3D Printing Watertight Enclosures and Pressure Testing Results

There is a widespread need for custom or low-volume watertight and gas-tight parts across several industries, such as marine research, underwater robotics, sustainable technologies engineering, oil and gas industries, and defense. Though some 3D printing technologies present an ideal solution for these parts, the common perception of additively manufactured parts is that they are porous and cannot be deployed in pressurized environments.

Through a partnership between Formlabs and the Undersea Robotics and Imaging Lab (URIL) at The University of Rhode Island, fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) multi-part assemblies were printed and tested in an underwater simulation pressure chamber.

The testing results prove that 3D printing can consistently produce enclosures that are watertight, can be deployed in highly pressurized environments, and that the workflow for creating them is accessible and affordable. In this white paper, we will provide the testing results and clear guidelines on how to affordably 3D print customized watertight enclosures

3D Printing Watertight Enclosures and Pressure Testing Results

There is a widespread need for custom or low-volume watertight and gas-tight parts across several industries, such as marine research, underwater robotics, sustainable technologies engineering, oil and gas industries, and defense. Though some 3D printing technologies present an ideal solution for these parts, the common perception of additively manufactured parts is that they are porous and cannot be deployed in pressurized environments.

Through a partnership between Formlabs and the Undersea Robotics and Imaging Lab (URIL) at The University of Rhode Island, fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) multi-part assemblies were printed and tested in an underwater simulation pressure chamber.

The testing results prove that 3D printing can consistently produce enclosures that are watertight, can be deployed in highly pressurized environments, and that the workflow for creating them is accessible and affordable. In this white paper, we will provide the testing results and clear guidelines on how to affordably 3D print customized watertight enclosures

Fabricating Watertight Parts

Waterproof vs. Watertightness

Waterproofness refers to a material’s inherent ability to repel water or prevent water from adhering to or being absorbed by a part. Watertightness refers to an object’s ability to prevent water from entering or exiting an enclosure, and has much to do with the construction of the enclosure or assembly as opposed to the fundamental nature of the components’ material.

While the waterproofness of different materials is inherently part of this experiment, the final results are based on the watertightness of multi-part enclosures. This is due to the utility of this type of data — creating watertight enclosures is difficult, and when done with traditional methods, can be laborious and expensive. 3D printing presents a novel way of conducting high-quality deep-sea and coastal research, as well as aiding in a multitude of industries that have to conduct operations underwater, including defense, oil and gas, utilities, and more.

Applications for Watertight Parts

Watertight parts are deployed in scenarios as diverse as offboard motors for boating and recreation, deep-sea robotic exploration, underwater photography, and more. When parts are watertight, they can also hold other fluids, and so they are extremely useful for applications where tubing carries liquids between components, such as automotive, chemical research, utilities, construction, and more.

For research applications in the ecology, geology, or climatology fields, creating customized equipment for study and sampling is often excessively expensive. Because each application is unique, and the environments where they’ll be deployed are ever-changing and difficult to manage from the surface, underwater, or fluidic components often have to have some degree of customization.

Fabrication Methods for Watertight Parts

Current methods for fabricating these watertight components typically involve well-known traditionally manufactured materials such as metal, injection molded plastics, or rubber. Mass-produced components are affordable, but to then configure them in such a way that meets the specific needs of the application can be difficult, and requires custom connectors, fixtures, or enclosures.

For multi-fit assemblies, these parts are sealed together through a combination of a screw thread features, interlocking or mating features, O-rings, or gaskets. Choosing O-rings can be extremely difficult, and dialing in the right parameters for your enclosure can be time-consuming. The Parker O-ring handbook has thousands of recommendations based on compression, diameter, thickness, material, pressurization, etc... The difficulty of the process of choosing a custom-sized O-ring leads many to fall back to standardization and mass-produced components, which limits the capacity for innovation and new applications.

3D Printing for Watertight Parts

Two SLA 3D printed watertight enclosures (left: Rigid 10K Resin, center: Clear Resin), and an SLS 3D printed enclosure (right: Nylon 12 Powder).

Since 3D printing has gained traction for customized or low-volume applications, there have been efforts to use 3D printing for underwater applications. Underwater machinery or robotic components in industries like research, oil and gas drilling, and construction are all unique — the types of parts and the functions they need to perform are specific to the needs of that venture. Therefore, underwater applications have traditionally been limited to well-funded ventures that can build expensive, customized machinery and equipment. 3D printing has the ability to change that — to fabricate customized goods for research and development at a fraction of the cost of traditional methods. To successfully deploy a 3D printed underwater solution, the right type of 3D printing technology and material should be carefully considered.

