In the labyrinth-like corridors at the University Hospital of Lübeck, one of the biggest in Germany, visitors tend to lose all sense of time and place. The future of medical technology is just next door, in the 3D printing lab of the Institute of Neuroradiology, headed by Prof. Peter Schramm. Here, Dr. Kemmling, staff neuroradiologist and researcher is using high-precision stereolithography (SLA) 3D printing to create models of brain arteries to personalize operations and reduce risks such as stroke.

After years of experience in the emergency room, Dr. Kemmling knows that performing endovascular surgeries is not only a matter of time, but also precision: Millimeters decide over life and death. The most advanced devices only work as intended when accurately placed.

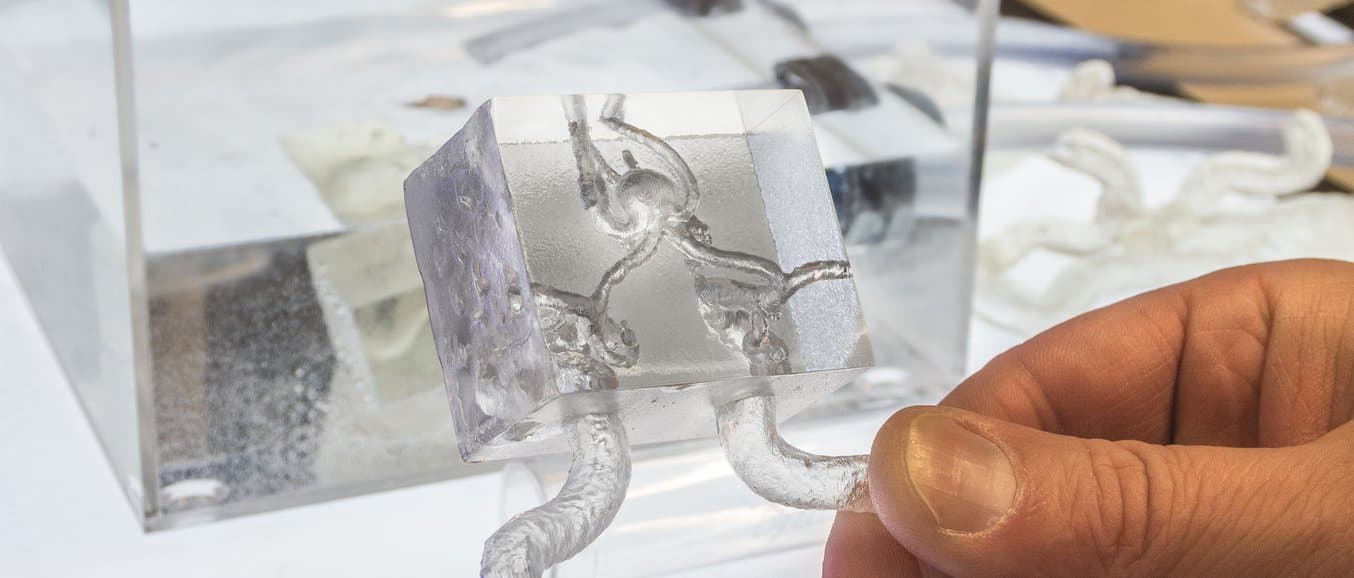

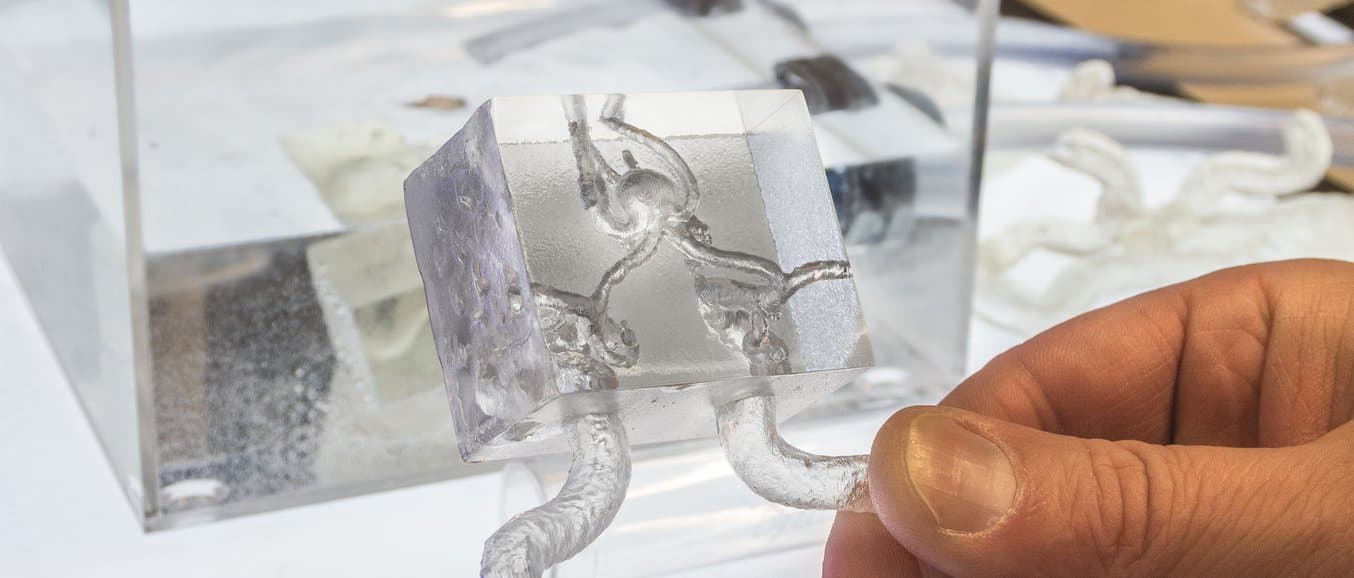

By 3D printing 1:1 replicas of patients’ brain arteries from CT scans, Dr. Kemmling offers a universal tool for research and training alike, creating an affordable, anatomically correct alternative to silicone models and animal testing. His vision: providing personalized treatment plans for each patient on a global scale.

Personalized Treatment for Aneurysm Patients

Aneurysms–a balloon-like bulge filled with blood that creates a widening of the cerebral arteries–affect up to 3 percent of the general population. The bigger and the more complex the aneurysm, the more likely it is to suddenly burst open, resulting in acute bleeding in the brain. Once ruptured, aneurysm will lead to death of the patient in 30 percent of the cases and to permanent disabilities for an additional 30 percent.

In most cases, aneurysms are discovered accidentally from MRI or CT scans, but not every aneurysm needs to be treated. The question is often: should the patient take on the risk of preventive treatment, or live with the knowledge that the aneurysm might rupture any time, leading to a likely much more severe outcome?

Nowadays, preventive endovascular surgery is possible with high-tech devices such as flow diverters, microscopic woven wire frames that inhibit blood flow into the aneurysm, eventually making it disappear. Flow diverters need to be accurately placed inside the fine brain arteries with micrometer precision. A second try is not an option–once the flow diverter expands within the artery, there is no way to adjust misplacement without significant risk.

