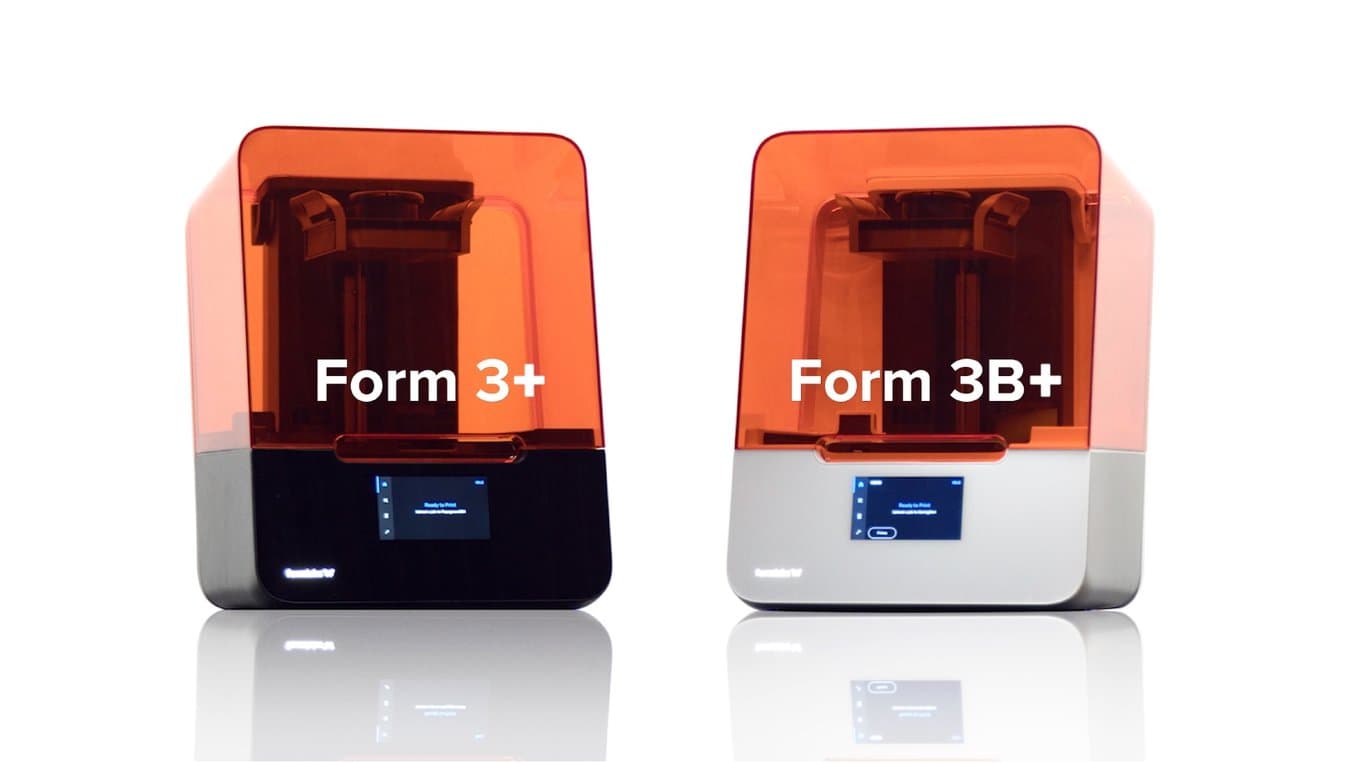

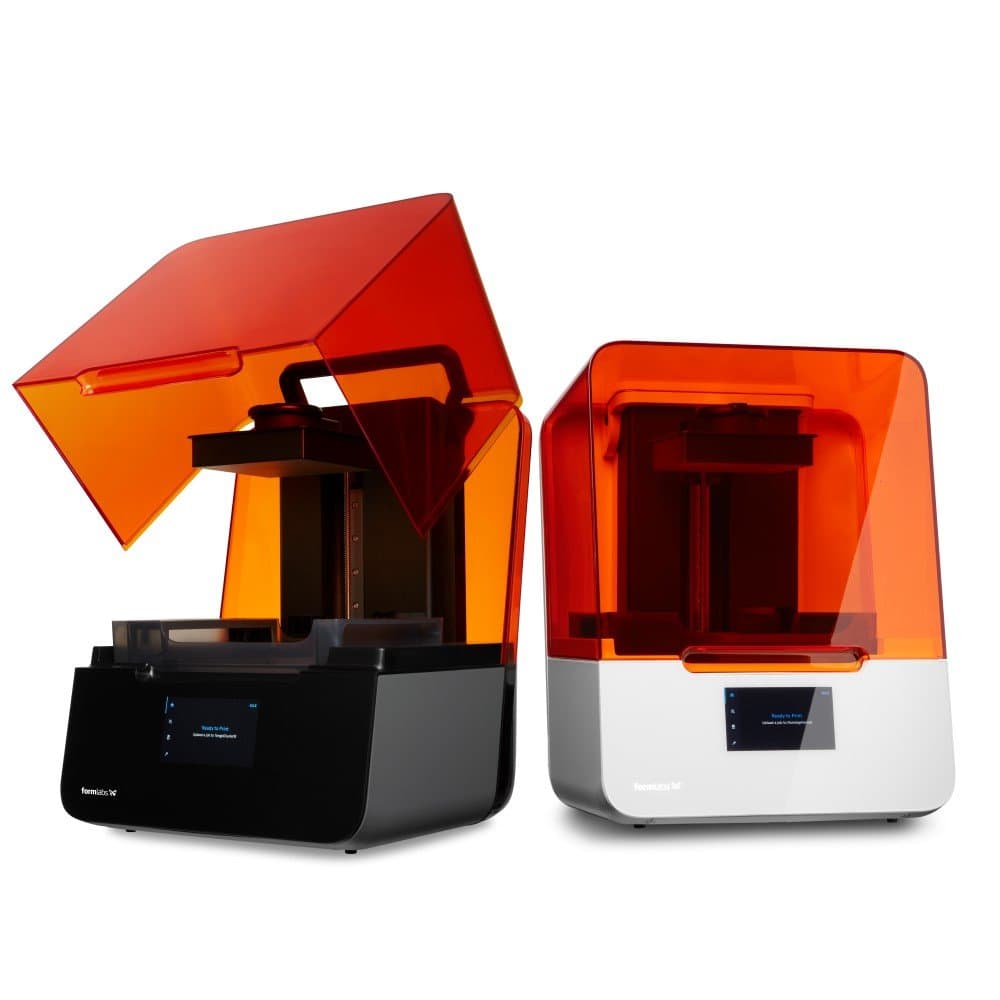

In 2019, Formlabs changed the way 3D printed parts are fabricated with the introduction of the Form 3 and Form 3B. These printers were powered by Formlabs’ trademarked technology, Low Force Stereolithography (LFSTM), and quickly became the highest selling professional SLA 3D printers on the market. Now, with the Form 3+ and Form 3B+, we are building on years of hardware and software innovations to take LFS 3D printing to the next level.

Our new software updates significantly increase print speeds—20 - 40% faster on some resins—and make support removal easier than ever. We’ve also introduced new features that further improve the user experience that Formlabs 3D printers are known for. Better yet, our Form 3 and Form 3B customers will benefit from these software improvements as well.

The new Form 3+ and Form 3B+ also entails new hardware components and subsystems which produce parts with smoother, clearer surfaces, increase printer reliability, and push print speed even further.

This article breaks down the improvements that launched with the Form 3+ and Form 3B+, and explains the key refinements we’ve made to our flagship desktop LFS 3D printers over the past few years.

Introducing the Form 3+ and Build Platform 2

See how the new Form 3+ and Build Platform 2 allow you to fabricate parts faster than ever with a hands-on overview.