Fused Deposition Modeling (FDM)

The most commonly known form of 3D printing technology, fused deposition modeling (FDM), does not create watertight parts. From this inability arose a general misconception that 3D printed parts in general cannot be used in watertight applications. FDM technology extrudes melted plastic through a nozzle, laying down layer after layer, but not chemically binding them together. FDM printed parts are anisotropic, meaning they have different mechanical properties based on the direction in which mechanical stress impacts them, and are less dense than a similar object produced via alternative methods. Because layers are not chemically bonded together, liquids can seep into the surface of the part through the microscopic gaps in between layers. Enclosures printed on FDM printers are therefore not watertight unless the parts are heavily post-processed and sealed through some extra step, such as vapor smoothing or coating. These parts will implode under pressure and crack along the layer lines.

Stereolithography (SLA)

Stereolithography (SLA) 3D printed parts, conversely, are watertight because each layer is chemically bonded to the next. SLA parts are formed by a process in which a laser cures liquid resin one layer at a time — crosslinking the polymer chains within that layer as well as with the layers directly before and after. This process creates smooth surface finishes with virtually no layer lines and a non-porous surface through which water cannot penetrate. The parts have extremely good tolerances, and so multi-piece assemblies, such as the enclosures used in the testing of this paper, can be threaded onto one another with almost no air gaps between them. When combined with a seal or gasket, the enclosures are fully watertight and can withstand immense pressure.

Selective Laser Sintering (SLS)

Selective laser sintering (SLS) technology creates parts by sintering a cross-section of the part on top of a powder bed, then covering it with new powder to begin again. The parts are somewhat isotropic, but can exhibit mechanical property differences depending on the force application direction. SLS parts are watertight when designed with the appropriate tolerances and sealing techniques.

URI Undersea Robotics and Imaging Laboratory: Design Approach

Open Source Design

The University of Rhode Island Undersea Robotics and Imaging Laboratory (URIL) has a mission to democratize deep-sea research. Accessibly priced 3D printers like Form 4 and large-format Form 4L have made it possible to design and fabricate highly sophisticated deep-sea exploration tools and share those designs with the broader scientific community.

The URIL has published several papers on their deep-sea research, including a guide to the novel design for DEEPi, a deep-sea imaging and control system, an investigation of the use of passive stabilization to support SLA printing aboard a moving vessel at sea, and an inquiry into the use of biomimicry in enclosure design based on nautiloid shapes. Principal Investigator Brennan Philips and PhD candidate Breanna Motsenbocker have been iterating their deep-sea camera and robotics enclosures for years and have published several papers detailing their findings. The lab has published its open-source design in an effort to make the fabrication process accessible to communities that have previously not had the funding to pursue underwater data collection or research.

The design presented here was chosen to have an internal volume large enough to fit a microcomputer (Raspberry Pi Zero) and a small battery. This volume requirement sets the parameters for the inner diameter and length of the housing. The thickness of the wall was chosen based on previous prototype housings and the goal depth rating (at least 1500 m). Since there are no reliable FEA methods to simulate the implosion pressure of 3D printed housings, the design was tested with a hydrostatic pressure chamber to ensure the design was watertight and thick enough to withstand the pressure at 1500 m. The Undersea Robotics and Imaging Lab has made both designs — one used in testing with thin walls and the other with thicker walls, untested — open source and available for public reproduction.

The multi-piece enclosure was designed for ease of use — each component has 3D printed threads that make it easy to screw and unscrew the collar from the end cap and body. In the field, researchers are often in small vessels that are moving with the waves, and using screw bolts can be inconvenient. The resolution of Form 4 Series printers means the screw threads can be integrated into the design along with the O-ring for complete watertightness, as well as functional assembling or disassembling in case of changes.

This basic housing design, though intended for one specific type of microcomputer, can be easily modified with penetrations or mounts for cameras, sensors, pass-throughs, etc. Furthermore, if the main body is kept the same, there can be multiple designs for endcaps and collars with varying purposes, sizes, and shapes, as long as the mating function of the screw threads can integrate with the body.

How to Choose an O-Ring for a 3D Printed Watertight Enclosure

The Undersea Robotics and Imaging Lab has experimented and found success with both face seal O-ring seals and bore seals, but prefers face seal O-ring seals.

