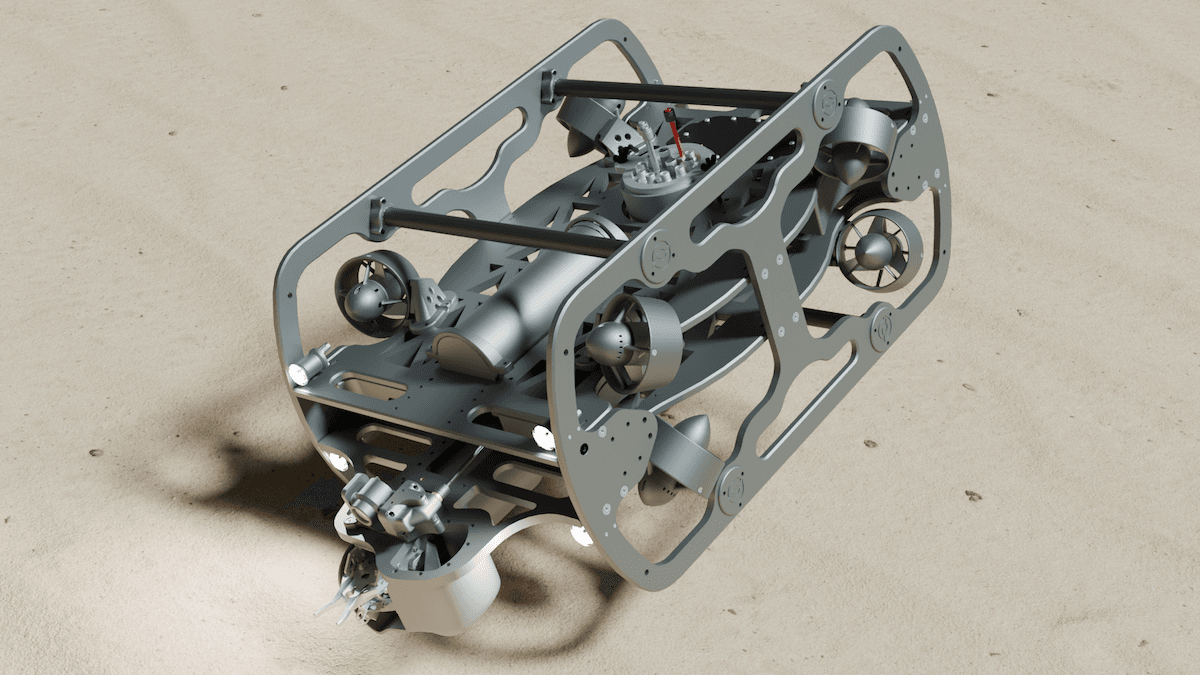

SoSub founder Kelsey Treloar and engineer Miles Lewis have reduced the cost and lead times of developing customized solutions like their remotely operated underwater vehicles (ROVs). Manufacturing complex, waterproof robotics systems like theirs would be next to impossible without 3D printing, which has allowed them to bypass traditional manufacturing’s impediments to start-up success.

“3D printing removes manufacturing as the bottleneck. The bottleneck becomes our own imagination — we have to come up with an interesting solution to a tricky problem, so the question isn’t ‘is it possible,’ it’s ‘can we come up with it.’ Which is a privilege to modern engineers,” says Lewis.

Maintenance and Identifying a Market Fit

SoSub's ROV's was first conceptualized as a solution to a problem Treloar encountered countless times - the process to repair commercial fishing nets was tedious and could be dangerous. There had to be a robotic solution .

Treloar didn’t set out to develop ROVs and design new underwater technology. Initially, SoSub began as a maintenance and repair outfit for fishing equipment and underwater machinery. Treloar noticed that they were being called to repair industrial fishing nets and equipment time and time again, conducting labor-intensive operations that required dive squads to manually sew nets back together underwater. Manual, repetitive work like this has been addressed by robotics for years on land, but the ocean environment adds an extra layer of complexity and cost. Existing solutions could cost hundreds of thousands of dollars and are typically reserved for well-funded research expeditions.

