Precise, Durable, and Affordable Custom Orthotic Insoles With 3D Printing

You can now produce custom orthotic insoles easily and affordably in house with a simple and clean digital workflow, reducing costs and labor needs, and improving turnaround time and comfort for your customers.

Why Go Digital?

Simpler Workflow, More Control

Lower Costs

Faster Turnaround Time

Fuse 1+ 30W: Compact, Industrial Quality SLS 3D Printer

See Also

Easily Start, Easily Scale

Get started easily with a low upfront cost and pay only for the capacity that you really need. Scale up as demand increases and minimize the risk of downtime with multiple printers. Avoid hidden costs, expensive service contracts, and electrical work and start printing within one day of delivery.

| Fuse 1+ 30W | Large Format MJF | |||

| CapEx for the Initial Setup | USD $50,000 - USD $55,000 | USD $500,000+ | ||

| CapEx per Additional Printer | USD $35,000 | USD $350,000+ | ||

| Service Plan per Year | USD $5,000 | USD $35,000+ | ||

| Power Requirements | Standard 120V (US) or 230V outlet | Dedicated 380-415V line | ||

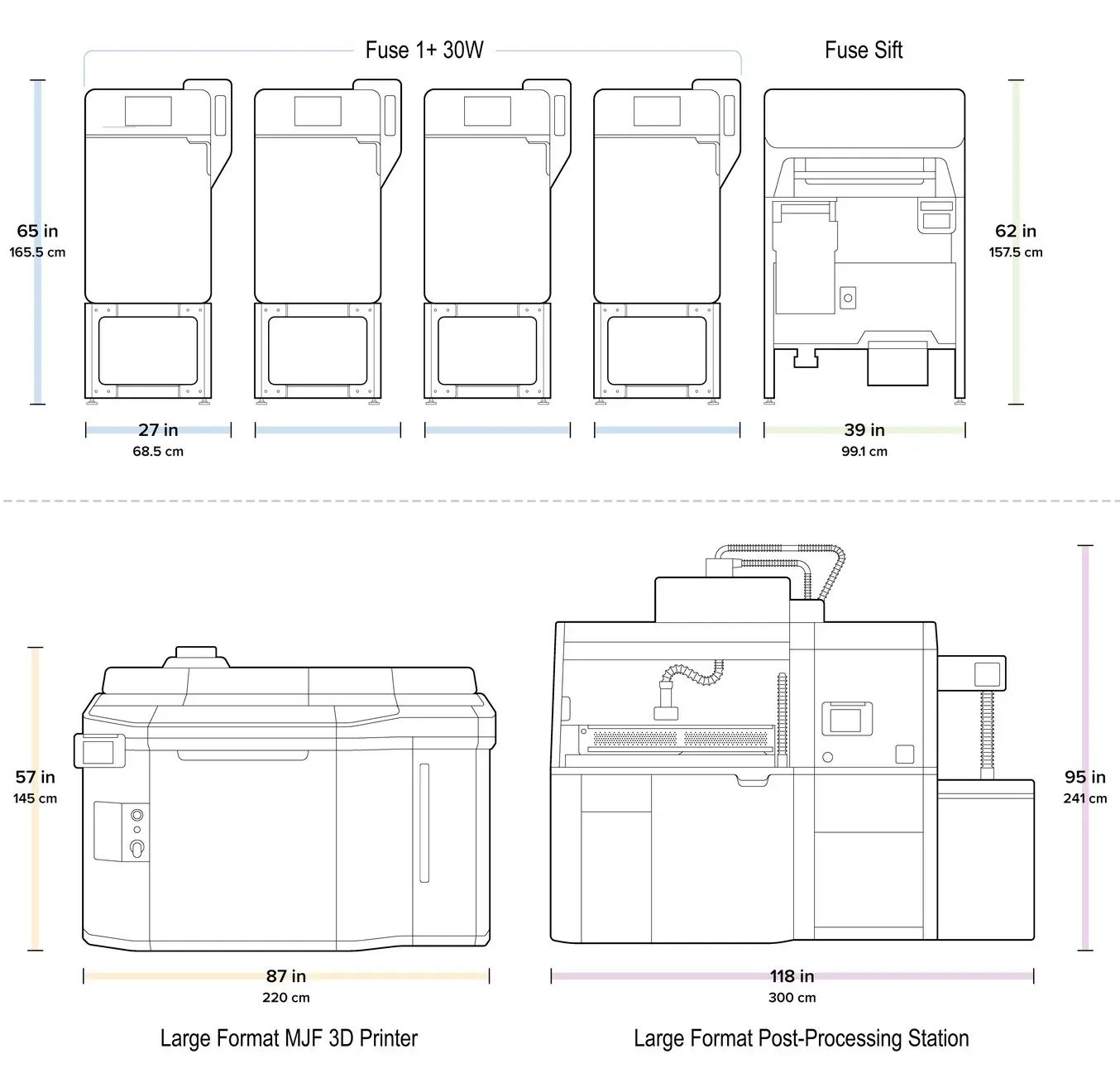

| Dimensions (L x W x H) | 68 x 64 x 107 cm 27 x 25 x 42 in | 221 x 119 x 145 cm 87 x 47 x 57 in |

Curious to see how much you can save? Contact our team to run the numbers specifically for your parts and business.

