3D Printing Solutions for Manufacturing

Rapid Prototyping From Concept to Pre-Production

Watch the video: How the Concept Cars of Tomorrow Are Made With 3D Printing

See Also

How the Concept Cars of Tomorrow Are Made With 3D Printing

Rome Snowboards Takes Functional Prototyping to New Levels

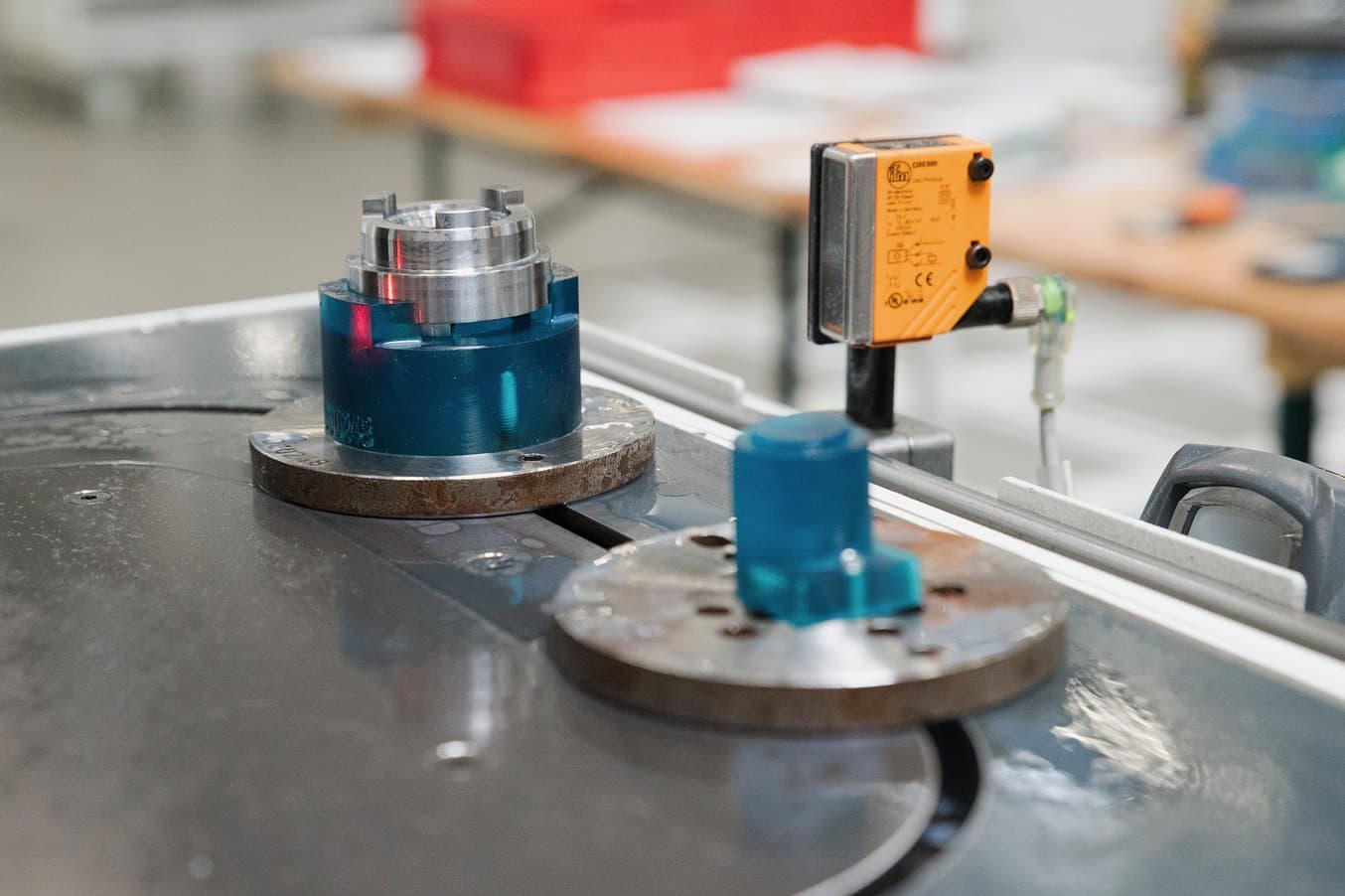

Streamlined Production With In-House Manufacturing Aids and Rapid Tooling

Watch the video: How Ashley Furniture 3D prints custom jigs and fixtures for their manufacturing site.

