Flame Retardant Resin

Engineering

SLA

Stiff & Strong

41 MPa

3,100 MPa

75 MPa

Select Printer Series and Resin Volume

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

Tests and certifications include: UL 94 V-0 at 3 mm thickness for flammability; FAR 25.853 Appendix F, Part I for flammability; and ASTM E662 for FST. For full test results and certifications, see the Technical Data Sheet.

Flame Retardant Resin has been added to your cart.

Why Choose Flame Retardant (FR) Resin

Accelerate time to market without the design constraints and upfront costs of traditional manufacturing with isotropic and highly detailed parts (XY resolution: 25um) with unlimited geometric freedom in any quantity (from 1 to 1000 parts) at any time.

Certified Flame Retardant

Produce certified flame retardant, UL 94 V-0 and FAR-rated 3D printed parts that meet necessary certification requirements for enduring hazardous environments.

Heat and Creep Resistant

Parts will perform well long-term in indoor and industrial environments with high temperatures or ignition sources.

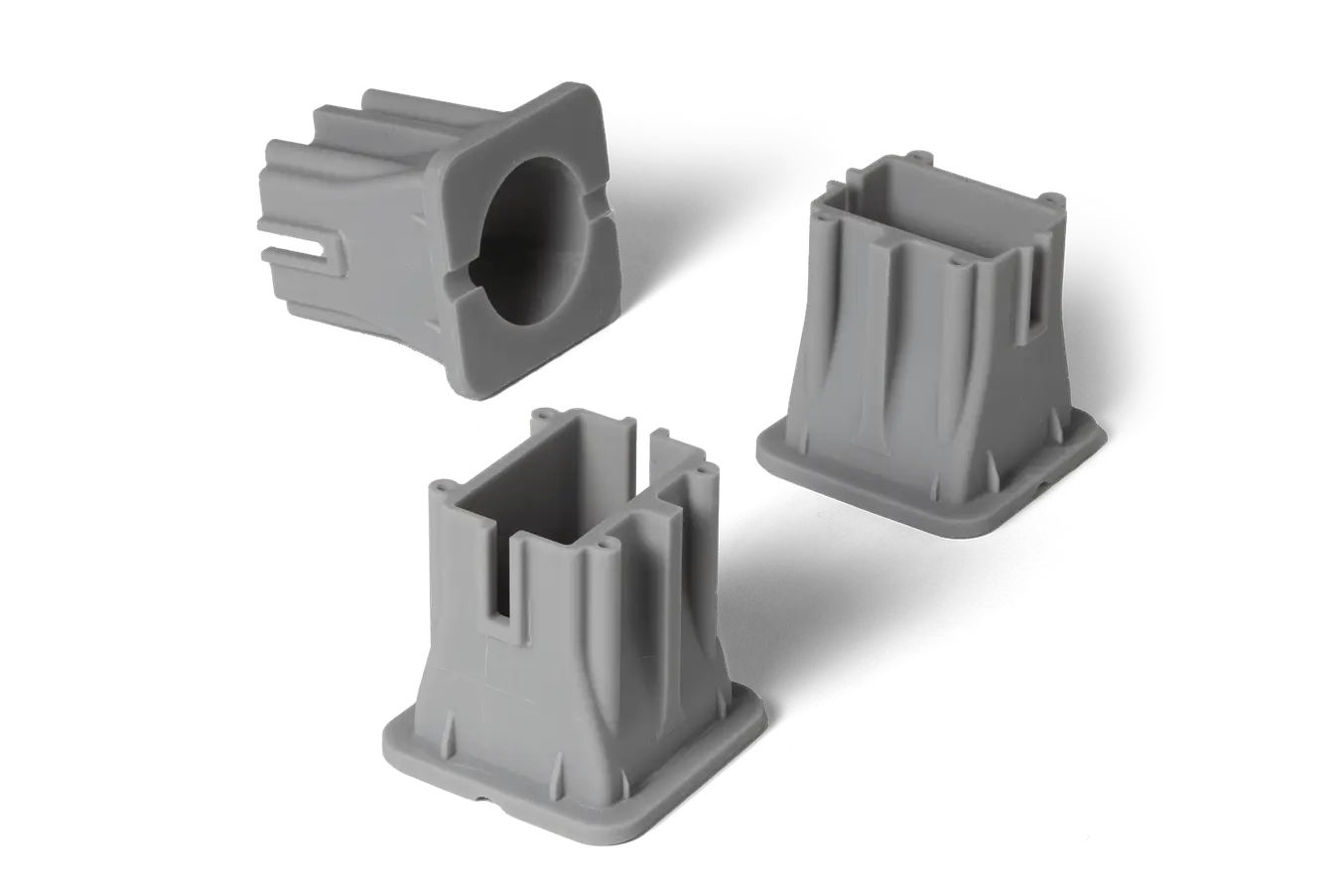

Look and Feel of Injection Molded Parts

Fabricate plastic parts with exceptional surface finish far superior to other fabrication methods such as FDM 3D printing.

Stiff and Functional

Produce stiff and functional parts with a 2.9GPa modulus that can handle post-fabrication operations such as tapping, trimming, and drilling.

Applications

Flame Retardant (FR) Resin is a cost and time-effective solution for fabricating self-extinguishing parts.

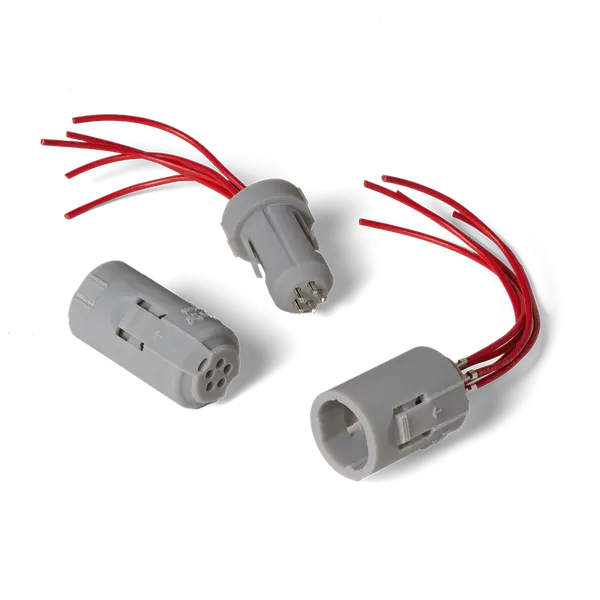

FR Resin is ideal for:

Material Properties

Post-cured at 70ºC for 60 minutes

Heat Deflection Temperature 0.45 MPa

Heat Deflection Temperature 1.8 MPa

Tensile Modulus

Ultimate Tensile Strength

Elongation at Break

Notched Izod

Post-cured at 80ºC for 120 minutes

Heat Deflection Temperature 0.45 MPa

Heat Deflection Temperature 1.8 MPa

Tensile Modulus

Ultimate Tensile Strength

Elongation at Break

Notched Izod

Post-Processing

Washing

The foundational step in any SLA post-processing workflow is to remove any excess resin on the surface of the parts through an alcohol or ether wash.

Curing

Post-curing Engineering and Specialty Resins is essential for parts to achieve their full strength and functionality. This step completes the chemical reaction initiated during printing, transforming the part from its green state into a fully finished component.