How a Formlabs Engineering Manager is Launching New Products While Working From Home

Software Engineer Josh Bradshaw's setup contains the Form 3L

In the wake of the COVID-19 pandemic, companies all over the world are adjusting to the new normal. It can be a daunting task, especially for hardware companies like Formlabs that require product prototyping and testing. Engineering teams that previously had access to materials, technologies, and tools in the office are now working from home. With product launches in the pipeline, notably the Form 3L, our engineering team needs to keep up with important deadlines to ensure the launch goes smoothly.

How do engineers find ways to work on a physical product without having full access to the office? How does the Form 3L team stay productive while working from home? Caitlin Reyda, engineering program manager at Formlabs, sheds some insight on managing a team that’s working on a product launching soon.

Communication is Key

As an engineering program manager, Reyda is no stranger to managing large teams--there are close to 80 people working with her at any one time. Before the COVID-19 pandemic hit, Reyda was making sure the team was on track to launch new products, specifically the Form 3L. Clear communication is an essential part of any team, but working from home can pose a barrier to conversations. While being in the office surrounded by coworkers is more conducive to conversation, working from home means being more active by communicating digitally. “I think it’s even more critical now that we are working from home, making sure that the information does get shared and especially because in the way that we used to have our open office layout, I think a lot of conversations would naturally happen in person and you would hear about those things,” Reyda said. “To be able to keep that chatter going...in some cases that’s more Slack conversations or more Slack groups. In some cases it’s more dedicated meetings so having more standups, having more opportunities to get people in a room together.”

Another key component of communication is keeping track of the work that’s being accomplished. Reyda said that most individual teams on engineering have started a daily work tracker in a spreadsheet--this improves transparency and visibility across the team.

Preparation Goes a Long Way

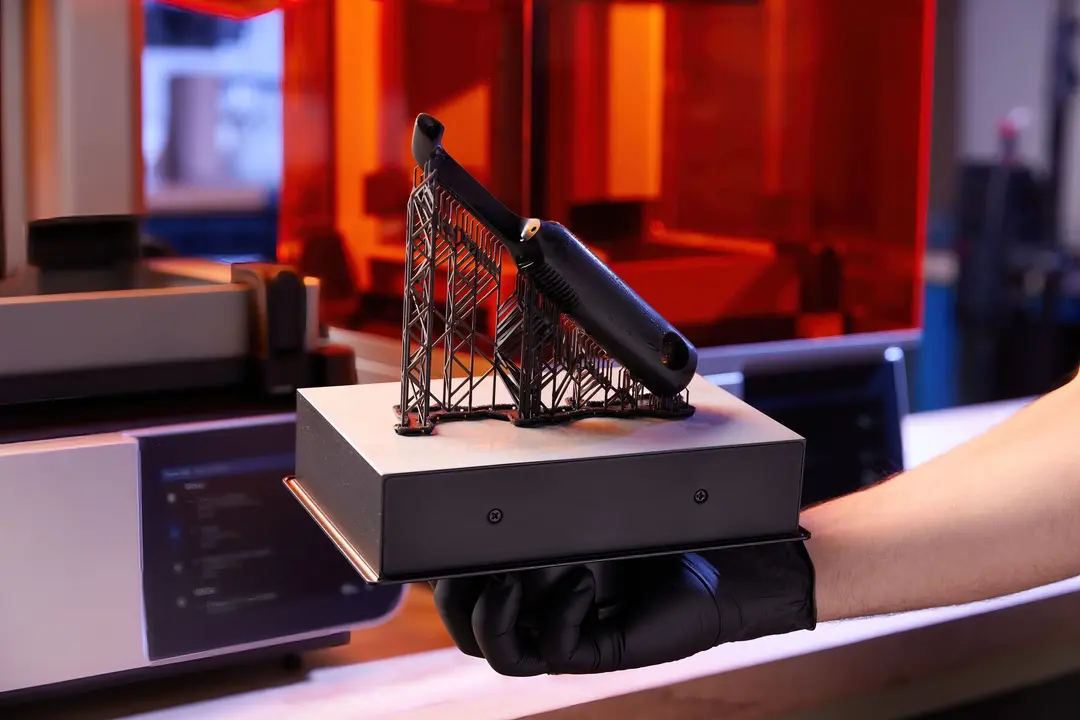

Beyond communication, a little bit of preparation goes a long way. Reyda had the foresight to create a distribution plan to get parts and other essential materials to engineers early on in the work from home phase. “In hardware you just have to be in the office, you need to have the physical parts. So fortunately we got that in right before, we hustled, we spent a lot of late nights hustling to get the prototypes built,” she said. “We had a whole distribution plan where we actually rented a U-Haul truck and sent Form 3L prototypes home with people and sent them home with the resins, sent them home with all of the accessories and some cases, wash and solvent, whatever they would need to be able to work remotely and so we were able to do that.”

On Reyda’s team, there are people working on a wide range of tasks: there are engineers actively printing, some engineers are working with prototypes that have already been printed, other engineers are running print testing to develop settings for Formlabs’ resins, and software developers are using the printers to develop firmware and run tests.

Reyda said it is critical to run the same tests they would do in the office. “We tried to send people home with folding tables or whatever they would need, tools around the office, paper towels and gloves, that was a big request.”

With a team that large, delegating tasks and deciding how to allocate resources and tools like printers can be challenging. But Reyda found a way to prioritize and maximize engineers’ skill sets. “A lot of it depended on the type of work so people who are more hands-on and typically need access to the prototypes we tried to prioritize, or people...who were a bit more generalists who could kind of wear a couple different hats and get more accomplished as a single person, we basically prioritized giving them a printer.”

Engineering From Home Keeps Product Development Schedules on Target

Missing targets means disaster, but engineering from home can keep set timelines on track. Reyda emphasized the importance of continuing to ship products. “If we’re all on such a tight timeline and trying to hit very aggressive targets, I think if we didn’t do that it would hurt us,” she said.

As an international team that works with factories in multiple countries, Formlabs engineers are currently unable to be on the ground in China for quality control due to the pandemic--typically Reyda would send two engineers. With two Formlabs engineers working full-time in China, the team is now building remotely. The U.S. team set up Zoom meetings with the engineers working in China, who set up multiple cameras and angles so everyone can have a wide shot view of the printer. “They’ll also set up multiple...Zoom calls so we’ll have one that’s focused on printer calibration, we’ll have another one that’s focused on printer assembly or printer rework or something else and so we can basically at home have dashboards where we can monitor this and be on the call and talk to them in person,” Reyda said. “I think this is actually great for the future too because it helps us not [need] to send people which will save money in the future as well.”

Despite the challenges the pandemic has posed, Reyda’s team is still able to meet deadlines and they’re actively building new prototypes, updating them, and improving designs. According to Reyda, “For managing a lot of it is...cohesive priorities...making sure everyone is aligned and trying to work towards the same list of priorities and updating that as frequently as needed.”