Thermoforming Thick PS and ABS Sheets With 3D Printed Molds: Download Our New Technical Study

The French Industrial Technical Center for Plastics and Composites (IPC) conducted research to evaluate the usability of 3D printed molds for low-volume thermoforming with thick PS and ABS sheets for automotive parts.

Download our white paper that documents the fabrication steps and trials thermoforming with 3D printed molds, as well as three more case studies, design recommendations, and molding conditions for forming common thermoplastics.

Why 3D Print Molds for Thermoforming?

Traditionally, thermoforming tools—also referred to as molds, forms, or bucks—are fabricated by CNC machined metal for large production, or wood or composite board (foam or fiberglass) for smaller batches. These processes all require expensive equipment and labor for CAM settings and machine operation. Outsourcing the mold comes with weeks of lead time and can cost thousands of dollars. As a result, producing limited quantities of thermoformed parts—for prototypes or low-volume batches—is usually not a viable option.

Desktop 3D printing is a powerful solution to fabricate tools rapidly and at a low cost. It requires minimal equipment, saving CNC time and skilled operators for other high-value tasks in the meantime. With in-house 3D printing, manufacturers and product designers can introduce rapid tooling into the product development process to validate design and material choices prior to transitioning to mass production. They can iterate quickly, accelerate product development and bring better products to market.

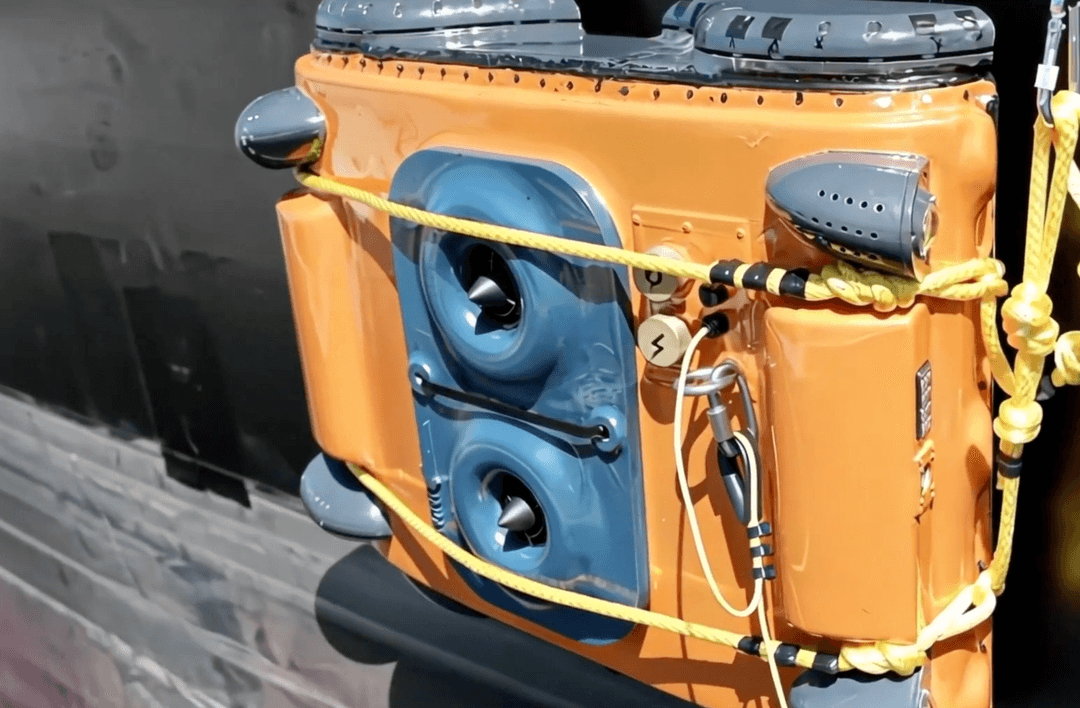

The torture-test part used in the study presented some common thermoforming challenges.

Stereolithography (SLA) 3D printing technology is a great choice for molding. It is characterized by a smooth surface finish and high precision that the tool will transfer to the final part and that also facilitates demolding. Molds produced by SLA 3D printers are chemically bonded such that they are fully dense and isotropic, producing functional molds at a quality not possible with other common 3D printing technologies, such as fused deposition modeling (FDM). SLA 3D printing also offers unmatched design freedom to create complex and intricate molds.

