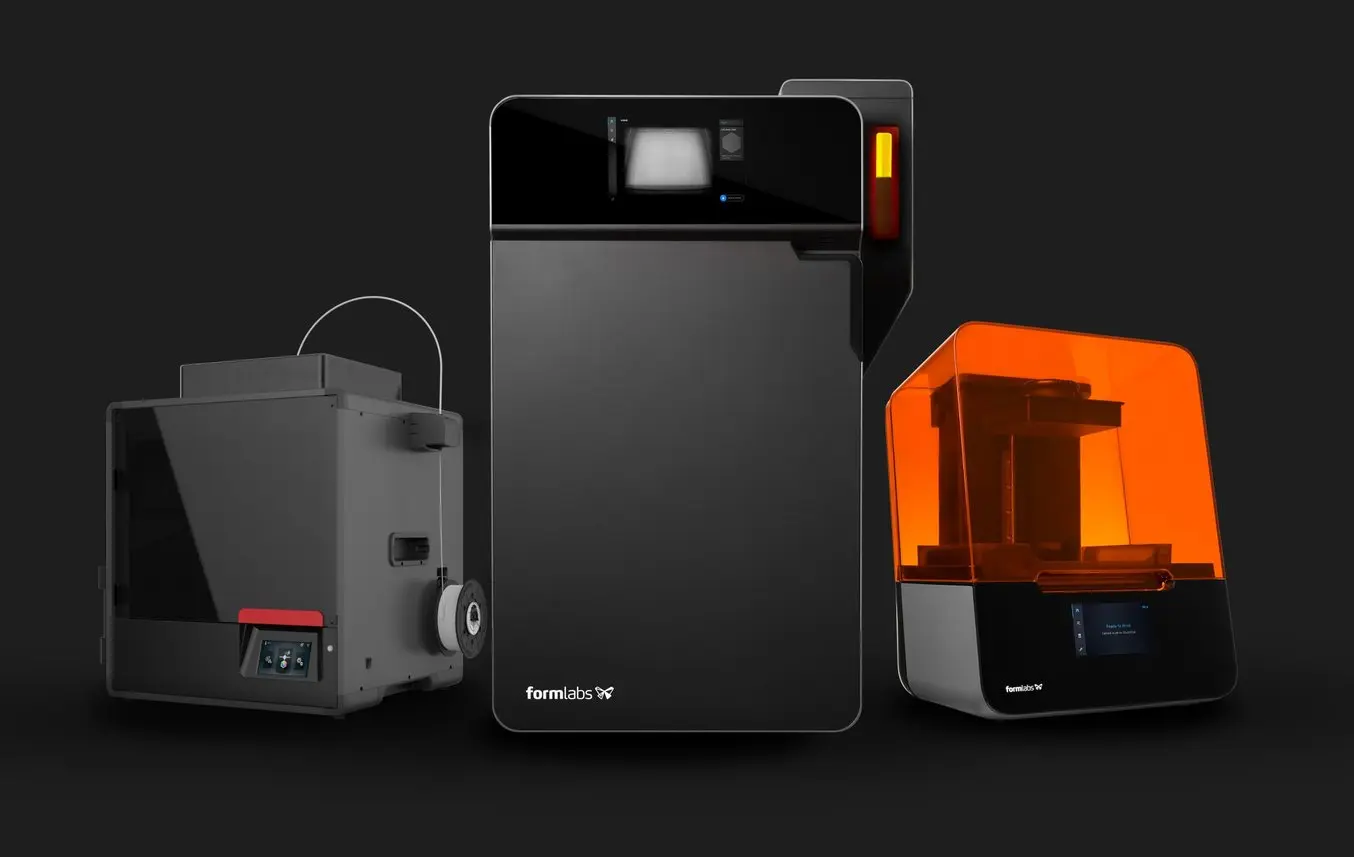

In 2011, three MIT graduate students built the first 3D printer that could achieve industrial, professional part quality at an affordable price. Through continuous commitment to innovation, Formlabs has become the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world.

form-3

Form 4

Blazing Speed Meets Industrial Production

Turn your ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4 professional 3D printer ecosystem. Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. With tight tolerances, parts printed in every resin on Form 4 will match your design parameters, every time.

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Ideal for:

form-3

Form 4B

Blazing Speed Meets Surgical Precision

Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using Form 4B, a blazing fast medical 3D printer that offers the most diverse materials library for healthcare.

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Ideal for:

Form 3L

Form 4L

Big Parts, Blazing Fast

Form 4L is a blazing-fast large-format masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your biggest ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4L ecosystem.

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Ideal for:

Form 3BL

Form 4BL

A New Era of Medical Manufacturing

Form 4BL is a blazing fast large-format medical 3D printer that offers the most diverse materials library for healthcare. Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using the Form 4BL ecosystem.

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Ideal for:

Fuse 1+ 30W

Fuse 1+ 30W

Truly Rapid SLS, For High-Performance Parts Within 24 Hours

Designed for maximum output and minimum waste, Fuse 1+ 30W is our compact industrial SLS 3D printer. Unlock unprecedented print speeds and material enablement to deliver truly rapid production in-house. From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11.8 in

Ideal for:

Maximize Your 3D Printer Fleet’s Throughput with 24/7 Production

Reach new levels of productivity with a fully-automated Form 3+ printer fleet you can operate from anywhere, at any time. Unlock 24/7 production with Formlabs Automation Ecosystem: Form Auto, Fleet Control, and the Resin Pumping System.

Factory Solutions

Factory Solutions is a tailored additive manufacturing solution for customers looking to scale to production now. Build your factory the way you want it with intuitive tools, transparent pricing, and proven processes.

Compare Formlabs Professional 3D Printers

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

No (available on Form 4B)

Maximum Part Size

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (60 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

23 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

39.8 × 36.7 × 55.4 cm

15.7 × 14.5 × 21.9 in

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

No (available on Form 4BL)

Maximum Part Size

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (145 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

19 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

66.4 x 52.8 x 79.4 cm

26.1 x 20.8 x 31.3 in

Technology

Selective Laser Sintering (SLS)

Material Type

Powder

Biocompatible Materials

Yes

Maximum Part Size

15.9 × 15.9 × 29.5 cm (Nylon 12 Powder)

6.3 × 6.3 × 11.6 in (Nylon 12 Powder)

Layer Thickness

110 microns

0.004 in

Laser Power

One 30W Ytterbium fiber laser

Supports

No supports required

Materials

8 high-performance industrial-grade materials, including nylon 11, nylon 12, TPU, polypropylene, and glass and carbon-filled nylon composites, or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Air environment, with the option to print in a nitrogen atmosphere for enhanced material properties and lower refresh rates.

Printer Dimensions (W × D × H)

64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27 × 42 in (65.0 in with stand)

How to Choose a 3D Printing Technology

Compare 3D printing technologies based on popular buying considerations like speed, applications, and cost.

Widest Range of Materials for Professional 3D Printers

Explore our 45+ advanced 3D printing materials, offering a wide range of optical, mechanical, and thermal properties. Our interactive materials catalog helps you make the right decisions based on your application and the properties you care the most about.

Explore 3D Printing Applications

Rapid Prototyping

Turn your ideas into high-fidelity prototypes that look and work like final products within a day and bring better products to market faster.

- Concept models

- Looks-like prototypes

- Functional prototypes