STERIS Achieves FDA Clearance for Vaporized Hydrogen Peroxide Sterilization for 3D Printed Medical Devices

Image courtesy of STERIS.

STERIS is a leading global provider of products and services that support patient care with an emphasis on infection prevention. In August of 2023, STERIS received FDA clearance for their V-PRO™ Low Temperature Sterilizers to sterilize hospital-manufactured 3D printed surgical guides and anatomical models. The FDA clearance includes Formlabs’ BioMed Amber Resin and BioMed Clear Resin as compatible materials for use**.

STERIS collaborated with Formlabs when validating both resins for use with this sterilization method. We sat down to talk with Randal Eveland, PhD, Senior Principal Scientist at STERIS, who works to expand the use of vaporized hydrogen peroxide in the healthcare field, to learn more about VHP sterilization of 3D printed medical devices, and how it benefits hospitals and healthcare providers. Ultimately, Eveland says, STERIS is “seeking to provide clarity and peace of mind to hospitals.”

**See the V-PRO maX 2 Sterilizer Operator Manual for details on 3D printed devices that can be sterilized.

Sterilizing 3D Printed Models with STERIS and Formlabs

While sterilizing 3D printed parts is an important step to consider, relevant information can be difficult to source. Learn how 3D printed parts are used with STERIS, a leading provider of infection prevention and other procedural products.

Sterilizing Medical Devices With Vaporized Hydrogen Peroxide

Vaporized hydrogen peroxide (VHP) can be used to sterilize medical devices, providing an alternative to higher-temperature sterilization options. VHP sterilizes by disrupting essential cellular components like proteins, DNA, and cell membranes. The highly reactive hydroxyl radicals generated from VHP cause oxidation and damage to these molecules, leading to cell death and inactivation of microorganisms.

Eveland says, “The benefits of vaporized hydrogen peroxide really are its materials compatibility and its low processing temperatures. We've become aware that certain configurations of devices, even with steam identified as a compatible method, can lead to some structural deformations after processing. So vaporized hydrogen peroxide as a low-temperature alternative provides for that type of dimensional stability of devices.”

