Enhancing the Surface Quality of SLS 3D Printed Parts With Vapor Smoothing: A Collaborative Study by Formlabs and AMT

Selective laser sintering (SLS) 3D printing is a proven manufacturing technique with high-performance materials — and those materials can go even further in performance and appearance when paired with advanced post-processing methods, such as vapor smoothing.

In this white paper, we will review the considerations and benefits of vapor smoothing, report results from testing Formlabs SLS powders with the AMT Vapor Smoothing System, and discuss applications, costs, and how you can get started.

Enhancing the Surface Quality of SLS 3D Printed Parts With Vapor Smoothing: A Collaborative Study by Formlabs and AMT

Selective laser sintering (SLS) 3D printing is a proven manufacturing technique with high-performance materials — and those materials can go even further in performance and appearance when paired with advanced post-processing methods, such as vapor smoothing.

In this white paper, we will review the considerations and benefits of vapor smoothing, report results from testing Formlabs SLS powders with the AMT Vapor Smoothing System, and discuss applications, costs, and how you can get started.

Introduction

Selective laser sintering (SLS) is a widely used 3D printing technology that fabricates intricate parts by employing a laser to sinter powdered materials layer by layer. This approach yields precise and robust components, yet it has one significant drawback: the resulting surface finish tends to be rough and porous, detracting from its applicability in scenarios where a smooth finish is paramount, such as high-friction assemblies or end-use part production. However, through the deployment of additional post-processing techniques, such as vapor smoothing, SLS parts can achieve surface quality and durability comparable to traditional injection molded parts.

In an attempt to understand and evaluate the effectiveness of vapor smoothing on SLS 3D printed components, Formlabs partnered with Additive Manufacturing Technologies (AMT). The joint endeavor focused on scrutinizing the impact of vapor smoothing on various parts printed on our Fuse Series SLS 3D printers, utilizing different materials such as Nylon 12 Powder, Nylon 11 Powder, TPU 90A Powder, Nylon 11 CF Powder, and Nylon 12 GF Powder.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Overview of Vapor Smoothing

Vapor smoothing is a chemical process that involves exposing the surface of an SLS 3D printed part to a solvent vapor. During the process, a combination of heat and solvent vapor selectively melts the surface, creating a smoother, sealed surface. The process predominantly alters the surface layers, leaving the inner core intact. The accuracy of the smoothing is controlled using tailored conditions within the process chamber to achieve the required surface finish, often with custom settings profiles developed by the vapor smoothing machine manufacturer.

The choice of solvent used for this process is largely dependent on the material type used in the printing process. Each material interacts differently with solvents; hence, the ideal solvent varies from one material to another. For instance, nylon 11 and nylon 12 are generally treated with the same solvent, whereas polypropylene requires a distinct chemistry for effective smoothing.

Vapor smoothing is typically conducted within a sealed environment, such as a vapor chamber, to avoid solvent evaporation. These specialized chambers, manufactured and marketed by companies like AMT, are often compact in size, comparable to the footprint of a Fuse 1+ 30W printer. This containment ensures a controlled, effective, and safe vapor smoothing process.

The components targeted for vapor smoothing are affixed to a rack, which is positioned within the vapor chamber. Once the chamber is securely sealed, the process commences by establishing the appropriate conditions, namely the chamber temperature and vacuum level. Solvent vapor is then introduced into the chamber to chemically interact with the parts and promote surface smoothing. The vapor smoothing process takes around two hours, start to finish. Because the time is constant irrespective of the number, geometry, or size of parts, it scales efficiently to higher volumes and batch production.

The Formlabs Fuse 1+ 30W SLS 3D printer (left) and the AMT PostPro SF100 (right).

Benefits of Vapor Smoothing

Surface Roughness and Color Uniformity

Vapor smoothing is primarily used for its ability to create a smoother and more polished appearance, similar to that of an injection molded part. This is particularly useful for parts that will be visible, such as end-use products or final iteration prototypes that require a Class A or B finish.

Formlabs and AMT have found an approximately 72% - 81% reduction in average surface roughness (Ra) after smoothing parts printed in Formlabs SLS Powders. Formlabs has found that vapor smoothing produces a consistent, opaque, semi-glossy surface finish on all Formlabs SLS Powders.

Custom perfume bottle packaging, including a black wrapping feature that was printed on the Fuse Series SLS 3D printer in Nylon 11 Powder and then vapor smoothed.