Learn more about how 3D printing pushes the boundaries in medical processes.

Using Dr. Kemmling’s innovative method, doctors can create and use accurate physical replicas of patients’ brain arteries to practice the procedure beforehand with the exact same tools used during endovascular surgery, verifying that the procedure will work in the operating room.

Practice also helps to reduce the time in the operating room by up to 50 percent, from 30-50 minutes with no training, to 25-15 minutes with repetitive training using a 3D model.

Learn how Dr. Michael Eames used a 3D printed model to plan a minimally invasive, low-risk solution for his patient, rather than the alternative of a complex, four-hour osteotomy, saving an estimated $5,500 in the operating room.

Using 3D Models for Brain Operations

“How do you become a neuroradiologist? You watch others for years, but at some point, you have to go inside the brain,” said Dr. Kemmling. He considers the fast and flexible production of 3D models a much-needed solution for bridging the gap from learning to doing.

Dr. Kemmling was one of the first to purchase the Form 2 SLA 3D printer in Germany. He can now print a set of eight aneurysm cases within two days. Silicone models, using a molding procedure, have a lead time of several weeks and do not provide the anatomic details of the 3D models.

Printed with Formlabs Clear Resin, 3D printed models have a resolution of 0.025 mm–less than the width of human hair. By standardizing his method, Dr. Kemmling wants animal testing to vanish.

Dr. Kemmling used Formlabs Clear Resin to produce 3D printed aneurysm models. Request a free sample of Clear.

By showing patients an actual model of their brain, Dr. Kemmling can directly demonstrate the procedure.

“When telling patients that it is possible to prepare the treatment with their specific anatomy, they are reassured,” Dr. Kemmling said.

“This is what your aneurysm looks like, this is where we have to go in, this is what we are going to do. With 3D printing being so affordable and easy to produce, patients can even take their models home.”

Taking Your 3D Printed Brain Arteries in Your Hand and Home

Christine, like many, was diagnosed with an aneurysm incidentally, after getting a routine MRI scan to investigate a headache that wouldn’t go away. Having never heard of aneurysms before, she was not immediately aware of the gravity of her situation.