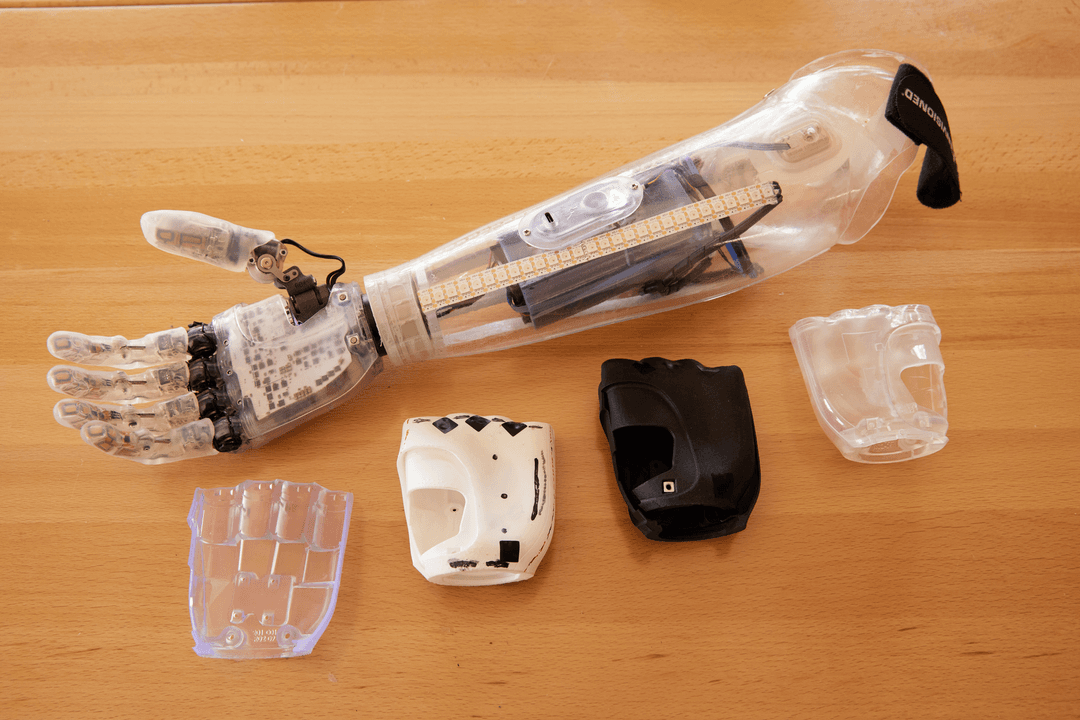

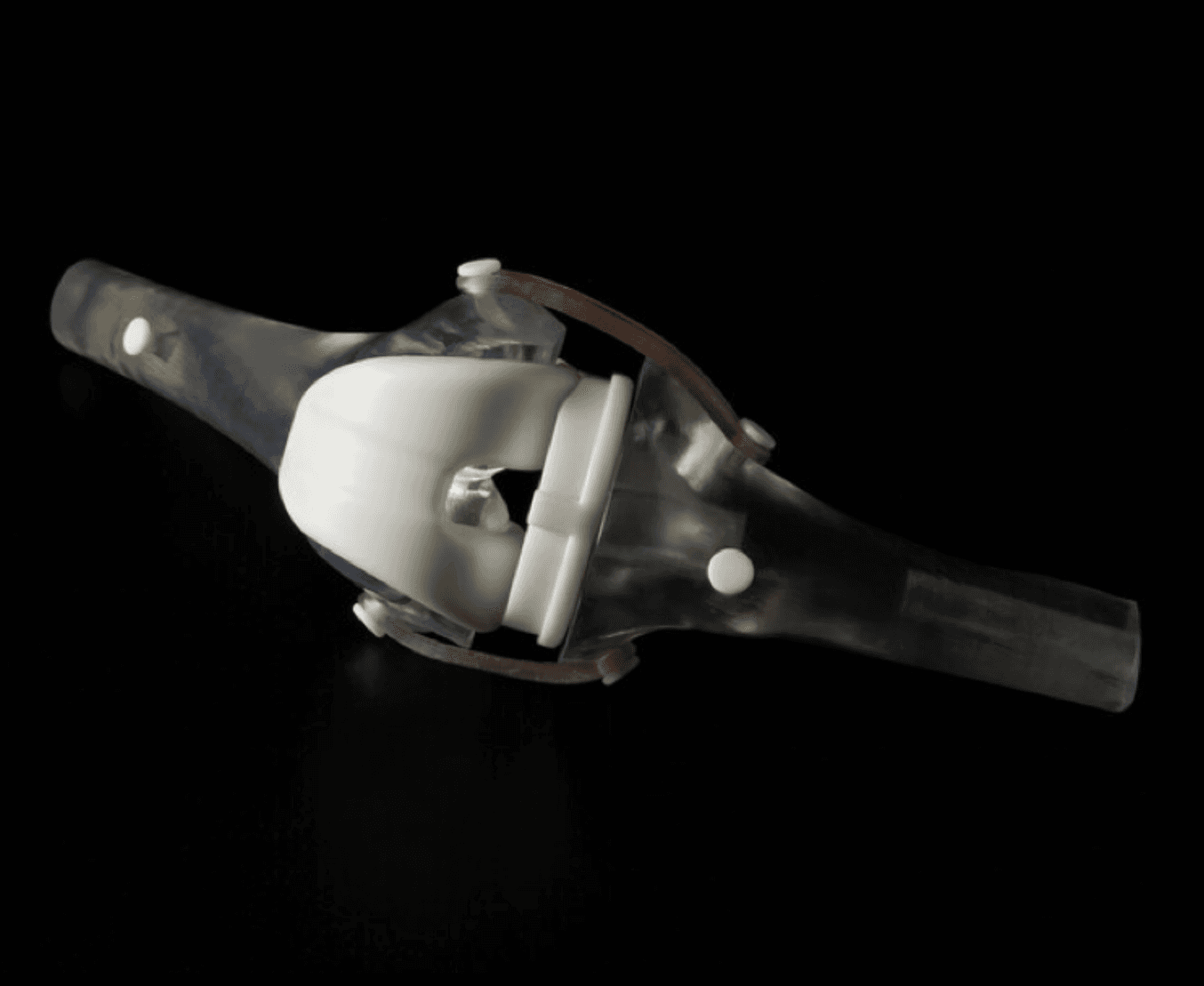

STERIS’s VHP sterilization products for healthcare providers are the V-PROTM Sterilizers, low-temperature sterilization systems validated to sterilize over 43 different materials used in medical devices, including diamonds, ceramic, tungsten carbide, and select proprietary materials used in 3D printing**. These materials were developed for the production of 3D printed medical devices including patient-specific surgical guides and anatomical models, both of which can be used in operating rooms to assist with surgeries.