See Also

Ashley Furniture: From One Idea to 700 3D Printed Parts in the Factory

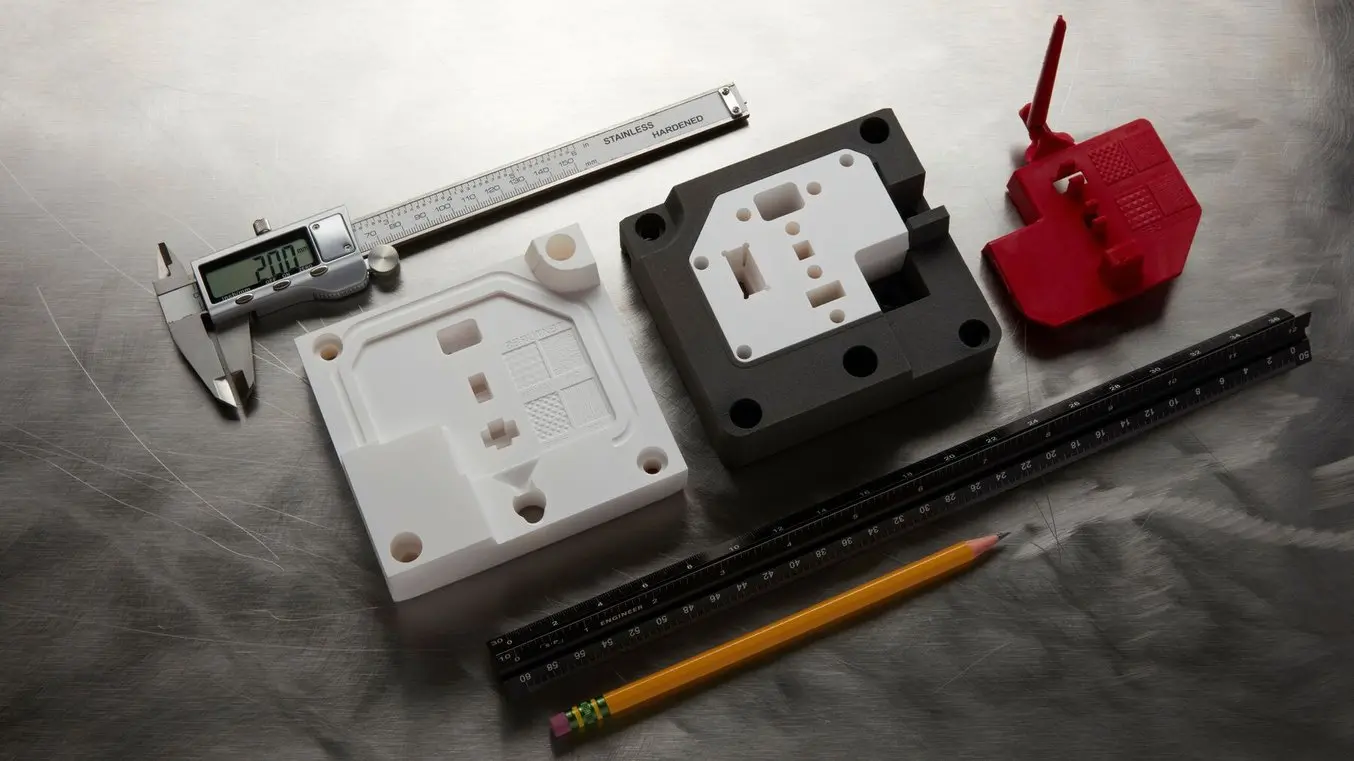

