Sectores tan diversos como la industria aeroespacial y el diseño de gafas cada vez utilizan más piezas impresas en 3D mediante sinterizado selectivo por láser (SLS) por sus buenas propiedades mecánicas y sus métodos de producción asequibles. Para mejorar todavía más sus propiedades mecánicas y estéticas, los usuarios de la impresión 3D SLS utilizan con frecuencia técnicas de posacabado como tintes, revestimientos, galvanizados o pinturas.

Teñir piezas impresas en 3D con el Nylon 12 White Powder en impresoras 3D SLS de la serie Fuse da acceso a un enorme abanico de oportunidades para que los clientes construyan prototipos atractivos y creen piezas listas para la producción con diversos colores.

En esta guía, describiremos el proceso para teñir impresiones 3D SLS y repasaremos las muchas ventajas que ofrece. Si quieres conocer el proceso de trabajo completo del tinte de impresiones 3D, descarga nuestro libro blanco.

¿Por qué deberías teñir tus piezas impresas en 3D mediante SLS?

Las piezas impresas en 3D mediante SLS se están volviendo más comunes en cada fase del proceso que va desde el diseño a la fabricación. Debido a la superficie ligeramente granulosa de las impresiones 3D SLS, las soluciones de posacabado como el alisado, los revestimientos y el tinte también están ganando popularidad.

El tinte es un método económico para dar color a las impresiones SLS, que potencia su estética sin menoscabar sus propiedades mecánicas. Independientemente de si se quiere producir una remesa pequeña de piezas coloreadas o de si lo que se busca es realizar una producción de gran volumen homologada mediante el sistema Pantone, existen métodos de tinte para cualquier proceso de trabajo.

Nuestro equipo probó cuatro métodos populares y nos comunicó los resultados. Esta guía mostrará un resumen de ellos, pero si quieres ver los resultados completos, tienes la opción de descargar nuestro libro blanco.

El tinte es ideal tanto para el prototipado funcional como para la producción de piezas de uso final con colores personalizados que se ajusten a la estética de una marca.

Solicita una pieza de muestra gratuita de SLS

Experimenta la calidad de Formlabs de primera mano. Te enviaremos una pieza de muestra gratuita de Nylon 12 White Powder impresa con la Fuse 1+ 30W a tu oficina.

Dyeing Equipment

We tested dyeing equipment to assemble the optimal setup for dyeing Nylon 12 White Powder. Below, we outline the hardware, dye mixture, and dye bath parameters that achieved the best results in our testing.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

| Método | Tamaño | Cantidad | Color | Estable frente a la radiación UV | Coste |

|---|---|---|---|---|---|

| Tinte en olla | ★★ | ★★ | ★★ | No | Menos de 50 € |

| Tinte ultrasónico | ★★★ | ★★★ | ★★★ | No | 100 € a 1000 € |

| Tinte a presión | ★★ | ★★ | ★★★★ | No | 100 € a 500 € |

| DM60 de DyeMansion | ★★★★★ | ★★★★★ | ★★★★★ | Sí | Más de 50 000 € |

The hardware that we recommend for dyeing is the ESVC-28 - Spectrum Thermal Circulator from Winco. This machine is affordable, available from multiple sources, and is easy to set up and use.

US Source: $699.99

EMEA Source: €659.99

APAC Source: $299

The Winco ESVC-28 Spectrum Thermal Circulator is an ideal solution for ultrasonic dyeing.

Any system that is able to reach the necessary temperatures of 80 °C to 90 °C as well as circulate the solution should be adequate for dyeing. We also recommend having stainless steel tongs nearby to assist in removing parts from the dye bath.

There are also industrial solutions available on the market for dyeing SLS parts, like the Dyemansion DM60, that are cost-effective for high volumes of parts and when extremely consistent results are necessary. This product is capable of holding up to 60 L of components per dyeing batch and will automatically inject the dye as well as rinse the parts post-dye.

The DM60 confers a much higher degree of consistency when compared to pot dyeing as well as improved UV stability of the dyes. An additional service offered by Dyemansion is tailored color development. For users with a strict color requirement or who are looking to dye a very high volume of parts (end-use parts, production runs of 1000+ units), using an industrial machine such as the DM60 may be a good choice.