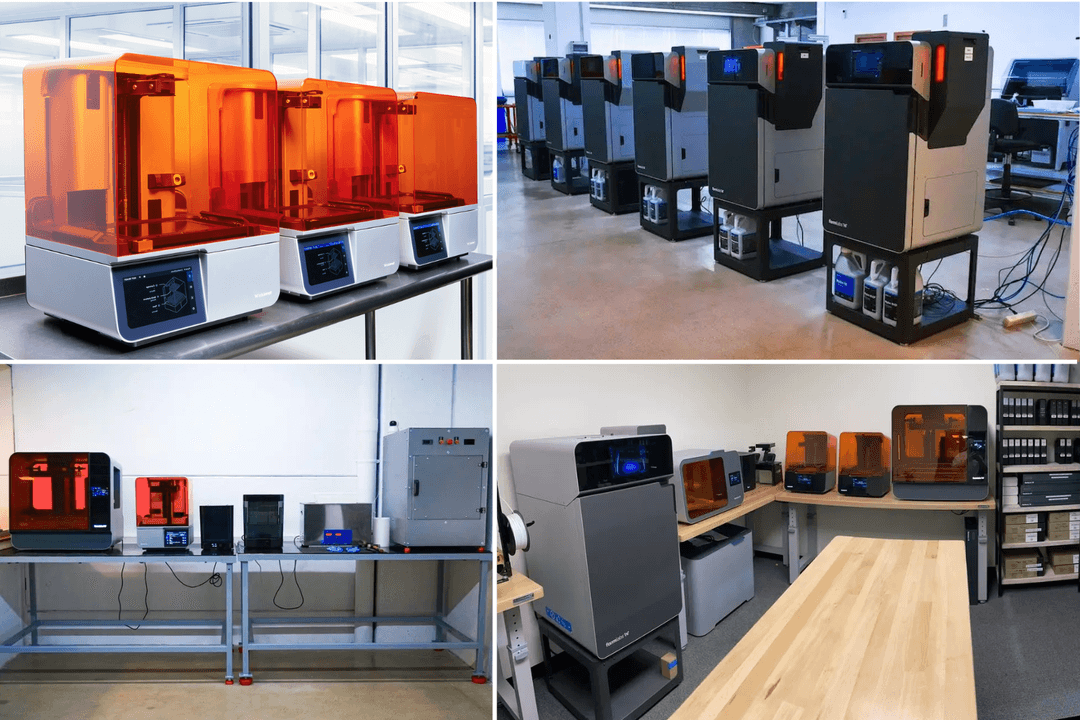

Desktop SLA printers, such as the Form 3+, can seamlessly be integrated into any workflow as they are easy to implement, operate, and maintain. While being compact enough for an office, the large format 3D printer Form 3L enables the fabrication of large-scale parts and molds. Additionally, Formlabs offers a wide range of engineering materials with mechanical and thermal properties that pair well with tool manufacture.

Research by IPC, an Industrial Technical Center Dedicated to Plastic and Composite Innovation

IPC is the Industrial Technical Center whose expertise is dedicated to plastic and composite innovation in France. IPC develops new means to support all businesses, in particular small and medium-sized companies. The center works closely with European key scientific players in order to support companies on R&D, innovation, technology, and skills transfer, regardless of the process used. IPC teams help manufacturers drive innovation by performing studies, establishing protocols, feasibility, and technology transfer. They have been exploring the potential of rapid tooling with 3D printing for years, in particular, the viability of 3D printed injection molds for low-volume production.

Recently, IPC conducted a research project dedicated to 3D printed tooling for vacuum forming in partnership with the VESTAL Group, a leading supplier of thermoformed parts and solutions, specialized in very large units for the medical, railway, leisure vehicle, and light, medium, and heavy commercial vehicle sectors. The company answers a high demand for prototypes, low and medium volumes of end-use production. The purpose of this study was to achieve prototyping tools capable of fabricating low to medium size batches in molding conditions close to production; with short lead time and reduced costs.