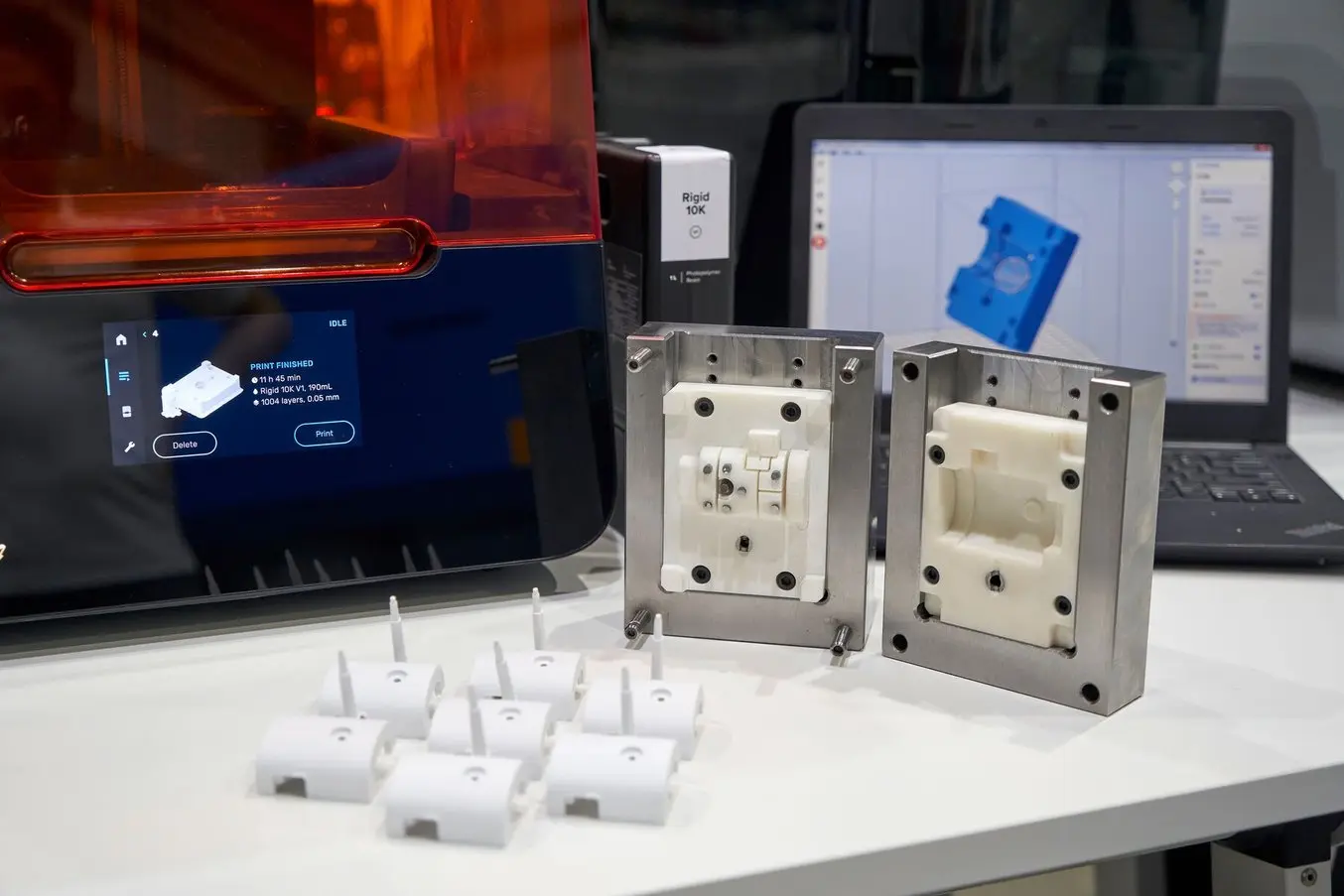

How a Contract Manufacturer Uses 3D Printed Molds for Low-Volume Production