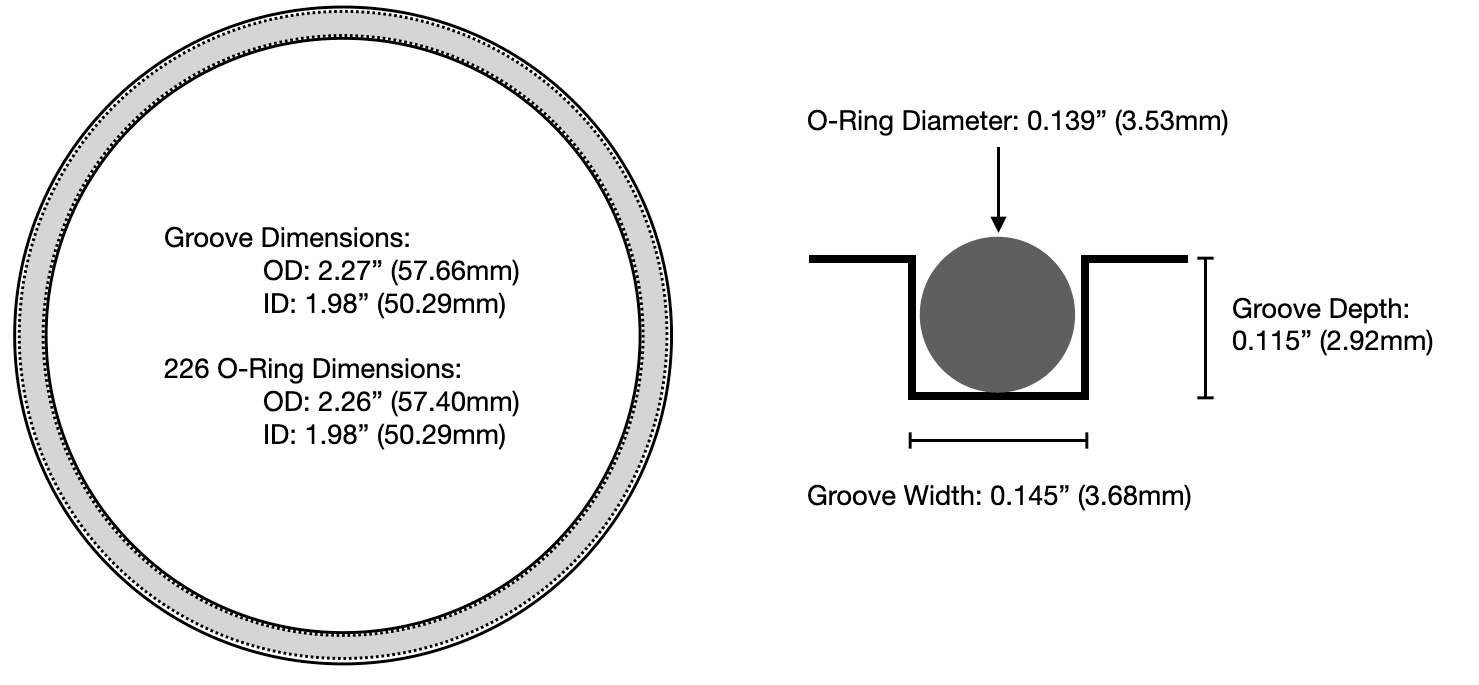

Once the inner and outer diameters for the housing are chosen, a face-seal O-ring can be selected based on the inner diameter. The O-ring should properly fit the face between the endcap and the body. ‘2-dash’ O-rings, or those with a ⅛” (0.139”) fractional width, create the most reliable seal for SLA printed parts.

A general observation is that thicker diameter O-rings are more resistant to compression in 3D printed parts. For groove dimensions, aim for a depth that is 15% - 20% less than the fractional diameter of the O-ring itself (e.g., 100* (1-(0.115”/0.139”)) = 17.2%). The groove must also be wider than the O-ring’s cross-section, allowing for some compression.

A good resource for guiding these dimensions in much more detail for many different use cases can be found in the Parker O-Ring Handbook.

Acrylic Covers: Advantages, Laser Cutting, and Securing Method

In the same fashion that gasket covers are used for low-pressure (<100 m depth) applications, the Undersea Robotics and Imaging Lab has had success combining face seal O-rings with 3D printed housings and laser-cut acrylic covers.

