How a 3D Scanning Company Created an In-House 3D Printing Service Bureau With the Form 3L

In 2010, David Lynshue saw an opportunity in the growing field of 3D scanning. He created Capture Me in 3D to help customers, from entrepreneurs to large established firms, bring objects to life in a digital space.

After finalizing his customer’s models in CAD software, Lynshue would refer business to local printing bureaus, often with mixed results. What if Capture Me in 3D brought the 3D printing business in-house? Could he do that affordably, without having to run a giant print farm? And would it help him expand his business into new markets?

Lynshue settled on a Form 3L. Read on to learn how in-house large format printing has accelerated business growth, what he likes about the Form 3L, and what’s next.

Buying Their First 3D Printer: The Form 3L

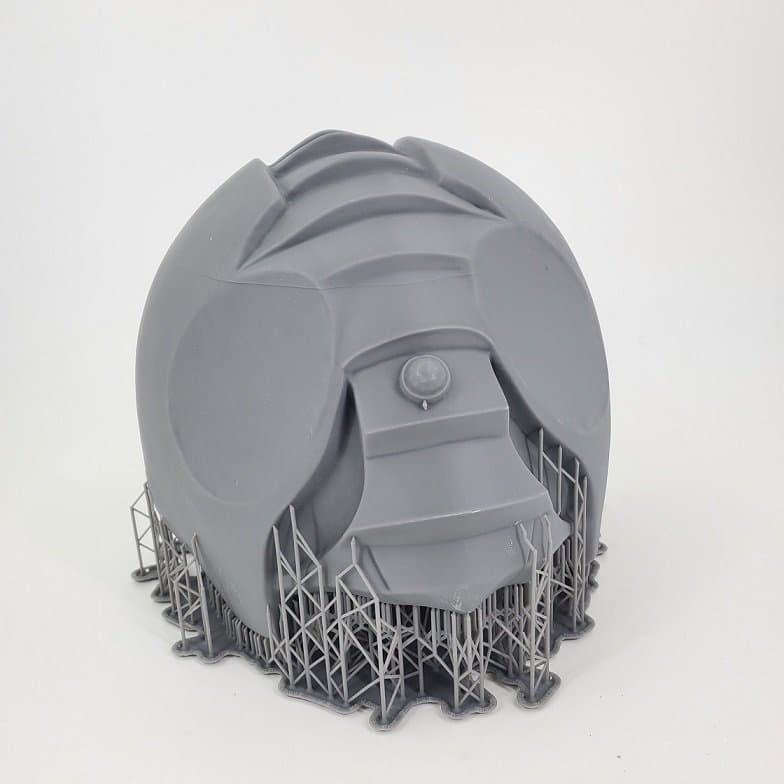

A full size helmet printed by Capture Me in 3D

For many years, Lynshue was eyeing the 3D printing market to see what was available for his small business. He wanted something that was easy to use, accessible for his staff, and could print at a reasonable build volume to meet his client needs. Running a small business meant Lynshue was price sensitive about bringing a printer in-house, and he didn’t have the time to run a large print farm.

Lynshue said, “We have always been interested in selective laser sintering (SLS) and stereolithography (SLA), but I was fearful about getting into 3D printing. Plus, some of the bigger format machines cost a lot of money. So for a long time I kept referring a significant amount of prints to other companies each month, instead of printing myself.”

As Capture Me in 3D’s scanning business expanded, Lynshue came in contact with Formlabs Castable Wax Resin when ordering molds for his jewelry clients. This was one of Lynshue’s first times experiencing Formlabs prints, and he was generally impressed with the quality of Castable Wax Resin. When the Form 3L started shipping, Lynshue decided this was the machine he wanted to try. “We were interested in the Form 3L due to the large print volume. Some other printers we were looking at were just too expensive for our business. Formlabs is a trusted brand. We heard of Formlabs before, and we went with an established company for our first 3D printer,” he said.

So far, the results have been exactly what Lynshue wanted. He’s been printing extensively with the Form 3L, creating whatever his clients need from molds to models.

Now that he has started printing in-house with the Form 3L, Lynshue believes that Capture Me in 3D will be able to quickly make its money back on the machine: “I can recover the entire cost of the Form 3L in a few months. We’re not a super small single person company, but we’re not Microsoft either. This machine was exactly what we were looking for.”

Despite being the company's first Formlabs printer, they were able to get the Form 3L up and running quickly. When Lynshue had questions about print speeds, he said “the Formlabs support team was able to provide us with quick tips and workarounds.” Formlabs’ print preparation software PreForm was designed for both new users and advanced users, generating auto supports and optimizing files to ease the printing process. Lynshue said that he “likes the auto support feature. I’m starting to learn and tinker with the STL files already.”

