Les pièces imprimées en 3D par frittage sélectif par laser (SLS) sont de plus en plus utilisées dans des secteurs aussi divers que l'aérospatiale et la conception de lunettes, en raison de leurs propriétés mécaniques supérieures et de leurs méthodes de production rentables. Pour améliorer encore leurs propriétés esthétiques et mécaniques, les utilisateurs de l'impression 3D SLS ont souvent recours à des techniques de post-traitement telles que la teinture, le revêtement, le placage ou la peinture.

La teinture des pièces imprimées en 3D avec Nylon 12 White Powder sur les imprimantes 3D SLS de la série Fuse débloque un énorme éventail de possibilités pour les clients, qui peuvent ainsi fabriquer des prototypes convaincants et fabriquer des pièces prêtes pour la production dans plusieurs couleurs.

Dans ce guide, nous décrirons le processus de teinture des pièces imprimées en 3D par SLS et passerons en revue les nombreux avantages de ce processus. Pour connaître l'ensemble du processus de teinture, téléchargez notre livre blanc.

Pourquoi faut-il teindre les pièces imprimées en 3D par SLS ?

Les pièces imprimées en 3D par SLS sont de plus en plus courantes à toutes les étapes du processus de conception et de fabrication. En raison de la surface légèrement granuleuse des pièces imprimées en 3D par SLS, les solutions de post-traitement telles que le lissage, le revêtement et la teinture gagnent également en popularité.

La teinture est une méthode peu coûteuse pour colorer les pièces SLS et améliorer leur esthétique tout en conservant leurs propriétés mécaniques. Qu'il s'agisse de petits lots de pièces colorées ou d'une production en grande série dans le système de couleurs Pantone, il existe un procédé de teinture adapté à chaque processus de travail.

Notre équipe a testé quatre méthodes de teinture populaires et a présenté ses résultats. Ce guide fournit une vue d'ensemble, mais pour voir les résultats complets, téléchargez notre livre blanc.

