ZapWizard’s ARC holster: the ARC is Leatherman’s most popular product, and ZapWizard offers multiple SLS 3D printed variants for ARC users looking to protect their multi-tool or add handy accessory tools like a small flashlight.

One employee, three hours a day, 3600 products shipped, $135,000 of personal investment, and just seven months to achieve a complete ROI. Too much to believe? Well, Josh Driggs, owner and sole operator of ZapWizard, begs to differ. With the Fuse 1 and a complete in-house SLS workflow, ZapWizard has shipped thousands of products in less than a year and paid off an over $100,000 investment into Driggs’ side-hustle.

By day, Driggs is a Mechanical Design Engineer for a manufacturer in Texas. By night, (just three hours a night) he designs, manufactures, and sells accessories for Leatherman products like customizable holsters for their advanced multi-tools. There’s a reason the Leatherman brand has become the generic term for utility knives and other tools; they’re the best of the best, relied upon by hunters, plumbers, tech workers, the military, and more.

Leatherman users have a thriving community looking for better ways to carry, protect, and optimize their products, and ZapWizard is often the first place they come across. From a nearly catastrophic supply chain change to more orders than ever, Driggs talked to us about how the Fuse 1 worked its magic.

“I utilize SLS 3D printing to its fullest potential. The Fuse 1 really did save my business.”

Josh Driggs, Owner, ZapWizard

Taking Work Home With You

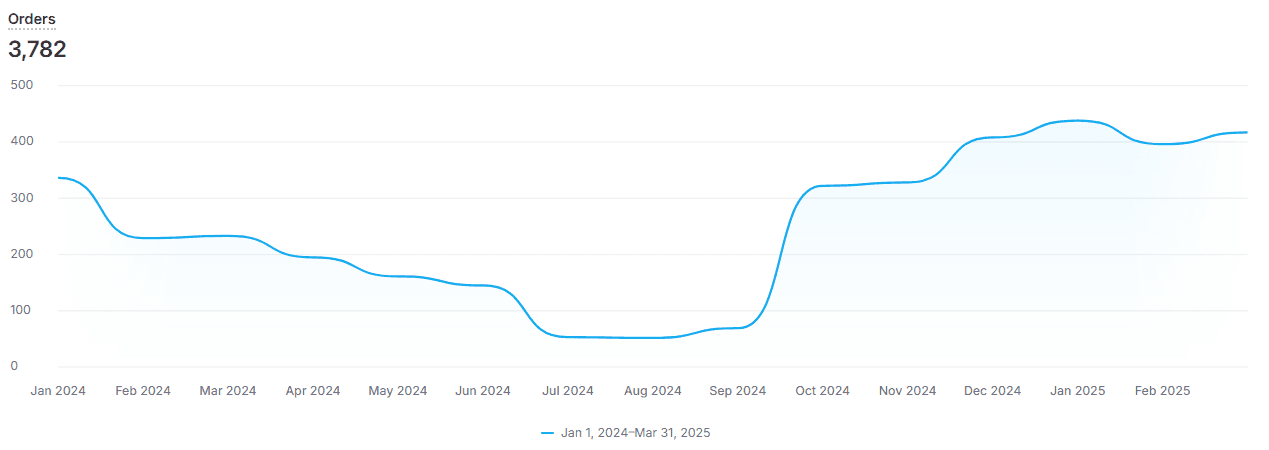

Shapeways had been raising the prices for their printed and drop-shipped orders throughout 2024, but when they declared bankruptcy July 2nd, Driggs had to find a solution in place of their marketplace platform. His in-house Fuse 1 printed its first parts Sept 20th, and it was only up from there.

Outside of his 9-5, Driggs has been operating a 3D printing service business for nearly a decade. He designed and sold Leatherman aftermarket parts like holsters, then worked with Shapeways to print and ship the parts. Working with a service bureau ate into his margin — for a $45 holster, his net profit was about $5 — but as a side-hustle with relatively low effort on the design side, the business model worked for him. “Despite the low profit margin, I was happy with their services because the business ran automatically for the most part,” says Driggs.

A change to Shapeways’ business model brought ZapWizard’s operation to a screeching halt, and he had only a few choices: shut down his business entirely, switch to another, even lower-margin partner, or do the production himself in-house.