“I did not panic before I saw how shocked my friends were,” Christine said.

When Dr. Kemmling showed Christine the 3D model printed from her scan, she was surprised how small the brain aneurysm was. With the help of the model, Dr. Kemmling explained the procedure and demonstrated it with the equivalent tools on a 1:1 scale.

Christine took the model home and showed it to concerned friends and relatives to explain what was inside her head and how she would be treated.

“I was impressed by the level of precision; not even an embroiderer could produce such fine details,” Christine said. “I did some further research and then decided that I would choose to go all the way through the artery for treatment of the aneurysm.”

The alternative was to perform a classic open brain surgery with a much longer recovery period. In contrast, endovascular treatment of the brain artery is less invasive for the patient, who usually can be discharged from the hospital within a few days. For Milius, this procedure took no longer than 30 minutes, a precise and time-efficient operation where the doctor was prepared with the 3D model.

The Future of 3D Printing in the Medical Field

Christine is healthy today. The latest tests have confirmed that the implanted flow diverter works and her aneurysm has completely disappeared.

So far, Dr. Kemmling has treated over 100 patients at the university clinic in Lübeck. While this number is too small at this point to compare to the treatment’s long-term success rate to alternatives, he can already confirm that performing endovascular operations on brain aneurysms is faster and more secure thanks to training with 3D printed medical models.

The team of the Institute of neuroradiology gives regular workshops both in the 3D lab and at international courses, to share their knowledge with fellow neuroradiologists.

Dr. Kemmling has already inspired more 3D printing applications in the medical field: another research group is now using 3D models printed in Dr. Kemmling’s 3D labs to test medication for blood clotting.

Learn more about setting up and managing multiple 3D printers in our free white paper.

In Dr. Kemmling’s view, 3D modeling and printing are easily adaptable for a range of procedures in the medical field. Generally, 3D models can be used to do experimental measurement in order to see how devices can be integrated into the body and how they affect the blood flow, making them relevant to all kinds of clinical areas.

Medical professionals are fast adopting personalized medical procedures using emerging technologies. Produced at a significantly lower cost and in substantially less time, 3D printed medical models are here to replace silicone models and animal testing. Dr. Kemmling’s method is replicable by any doctor with a 3D printing lab and the ambitions to treat every patient individually.

Get Started 3D Printing Surgical Models In-House

Ready to start 3D printing patient-specific models? Download our white paper for a step-by-step walkthrough of the workflow for creating high-accuracy tactile reference models for preoperative planning, enhanced patient consent, intraoperative visualization, and sizing or pre-fitting medical equipment.

In the labyrinth-like corridors at the University Hospital of Lübeck, one of the biggest in Germany, visitors tend to lose all sense of time and place. The future of medical technology is just next door, in the 3D printing lab of the Institute of Neuroradiology, headed by Prof. Peter Schramm. Here, Dr. Kemmling, staff neuroradiologist and researcher is using high-precision stereolithography (SLA) 3D printing to create models of brain arteries to personalize operations and reduce risks such as stroke.

After years of experience in the emergency room, Dr. Kemmling knows that performing endovascular surgeries is not only a matter of time, but also precision: Millimeters decide over life and death. The most advanced devices only work as intended when accurately placed.

By 3D printing 1:1 replicas of patients’ brain arteries from CT scans, Dr. Kemmling offers a universal tool for research and training alike, creating an affordable, anatomically correct alternative to silicone models and animal testing. His vision: providing personalized treatment plans for each patient on a global scale.

Personalized Treatment for Aneurysm Patients

Aneurysms–a balloon-like bulge filled with blood that creates a widening of the cerebral arteries–affect up to 3 percent of the general population. The bigger and the more complex the aneurysm, the more likely it is to suddenly burst open, resulting in acute bleeding in the brain. Once ruptured, aneurysm will lead to death of the patient in 30 percent of the cases and to permanent disabilities for an additional 30 percent.

In most cases, aneurysms are discovered accidentally from MRI or CT scans, but not every aneurysm needs to be treated. The question is often: should the patient take on the risk of preventive treatment, or live with the knowledge that the aneurysm might rupture any time, leading to a likely much more severe outcome?

Nowadays, preventive endovascular surgery is possible with high-tech devices such as flow diverters, microscopic woven wire frames that inhibit blood flow into the aneurysm, eventually making it disappear. Flow diverters need to be accurately placed inside the fine brain arteries with micrometer precision. A second try is not an option–once the flow diverter expands within the artery, there is no way to adjust misplacement without significant risk.

Learn more about how 3D printing pushes the boundaries in medical processes.