Complex O-ring groove profiles can be used in these designs, as long as a sufficient radius is provided for the O-ring. 2-dash O-rings (0.139” in fractional width) can handle groove radius bends as small as 0.375.” To predict the correct O-ring size, use the overall inner radius length of the entire O-ring groove to calculate an equivalent inner diameter of an O-ring that comes close to it, then order two to three sizes in that same range for an actual test fit. Accurately predicting the crush depth of these more complex shapes is not possible, but using 0.375” thick acrylic works well for anything up to 100 m depth.

Watertightness Testing and Results

Printing, Post-Processing, and Material Choice

FDM, SLA, and SLS technologies were used to create the enclosures; the Nylon 12 GF Powder was printed on the Fuse 1+ 30W SLS printer, while the other materials (Grey Resin, Clear Resin, BioMed Amber Resin, and Rigid 10K Resin) were printed on the Form 3+ SLA printer. FDM printed parts printed on a Craftbot machine using PLA filament were found to absorb water immediately upon submersion, and were eliminated from testing.

Both SLA and SLS technologies are relied upon in engineering and research disciplines, but excel in different situations. SLS technology is excellent for low-volume production of end-use parts, has a library of familiar materials including nylon and TPU, and creates strong, industrial-quality parts. SLA printers excel where smooth surface finish and very specific material properties are required. In this test, both the smooth surface finish of the SLA parts and their density lent themselves to performing well in a pressurized environment.

The four SLA materials chosen represent different strengths:

- Grey Resin: An all-purpose, extremely consistent material ideal for prototyping and smooth surface finishes

- Clear Resin: A highly accurate and consistent material that can be polished to almost complete optical transparency for applications where visualization of inner components is crucial

- BioMed Amber Resin: A biocompatible material used for regulatory-approved medical device prototyping and manufacturing

- Rigid 10K Resin: A highly glass-filled resin that is ideal for industrial parts that need to withstand significant load without bending, such as rapid tooling for injection molding.

The SLS powder chosen, Nylon 12 GF Powder, is a glass-filled material with enhanced stiffness and heat resistance to endure demanding manufacturing conditions. It is ideal for applications where structural rigidity and thermal stability are critical.

Post-processing methods, such as polishing, media blasting, coating, plating, or dyeing, can have an effect on the porosity of 3D printed parts as well as their surface finish. Some of these methods can be used to achieve a higher degree of watertightness. For this experiment, some of the Rigid 10K Resin enclosures were media blasted, which smooths the surface finish and removes surface porosity.

Because no industry-standard values exist for these 3D printed materials in terms of implosion testing, at the beginning of their research, the URIL created a custom-fabricated implosion chamber to mimic the pressures felt at thousands of meters below sea level.

