Color is all around us, and a key attribute in the parts, models, and tools we interact with. When making models, devices, and other 3D printed parts, color is used to identify and distinguish, blend in, or stand out. And, since adding color to injection-molded parts is easy and inexpensive, there’s demand for color part production.

With Formlabs' Color Resin, it’s possible to directly print colored parts with stereolithography (SLA) 3D printers. The color picker for Color Resin allows multiple inputs, including RGB and hex, showing a selected vs. achievable color with the ability to use sliders to make slight adjustments.

For brands and products requiring precise colors in different materials, color matching is vital. To achieve the desired color for any product, including those printed with Color Resin, it’s important to understand how visible color is affected by variables including lighting conditions, finish, and surface texture, as well as the differences between additive and subtractive color. Below, we explore key considerations for color matching and tolerancing.

Color Spaces

In order to achieve precise, matched colors, a number of variables must be considered, starting with color space. Color space is used to communicate color, most often by locating it as one would on a map. Color spaces include:

-

CIELAB (LAB or L*a*b*) color values are oriented in a 3D space on a light/dark axis, red-green axis, and yellow-blue axis.

-

CIELCH (L*C*h*) is in the same color space as CIELAB, but uses different measurements to describe a color. While L*a*b* uses Cartesian coordinates, L*C*h˚ uses polar coordinates of lightness, chroma, and hue.

-

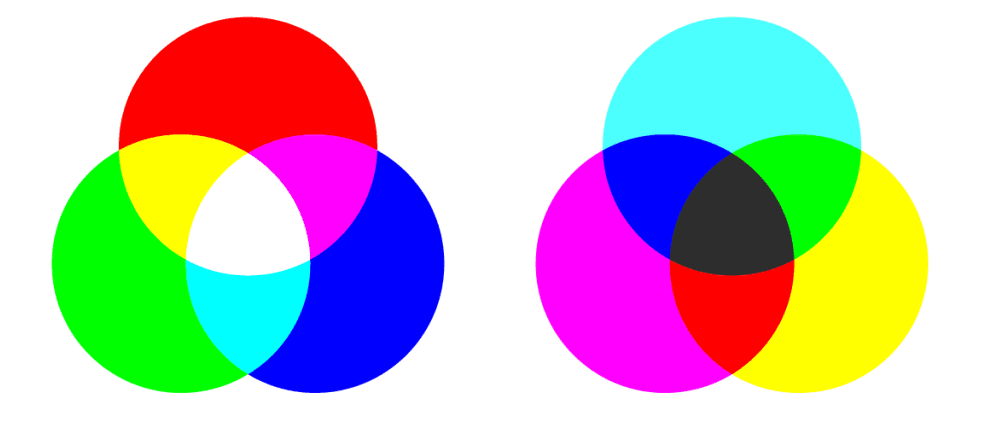

RGB refers to the mixing of light to form color (additive), with the three primaries in this model being red, green, and blue. Digital displays often use RGB profiles. Hex color codes are the hexadecimal or six-digit codes of numbers and letters that represent the intensity of red, green, and blue required to produce a specific color.

-

CMYK (cyan, magenta, yellow, and black) is a subtractive color model most often used in color 2D printing.

These are just some of the most commonly used color spaces, and there is nuance and overlap to each. Selecting a color space depends on the physical requirements of an application as well as the range of colors required. For example, hex codes are commonly used in HTML as the output is displayed on a screen and therefore uses light to create color. LAB space is bigger than RGB as it encompasses more colors than can be achieved in the RGB space. sRGB, the standard color space for computer monitors, is smaller than Adobe RGB, often used for photography.

Color Tolerancing & ΔE (Delta E)

If color space is a map of color, color tolerancing is the measurement between different colors on the map. A number of factors can affect how humans perceive color differences, from differences person-to-person to lighting conditions, surface texture, and color relativity (how a color can appear different depending on its background color). Spectrophotometers — tools for measuring color — are therefore used to attain more accurate color measurements.