Treloar started experimenting — he taught himself how to CAD and began looking for different ways to manufacture the waterproof parts he was designing. “We started looking for non-resource intensive ways to make them, ways that were economical for a company like us to do it. First with FDM 3D printers, then exploring other ways,” says Treloar.

Repairing nets can be dangerous - robotic systems limit danger for human divers and 3D printing makes these robotic systems cost-efficient for the fisheries hiring SoSub.

The Right Technology

FDM 3D printed enclosures (like the one on the left) are not watertight, as FDM 3D printed parts have microscopic gaps in between layers of filament.

Right away, FDM technology posed challenges. FDM printers can’t create watertight parts — microscopic gaps in between layers that aren’t chemically bonded to each other allow water to seep in, especially once pressure grows with depth beneath the surface.

Luckily, a colleague had experience with SLA 3D printers. “He was adamant that resin technology was good enough, so we went with it and it worked out. Nothing else I’ve seen so far can do it and we wouldn’t have been able to develop these parts any other way,” says Treloar.

Since getting started with resin 3D printers, SoSub has expanded their 3D printing fleet to four large-format Form 3L SLA printers and one Form 3 desktop unit. “The printers laid the foundation for us to even start doing this work,” Lewis says.

3D Printing Watertight Enclosures and Pressure Testing Results

In this white paper, we will provide the testing results and clear guidelines on how to affordably 3D print customized watertight enclosures.

Sub Surface Parts: Up to the Challenge

Underwater robotics require parts that can handle repeated loads, maintain tight tolerances, and achieve precise dimensional accuracy so that they can create assemblies, tightly sealed with O-rings without any gaps caused by bumps, ridges, lines, or printing artifacts. Parts that fit that list of specifications are traditionally machined from metal or injection molded, but outsourcing to providers is expensive and can take weeks or months.

3D printing provides a method for Lewis and Treloar to design, prototype, and test parts that can mimic injection molded plastics or even machined plastics.

“If you look at the industry for ROVs, they would be machined or injection molded, with long lead times and be hugely overpriced. Because it’s such a niche market, components could cost thousands of dollars. One of the competitive edges for SoSub is that we can do things very quickly but also very inexpensively with 3D printing.”

Kelsey Treloar, Founder and CEO, SoSub

The Formlabs materials can handle not just the smooth surfaces necessary for these end-use parts, but also the pressure of underwater operations. SoSub has rated enclosures printed in Rigid 10K Resin, Tough 2000 Resin, and Grey Resin for waterproofness even hundreds of meters deep. “We took a small off-the-shelf server for $100 and 3D printed an enclosure. It significantly outperformed what we expected, and it went down 600 meters. You can make a subsea server actuator rated to 600 meters in half a day,” says Lewis. Another Rigid 10K Resin enclosure succeeded beyond 1000 meters below the surface as well.

One major advantage to the Formlabs workflow has been the estimated mechanical performance in Autodesk’s Fusion 360 software for Formlabs resins. “With Formlabs engineering materials, they publish the data for FEI analysis for simulation. We can’t do that with other materials. If a customer wants a strength estimate for their part, we can do that, and say, ‘it should be able to handle this.’ Then we can do the testing to confirm it,” says Lewis.

Adding Complexity to Simplify Things

SoSub's 3D Form 3L 3D printers allow them to design, test, and produce end-use parts that are watertight and dimensionally accurate.

In addition to cost and lead time, SoSub is creating parts that can’t be traditionally manufactured due to complexity, and this has influenced their approach to creating new parts. To reduce the number of separate components in an assembly for ease of handling and operation, SoSub designs with additive manufacturing in mind. “Things you would traditionally manufacture with machining would be totally impossible and extremely expensive. So you actually have to flip your thinking and make parts as complex as possible in a single part to print the whole thing. You can just eliminate eight manufacturing processes, making both assembly and the design process faster and easier,” says Lewis.