Superior Quality End-Use Parts

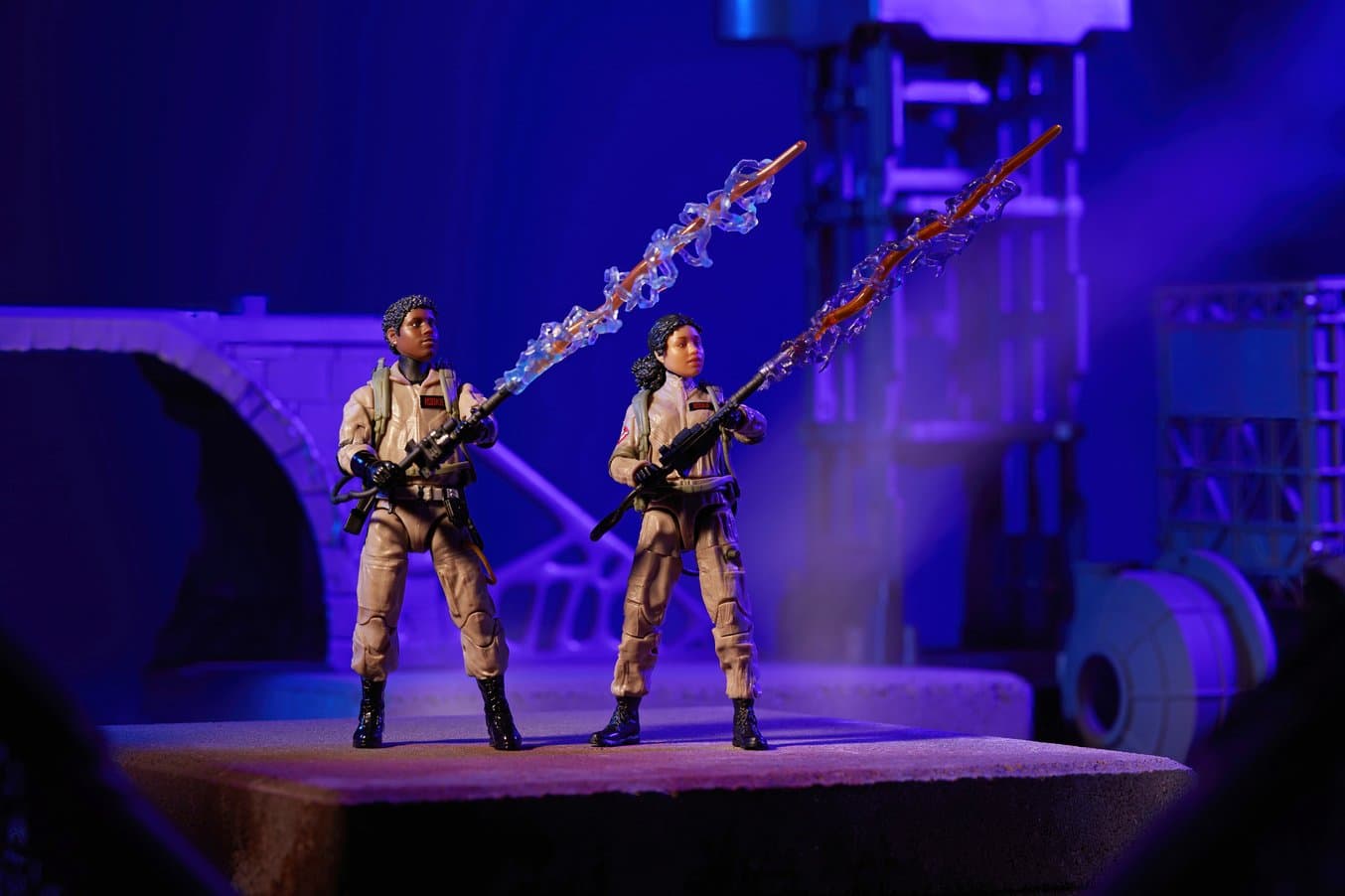

Watch the video: How Hasbro produces mass customized action figures.