These larger format solutions take much of the manual labor out of the dyeing process and include programmed settings for different types of parts and colors. However, higher upfront costs mean the return on investment will be faster for those printing very high volumes of parts.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Cómo teñir piezas impresas en 3D mediante SLS

Formlabs has conducted extensive testing to determine what colors can be achieved with SLS printed parts using accessible, low-cost dyeing techniques. The dye used was RIT ProLine dye, a low-cost, easily accessible powder that contains a mixture of direct, acid, and disperse dyes, and is effective on nylon fibers. Further variables tested include temperature, acidity, saturation of dye, duration of dye time, and detergent additive in the dye solution. Both Nylon 12 Powder and Nylon 12 White Powder parts were tested and the effect of each variable is covered below.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

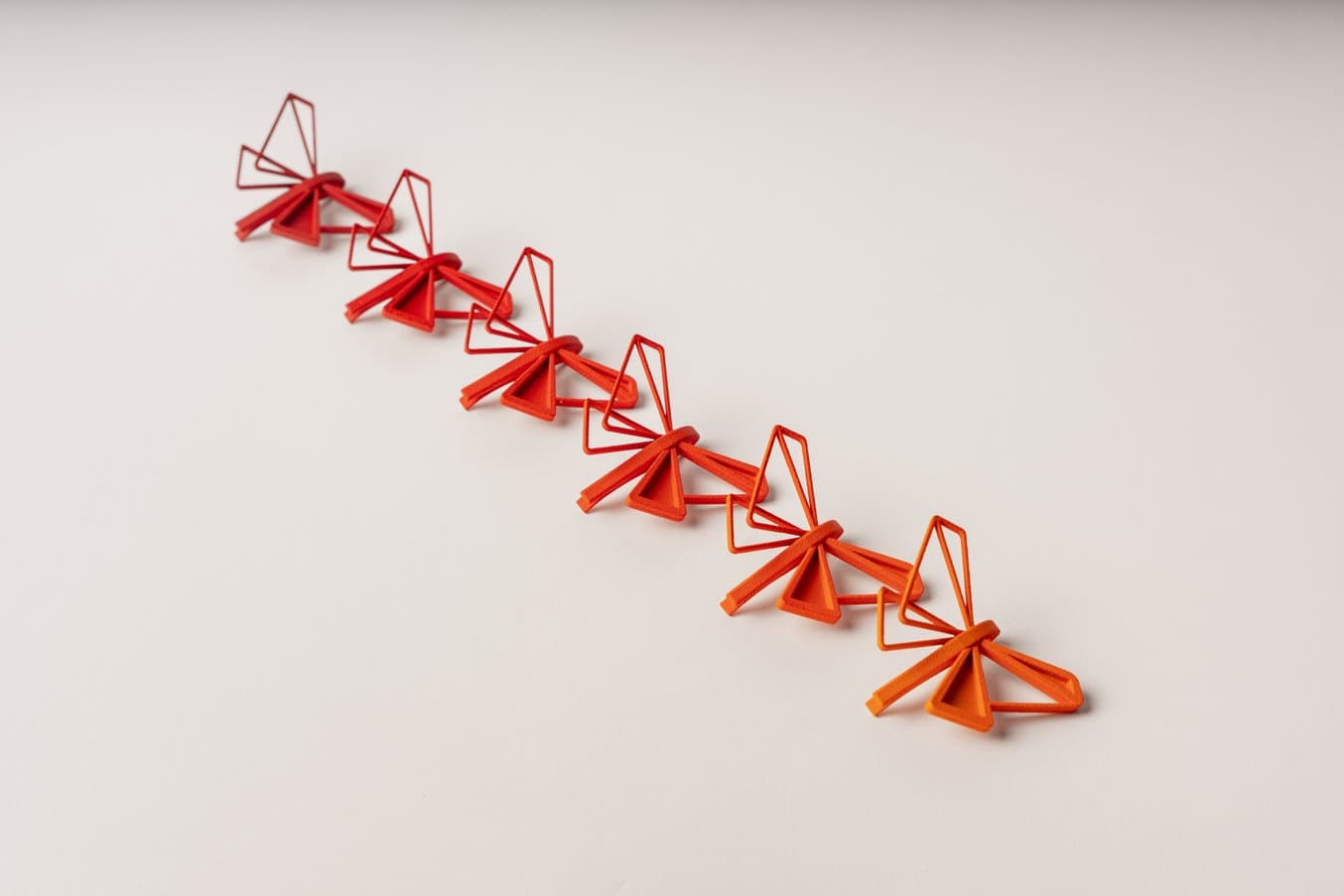

Temperature and time have a huge impact on the final part color. Based on our tests, higher temperatures lead to a more saturated color in a shorter amount of time.

The parts in this image were dyed in the same dye bath, at 90 °C, with parts removed at 3-minute intervals from right to left.

If a lighter shade is desired, consider reducing the dye solution temperature to 70 °C or lower. At higher temperatures, saturation can occur extremely quickly, leaving very little margin for deviation and potentially resulting in variance of finished parts. There is an increase in part uptake of dye over time but this trend plateaus at 20-25 minutes as the part reaches a saturation point where no more dye can penetrate the surface.

Changing Dye Bath Colors

When changing the colors of a dye bath, first drain the entirety of the current solution and dispose of it according to local regulations and the dye’s safety data sheet (SDS). Alternatively, the dye bath can also be stored in liquid form to be used at a later date, according to local safety regulations.

As a dye solution is heated and cycled, some settling can occur. Due to this, the walls and base of the tank should be wiped down after draining to ensure no cross-contamination of colors occurs. Once these two steps are completed, a rinse with clean water is recommended to make sure any remaining dye in the circulation system is removed.

Only after the machine is cleaned should a new dye solution be prepared. If multiple colors are going to be used frequently, getting multiple circulators to prevent frequent swapping is an option.

Ken Pillonel designed an easy workaround for this step, using large flasks filled with dye solution within the tank, and a rotating magnet on the bottom of them to agitate the liquid. This way, he can use different flasks for each dye color, without waiting for cooling and cleaning. To learn more about his method and this workaround, watch his video, shared at the end of the article.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