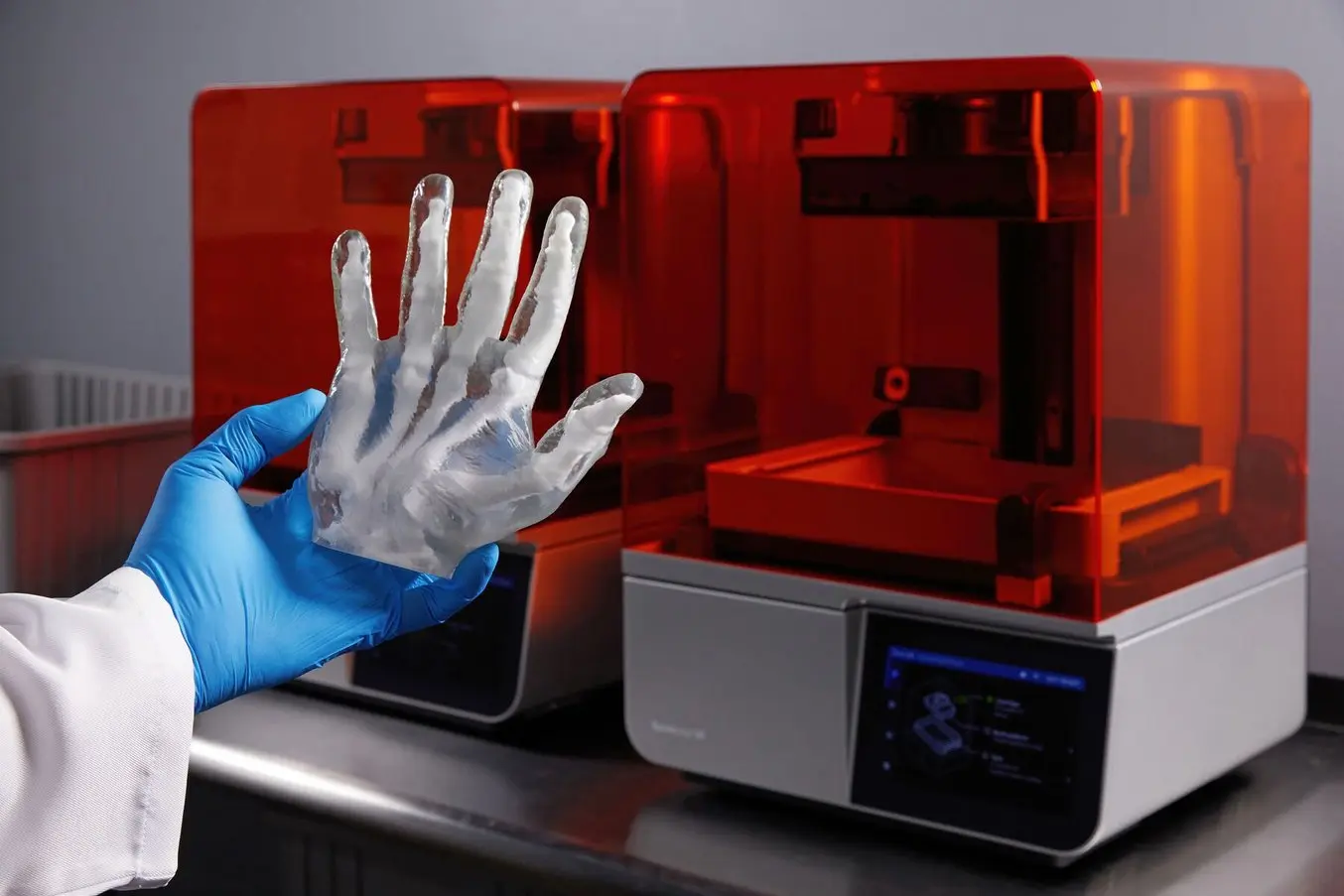

BioMed Amber Resin and BioMed Clear Resin (pictured) are validated resins for 3D processing in STERIS V-PRO Sterilizers**.

