Formlabs is excited to announce Tough 1500 Resin, the newest addition to our library of resins for our line of desktop stereolithography (SLA) 3D printers, including the Form 3 and Form 2.

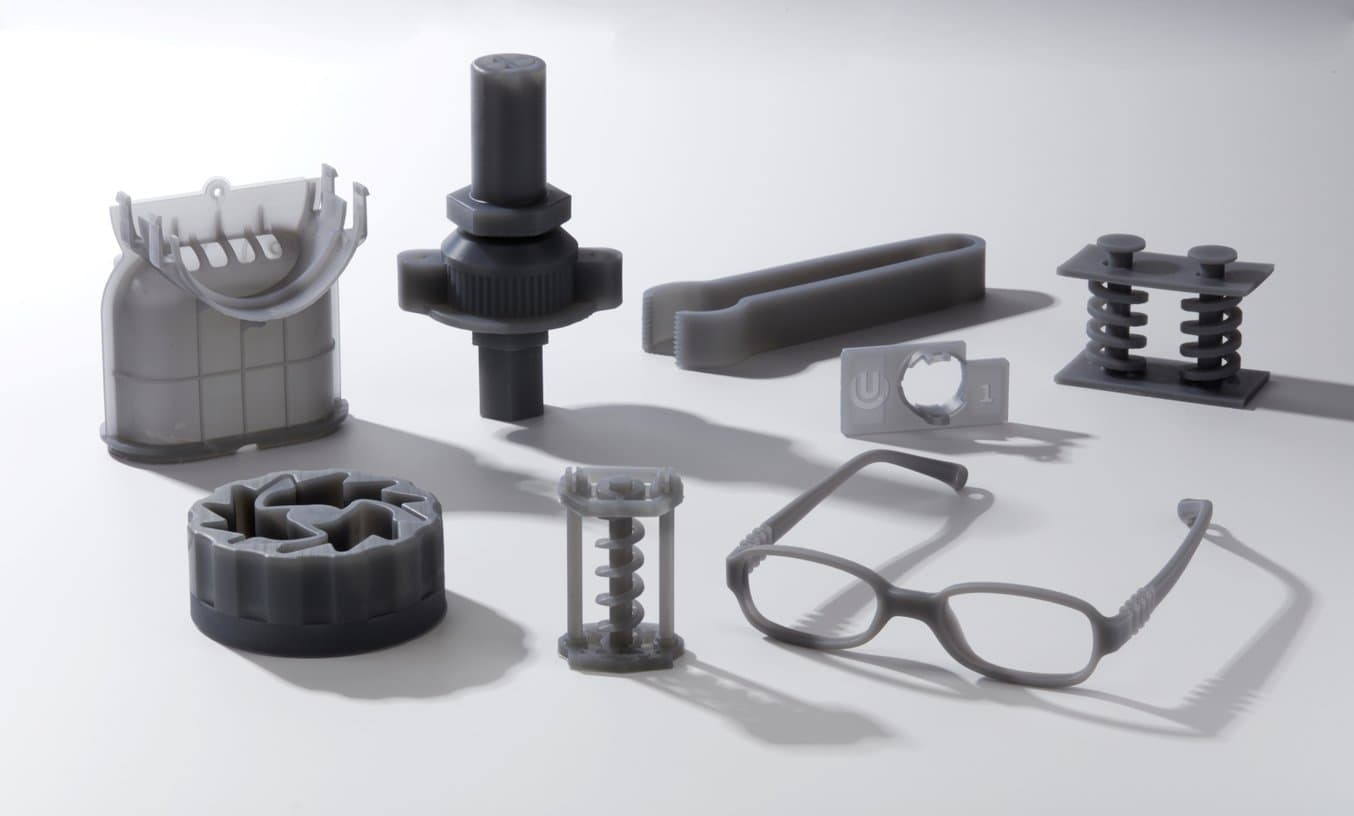

Tough 1500 Resin produces stiff and pliable parts that bend and spring back quickly under cyclic loading. This material is ideal for functional prototypes, jigs and fixtures, and connectors undergoing temporary deflection. It also simulates polypropylene parts in terms of stiffness and strength.

