How to 3D Print With Formlabs Resins on Third-Party Resin 3D Printers

A core mission of Formlabs continues to be increasing access to 3D printing, across our hardware, materials, and software products. With the announcement of the new Form 4 mSLA 3D printer, Formlabs has also released new resin formulations engineered to work incredibly well with similar printing technologies.

While these materials perform the most reliably and accurately when used with the Form 4 ecosystem, they can also be used in lower-powered resin printers. In an effort to allow anyone to produce reliable and robust 3D printed parts safely, we are now releasing print settings for our General Purpose V5 and Tough 2000 V1.1 resins to be used in a variety of low-cost resin 3D printers.

Validated Print Settings for Third-Party Resin 3D Printers

Formlabs Materials Scientists and Settings Optimization Engineers have printed hundreds of times and invested weeks of research and development into creating and validating these settings, ensuring consistent and high-quality prints with minimal hassle. Settings are available for download below and are integrated into both Chitubox and Lychee slicers.

Validated settings are currently available for the following printers:

- Elegoo Mars 4

- Phrozen Sonic Mighty 8K

- Anycubic Photon M2

Settings profiles include standard print settings values, as well as wash and cure specifications when used with the Anycubic Wash/Cure Combo 3.0. All final properties match the values stated on the TDS within +/- 20%. It is possible to more closely match the stated TDS values when printing on a low cost printer if the parts are post-cured with a curing unit that utilizes both light and heat, such as the Form Cure, while following the recommended curing schedule.

Due to the large variety of non-Formlabs printer types and models, it is difficult for the Formlabs Support Team to provide meaningful service. Please contact the manufacturer of the 3D printer for technical support. Reach out to Formlabs if the resin cartridge arrives damaged.

We want to hear from you! What resins and/or printers would you like to see us make settings for next?

Fast, Strong, and Safe General Purpose and Engineering Resins

Whether you’re a hobbyist, educator, or small business owner, versatility is key when it comes to 3D printing materials and Formlabs’ General Purpose and Engineering Resins offer just that. From functional prototypes to intricate models, these resins handle a wide range of applications with ease.

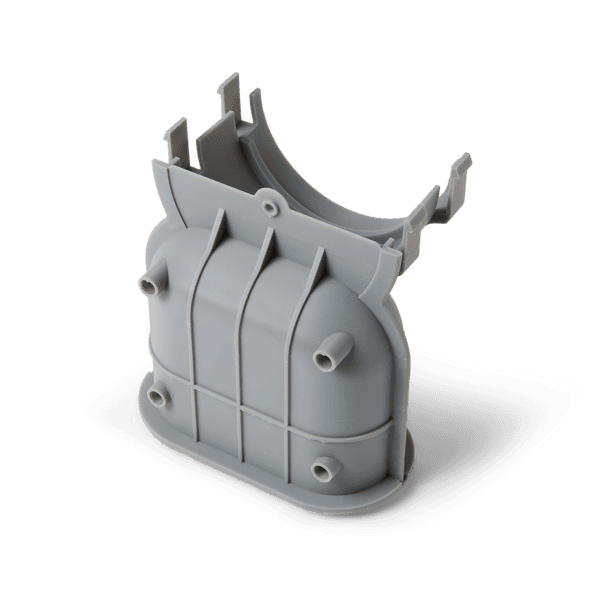

Grey Resin

Create parts that are stiff and strong with a surface finish that rivals injection molding.

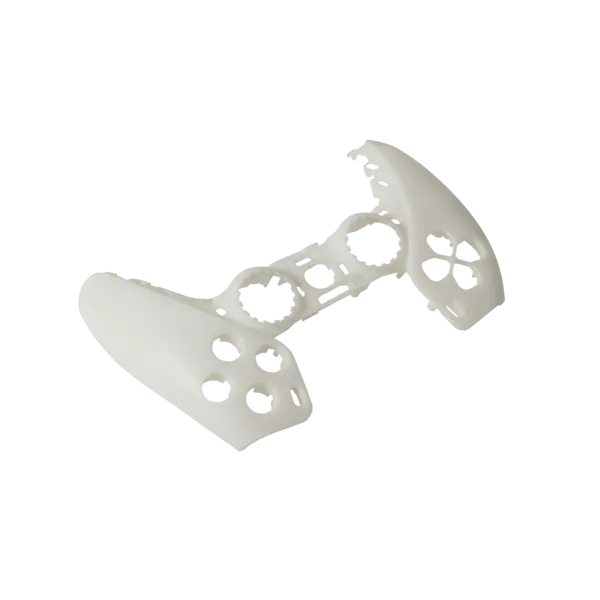

White Resin

Create parts that are stiff and strong with a surface finish that rivals injection molding.