Bacteria Growth and Moisture Absorption

Vapor smoothing also helps to seal the surface of the part, reducing porosity and improving its resistance to moisture and bacterial growth. This can be particularly beneficial in applications where the part will be exposed to harsh conditions and solvents, such as automotive or aerospace components (see the Moisture Absorption Results chapter for details), or where bacterial growth is a concern. Formlabs and AMT found a 60% reduction in MRSA bacteria growth on Nylon 12 Powder parts.

3D printed lightweight, customized shin guards are an application that benefits from reduced bacterial growth. Printed in Nylon 11 Powder and vapor smoothed.

Non-Line-of-Sight Application

One of the standout advantages of vapor smoothing is its 'non-line-of-sight' application, signifying that the solvent vapor can uniformly interact with all surfaces of the part, including those concealed from direct view. This attribute presents a significant edge over HVLP spray-applied coatings, which pose challenges when applied to hidden, internal, or complex surfaces, particularly in the case of intricate geometries such as lattices. Consequently, vapor smoothing ensures a uniform, comprehensive surface finish, regardless of the complexity of the part's structure.

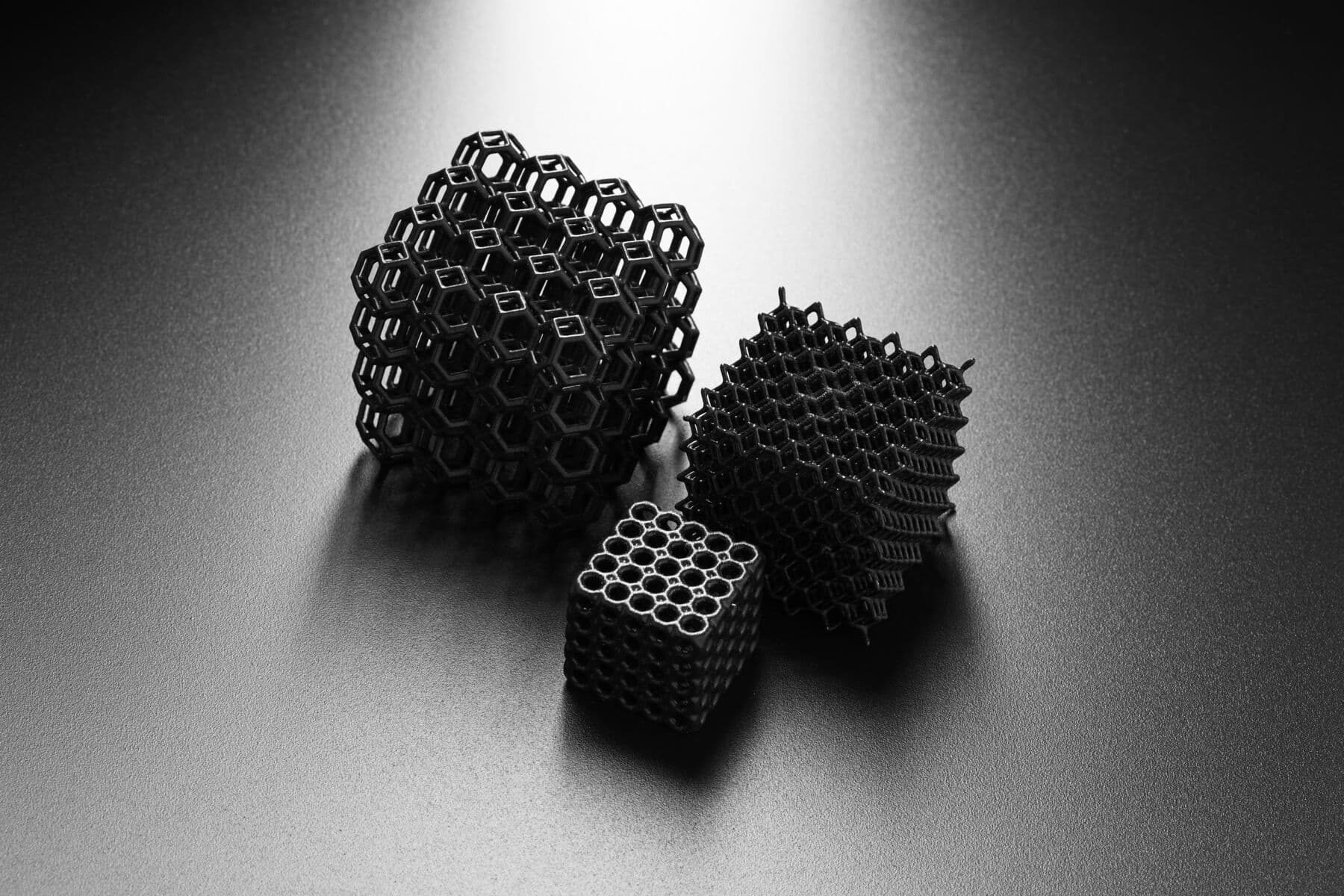

Lattice cubes printed in TPU 90A Powder after vapor smoothing.

Preservation of Mechanical Properties

A further advantage of vapor smoothing lies in its minimal impact on the inherent mechanical properties of the base material. Formlabs with AMT revealed only a minor variance in mechanical properties, with results deviating only a few percent from the original. This signifies that the benefits of vapor smoothing — improved aesthetics and surface finish — can be accomplished without impinging upon the part's functional performance or structural integrity. This makes vapor smoothing an exceptionally effective post-processing technique that balances both form and function in 3D printed components.

Process and Design Considerations for Vapor Smoothing

Vapor smoothing SLS parts requires careful consideration of certain process parameters and design features to ensure optimal results. Below are key points to consider:

- Predefined Profiles: Make certain that your vapor smoothing equipment has predefined profiles configured specifically for Formlabs SLS Powders.

- Grouping Similar Parts: Whenever possible, group together parts with similar wall thicknesses. This encourages uniformity in the smoothing process and prevents disparities in the final results due to varying material characteristics.

- Connection Points: To ensure complete coverage during the vapor smoothing process, it's advisable to add a connection point to parts. This allows the parts to be attached or hung via a clip, ensuring that all surfaces can be evenly smoothed.

- Part Orientation: It's crucial to correctly orient parts in the vapor chamber. For parts with cupped features, they should be oriented pointing downwards. This prevents the pooling of solvent in these features.