How 3D Printing Has Changed His Business

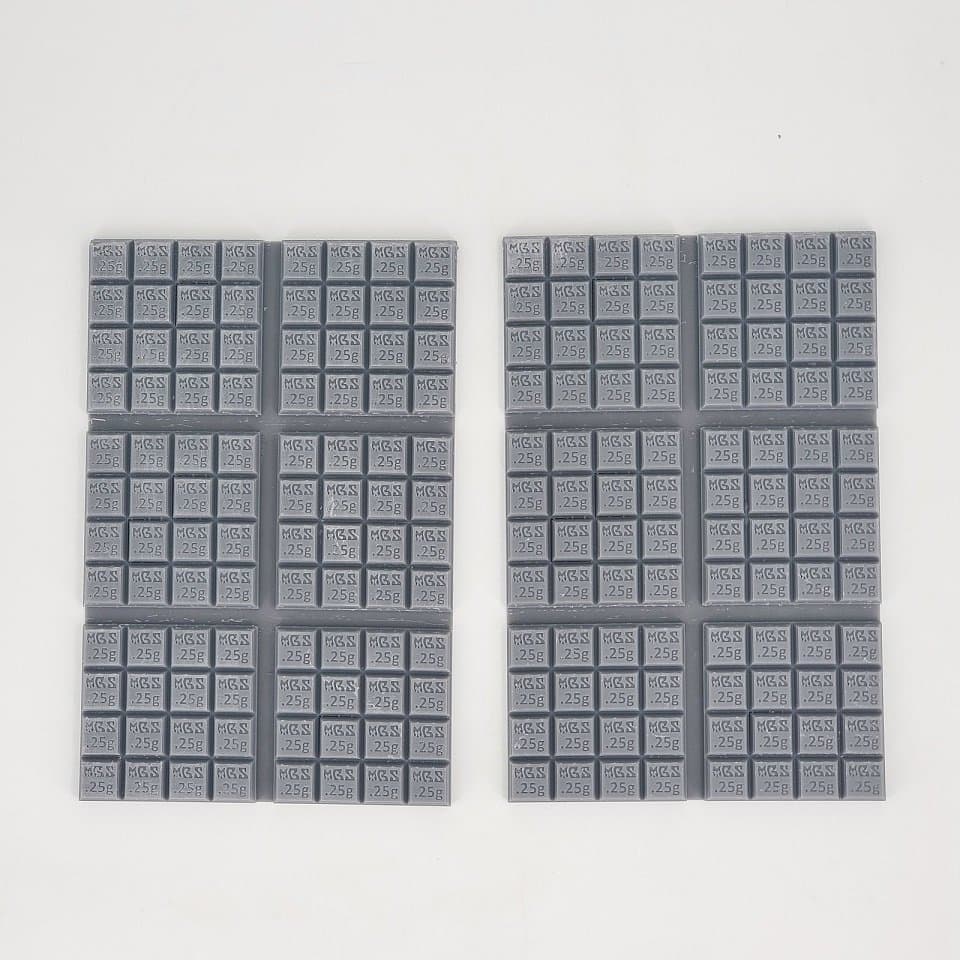

Chocolate molds printed on a Form 3L

For Lynshue, in-house 3D printing with the Form 3L has three benefits:

- Bringing 3D printing in-house and eliminating outsourcing. Now the business can scan, develop, consult, and print in-house, delivering final parts to clients in record time. Lynshue also has quality control over the parts, guaranteeing that his clients are getting the best possible final product.

- Using physical 3D models to close large deals. For example, Lynshue will print a model on his Form 3L and submit it to try and close a deal, knowing the part quality is good enough to impress prospective clients.

- Printing parts that he needs for internal projects. This includes printing parts for a brand new photogrammetry setup.

Bringing 3D printing in-house has allowed the company to accommodate a wider range of customers. Printing full sized molds on the Form 3L has been a huge success. Lynshue said that “we have clients looking to create a master for their silicone molds. I even help teach some of the clients how molding works! It’s amazing the first time you see the full-size print come off the platform. I’ve been outsourcing parts for a long time, but seeing the full Form 3L part with supports is impressive.”

One highlight has been the creation of full-sized molds for a California based chocolate edibles company. “Most people don’t know how competitive the cannabis market is. The biggest factor for brands is standing out with unique and custom designs. With 3D printing, that’s exactly what brands can do” A single custom 3D printed mold on the Form 3L can be used to create hundreds of end use parts, which makes it an excellent financial proposition for both Capture Me in 3D and the edible companies. “People think 3D printing is expensive, but when you’re printing in small batches, especially molds, it’s really competitive. We’re not looking to manufacture millions of items on the printer,” said Lynshue.

Lynshue has been printing his chocolate molds in standard Grey Resin. Grey Resin has two benefits, one being the high-quality finish that makes molding easy. Second is that clients that want to chrome plate the molds, or perform additional post processing steps, which is made easy due to Grey Resin’s smooth finish. Lynshue said that “the supports on the Grey Resin come off easier, leaving less support marks than other resins we have tested. Grey Resin has been our go-to.”

Learn More About Form 3L

According to Lynshue, “we’re personally less interested in smaller format prints right now; the larger format space is growing quickly and that’s where we want to be. We are seeing strong demand for large project orders.” After just a couple of months using the Form 3L, Lynshue is thinking about what’s next. “We might get another Form 3L. We might buy a Fuse 1 to get access to SLS 3D printing. We’re open to adding another printer as the company grows.”

The print possibilities are endless with the Form 3L, a cost-effective, high quality large format LFS 3D printer. Take control of large-scale part production, increase your throughput, and bring your biggest ideas to life with the Form 3L, a cost-effective large format 3D printer that doesn’t compromise on the details. To see a Form 3L part for yourself, request a sample part below.

Why Large-Format Printing Matters

Want to learn more about the Form 3L and Form 3BL ecosystem, and how they compare to other methods of creating large prints?

In this free report, we look at how in-house large-format 3D printing with the Form 3L stacks up against other methods of production, chiefly outsourcing and using FDM printers. We also compare costs between methods, and review when it would be best to bring the Form 3L in-house.