Print and Post-Process Parts Faster Than Ever

Many of the key improvements highlighted in the launch of Form 3+ and Form 3B+ are enabled by our newest software updates, continuing to ensure customers will see their Formlabs products regularly improve post-purchase. These benefits are being introduced with the Form 3+ and Form 3B+, but we are excited that these updates can also be utilized by Form 3 and Form 3B printers in the field.

Rapid Print Speeds

We’ve pushed the critical components of LFS 3D printing further than ever before to unlock faster printing. A key component to LFS 3D printing is the Light Processing Unit (LPU), which consists of a system of lenses and mirrors that precisely control the laser used to cure the liquid resin into solid parts. An expanded laser power operating range, a reworked motion profile for the LPU, faster galvanometer moves, and other key print process improvements have unlocked 20-40% faster print speeds on some resins.

| ||||||

| ||||||

| ||||||

| ||||||

|

For when fine detail is key, we have expanded our Adaptive Layer Thickness functionality to all Formlabs resins. Adaptive Layer Thickness is an advanced print mode that analyzes the geometry of parts imported into PreForm and assigns layer heights throughout the sliced model, using thicker layers to maximize print speeds in some areas of the print while using smaller layers to preserve fine details in other areas. Select this print setting to maximize print speed while preserving fine details.

Enhanced Light Touch Supports

When we announced Form 3 and Form 3B, we also introduced light touch support tips - designed to break off by hand and minimize post-processing effort. With the launch of Form 3+ and Form 3B+, we have completely redesigned our support tips for an enhanced light touch support removal experience. Our new support tip shape has been engineered to avoid removing extra material from the surface of the part, so you don’t have to worry about filling surface divots for a great surface finish. The new shape also makes our new supports easier to remove by hand, significantly reducing post-processing times.

Preheating and Sleep Mode

Before a print begins, the build chamber must be heated to ensure optimal printing conditions. Previously, this process would only begin once a user confirmed a print on the touchscreen - but why wait? Enabling the new preheating feature reduces the time it takes for a print to start after uploading. Once the printer receives a job, it will start heating the air inside the printer to reduce the time needed to start the print.

The new sleep mode feature ensures that the printer will be placed in a low-energy state on-demand or after a configurable delay when not in use, minimizing energy consumption, ambient light, and giving peace of mind when closing up for the day.

New Hardware Ensures Consistent High-Quality Prints

Form 3+ and Form 3B+ bring specific advantages that make our flagship desktop LFS printers more reliable than ever before. These benefits are enabled by strategic hardware changes and manufacturing improvements we’ve implemented since launching our Form 3 line of printers.

Improved Print Times in Early Layers

All resin-based printers need to apply extra laser power to early layers to ensure printed parts and support rafts adhere to the build platform. On the Form 3+ and Form 3B+, we have implemented new hardware and improved manufacturing processes that enable tighter alignment between the LPU and the build platform. This allows us to deliver less laser exposure to early layers, reducing print times by five to 15 minutes in the first few layers of the print.

