Formlabs offers two types of resin tank options for the Form 2: the Standard Resin Tank and Resin Tank LT for long-term use. Resin Tank LT offers a longer lifetime than the Standard Resin Tank, especially for tanks going through a lot of use. User print data shows this tank also offers higher print success rates.

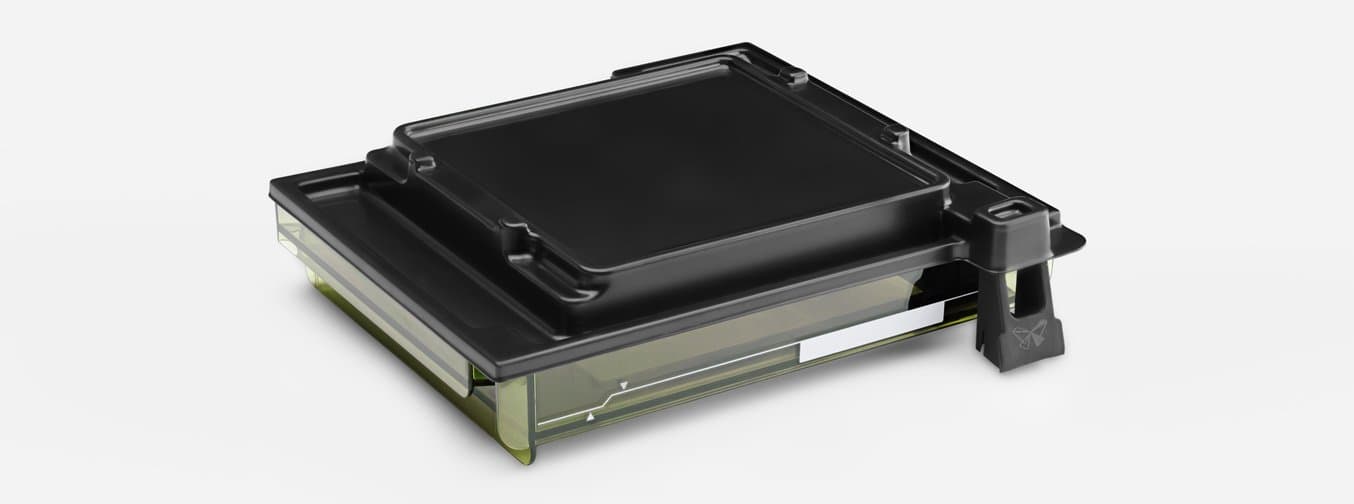

The Form 2’s integrated resin system, comprised of the resin tank, heater, and cartridge, was created to make material management easy. The removable resin tank is heated to maintain a consistent material temperature to ensure successful printing and allows for easy switching between materials and storage.

In the rest of this post, we’ll cover the benefits of Resin Tank LT and why you should consider using Resin Tank LT in your Form 2 workflow.

Note: "LT” is used to designate Formlabs products designed for long-term use, like Dental LT Clear and Resin Tank LT.

Longer Lifetime, Better Results

The Form 2 Resin Tanks gently peel away from a printed part after each layer is formed. After using 1-2 liters of resin on a Standard Tank, you may notice the print surface starts to look cloudy. This clouding is a sign of wear which negatively affects print quality and can lead to failed prints, requiring that you replace the tank. Resin Tank LT was developed to reduce tank wear and extend the useful lifetime of your tank.

We define the lifetime of a tank as the number of 1L cartridges you can use with one tank before it can no longer print a FormTest successfully. Based on this test, our suggested lifetime for Standard Tank is 1-2 L of resin before it may need replacing. Resin Tank LT has at least twice the lifetime of a Standard Resin Tank when printing with Engineering or Dental Resins and at least five times the lifetime when printing with Standard Resins.

Pro tip: To make both Resin Tank LT and Standard Tanks last even longer than the suggested lifetime, avoid printing in the same place on the tank repeatedly. You can track this by using the heat maps on the Formlabs Dashboard.