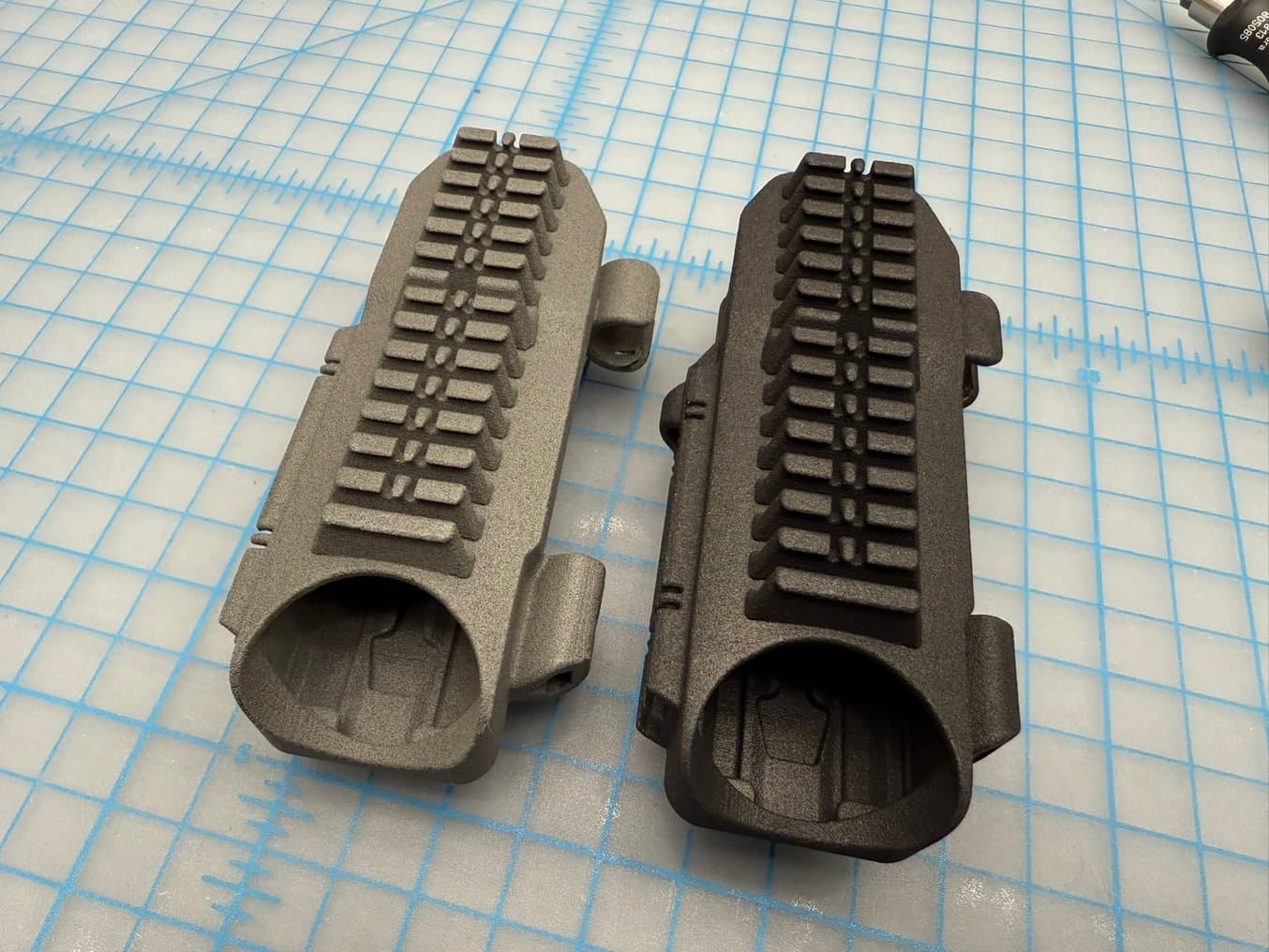

Driggs sent his three most popular designs to five different US vendors and even a couple of overseas contract manufacturers as well. But when he received the parts back, the tolerances, coloring job, and surface finish were all wrong. “Even when you specify the material and the type of technology, they can’t guarantee print orientation or a consistent dyeing process,” says Driggs. It was time to go all-in on a solution he knew could work.

Building Out a (Garage) Fuse Facility

The 'After' showcasing his new 3D printing set-up, epoxied floor, and full build-out.

The 'Before.' Taking the entire workshop from this to his state-of-the-art manufacturing facility cost about $135,000, an investment Driggs paid off in just seven months of producing parts in-house.