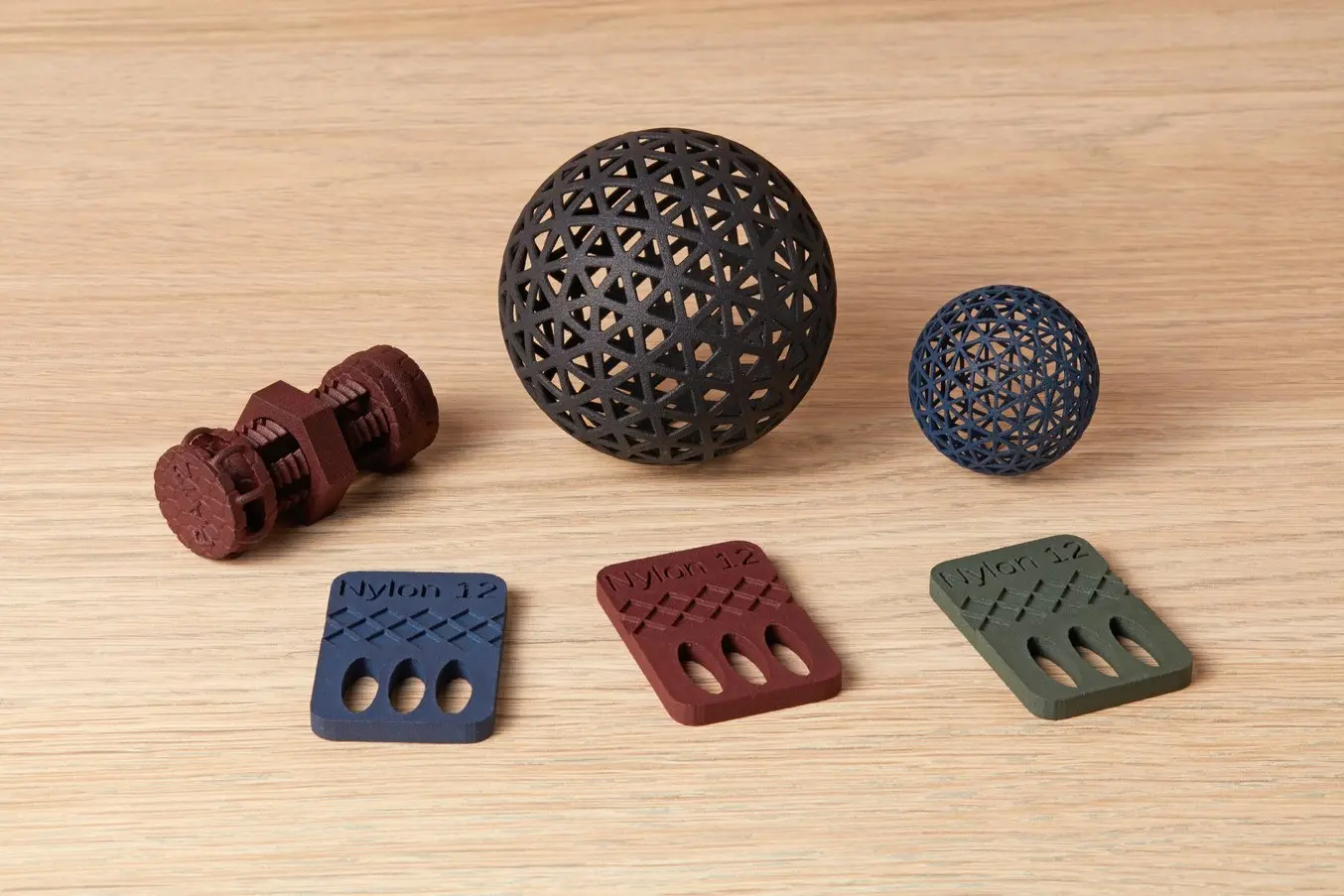

La teinture est idéale à la fois pour le prototypage fonctionnel et pour la production de pièces finales sur mesure, avec des couleurs personnalisées correspondant à l'esthétique de la marque.