Black Resin

Create parts that are stiff and strong with a surface finish that rivals injection molding.

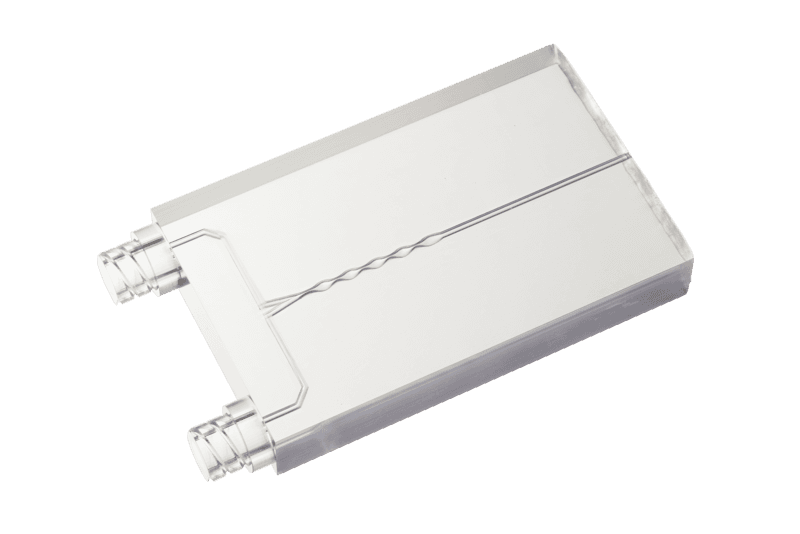

Clear Resin

Create parts that are stiff and strong with a smooth surface finish that rivals acrylic.

Tough 2000 Resin

Produce functional prototypes as well as jigs, fixtures, and end use parts with similar strength and stiffness to ABS.

Despite being standard resins, Formlabs General Purpose V5 Resins are strong and non-brittle, performing more like resins marketed as “ABS-Like” on Amazon and by other manufacturers. Similarly, Tough 2000 Resin performs more like real ABS, with incredible toughness and durability.

| Mechanical Property | Practical Meaning | Clear Resin | Black Resin | Grey Resin | White Resin | Tough 2000 Resin |

|---|---|---|---|---|---|---|

| Tensile Modulus (MPa) | Stiffness When Pulled | 2575 | 2450 | 2500 | 2500 | 2200 |

| Elongation at Break | Ductility | 10% | 14% | 15% | 15% | 48% |

| Ultimate Tensile Strength (MPa) | Strength When Pulled | 51 | 57 | 54 | 54 | 46 |

| Notched Izod (J/m) | Strength When Impacted | 29 | 29 | 34 | 34 | 40 |

| Heat Deflection Temperature at 0.45 MPa | Heat Resistance | 56℃ | 61℃ | 62℃ | 62℃ | 63℃ |

Why Choose Formlabs Resins?

Safety

When operating 3D printers in homes or offices, it’s important to consider the safety of the environment and the people in it. Many low-cost resins available on Amazon or other stores today use components that produce very strong odors and fumes. Users, friends, and family in close proximity to printers often complain of headaches as well as eye and throat irritation. Formlabs resins were specifically engineered to be extremely low odor and to produce minimal volatile organic compounds (VOCs), with all safety information clearly marked on easy to read safety data sheets.

Quality Control

All resins are manufactured at Formlabs Ohio by a staff focused on maintaining the highest levels of safety and quality control. Each batch is checked for key material properties before leaving the facility to ensure little to no variation between cartridges.

Documentation

When it comes to 3D printing, reliability is paramount. Formlabs has built a reputation for producing resins that deliver consistent and reliable results, and a key part of that is documentation. You can always trust that the published Technical Data Sheets (TDS) and Safety Data Sheets (SDS) are readily available, easy to read, and up to date, helping to ensure consistent print results and safe printing practices.

Upgrade to Professional Resin 3D Printing With Form 4

The quality and performance of prints from non-professional resin 3D printers can't match the reliability achieved with the Form 4 printer. The Form 4 is designed to handle higher viscosity materials with ease, thanks to its advanced features like an integrated wiper and heater that ensure optimal resin consistency and performance throughout the printing process. The combination of higher grade hardware and robust print settings results in superior dimensional accuracy and more reliable, repeatable parts.

Unlike hobbyist resin printers, the Form 4's precision engineering and robust build quality consistently deliver professional-grade results, making it the best choice for anyone serious about achieving the highest standards in 3D printing.