Luckily, Driggs had some experience with a reliable, accessible production method. He had been using the Fuse 1 at his day job for years, and had even been on the reservation list since its announcement in 2017 — his company has one of the very first production units.

“I knew the Fuse 1 was a workhorse and reliable. The machine was never the question, I just needed to figure out the finances of doing it myself.”

Josh Driggs, Owner, ZapWizard

Though Driggs uses the Fuse 1 at his day job for jigs, fixtures, and small manufacturing aids on their factory floor, it wasn’t a high-volume machine. He estimates their Fuse 1 prints about 200 parts a year, and he was looking to figure out a production setup that went way beyond that.

Though he tried ultrasonic part dyeing, Driggs settled on a pressure pot dyeing method to create dark black parts.

The Fuse 1 printed parts absorb RIT dye easily, presenting a professional looking black finish after a pressure-pot dyeing cycle.

He started with a garage build-out, including new ventilation systems, a new epoxy floor, work benches, a Form 4 stereolithography (SLA) 3D printer, an FDM 3D printer, a fiber laser, and two entry-level CNC machines. The workshop build-out totalled about $135,000 of investment, including the Fuse 1, Fuse Sift, Fuse Blast, and a pressure pot dyeing set-up.

Turning Up the Volume

Driggs’ order volume has remained steady and he’s able to pack his Fuse 1’s build chambers to about 25% packing density — ensuring there’s nearly no excess unsintered powder that cannot be reused.

With the hands-on labor of production reduced by the automated Fuse Blast, Driggs can work on testing new variants and iterating on his already expansive 300-product catalog.

At first, Driggs was apprehensive about the investment and the possibility that he had taken on too much at once, all in-house. “I was concerned that I wouldn’t be able to pack the holsters densely enough, and that a full build wouldn’t be ready in time to get orders out quickly,” says Driggs. But using PreForm’s tools and a little trial and error, Driggs was able to settle on a steady, reliable production schedule that kept the Fuse 1 running steadily five days a week.

Driggs runs a half-volume build overnight with a 25% packing density and between 12-15 different parts. The next afternoon, he comes into his workshop after getting home from his day job, and does the post-processing. With only about 40 minutes of hands-on labor time total for sifting and blasting, Driggs can work on answering customer inquiries, printing shipping labels, packing boxes, and even doing some design work.

“I’ve been able to match my packing density to the refresh rate, along with about a 5% powder loss, so I have no excess unusable powder. It works out perfectly. I get about 12 orders a day, they go into the print overnight, and I can ship them out the next day.”

Josh Driggs, Owner, ZapWizard

The Ideal Solution for a Niche Crowd

ZapWizard offers over 300 variants, including nearly 40 different versions just for the Leatherman ARC multi-tool. Having a digital inventory means that there’s something for everyone, broadening Driggs’ reach as a small business and increasing customer satisfaction.

A big part of ZapWizard’s success is the breadth of products he offers, and his ability to make changes on the fly, something that only SLS 3D printing can make cost-efficient. He offers over 300 variants and models of the Leatherman Holsters, and for customers who reach out with a specific request, he often designs something unique.

“I might tweak something 15 times before I settle on a final holster design, changing something by just 0.1 or 0.2 mm. That’s only because I had SLS 3D printing available, to react that fast and be proactive.”

Josh Driggs, Owner, ZapWizard

One customer, a plumber, reached out to Driggs asking to make a more robust holster. The customer told him that when he’s climbing around in basements and crawl spaces, the Leatherman would get dinged up with an open face holster. Driggs designed an armored version in just two days and was able to answer complaints with customization.

The fast, agile, responsive business model has not only reignited interest from Drigg’s customer base, it has also paid off his entire investment into his garage build-out in just seven months. With only two or three hours of work a day after his 9-5, ZapWizard has generated enough profit to cover all his expenses.

To make sure Driggs never forgot the Serial Name of his Fuse 1 printer, he made a little addition to the outside: ZanyGrackle.

The Fuse 1 and Fuse Sift fit right into the garage workshop, which Driggs modeled in SketchUp before starting his renovation.

“I’ve printed 3600 parts in just seven months and paid off all my debt from the build-out. My business has only increased; people are reacting to seeing me back online and the level of customization.”

Josh Driggs, Owner, ZapWizard

To learn more about the Fuse Series, visit our page. To test one of our Fuse Series SLS Powders for yourself, request a free 3D printed sample.