- OEM Consultation: Lastly, never hesitate to contact your equipment provider for further optimization suggestions. Their expert advice can provide additional insights and fine-tune the vapor smoothing process to maximize outcomes.

Vapor Smoothing Profiles

Each vapor smoothing company and machine has its own set of parameters and solvents used to smooth parts. The parameters most often adjusted are temperature and pressure. Additionally, each SLS material will have its own profile developed by the vapor smoothing manufacturer to ensure the best quality results.

In a collaborative effort, Formlabs and AMT have developed specialized machine profiles tailored specifically for all Formlabs SLS materials. These profiles are designed to provide the best possible surface finish when vapor smoothing parts produced using Formlabs SLS powders.

For access to these specially developed profiles, please reach out to AMT directly. TPU 90A Powder has been shown to vapor smooth less consistently than rigid materials, like nylon. Print TPU 90A Powder parts vertically to achieve the best vapor smoothing results.

Part Geometry

In addition to a profile for each SLS material, vapor smoothing machines may also have profiles that are specific to part geometry. Part geometry, such as wall thickness and total part size, can affect the smoothing process and should be accounted for in the vapor smoothing profile settings. For example, AMT has machine profiles for thin Nylon 12 Powder parts (3 mm wall thickness).

Attempting to smooth parts that have both very thin walls and very thick walls on the same part, or batches that include parts of both geometry types, can result in non-uniform smoothing, with surfaces that have bubbling or inadequate smoothing. Parts with similar geometries should be grouped together in batch runs as much as possible.

Racking and Witness Marks

During the vapor smoothing process, parts need to be suspended from a metal wire rack, which requires some geometry on which to attach a wire or clip. If your part does not have a feature on which it can be suspended, consider adding a connection point, such as a small through-hole or sacrificial breakaway tab. In general, due to the flow of the solvent over the part surface, witness marks on vapor smoothed parts are extremely minimal.

For production runs with many parts, it is also possible to connect all parts together in the 3D print, creating a structure similar to a casting tree. While this method results in additional powder consumption, connecting parts together in the 3D print can greatly reduce the labor time involved in the racking process and can include convenient breakaway points from which to separate parts after smoothing.

Mitigating Solvent Pooling

Given that the solvent is vaporized within the chamber during the smoothing process, it is susceptible to pooling in cup-shaped geometries on the printed part. This can potentially lead to uneven bubbles forming on the part's surface. To prevent this, it is recommended to hang parts with cup-shaped features facing downwards, which encourages solvent runoff. Alternatively, consider eliminating such features from the part's design whenever feasible.