A four printer Fuse 1+ 30W setup is the size of one large-format MJF setup.

See Also

Tested for Performance and Functionality

Discover How 3D Printing Revolutionized One Lab's Workflow

Watch the video: How 3D Printers Digitized Insole Production at a Family-Owned Podiatry Lab

See Also

4 Easy Steps to Deliver Millions of Patient Steps

1. Scan

Scan foam impressions, casts, or patients directly using a smartphone or iPad-based scanner, professional gait scanners, or pressure plates.

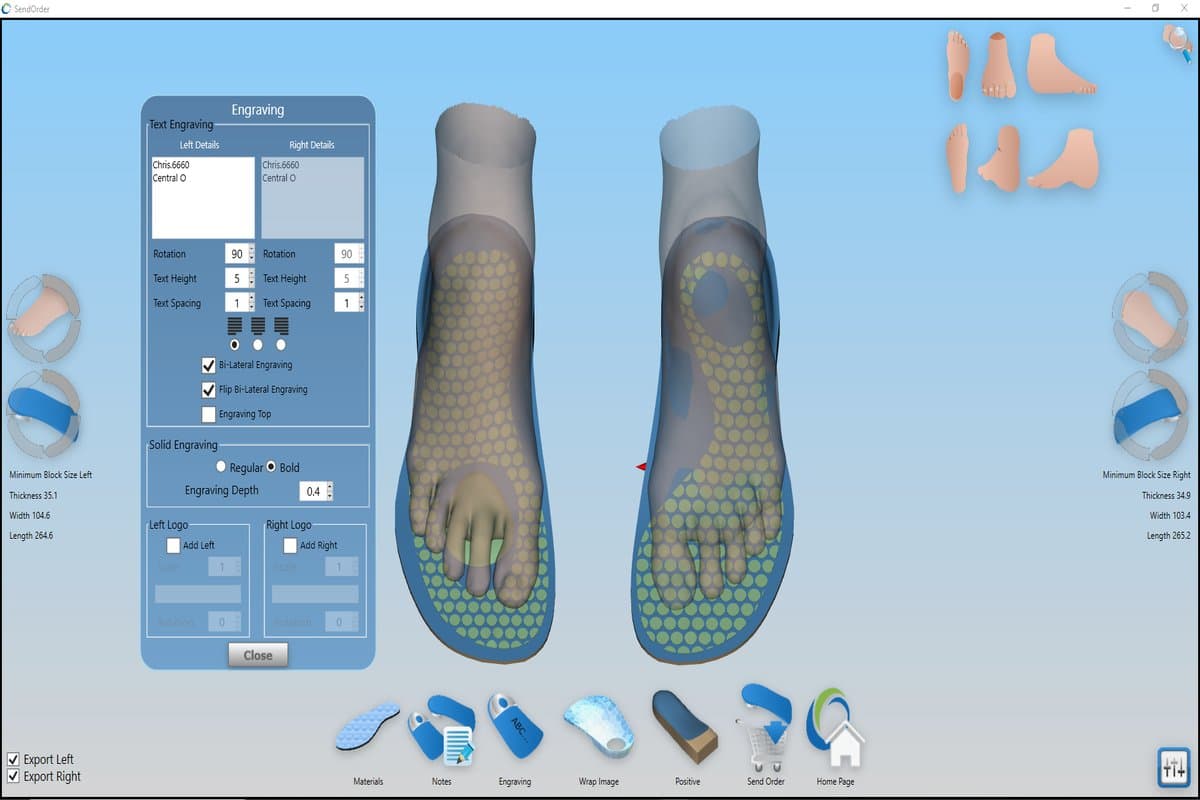

2. Design

Use insole design software to create the desired features and supports. Include heel cups and other features to avoid manual steps while finishing.

3. Print

Produce the insoles or insole shells in batches on the Fuse 1+ 30W and post-process the parts on the Fuse Sift.

4. Finish

Assemble the 3D printed insole with covers, posts, and pads as needed. Eliminate manual trimming or grinding by leveraging a digital scan and precise design.

Get Started With 3D Printing Insoles

Get in touch with our medical 3D printing experts for a 1-1 consultation to find the right solution for your business, receive ROI analysis, test prints, and more.