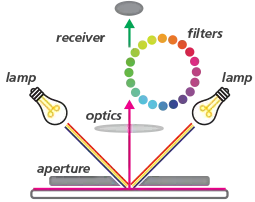

Spectrophotometers are used to precisely measure physical color and achieve custom color matching. (Image: X-Rite)

Spectrometers measure color by shining it with light and measuring the spectral response. (Image: X-Rite)

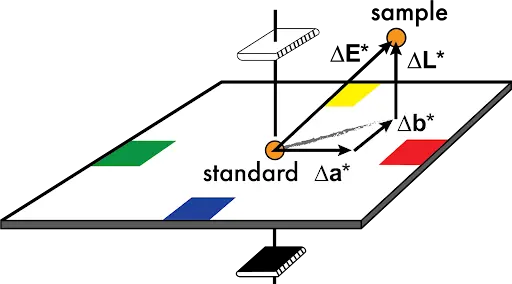

To measure the difference between two colors is to determine the delta. A ΔE (delta E) value takes into account the differences in brightness (ΔL), chroma or saturation (ΔC), and hue (ΔH).

The ΔE as mapped out in the L*a*b* color space. (Image: Alpolic)

ΔE 2000 (DE 2000 or deltaE) is the universally accepted ΔE for measuring differences in color, as it is the most current version of the formula. The color space is not perceptually uniform, meaning the euclidean distance between two colors isn't normalized. ΔE 2000 is a superior calculation method because it tries to normalize the color space such that a ΔE 2000 that is less than one is not perceivable by the human eye. These formulas are evolving as we continue finding better ways to normalize the color space to how we perceive colors.

Why Is Color Matching Difficult?

Determining equivalent colors across two digital color spaces can be simple. Determining or measuring equivalency between two physical color spaces, or between a physical color space and a digital space, is complicated by the factors outlined below.

Subtractive Color vs. Additive Color

Moving from digital to physical color is a hurdle, whether that’s from RGB on a computer screen to CMYK inkjet printer, or hex code to a paint color. This is because digital colors (such as those on a monitor) are additive colors with a backlight. Physical colors (those of objects) are subtractive colors that are affected by the light source and the pigments being used.

Additive colors at left and subtractive colors at right.

A color is a spectral curve between 400-700 nm; the difference between additive and subtractive color is how that spectral curve is generated. Due to this, digital colors will never perfectly match physical colors, but there are ways to approximate a match.

For example, there are many colors in the LAB space that cannot be displayed on an RGB screen. Additionally, colors shown in RGB on a screen (additive) will not look the same when printed in CMYK (subtractive). Many designers will select the color profile of their monitor to limit the tolerance between the screen and the final, physical product.

Color Standards: PANTONE & RAL

Color standards are communication tools, ways of defining or naming physical colors so that people can achieve the same color without sending a physical sample. In plastics, the largest color standard is the PANTONE plastic standard. In Europe, RAL is also used for coatings and plastics. Both PANTONE and RAL are private companies that offer paper and plastic color samples. These physical references enable color consistency in the same material without moving from digital to physical spaces.

Join Formlabs

Do you want to help equip every designer, engineer, researcher, artist, and healthcare professional in the world with high-quality, in-house production?

Lighting Conditions and Illuminant Metamerism

The color we see is heavily influenced by the lighting conditions under which we see it. An object will appear one color in daylight, and another under fluorescent lighting.