Combinaciones de colores y materiales

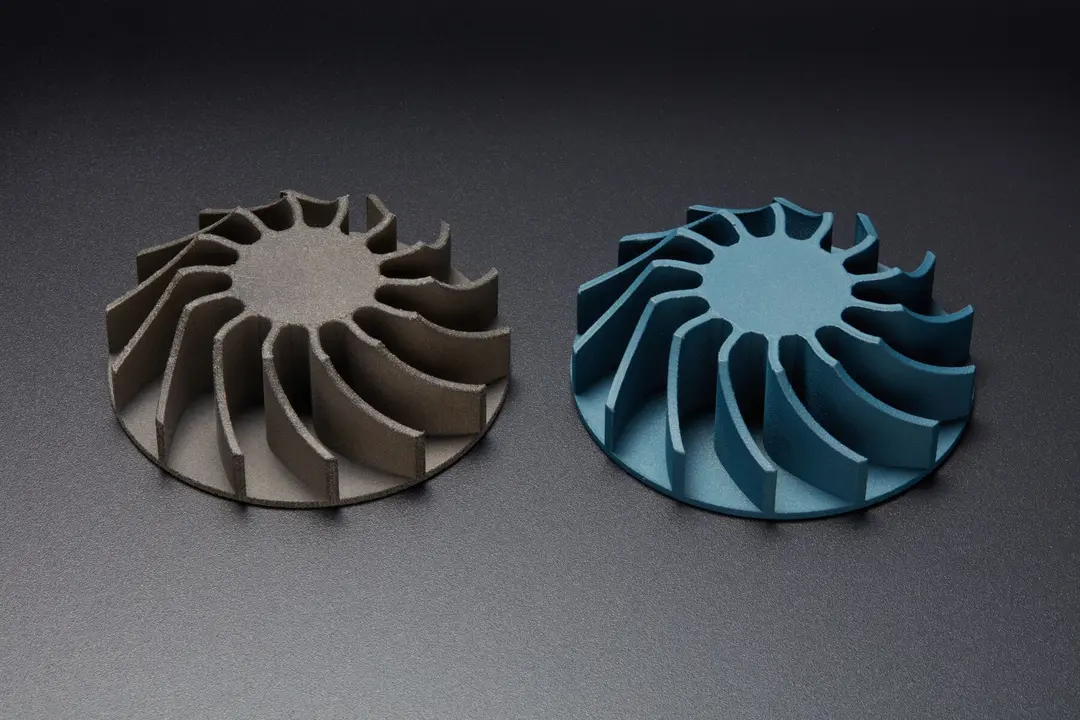

Tinte de piezas blancas

Teñir el Nylon 12 White Powder es la mejor opción para obtener la gama de colores más amplia. El Nylon 12 White Powder se debe utilizar para todos los colores claros, incluidos los pasteles, y los colores vivos.

Piezas impresas en 3D con el Nylon 12 White Powder que se han teñido en una estación de tinte ultrasónico.