In addition to increased longevity, we also keep track of print success in the field by collecting data from customers who opt in to sharing their print successes. Print success is indicated by a thumbs up after a completed print and print failures are indicated by a thumbs down. Using aggregated print data from over 600,000 prints from people who opted in, we found using Resin Tank LT reduces the likelihood of a print failure by as much as 57% compared to a Standard Tank.

See the table below for the failure reduction percentage for each resin.

Reduction in field-reported Form 2 print failures for Resin Tank LT vs Standard Tank over a 6 month period

| Material | Reduction in Failures |

|---|---|

| Castable Wax | 57.14% |

| Castable Resin | 57.14% |

| Tough Resin | 54.17% |

| High Temp Resin | 43.59% |

| Dental Model Resin | 42.11% |

| Dental SG Resin | 40.00% |

| Grey Resin | 38.46% |

| Durable Resin | 37.50% |

| Dental LT Clear Resin | 26.67% |

| Black Resin | 20.00% |

| Clear Resin | 16.67% |

| White Resin | 14.29% |

| Color Base Resin | 10.53% |

Expanded Materials Development Possibilities

Resin Tank LT expands material development possibilities into new chemistries that do not perform well with a Standard Tank print surface alone. Since we first launched these tanks in September 2017, we have developed advanced engineering materials like Rigid Resin, Grey Pro Resin, and Elastic Resin that require Resin Tank LT to print.

As Formlabs continues to develop new materials that expand our printers’ capabilities, we now recommend Resin Tank LT whenever possible, for all materials, to take advantage of increased tank lifetime, higher print success rates, and our advanced Engineering Resins.

A New, Anti-Spill Design

Resin Tank LT simplifies material management even further. In addition to extending the longevity of the tank, we’ve made a few design tweaks—including more accurate printer detection, anti-spill geometry, and easier wiper release—for streamlined workflows.

As with our Standard Tank, Resin Tank LT comes with a reusable lid and wiper, making it easy to stack tanks and store resin outside of the machine.

An Integrated System for Rigorous, Nonstop Printing

With a longer lifetime, higher print success, and expanded materials possibilities, we are excited to see that many users of Formlabs printers have already switched to using Resin Tank LT. We’re also looking forward to exploring future resin formulations with interesting new properties made possible by this tank.

Resin Tank LT works with all Formlabs materials except Ceramic Resin and is especially useful for printing at high volumes in a production environment. Some resins, like our Dental Resins, Engineering Resins, and Castable Wax Resin, are known to wear down tanks more quickly. For these materials, we highly recommend Resin Tank LT.

Compatibility Table of Resins and Tanks

| Material | Resin Tank LT (Recommended) | Standard Resin Tank |

|---|---|---|

| Standard Resins (Black, White, Grey, Clear) | ✔️ 5X lifetime | ✔️ |

| Dental Resins (Dental Model, Dental SG, Dental LT Clear, Dentures Resins) | ✔️ 2X lifetime | ✔️ |

| Draft Resin | ✔️ 2X lifetime | ✔️ |

| High Temp Resin | ✔️ 2X lifetime | ✔️ |

| Durable Resin | ✔️ 2X lifetime | ✔️ |

| Tough Resin | ✔️ 2X lifetime | ✔️ |

| Flexible Resin | ✔️ 2X lifetime | ✔️ |

| Castable Wax Resin | ✔️ 2X lifetime | ✔️ |

| Castable Resin | ✔️ 2X lifetime | ✔️ |

| Color Base Resin | ✔️ 2X lifetime | ✔️ |

| Grey Pro Resin | ✔️ required | ❌ |

| Rigid Resin | ✔️ required | ❌ |

| Elastic Resin | ✔️ required | ❌ |

| Ceramic Resin | ❌ | ✔️ |

Try Resin Tank LT

If your workflows would benefit from a tank with a longer lifetime and higher print success, visit the store to try it out. Resin Tank LT is available with no lead time and is now included in all Formlabs Basic and Complete Packages.