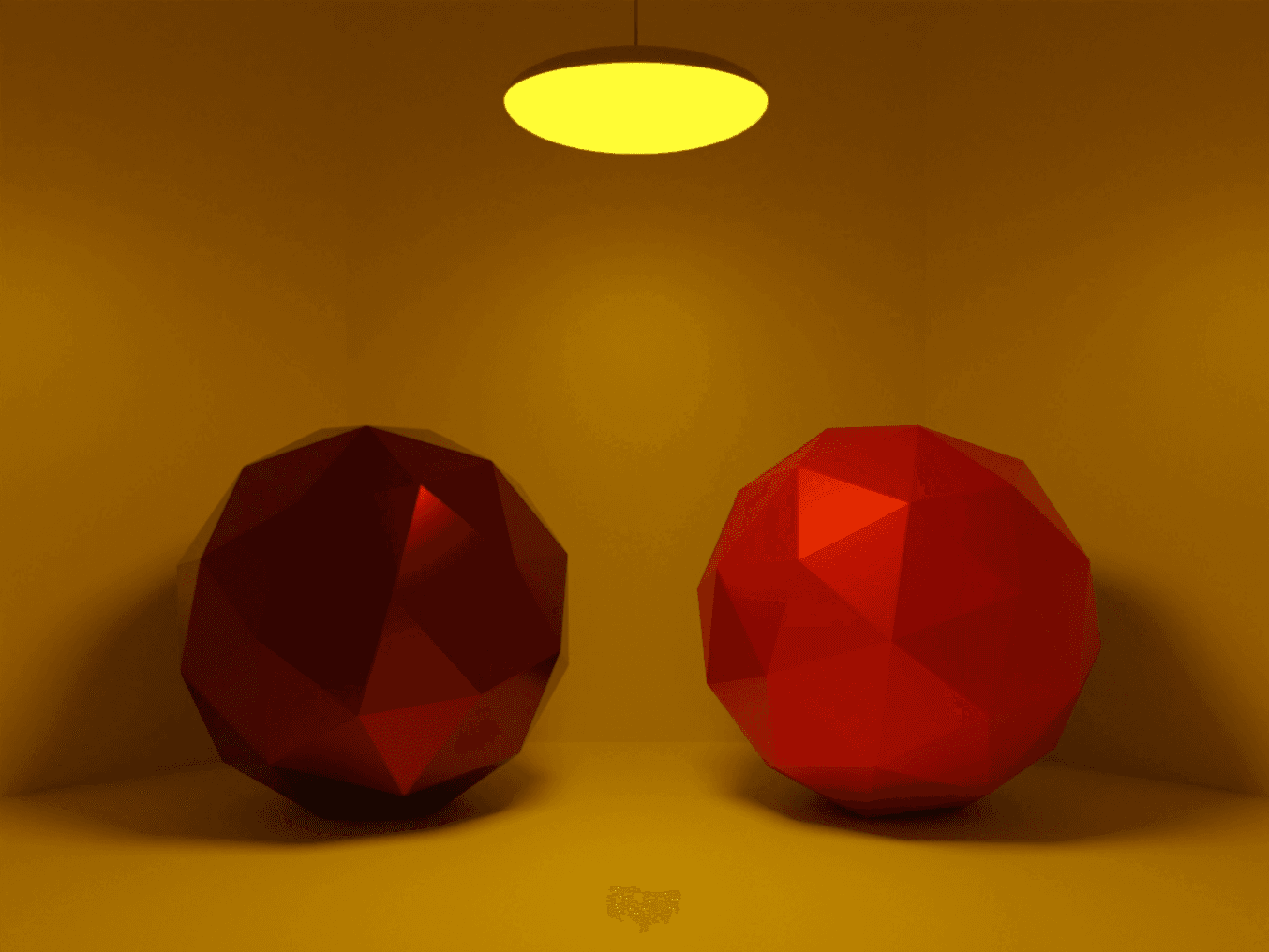

In some instances, two material samples that match under one light source may not match under another. This is called illuminant metameric failure or illuminant metamerism.