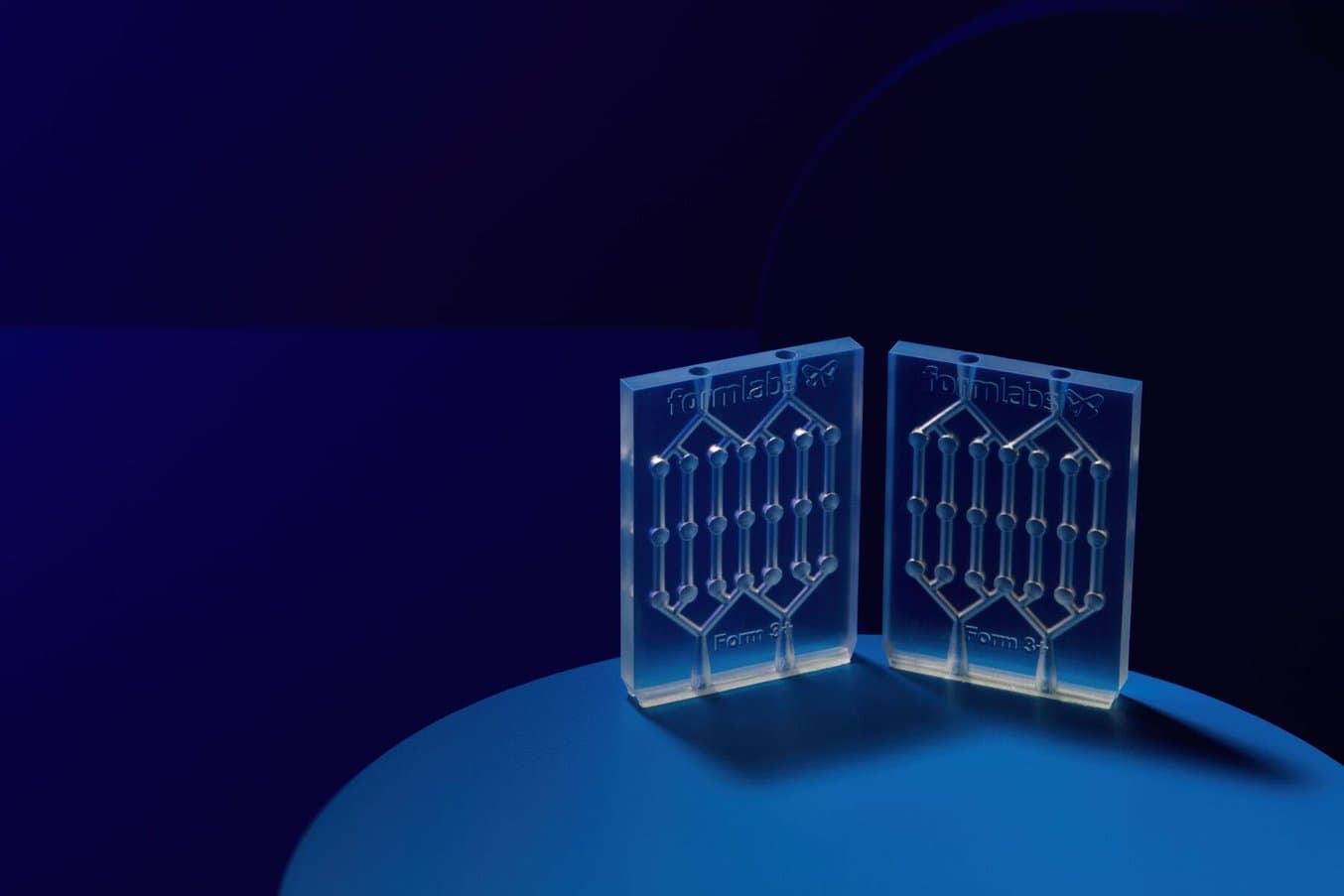

Improved Optical Clarity Through Better Layer Registration

In SLA printing, even microns of error between layers can result in visible surface defects. Form 3+ and Form 3B+ include an updated stabilization component for the LPU, which results in smoother travel and improved alignment between layers. This improves the surface quality of many parts and enhances the optical clarity of translucent resins.

This difference in optical clarity is especially noticeable in Clear Resin, as shown below.

Request a Free Sample Part Printed on the Form 3+

See the difference in quality and optical clarity with a millifluidics sample part printed with Clear Resin on the Form 3+.

Reliability Across Different Printing Environments

Form 3+ and Form 3B+ printers include a redesigned airflow and thermal measurement system, ensuring the printer can function as intended in a wide range of working environments. Form 3+ improves airflow and reads temperature closer to the print bed, making it less affected by ambient air temperatures.

This means Form 3+ and Form 3B+ printers perform consistently across warmer and cooler environments in its operating range. Now, you’ll spend less time heating the build chamber in cooler environments and start printing more quickly.