Tough 1500 Resin is the most resilient material in our newly segmented family of Tough and Durable Resins. This family of resins, which includes Tough Resin, Tough 1500 Resin, and Durable Resin, behave relatively similarly under an applied force, but can be clearly differentiated by comparing key properties such as stiffness and elongation.

Find a Reseller Request a Sample Part

When To Use Tough 1500 Resin

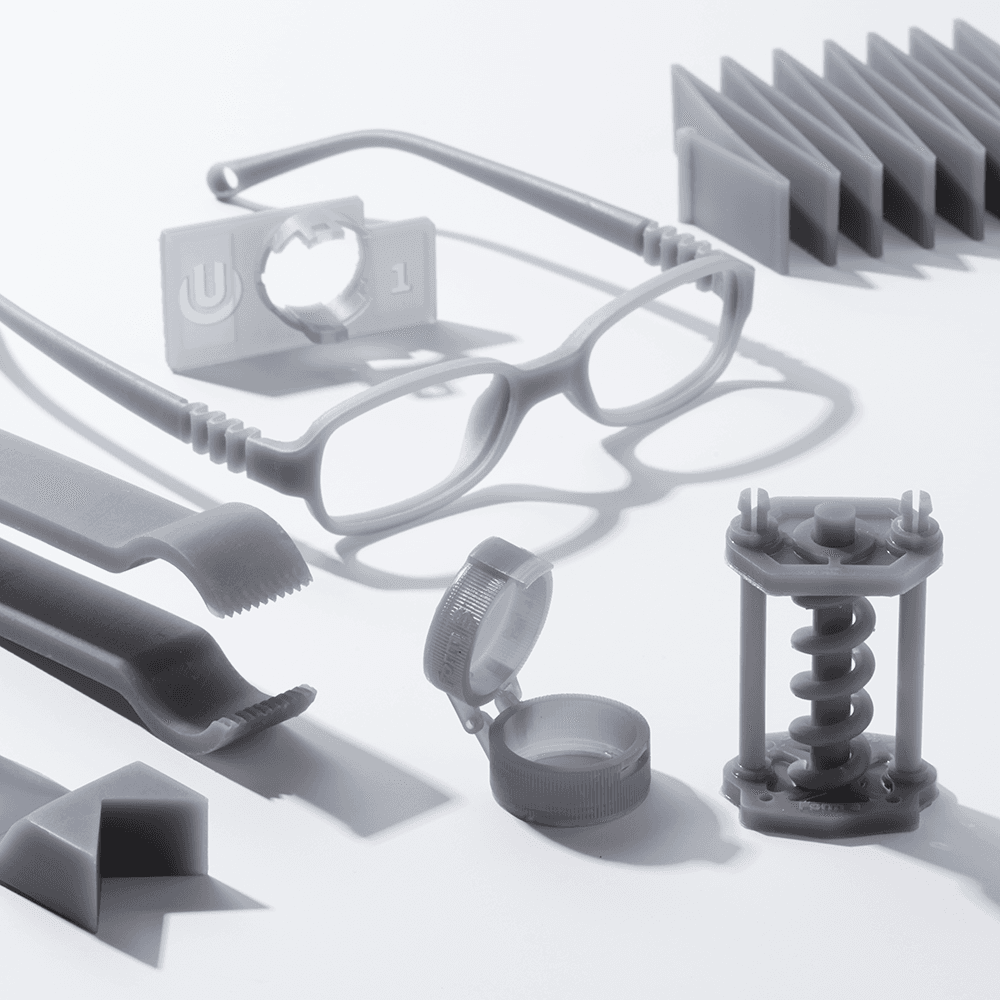

Tough 1500 Resin is ideal for prototypes and connectors that bend and quickly return to shape, such as springs, snap fits, press fits, and hinges.