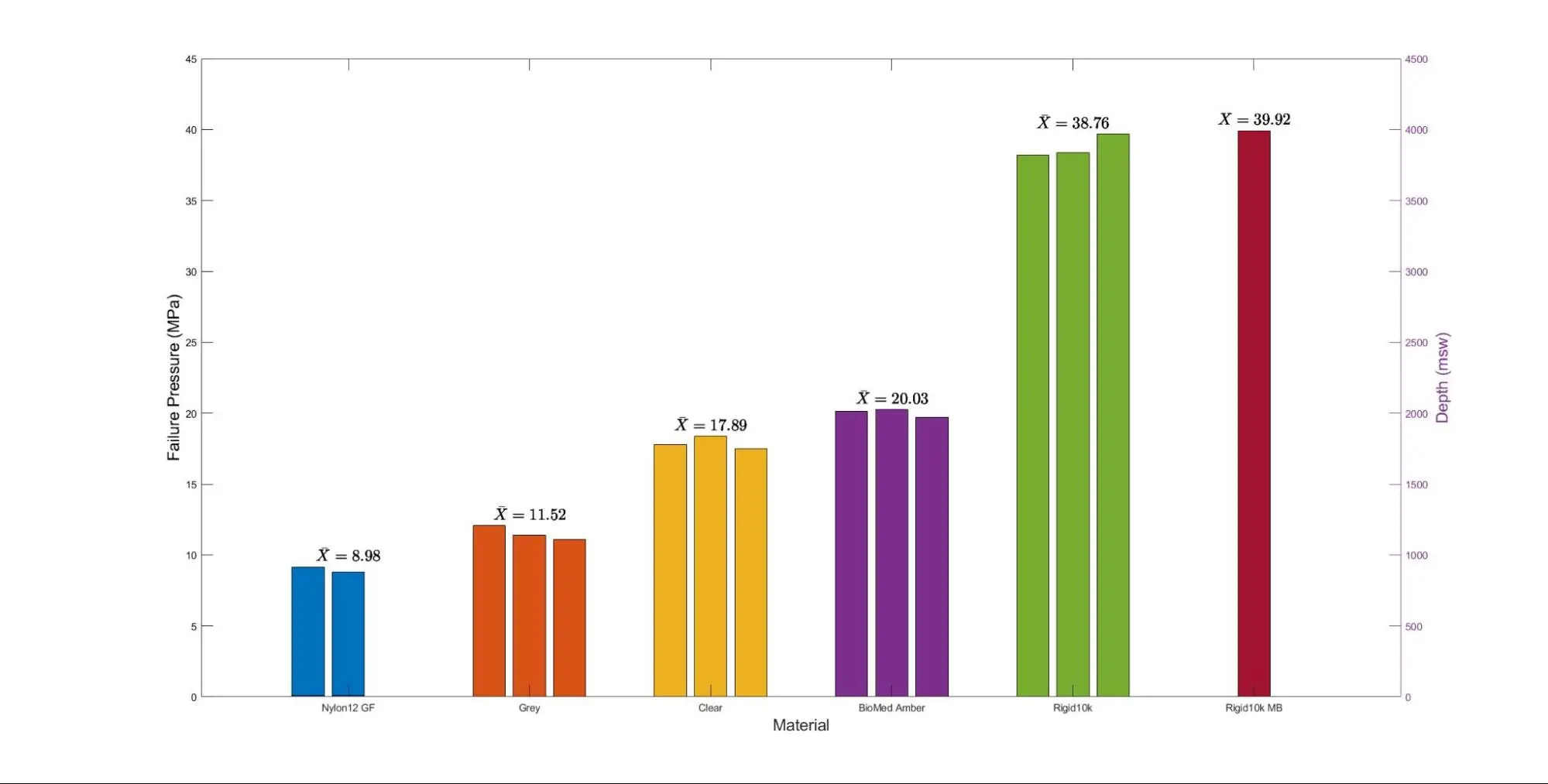

Pressure Testing Results

Nylon 12 GF Powder (left) imploded at the lowest pressure, an average of 1304 psi, while BioMed Amber Resin (right) withstood a much higher pressure, implosing at an average of 2907 psi.

| Printing Process | Material | Average Implosion Pressure (PSI) | Range (PSI) |

|---|---|---|---|

| SLS | Nylon 12 GF Powder | 1304 | 48 |

| SLA | Grey Resin | 1672 | 139 |

| SLA | BioMed Amber Resin | 2907 | 80 |

| SLA | Rigid 10K Resin (unblasted) | 5626 | 215 |

| SLA | Rigid 10K Resin (media blasted) | 5794 | - |

When reviewing the results, it’s important to note that even the lowest average implosion pressure, 1304 psi for Nylon 12 GF Powder enclosures printed on the Fuse Series SLS printers, represents a considerable depth. 1304 psi is the water pressure at depths of close to 1000 m underwater, far deeper than the areas studied by the many coastal communities that can benefit from affordable, accessible deep-sea research.

Discussion of Results

The results demonstrate that SLA and SLS 3D printing are effective methods for creating watertight enclosures when combined with O-ring seals, with SLA 3D printing as the clear winner. FDM printed parts were found unsuitable for this application, as they take on water immediately upon submersion and cannot withstand any amount of pressurization.

The stiffer SLA materials performed the best under pressure, and post-processing methods such as media blasting can further improve performance by reducing surface porosity.

Rigid 10K Resin, printed on the Form 4 Series and media blasted, is the best choice for creating watertight parts, and can withstand pressures of over 5500 psi. O-ring selection and enclosure design are important steps in creating a fully watertight enclosure, and open-source designs such as the one created by Motsenbocker at the URIL can be used to rapidly and cost-effectively create watertight parts and assemblies.

These findings prove that 3D printing, especially with accessible and inexpensive printers like the Formlabs Form 4 Series, can help democratize ocean research and open up new avenues of exploration for coastal communities. The advanced materials available, coupled with a proven and easy workflow, make the technology an ideal solution for low-cost, high-value research.

To inquire about the URIL and their work exploring coastal communities and deep-sea environments, visit their website.