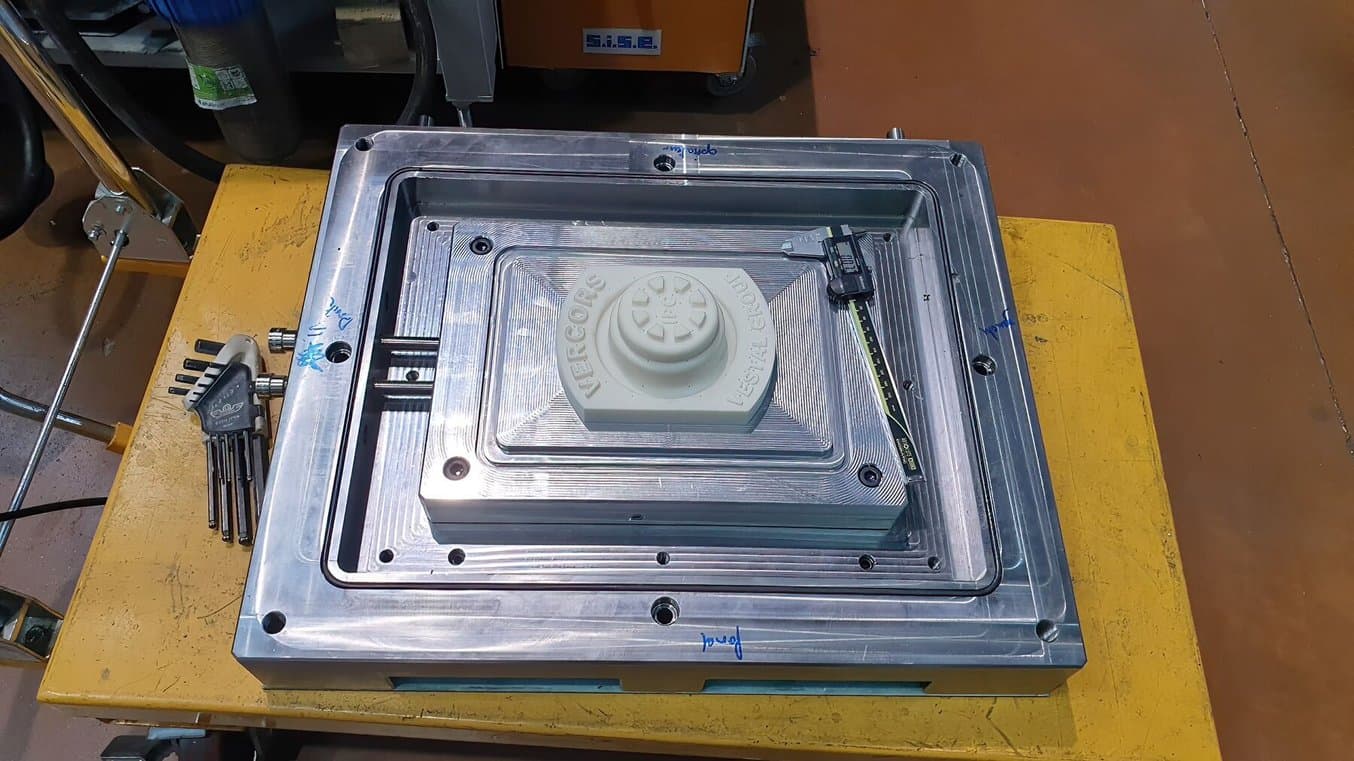

The 3D printed tool was fixed on a steel plate.

Study Details and Benchmarks Geometries

IPC conducted feasibility and longevity tests on 3D printed torture-test tools presenting some common thermoforming challenges.