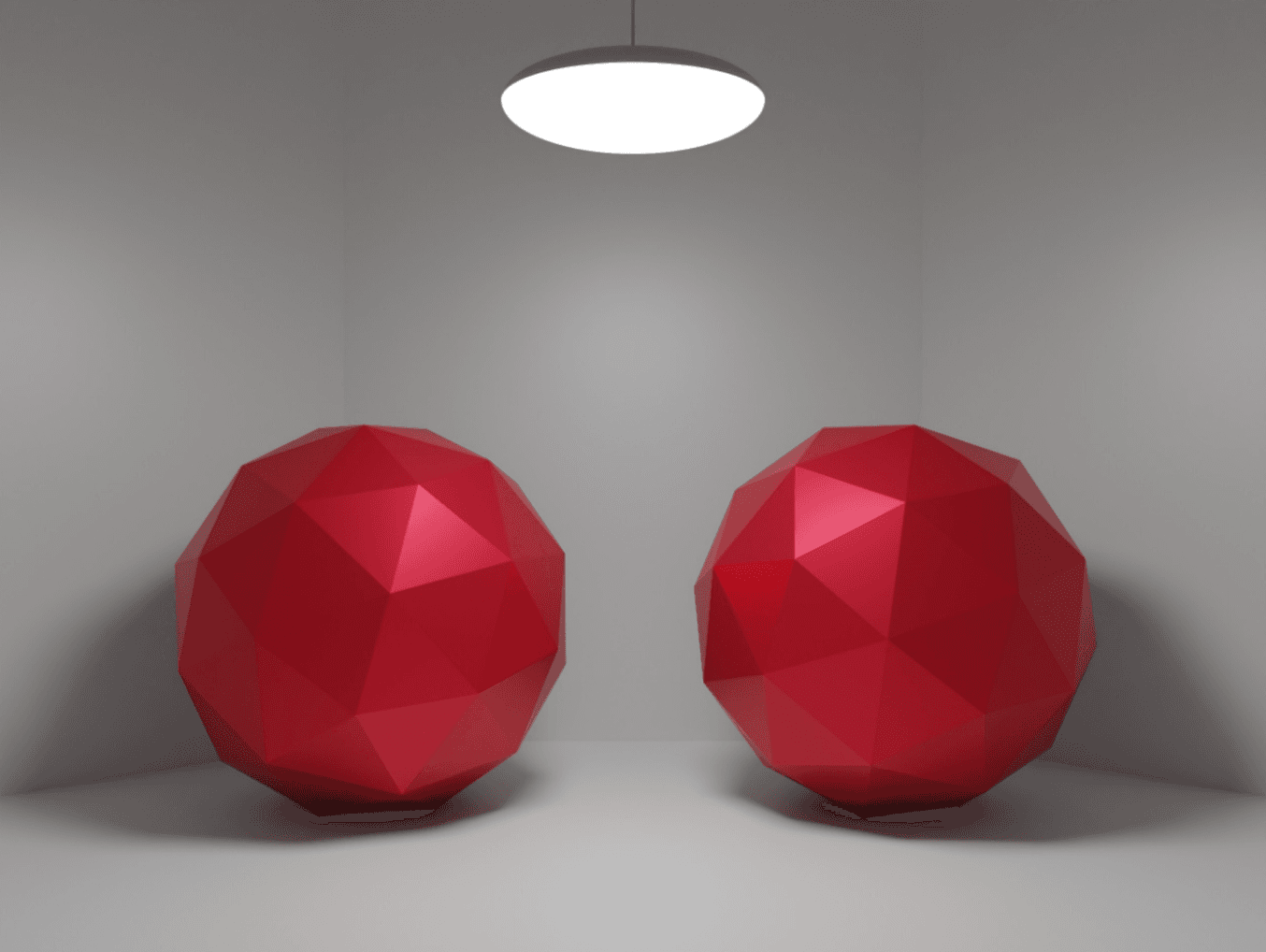

In natural lighting, these two objects appear to be red. (Image: datacolor)

In incandescent lighting, the left-hand object is a much darker red than the right-hand one. (Image: datacolor)

For this reason, choosing a standardized lighting condition is necessary when comparing colors. When developing materials and verifying color accuracy at Formlabs, color matching is done using D65, a lighting source meant to simulate sunlight (the most universal source of light we all have).

Light and Pigment

When adding pigment to create a color, the type and amount of pigment used will affect what spectrum of light reflects off an object and, therefore, what is visible to the human eye.

Optical brightening agents (OBAs) are additives that affect light, altering how humans see a color. OBAs absorb a range of light that is imperceptible to the human eye and emit in a range visible to humans. Optical brighteners are added to create a bright white, for example, to make copy paper appear more white.