Tinte de piezas grises

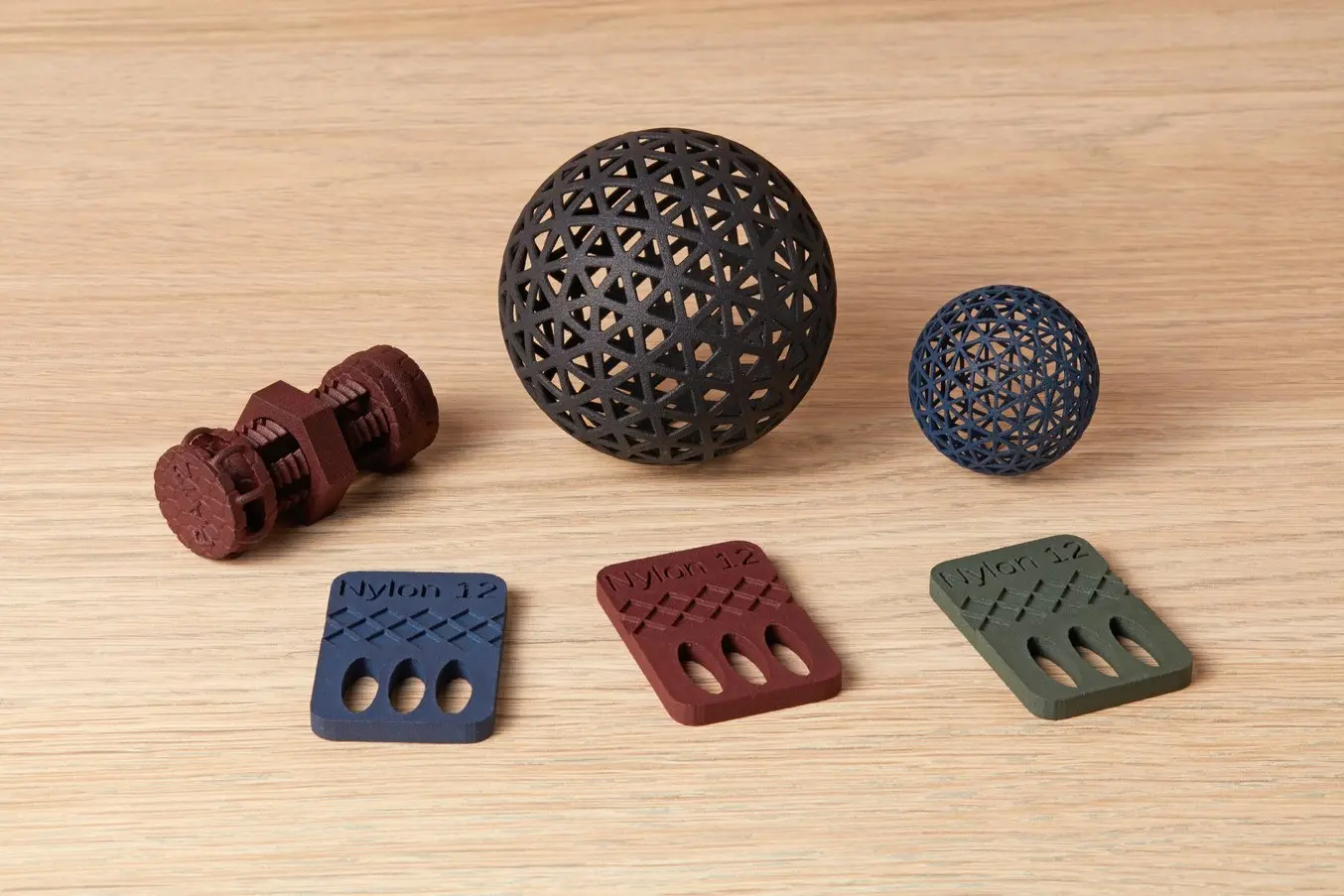

El proceso descrito en nuestro libro blanco se ha utilizado con éxito para teñir impresiones realizadas con el Nylon 12 Powder. Sin embargo, como las piezas impresas con el Nylon 12 Powder son de color gris oscuro, solo se pueden teñir de tonos de color oscuros, que suelen ser más apagados.

Piezas de Nylon 12 Powder de color gris oscuro, teñidas con tonos de color más oscuros.

Tinte de piezas negras

Si el negro es el color final deseado, recomendamos utilizar el Nylon 12 Powder estándar de Formlabs con Rit ProLine Black. Este material tiene un sustrato más oscuro, lo que hace que la transición al negro sea más uniforme.

Aunque es posible teñir de negro piezas hechas con el Nylon 12 White Powder, no es recomendable. El sustrato más claro hace que los colores oscuros sean más difíciles de teñir que hacerlo con el estado oscuro inicial del Nylon 12 Powder.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

Coste

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Mano de obra

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Geometría de la pieza

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

Coste

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Mano de obra

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Geometría de la pieza

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Geometría de la pieza

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Dyeing is ideal for both functional prototyping and end-use production of parts with custom colors to match brand aesthetics.

Tinte de piezas de nylon impresas por SLS: El experimento de Ken Pillonel