Safety and Facility Considerations

AMT provides a comprehensive site preparation guide for all PostPro SF machines to ensure the installation and operation of the vapor smoothing systems align with safety standards. This guide includes vital safety and handling training for operators, a critical step in mitigating potential risks.

In terms of space requirements, vapor smoothing systems by AMT are relatively compact, necessitating as little as 2.2 meters (7.2 feet) in width and 3.2 meters (10.5 feet) in depth of floor space, contingent on the specific model and throughput. For comprehensive installation and safety information, contact AMT directly. Ensuring that these considerations are addressed allows for a safe and efficient deployment of vapor smoothing systems in your workspace.

Comprehensive Assessment of Formlabs Materials Post Vapor Smoothing

Formlabs and AMT performed extensive testing to characterize the effects of chemical vapor smoothing technology by AMT on the material properties of a variety of parts printed using Formlabs SLS technology. The testing focused on surface quality, mechanical properties, cytotoxicity, and antimicrobial properties. Testing was done on Nylon 12 Powder, Nylon 11 Powder, TPU 90A Powder, Nylon 11 CF Powder, and Nylon 12 GF Powder.

The results demonstrate that AMT PostPro vapor smoothing systems can improve the surface quality of the parts and provide antimicrobial properties without any negative cytotoxicity effects.

Test Methods

| Test | Sample Type and Test Standard | Total Number of Samples in Each Material | Unprocessed | Processed |

|---|---|---|---|---|

| Tensile Test | ASTM D638 Type 1 | 20 | 10 |

10 |

| Surface Roughness* | ASTM D638 Type 1 | 10 | 5 | 5 |

| Microscopy Analysis** | 10 mm2 square | 2 | 1 | 1 |

| Cytotoxicity | ISO 10993-5 (2009); ISO 10993-1 (2021); ISO 10993-12 (2021) | 5 | 0 | 5 |

| Antimicrobial | ISO 22196 | 8+1 reference | 1 | 8 |

| Moisture Absorption | Percent weight gain over 24 hours for a printed 1 x 1 x 1 cm cube immersed in the respective solvent | 10 | 5 | 5 |

*Surface roughness analysis was conducted with a Mitutoyo Surftest SJ-210 with a stylus tip radius of 2μm, tip angle 60°, and

measuring force 0.75kN. Five measurements at different areas of each surface were made before and after processing.

**Microscopy analysis was done using a Hirox KH-8700 digital microscope with MX(G)-2016Z lens. Analysis was done at a

magnification of 60x.