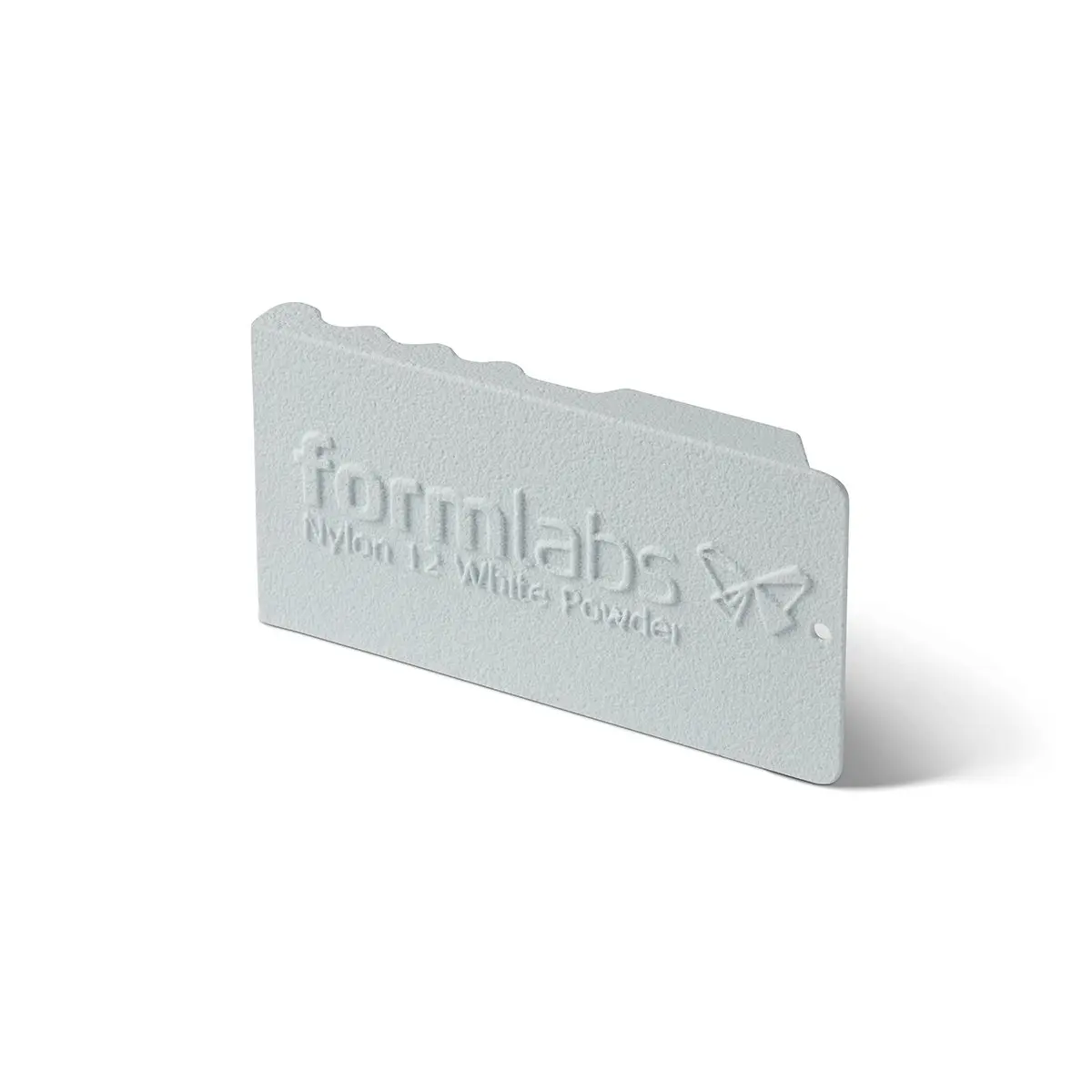

Commander un échantillon SLS gratuit

Examinez et constatez par vous-même la qualité Formlabs. Nous vous enverrons un échantillon gratuit imprimé avec Nylon 12 White Powder sur la Fuse 1+ 30W à votre bureau.

Dyeing Equipment

We tested dyeing equipment to assemble the optimal setup for dyeing Nylon 12 White Powder. Below, we outline the hardware, dye mixture, and dye bath parameters that achieved the best results in our testing.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

| Méthode | Taille | Quantité | Couleur | Stable aux UV | Coût |

|---|---|---|---|---|---|

| Bain de teinture | ★★ | ★★ | ★★ | Non | Moins de 50 € |

| Teinture par ultrasons | ★★★ | ★★★ | ★★★ | Non | De 100 à 1000 € |

| Teinture haute pression | ★★ | ★★ | ★★★★ | Non | De 100 à 500 € |

| DyeMansion DM60 | ★★★★★ | ★★★★★ | ★★★★★ | Oui | Plus de 50 000 € |

The hardware that we recommend for dyeing is the ESVC-28 - Spectrum Thermal Circulator from Winco. This machine is affordable, available from multiple sources, and is easy to set up and use.

US Source: $699.99

EMEA Source: €659.99

APAC Source: $299

The Winco ESVC-28 Spectrum Thermal Circulator is an ideal solution for ultrasonic dyeing.

Any system that is able to reach the necessary temperatures of 80 °C to 90 °C as well as circulate the solution should be adequate for dyeing. We also recommend having stainless steel tongs nearby to assist in removing parts from the dye bath.

There are also industrial solutions available on the market for dyeing SLS parts, like the Dyemansion DM60, that are cost-effective for high volumes of parts and when extremely consistent results are necessary. This product is capable of holding up to 60 L of components per dyeing batch and will automatically inject the dye as well as rinse the parts post-dye.

The DM60 confers a much higher degree of consistency when compared to pot dyeing as well as improved UV stability of the dyes. An additional service offered by Dyemansion is tailored color development. For users with a strict color requirement or who are looking to dye a very high volume of parts (end-use parts, production runs of 1000+ units), using an industrial machine such as the DM60 may be a good choice.