Squid Lock: 3D Printing From Design to End-Use

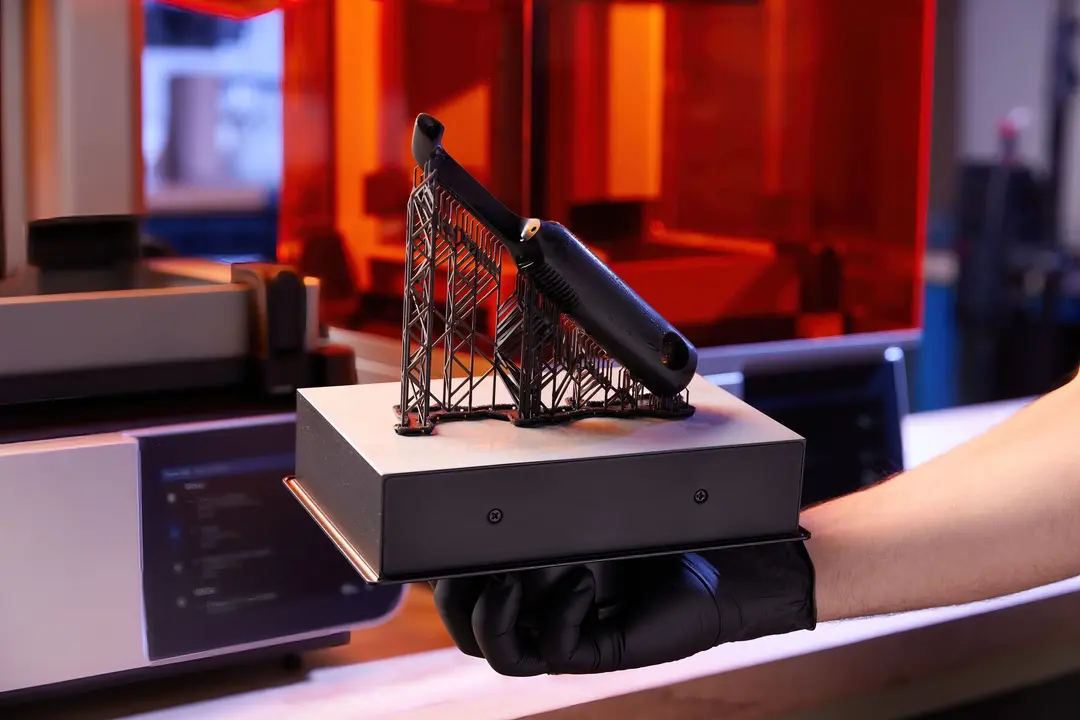

Tough 2000 Resin has good strength and excellent dimensional accuracy - so it's perfect for watertight enclosures on the main body of the Squid Lock.