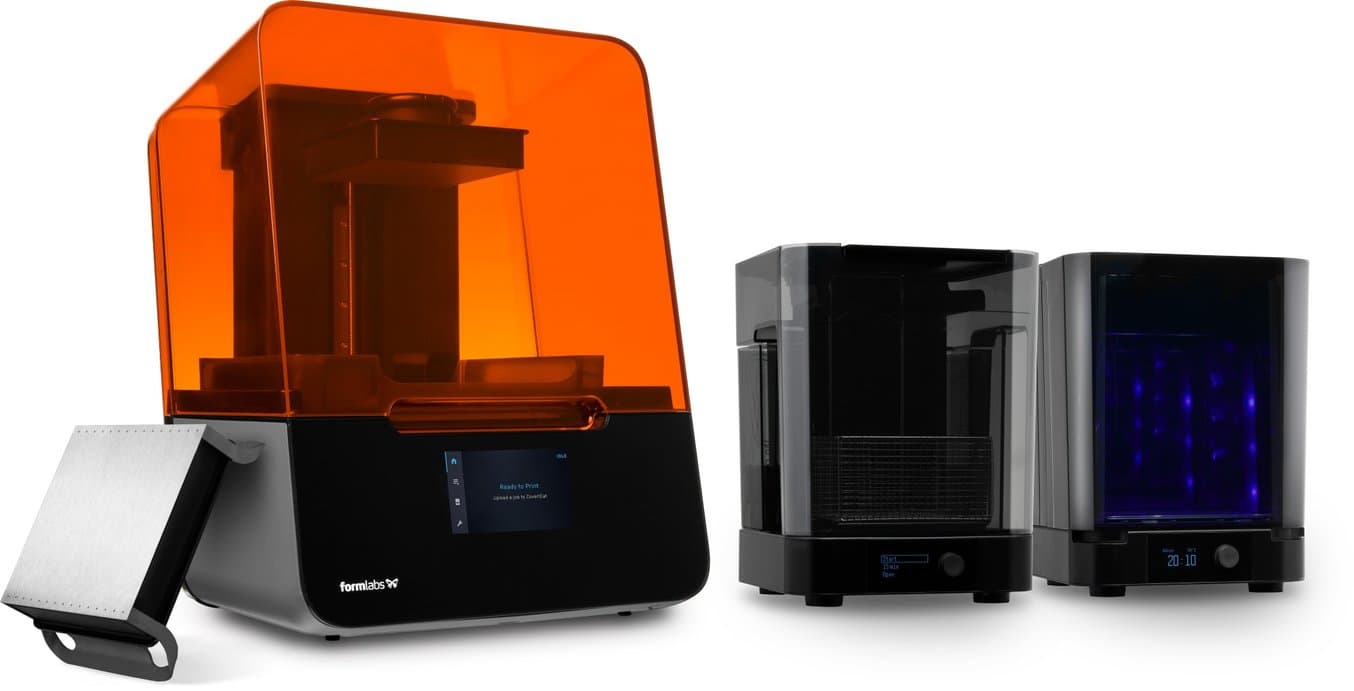

A Comprehensive Printing Experience

These improvements build on an ecosystem that has been engineered to make the entire 3D printing process as seamless and intuitive as possible. Form 3+ and Form 3B+ continue to push the boundaries of what’s possible with 3D printing, supported by peripheral hardware devices and software solutions that comprise the Formlabs ecosystem.

Experience the New Form 3+ and Form 3B+ Ecosystem

Form 3+ and Form 3B+ refine the LFS printing experience that made the Form 3 and From 3B so successful, making desktop printing more reliable and powerful than ever before. Alongside Form 3+ and Form 3B+, we have also launched Build Platform 2—equipped with our next generation patented Quick Release Technology—which instantly releases parts from the build platform, saving valuable post-processing time and eliminating risk of damaging your part. With the entire printing workflow continuing to evolve, there’s never been a better time to print with Formlabs.

Form 3+ and Form 3B+, along with Build Platform 2, are now available. Contact us.