Surface Roughness Test Results

| Material | Results Post Vapor Smoothing (RA) | Percent Reduction |

|---|---|---|

| Nylon 12 Powder | 2.33 | 75% |

| Nylon 11 Powder | 2.65 | 73% |

| TPU 90A Powder | 3.26 | 81% |

| Nylon 12 GF Powder | 2.80 | 72% |

| Nylon 11 CF Powder | 2.28 | 80% |

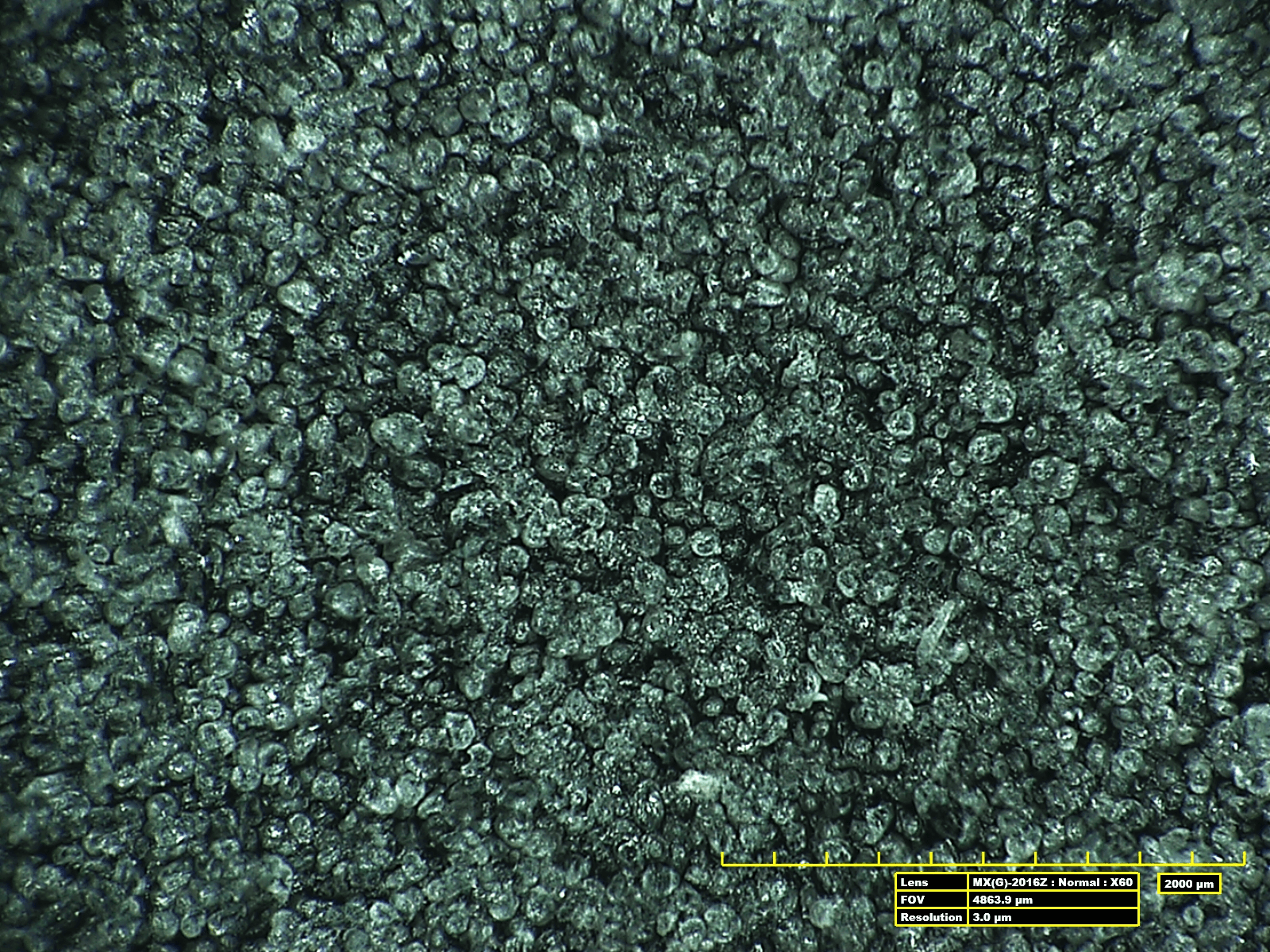

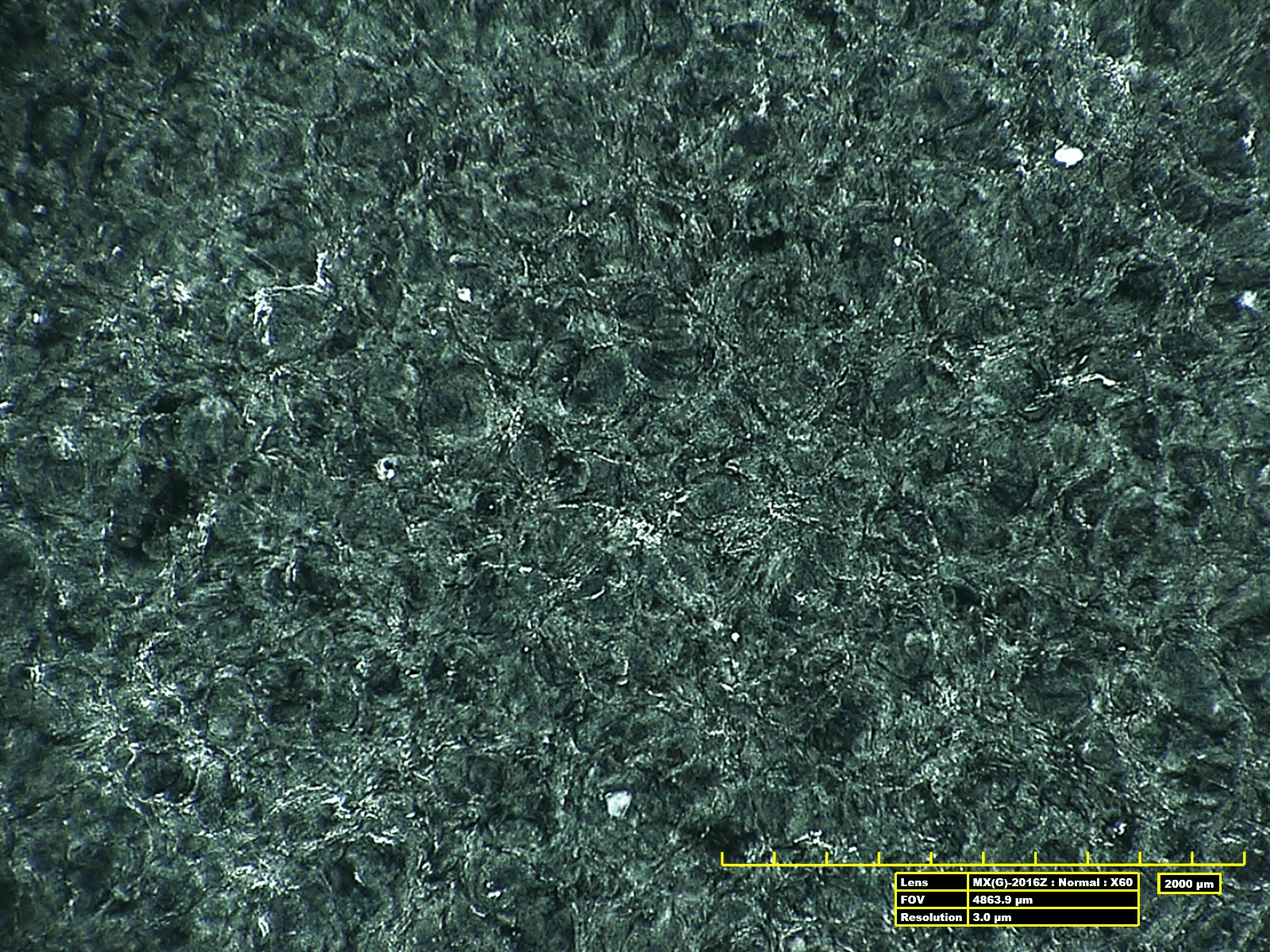

These images show a 60x magnified view of the surface of a flat Nylon 12 Powder printed part, prior to vapor smoothing (left) and after vapor smoothing (right).

Microscopy images reveal an abundant presence of unsintered material (left image), crevices, and surface porosity on the as-printed surfaces. These artifacts are completely removed by the PostPro chemical vapor smoothing process, leaving the surface smooth, sealed, and uniform (right image).

Mechanical Test Results

After vapor smoothing, the general mechanical properties of the printed material were preserved within a few percentage points in all cases — and in some cases, they were even slightly improved.

Ultimate Tensile Strength (X/Y) (MPa)