Talk to Our Medical Sales Team

Whether you need to make patient-matched surgical tools or are prototyping for a cardiac medical device, we’re here to help. Formlabs Medical team are dedicated specialists who know exactly how to support you and your company's needs.

Workflow

Sterile processing departments typically receive items along with instructions for disinfection and preparation for sterilization, including cleaning chemistries, washing and drying instructions, and packaging. Once the item has been cleaned, dried, and packaged, it is placed into an appropriate sterilization cycle.

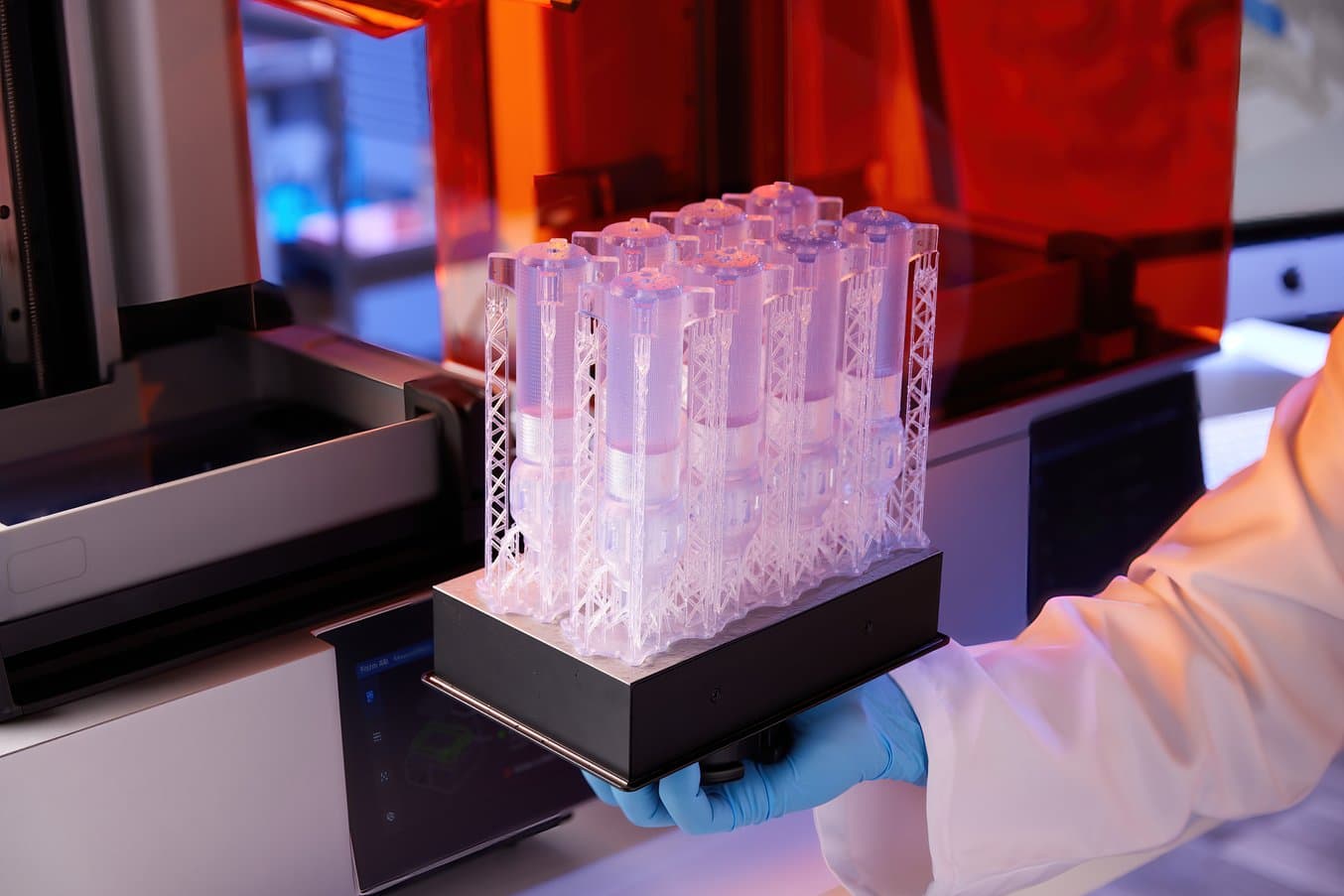

For 3D printed parts in validated resins, STERIS provides guidance for cleaning and packaging. The sterile processing department can then select the V-PRO Sterilizer Specialty Cycle identified for their material which will then sterilize the packaged 3D printed parts. Eveland says, “The manual cleaning process is fairly straightforward depending on the complexity of the device. The absence of patient soils on 3D printed devices minimizes the steps of the cleaning. Simple devices can be washed and rinsed in minutes while more complex devices will take longer. Devices are typically air dried or forced air may be used. The total length will be dependent on the facility and its policies and procedures. The sterilization cycles can vary depending on the materials.”

Once a device is loaded into the V-PRO maX 2 Sterilizer, the appropriate Specialty Cycle is selected on the touchpad. When the cycle is complete, devices are available for immediate use. This process helps sterile processing departments to sterilize 3D printed parts of patient-specific surgical guides or anatomical models.

Resin Sterilization Information for Formlabs Resins**

| Material | Printer | Specialty Cycle | Lumen Inner Diameter (ID) x Length (L) |

|---|---|---|---|

| BioMed Amber Resin | Form 3B, Form 3B+, Form 3BL* | F | ≥3 mm ID x ≤30 mm L |

| BioMed Clear Resin | Form 3B, Form 3B+, Form 3BL* | D | ≥3 mm ID x ≤30 mm L |

Information courtesy of STERIS. View the entire table here**.

Testing has not yet been completed for Form 4B Series 3D printers.

Introducing Form 4B: Faster Production, Higher Precision, Regulatory Equivalence

Join Formlabs for an exclusive look at the Form 4B & how it boosts production, achieves unmatched accuracy, and integrates smoothly (regulatory equivalency explained).

Working With Hospitals and Sterile Processing Departments