Tough 1500 Resin is also ideal for jigs and fixtures that require repeated deflection and impact absorption. Balancing stiffness, strength, and impact resistance, Tough 1500 Resin is perfect for many manufacturing settings.

Prototype Polypropylene Parts With Tough 1500 Resin

Polypropylene is a common thermoplastic used in numerous consumer packaged goods products. Use Tough 1500 Resin to simulate the strength and stiffness of products that will be manufactured out of polypropylene.

Technical Deep Dive: Tough 1500 Resin

As with any material, to better evaluate when to use Tough 1500 Resin, it’s important to understand its technical properties. Tough 1500 Resin balances elongation and modulus, exhibiting high resilience and fast springback.

- Elongation is a measure of how far a material can stretch or bend.

- Modulus is a measure of stiffness, or how easy it is to stretch or bend the material.

Parts printed in this material can bend significantly and quickly spring back to their original shape.

Technical Data of Tough 1500 Resin After Post-Curing

| Ultimate Tensile Strength | Tensile Modulus | Elongation at Break | Flexural Modulus | Notched Izod |

|---|---|---|---|---|

| 33 MPa | 1500 MPa | 51% | 1400 MPa | 67 J/m |

Data was obtained from parts printed using Form 2, 100 μm and post-cured with a Form Cure for 60 minutes at 70 C.

The “1500” in Tough 1500 Resin represents its tensile modulus (in MPa). As Formlabs reformulates and develops new engineering materials, we will be transitioning to this “adjective + number” naming convention. In the case of the Tough and Durable Resins, we’ll continue using tensile modulus as the key distinguishing property, allowing you to identify where each material falls on a spectrum of stiffness.

Creating Tesla Sensor Mounts with Tough 1500 Resin

Unplugged Performance is the world leader in premium performance upgrades for Tesla vehicles. Some of these upgrades involve installing customized car bumpers.

Before 3D printing, it would take Unplugged Performance roughly 45 minutes to remove each sensor mount from the existing bumper and another 10 minutes to bond it onto the new bumper. At six sensors per car, in addition to other custom upgrades, they were only able to complete one car every one-and-a-half days.

With their Formlabs printer, Unplugged Performance now prints new sensor mounts in batches of 30. This eliminates the costly time spent removing the sensor mounts from the existing bumper and leaves them with only the bonding step of their workflow. This helped improve their throughput to three cars per day.

Unplugged Performance uses Tough 1500 Resin for the printed mounts due to its compliant nature, which enables it to clip onto and secure the various sensors. Tough 1500 Resin’s high impact strength enables safe mounting of the sensors in the car’s bumper as well.

Unplugged Performance also prefers the grey color of Tough 1500 Resin compared to Tough Resin and Durable Resin. This has opened up new opportunities to create visible custom parts that blend seamlessly into the car’s interior.

Experience Tough 1500 Resin

Tough 1500 Resin offers a unique balance of stiffness and pliability that allows parts made from this material to deform and return to form quickly. See it for yourself by requesting our new Tough 1500 Resin spring system sample part.

This part comes in three easy-to-assemble pieces. One of these pieces ships on supports, allowing you to experience the ease of support removal with parts printed on the Form 3. After removing the supports from the spring coil and placing it on the center rail, align the top component with the guide rails and press over the connector pins. Once assembled, squeeze the spring repeatedly to experience the high resiliency of Tough 1500 Resin.

High Performance Engineering Materials For Everyone

Formlabs is dedicated to making professional in-house fabrication tools accessible to every business. Tough 1500 Resin is the latest of many advanced materials to be added to our Resin Library and the first new Engineering Resin to be added to the Form 3 ecosystem. To view our complete library of engineering materials for the Form 2 and Form 3, visit our Engineering Resins page.

Webinar: Introducing Tough 1500 Resin

In this on-demand webinar, a Formlabs Materials Product Manager will walk through our family of Tough and Durable Resins at Formlabs and deep dive into our latest material, Tough 1500 Resin.