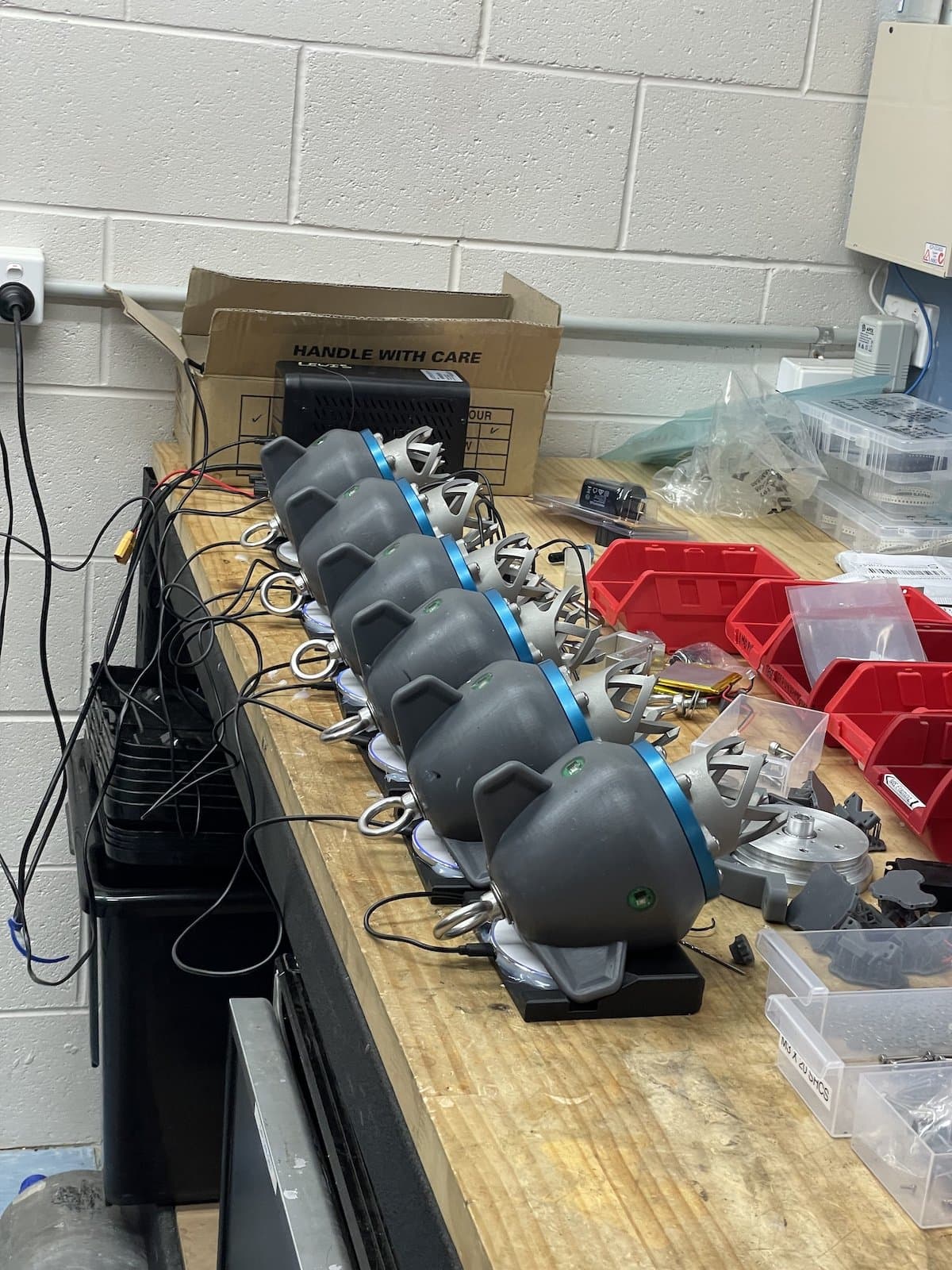

The assembled squid lock has a Form 3L enclosure printed in Tough 2000 Resin with 3D printed metal 'teeth' to lock into the netting.

3D printing has enabled SoSub to find creative solutions to complicated problems. The SoSub team were called out to the offshore fish farms outside Melbourne to develop an ROV for a very specific job. Large fishing nets need to be pulled off boats and spread out in the water, a job typically done by divers that was labor-intensive and repetitive. The difficulty was designing an actuator that could act as dexterously as human hands, while the net was floating in water, and grab onto it sufficiently. The answer was SoSub’s ‘Squid Lock,’ a robotic part that can swim up to a net, grab and lock into the floating fabric, then pull it away, exerting about 400 kg of force, without tearing or coming detached.

“We went from a very rough concept to working on a final product in a month and a half with 3D printed testing prototypes in Grey Resin for the teeth and Tough 2000 Resin for the housing. 3D printing gives us the confidence that we can actually do something within a tight lead time. It allows us to take more design risks,” says Treloar.

SoSub delivered eight fully functional Squid Locks to the farm within two months. The final design has teeth 3D printed in metal, but still has the Tough 2000 Resin housing. “Grey Resin is quite good with detail, and Tough 2000 Resin is quite a strong material, for when we want something that has detail like Grey but stronger,” says Lewis.

Digital Plans for the Future

SoSub has just begun to answer the overwhelming demand for customizable machinery in maritime industries. In the future, they’re looking beyond end-to-end solutions. “Eventually we want to get to hundreds of units a year, and we’ll still use 3D printing. We can have customers buy printers themselves and then sell them the files, so everything can be fabricated on-site,” says Treloar. For now, SoSub’s customer base for fully printed solutions is still growing, but Treloar and Lewis are confident that 3D printing can adapt to new and more complicated projects. “We’re using it for all kinds of different things. Not just the original thing we purchased them for, but it starts opening up your mind to new things you can try,” says Treloar.

To learn how to 3D print waterproof enclosures, download our white paper. To explore the Form 3L, visit our page.