Fluorescent colors are ultraviolet reactive, and, like OBAs, absorb a range of light invisible to the human eye and then emit it in a range humans can see. Because resin 3D printers cure liquid resin with light, both OBAs and fluorescent colors cannot be added to a resin for 3D printing, as the additive would prevent the resin from properly curing.

The amount of pigment in a material also affects light. For example, a pale yellow pane of cured resin will appear more transparent than a sample with more pigment, which will appear more opaque and more saturated with color. This is because the pigment blocks light.

For resin 3D printing, colors that are too saturated with pigment will not print correctly, as the pigment blocks the 405 nm light used to cure the resin. So, while tens of thousands of custom colors can be directly printed in resin, certain colors or effects are not available due to their effects on curing.

Coloring With Dyes

One way to produce colored parts is to dye them. Dyes can either be added to a material before it is used to produce a product (such as alcohol dye to liquid resin or dyeing wool before spinning and weaving) or a part can be dyed once it has been produced. Note that, as physical colors, dyes will never emit light and thus never be equal to digital colors.

Dyes are often used to add color to selective laser sintering (SLS) 3D printed parts. The color of dyed parts differs depending on the type of material being dyed, the length of time the part is in a dye bath, and the saturation of the dye bath. Learn more about color and dyeing SLS 3D printed parts here.

Alcohol dyes can be added to clear resins to create colored parts. The alcohol dye can either be added directly to the resin cartridge, or clear parts can be dyed after printing. Learn more about using alcohol dyes with clear resins here.

Parts 3D printed in Nylon 12 White Powder using SLS 3D printing that were dyed in an ultrasonic dye station.

Clear Resin is mixed with alcohol ink and then printed using SLA 3D printers.

2D vs. 3D Printed Color: Finish and Texture

2D printed colors sit on top of a paper surface, the same way paint sits on top of a painted object. 2D printed colors can be coated or uncoated. This coating affects how the same color appears. For example, a matte black looks greyish, while the same black in gloss appears darker. Texture can also affect perceived color as a color part will appear darker or lighter based on the diffused light.

This means that, when 3D printing with Formlabs Color Resin, a gloss or semi-gloss finish will result in the appearance of the richest looking color. Print orientation therefore matters as top surfaces will always be more glossy than side surfaces. Additionally, wash parts printed in resin with fresh solvent. Used or saturated solvent will be tacky, and therefore attract more dust and diffuse more light, giving the part a dull appearance.

When measuring color, Measuring Specular Excluded (SPEX) means the surface characteristics (gloss, texture, etc.) are included when taking a reading. On the other hand, Measuring Specular Included (SPIN), negates the effects of surface finish and texture and measures only the color. Due to this, color matching is done with SPIN, ignoring the surface effects and measuring the color only.

These sample textures were all printed in the same print batch using the same Color Resin (User Input Color Code: RGB 000-134-171). However, the textures cause the human eye to perceive slight differences in color.

How color is added to a part also affects how it appears. Pigments are added to a base. The base limits how much pigment can be added. This is why Color Resin is limited in saturation: the base resin can only hold a certain amount of pigment before the mechanical properties or even the ability to print is diminished.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Start Printing in Color

With an understanding of the variables affecting color, it’s easier to match colors. Parts printed with Formlabs 3D printers can be painted, coated, dyed, and, for SLA, printed in full color. Each of these methods can achieve different surface finishes, affecting how the color will appear on the final part.

Direct printing of custom colored 3D parts is achievable with Color Resin and SLA 3D printers. Knowing how lighting conditions, material, texture, and finish affect visible color is key when selecting colors that meet your requirements. When picking a color for Formlabs Color Resin, it's important to keep these variables in mind. To match colors, take measurements using SPIN, ensuring textural characteristics are excluded from the reading.

Ordering a color online means the color is being viewed in RGB (additive color). However, physical color is subtractive, meaning while colors can appear similar, they cannot ever be identical.

Approaching color matching with an understanding of the language and variables makes it easier to achieve the desired colors. Order Color Resin or explore Formlabs 3D printers to start printing. To discuss which processes and materials are best suited to achieving the color parts you need, contact sales.