These larger format solutions take much of the manual labor out of the dyeing process and include programmed settings for different types of parts and colors. However, higher upfront costs mean the return on investment will be faster for those printing very high volumes of parts.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Comment teindre les pièces imprimées en 3D par SLS

Formlabs has conducted extensive testing to determine what colors can be achieved with SLS printed parts using accessible, low-cost dyeing techniques. The dye used was RIT ProLine dye, a low-cost, easily accessible powder that contains a mixture of direct, acid, and disperse dyes, and is effective on nylon fibers. Further variables tested include temperature, acidity, saturation of dye, duration of dye time, and detergent additive in the dye solution. Both Nylon 12 Powder and Nylon 12 White Powder parts were tested and the effect of each variable is covered below.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

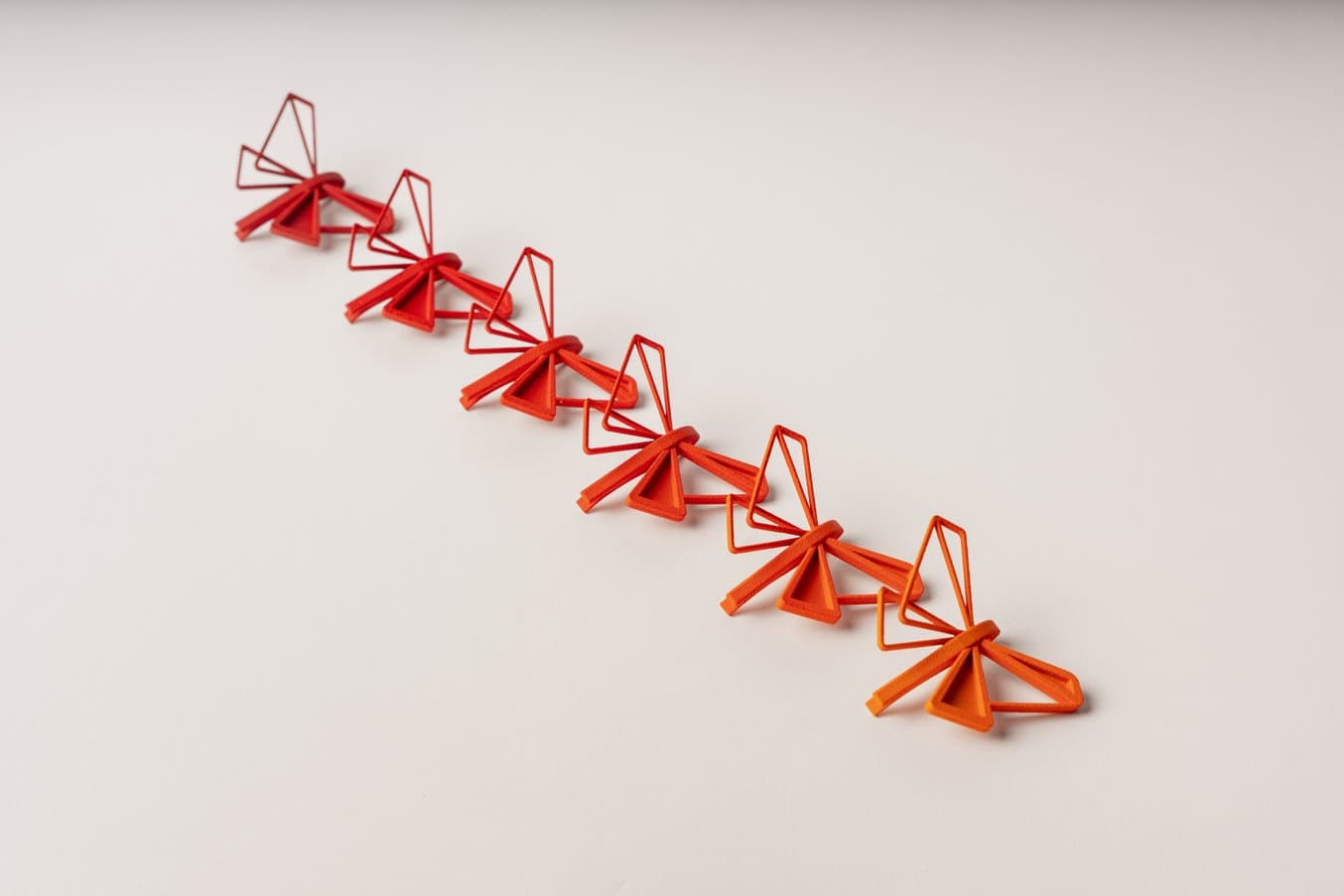

Temperature and time have a huge impact on the final part color. Based on our tests, higher temperatures lead to a more saturated color in a shorter amount of time.