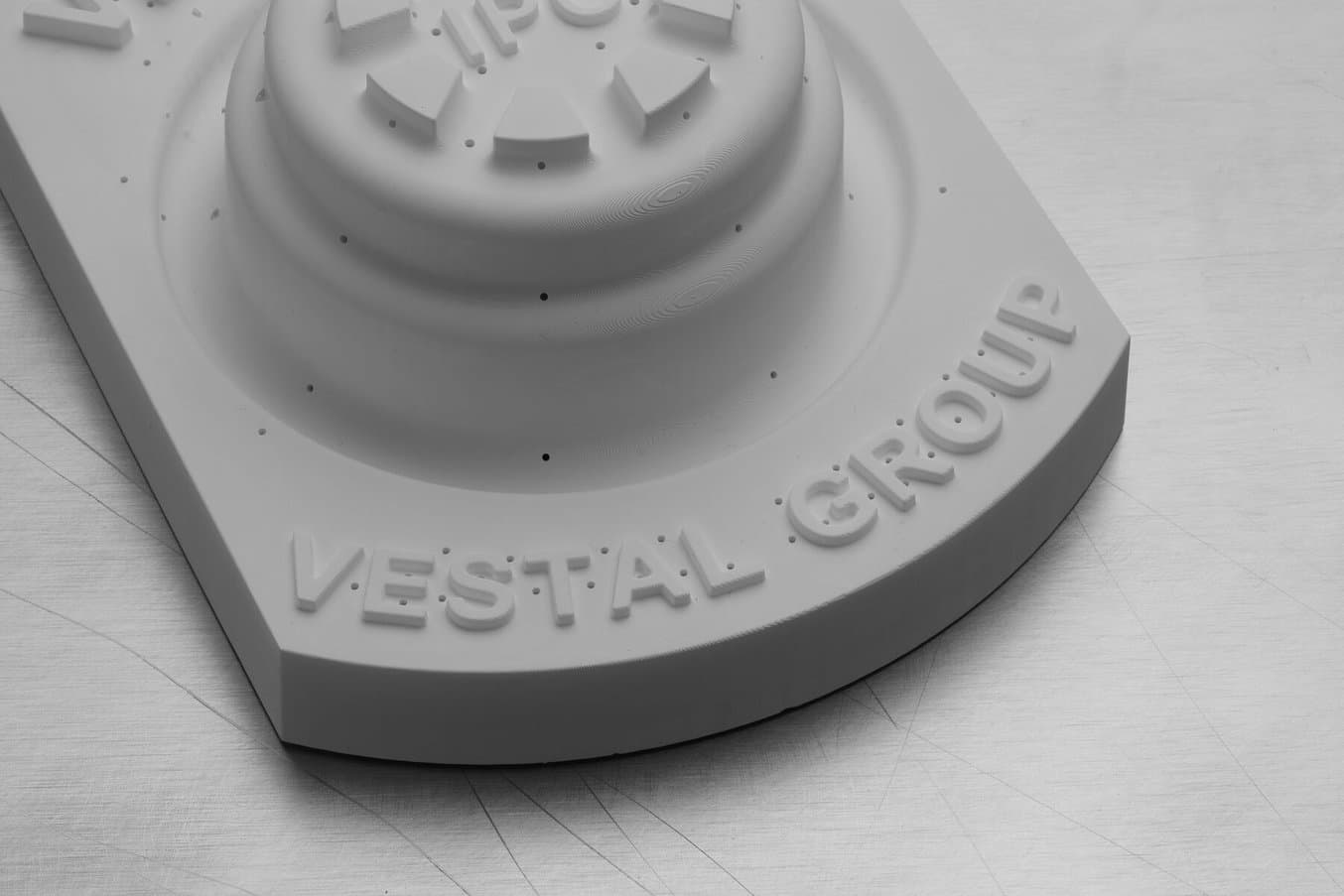

The torture-test part was designed respecting the following specifications:

- Presence of embossed and engraved details.

- General draft angle at 3°.

- Presence of zone without draft angle.

- Presence of writing at 2mm thickness embossed and engraved.

- Presence of areas with sharp edges.

- Presence of areas with a radius of 5 mm.

- Vacuum holes diameter from 0.8 mm to 1.2 mm maximum.

- Part dimensions at 60 x 130 x 168 mm.

The 3D printed thermoforming tool included cooling channels for thermal regulation.

Results

Molds printed in Rigid 10K Resin were successfully used to thermoform 3 mm thick PS sheets.

The study demonstrated that molds 3D printed with Formlabs Rigid 10K Resin are able to thermoform thick PS sheets, for up to 20 to 50 cycles. Incorporating cooling channels in the mold design increases the mold longevity while maintaining a reasonable cycle time for low to medium production. Lead times are 3 to 7 times shorter than with traditional tooling, and costs are cut at least in half.

Download the full report to see the details of the technical study, including 3D printing guidelines and insights on the mold assembly and process conditions.