Using Dr. Kemmling’s innovative method, doctors can create and use accurate physical replicas of patients’ brain arteries to practice the procedure beforehand with the exact same tools used during endovascular surgery, verifying that the procedure will work in the operating room.

Practice also helps to reduce the time in the operating room by up to 50 percent, from 30-50 minutes with no training, to 25-15 minutes with repetitive training using a 3D model.

Learn how Dr. Michael Eames used a 3D printed model to plan a minimally invasive, low-risk solution for his patient, rather than the alternative of a complex, four-hour osteotomy, saving an estimated $5,500 in the operating room.

Using 3D Models for Brain Operations

“How do you become a neuroradiologist? You watch others for years, but at some point, you have to go inside the brain,” said Dr. Kemmling. He considers the fast and flexible production of 3D models a much-needed solution for bridging the gap from learning to doing.

Dr. Kemmling was one of the first to purchase the Form 2 SLA 3D printer in Germany. He can now print a set of eight aneurysm cases within two days. Silicone models, using a molding procedure, have a lead time of several weeks and do not provide the anatomic details of the 3D models.

Printed with Formlabs Clear Resin, 3D printed models have a resolution of 0.025 mm–less than the width of human hair. By standardizing his method, Dr. Kemmling wants animal testing to vanish.

Dr. Kemmling used Formlabs Clear Resin to produce 3D printed aneurysm models. Request a free sample of Clear.

By showing patients an actual model of their brain, Dr. Kemmling can directly demonstrate the procedure.

“When telling patients that it is possible to prepare the treatment with their specific anatomy, they are reassured,” Dr. Kemmling said.

“This is what your aneurysm looks like, this is where we have to go in, this is what we are going to do. With 3D printing being so affordable and easy to produce, patients can even take their models home.”

Taking Your 3D Printed Brain Arteries in Your Hand and Home

Christine, like many, was diagnosed with an aneurysm incidentally, after getting a routine MRI scan to investigate a headache that wouldn’t go away. Having never heard of aneurysms before, she was not immediately aware of the gravity of her situation.

“I did not panic before I saw how shocked my friends were,” Christine said.

When Dr. Kemmling showed Christine the 3D model printed from her scan, she was surprised how small the brain aneurysm was. With the help of the model, Dr. Kemmling explained the procedure and demonstrated it with the equivalent tools on a 1:1 scale.

Christine took the model home and showed it to concerned friends and relatives to explain what was inside her head and how she would be treated.

“I was impressed by the level of precision; not even an embroiderer could produce such fine details,” Christine said. “I did some further research and then decided that I would choose to go all the way through the artery for treatment of the aneurysm.”

The alternative was to perform a classic open brain surgery with a much longer recovery period. In contrast, endovascular treatment of the brain artery is less invasive for the patient, who usually can be discharged from the hospital within a few days. For Milius, this procedure took no longer than 30 minutes, a precise and time-efficient operation where the doctor was prepared with the 3D model.

The Future of 3D Printing in the Medical Field

Christine is healthy today. The latest tests have confirmed that the implanted flow diverter works and her aneurysm has completely disappeared.

So far, Dr. Kemmling has treated over 100 patients at the university clinic in Lübeck. While this number is too small at this point to compare to the treatment’s long-term success rate to alternatives, he can already confirm that performing endovascular operations on brain aneurysms is faster and more secure thanks to training with 3D printed medical models.

The team of the Institute of neuroradiology gives regular workshops both in the 3D lab and at international courses, to share their knowledge with fellow neuroradiologists.

Dr. Kemmling has already inspired more 3D printing applications in the medical field: another research group is now using 3D models printed in Dr. Kemmling’s 3D labs to test medication for blood clotting.

Learn more about setting up and managing multiple 3D printers in our free white paper.

In Dr. Kemmling’s view, 3D modeling and printing are easily adaptable for a range of procedures in the medical field. Generally, 3D models can be used to do experimental measurement in order to see how devices can be integrated into the body and how they affect the blood flow, making them relevant to all kinds of clinical areas.

Medical professionals are fast adopting personalized medical procedures using emerging technologies. Produced at a significantly lower cost and in substantially less time, 3D printed medical models are here to replace silicone models and animal testing. Dr. Kemmling’s method is replicable by any doctor with a 3D printing lab and the ambitions to treat every patient individually.

Get Started 3D Printing Surgical Models In-House

Ready to start 3D printing patient-specific models? Download our white paper for a step-by-step walkthrough of the workflow for creating high-accuracy tactile reference models for preoperative planning, enhanced patient consent, intraoperative visualization, and sizing or pre-fitting medical equipment.