See Also

Hasbro and Formlabs Make Anyone a Hero With Custom-Made Action Figures

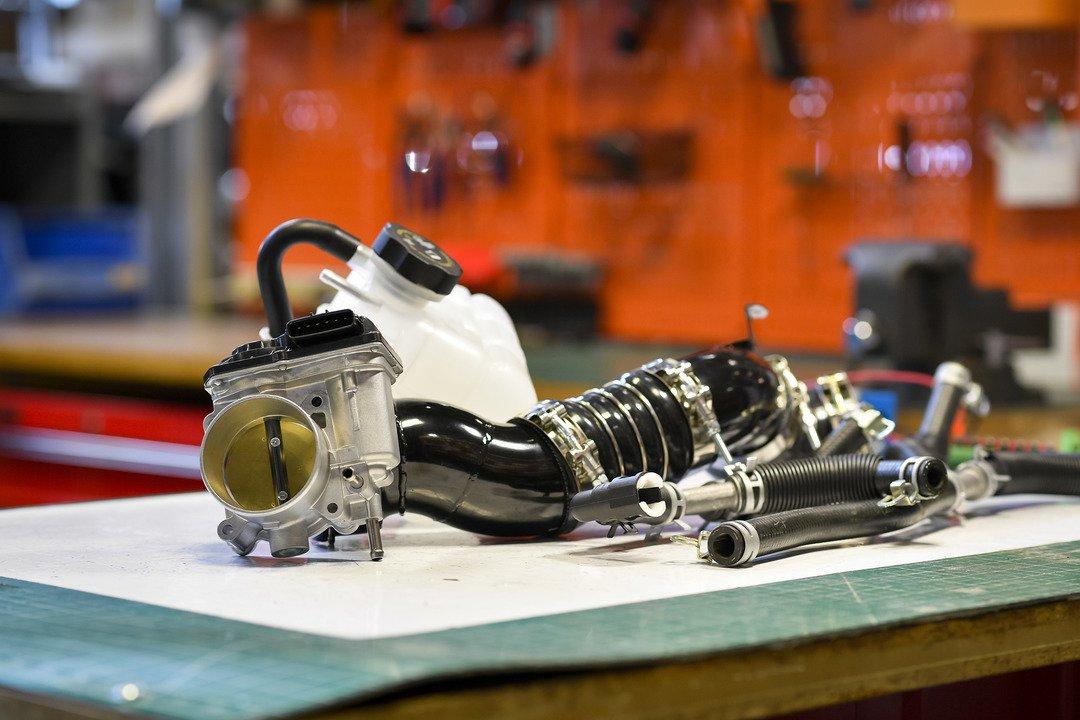

Producing Custom Control Systems for Machines and Vehicles Using SLS 3D Printing

Battle Beaver Uses SLS 3D Printing to Customize Game Controllers

From Design to Final Product Faster Than Ever Before

Never again wait weeks for tooling and parts to arrive from a supplier. Create end-use parts in a matter of hours, right in your office or on your factory floor to save months of development time and be able to respond to customer demands faster.

Design and Iterate

Leverage Formlabs’ extensive range of materials and the same tools that you’ll use for production to iterate and improve your designs each day. Forget about the design restrictions of traditional processes—custom parts and complex designs can be produced with 3D printing in a cost-efficient manner.