The parts in this image were dyed in the same dye bath, at 90 °C, with parts removed at 3-minute intervals from right to left.

If a lighter shade is desired, consider reducing the dye solution temperature to 70 °C or lower. At higher temperatures, saturation can occur extremely quickly, leaving very little margin for deviation and potentially resulting in variance of finished parts. There is an increase in part uptake of dye over time but this trend plateaus at 20-25 minutes as the part reaches a saturation point where no more dye can penetrate the surface.

Changing Dye Bath Colors

When changing the colors of a dye bath, first drain the entirety of the current solution and dispose of it according to local regulations and the dye’s safety data sheet (SDS). Alternatively, the dye bath can also be stored in liquid form to be used at a later date, according to local safety regulations.

As a dye solution is heated and cycled, some settling can occur. Due to this, the walls and base of the tank should be wiped down after draining to ensure no cross-contamination of colors occurs. Once these two steps are completed, a rinse with clean water is recommended to make sure any remaining dye in the circulation system is removed.

Only after the machine is cleaned should a new dye solution be prepared. If multiple colors are going to be used frequently, getting multiple circulators to prevent frequent swapping is an option.

Ken Pillonel designed an easy workaround for this step, using large flasks filled with dye solution within the tank, and a rotating magnet on the bottom of them to agitate the liquid. This way, he can use different flasks for each dye color, without waiting for cooling and cleaning. To learn more about his method and this workaround, watch his video, shared at the end of the article.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

Combinaisons de couleurs et de matériaux

Teinture des pièces blanches

La teinture de Nylon 12 White Powder est la meilleure option pour obtenir la plus large gamme de couleurs. Nylon 12 White Powder doit être utilisée pour teindre toutes les couleurs claires, y compris les pastels, et les couleurs vives.