Working with hospital sterile processing departments enables STERIS “to have discussions with the users on what their needs are, and look forward to see what new areas are coming to them. 3D printing was one of those areas.” With 3D printing, the hospital is a medical device manufacturer. Eveland says, “From all the interactions I've had with them, it's something that they're not really used to and presents challenges. They have quality practices in the hospital, for certain, but when you say that the FDA is now going to regulate you as a medical device manufacturer, this will introduce new responsibilities they don’t currently have to address.”

In hospitals, radiology, segmentation, and the software used to generate devices are all covered by FDA clearances. However, the creation and sterilization of the printed device was in the hospital’s hands. STERIS was approached by a sterile processing department that needed assistance to disinfect devices they’d printed. Eveland says, “This was an area we really thought we could help, both in immediate terms and the long term. So we collaborated with Formlabs to qualify a steam sterilization method, but then we began the collaboration for the V-PROTM Sterilizer.”

The V-PRO™ Low Temperature Sterilizer from STERIS was developed to help hospital sterile processing departments. Image: STERIS.

Medical devices can be moisture and temperature-sensitive, in which case a low-temperature sterilization method, like VHP, may help avoid steam sterilization’s effects on the mechanical properties and dimensions of the sterilized device.

The goal was to attain FDA clearance for VHP sterilization of 3D printed medical devices in five resins, including Formlabs BioMed Clear Resin and BioMed Amber Resin. This would provide hospitals with a validated method for the sterilization of anatomical models and surgical guides printed on validated printers — in the case of Formlabs, Form 3B/+ and Form 3BL 3D printers.* Then, hospitals could point to STERIS's clearance for these materials as the validation they needed for this step in the process**.

BioMed Resin Swatches

Each BioMed Resin swatch features embossed and debossed designs, 0.5-2.0 mm cutout thicknesses, as well as regulatory information unique to that resin.

Collaborating With Formlabs on FDA Clearance

“One of the areas where we've collaborated with Formlabs is to verify that Formlabs biocompatible materials BioMed Amber and BioMed Clear maintain their biocompatibility after sterilization.”