Ken Pillonel, ingeniero y fundador del popular canal de YouTube Exploring the Simulation, se ha convertido en una "fábrica de plásticos de una sola persona" gracias al ecosistema SLS de la serie Fuse. Tras expandir sus capacidades y añadir una unidad más de la impresora Fuse 1+ 30W, la Fuse Sift y la Fuse Blast, Pillonel ha podido fabricar sus estuches de carga de uso final para AirPods usando Nylon 12 Powder teñido. Para profundizar en la impresión 3D SLS para piezas de uso final, en cómo preparar un proceso de trabajo con nitrógeno y en cómo conseguir un proceso de trabajo de tinte que sea preciso, repetible y de alta calidad, ve el vídeo de Pillonel que aparece a continuación.

Cómo empezar a teñir impresiones 3D SLS

Al disponer de procesos de trabajo asequibles como el tinte ultrasónico, teñir piezas impresas mediante SLS es un modo fácil y accesible de potenciar la estética de tus impresiones.

Teñir piezas de Nylon 12 White Powder y Nylon 12 Powder utilizando equipamiento y consumibles de tinte fácilmente accesibles es un método rentable y eficiente para aplicar color a las piezas acabadas, independientemente del tono deseado. Este proceso ofrece una alternativa viable a los revestimientos tradicionales, ya que requiere un trabajo manual mínimo y colorea geometrías complejas de forma eficaz.

Si estás explorando un uso que requiere piezas de nylon en color impresas en 3D mediante SLS, ponte en contacto con un representante para saber más sobre el ecosistema Fuse y el tinte de piezas de nylon.

Si quieres saber más acerca de la impresión 3D SLS o de cómo teñir piezas impresas en 3D mediante SLS, ponte en contacto con nuestro equipo. Para conocer los resultados completos de nuestros ensayos y el proceso de trabajo paso a paso, descarga el libro blanco.