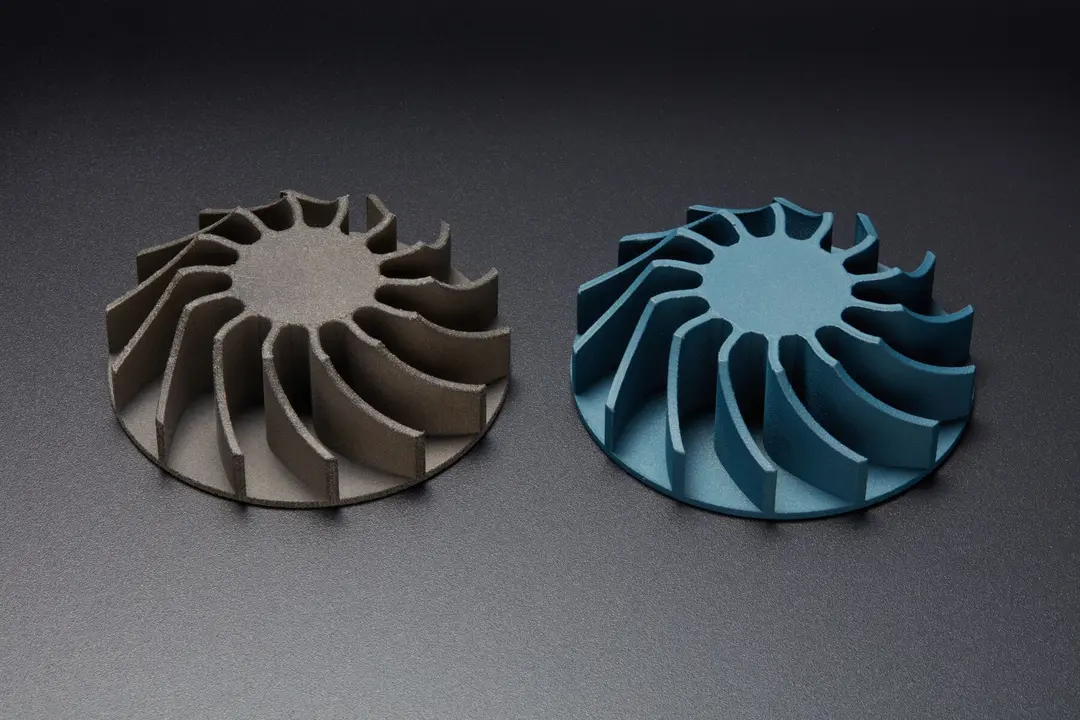

Pièces imprimées en 3D avec Nylon 12 White Powder teintées dans une station de teinture à ultrasons.

Teinture des pièces grises

Le processus décrit dans notre livre blanc a été utilisé pour teindre avec succès des pièces en Nylon 12 Powder. Cependant, comme les pièces imprimées avec Nylon 12 Powder sont de couleur gris foncé, seules des nuances de couleurs plus foncées sont possibles, et celles-ci sont souvent plus ternes.

Des pièces en Nylon 12 Powder gris foncé teintées dans des tons plus sombres.

Teinture des pièces en noir

Si la couleur finale souhaitée est le noir, nous recommandons l'utilisation de Nylon 12 Powder standard de Formlabs avec Rit ProLine Black. Ce matériau a un substrat plus foncé, ce qui rend la transition vers le noir plus uniforme.

Il n'est pas recommandé de teindre les pièces en Nylon 12 White Powder en noir, bien que cela soit possible. Le substrat plus léger rend les couleurs foncées plus difficiles à obtenir par rapport à la teinture de l'état foncé initial de Nylon 12 Powder.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

Coût

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Main d'œuvre

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Géométrie de la pièce

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

Coût

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Main d'œuvre

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Géométrie de la pièce

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Géométrie de la pièce

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Dyeing is ideal for both functional prototyping and end-use production of parts with custom colors to match brand aesthetics.

Teinture de pièces en Nylon Powder SLS : l’expérience de Ken Pillonel

Ken Pillonel, ingénieur et fondateur de la chaîne YouTube populaire Exploring the Simulation, a créé une « usine de plastique à lui tout seul », avec l’écosystème SLS de la série Fuse. Après avoir développé ses capacités et ajouté une deuxième imprimante Fuse 1+ 30W, Fuse Sift et Fuse Blast, Ken Pillonel a pu fabriquer ses boîtiers de charge Airpods destinés à l’utilisation finale en Nylon 12 White Powder teinté. Pour une discussion approfondie sur l’impression 3D SLS pour les pièces d’utilisation finale, la mise en place d’un flux de travail à l’azote et la détermination d’un flux de travail de teinture précis, reproductible et de haute qualité, regardez la vidéo de Ken Pillonel ci-dessous.

Se lancer dans la teinture des pièces imprimées en 3D par SLS

Avec des flux de travail abordables tels que la teinture par ultrasons, la coloration de pièces SLS est une méthode simple et économique pour améliorer l'esthétique de vos créations.

La teinture de pièces en Nylon 12 White Powder et Nylon 12 Powder à l'aide de matériel et de consommables de teinture facilement accessibles est une méthode rentable et efficace pour colorer des surfaces finies, quelle que soit la teinte souhaitée. Ce procédé offre une alternative viable aux revêtements traditionnels, qui nécessitent une main-d'œuvre minimale et permettent de colorer efficacement des géométries complexes.

Si vous envisagez une application nécessitant des pièces en nylon imprimées par SLS et colorées, contactez un représentant pour en savoir plus sur l'écosystème Fuse et la teinture des pièces en nylon.

Pour en savoir plus sur l'impression 3D SLS ou la teinture de pièces imprimées en 3D SLS, contactez notre équipe. Pour consulter les résultats complets des essais et le processus de travail étape par étape, téléchargez le livre blanc.