Randal Eveland, PhD, Senior Principal Scientist, STERIS

Technical and safety data sheets for Formlabs materials as well as medical device standards, statements, and certifications, are available via Formlabs’ Regulatory Affairs and Quality Assurance (RAQA) team, who offer free consultations to help support medical device companies working with 3D printing. In the case of STERIS, Formlabs provided material master files for biomedical resins, print support, and technical expertise as STERIS worked to provide the necessary information and testing needed to obtain FDA clearance.

On August 11, 2023, FDA Roundup identified the V‑PRO™ maX 2 Low Temperature Sterilization System as the first FDA-cleared sterilization system for the sterilization of 3D printed medical devices in healthcare facilities. These medical devices include surgical guides and anatomical models printed in BioMed Clear and BioMed Amber on Form 3B/+ and Form 3BL**. Additionally, the V-PRO maX 2 Sterilizer is CE-marked under the EU's Medical Device Regulation (MDR), and is registered for sale in Australia and Asia.

“We collaborated with Formlabs to validate the performance of BioMed Clear and BioMed Amber resins with the V‑PRO™ maX 2 Sterilizer. We received FDA clearance for sterilization of those materials and the clearance for surgical guides and anatomical models within a specific design window created with the identified Formlabs printers**.”

Randal Eveland, PhD, Senior Principal Scientist, STERIS

With the ability to 3D print medical devices as needed, healthcare providers can save on up-front costs. In-house printing in hospitals allows for fast turnarounds of potentially life-saving devices, and more thorough preoperative preparation. Now, rather than ordering or sourcing a personalized medical device, hospitals can design, print, and sterilize it in-house. Prior to receiving FDA clearance, sterilization was the main pain point in this manufacturing process. But, with FDA clearance of the V-PRO maX 2 Sterilizer, STERIS has provided a cleared solution for some of these devices.

To further disseminate this information, STERIS published the results on efficacy, biocompatibility, and material compatibility in February 2024 in the Journal of 3D Printing in Medicine.1 The report details the testing and analysis executed by STERIS, including tables detailing mechanical property evaluations, dimensional analysis, residue, biocompatibility, and more, giving healthcare professionals access to detailed information for evaluation and decision-making.

Creating Bone Simulation Models for Cutting and Drilling

3D printed bone-simulation models are revolutionizing medical training, surgical planning, research, and medical device development. This application guide walks through the bone-simulation material options for stereolithography (SLA) 3D printing and the entire in-house manufacturing process for bone-like anatomical models intended for cutting and drilling.

Formlabs Biocompatible Resins: A Comprehensive Guide To Choosing the Right Material

This paper aims to help users compare and contrast our biocompatible offerings, and determine the best fit for their medical applications.

Providing Peace of Mind

3D printed surgical guides and anatomical models have been shown to aid in patient education and consent, surgical planning and training, and surgical outcomes. In the investigation “Medical 3D Printing Cost-Savings in Orthopedic and Maxillofacial Surgery: Cost Analysis of Operating Room Time Saved with 3D Printed Anatomic Models and Surgical Guides,” in Academic Radiology, results indicated means of 23-62 minutes of time were saved per case. At this rate, an estimated 63 models or guides per year (just over one per week) would be the minimum number to break even.2

FDA clearance of vaporized hydrogen peroxide V-PRO™ Low Temperature Sterilizers, therefore enables hospitals to more easily leverage 3D printed parts, potentially leading to time and cost savings for hospitals and patients.

To learn how Formlabs 3D printers can be used for your medical applications, contact sales or visit our 3D printing solutions for healthcare webpage to learn how Formlabs can support your medical device development and production.

-

Eveland R, Antloga K, Meyer A, Tuscano L; ‘Low Temperature Vaporized Hydrogen Peroxide Sterilization of 3D Printed Devices’ 3D Printing in Medicine, 3D Print Med 10, 6 (2024). https://doi.org/10.1186/s41205-024-00206-1

-

Ballard DH, Mills P, Duszak R Jr, Weisman JA, Rybicki FJ, Woodard PK. Medical 3D Printing Cost-Savings in Orthopedic and Maxillofacial Surgery: Cost Analysis of Operating Room Time Saved with 3D Printed Anatomic Models and Surgical Guides. Acad Radiol. 2020 Aug;27(8):1103-1113. doi: 10.1016/j.acra.2019.08.011. Epub 2019 Sep 18. PMID: 31542197; PMCID: PMC7078060.

V-PROTM is a trademark of STERIS