Manufacture

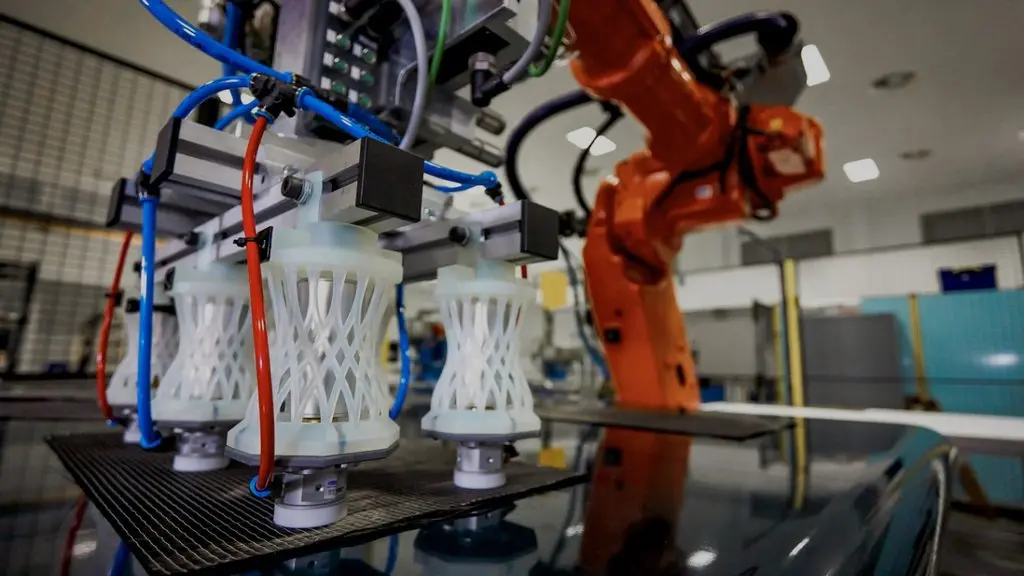

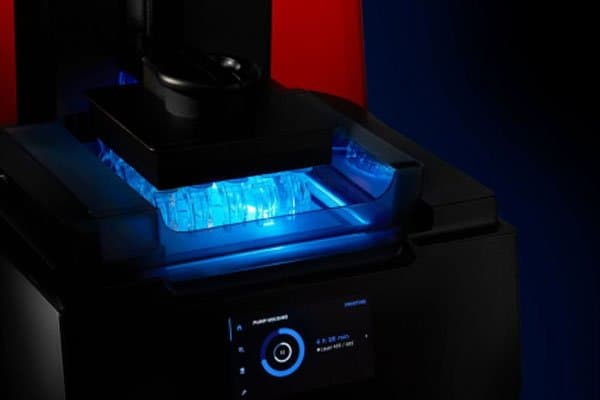

Move to production by relying on the repeatability and consistency of the Formlabs SLA and SLS 3D printers. Produce end-use parts directly with 3D printing, use 3D printed rapid tooling with your traditional manufacturing methods, and shock-proof your supply chain by printing manufacturing aids and repair parts in-house.

Deliver to Market Faster Than the Competition

Complete your workflow with Formlabs post-processing solutions, use the 3D printed part as a component or sub-assembly in manufacturing, and beat your competition to market by streamlining operations.

Scale Up and Be Agile

Scale up as the demand grows without excessive equipment costs, diversify your operations, and answer to the market and your customers faster than your competition without needing to invest in costly tooling changes.

Reduce Costs and Improve Stability by Bringing 3D Printing In-House

Prepare for the unexpected and minimize downtime with on-demand repair and replacement parts, protecting your investment in expensive industrial manufacturing equipment.

16h 57m

$4.42

7-10 business days

$47.72

For a production facility, every minute without a replacement part represents lost value. With an in-house industrial SLS 3D printer like the Fuse 1+ 30W, manufacturers easily design and produce replacement parts in just a few hours.

A Full Suite of 3D Printing Solutions

Form 4

Small to mid-size prototypes and parts

Molds and dies

Connectors and brackets

QA and go/no-go gauges

Form 3L

Mid-size to large prototypes and parts

Molds and dies

Assembly jigs

Toolholding and fixtures

Fuse 1+ 30W

Functional prototypes

End use parts: enclosures, connectors, manifolds

Long-lasting, durable jigs and fixtures

High-Performance Materials for Engineering and Manufacturing

Formlabs has an extensive library of proprietary 3D printing materials suitable for even the most demanding applications.

Tough and Durable Resins

Nylon 12 Powder

Polyurethane Resins

Rigid 10K Resin

Upgrade Your Prototyping and Production with Additive Manufacturing Today

Explore our 3D printers to find the right solution for your business or contact a Formlabs Solution Specialist for a 1-1 consultation.