| Material | As Printed | Vapor Smoothed |

|---|---|---|

| Nylon 12 Powder | 50 | 49 |

| Nylon 11 Powder | 49 | 50 |

| Nylon 12 GF Powder | 52 | 59 |

| Nylon 11 CF Powder | 52 | 59 |

| TPU 90A Powder | 9 | 10 |

Elongation at Break

| Material | As Printed | Vapor Smoothed |

|---|---|---|

| Nylon 12 Powder | 11% | 12% |

| Nylon 11 Powder | 40% | 49% |

| Nylon 12 GF Powder | 4% | 6% |

| Nylon 11 CF Powder | 15% | 19% |

| TPU 90A Powder | 251% | 263% |

Antimicrobial Results

After vapor smoothing, Nylon 12 Powder shows a 61% reduction in MRSA growth and a 32% reduction in E.Coli growth. Samples were tested through BioLabTests. Contact Formlabs for the full certificate of analysis.

Nylon 12 Powder Antimicrobial Results

| 0 hrs | 24 hrs | Log10 | % Reduction | |

|---|---|---|---|---|

| Vapor Smoothed (MRSA) | 7.99 x 104 | 7.60 x 104 | 0.41 | 61% |

| Control (MRSA) | 7.99 x 104 | 1.93 x 105 | N/A | N/A |

| Vapor Smoothed (E.Coli) | 9.12 x 104 | 8.43 x 105 | 0.17 | 32% |

| Control (E.Coli) | 9.12 x 104 | 1.24 x 106 | N/A | N/A |

Cytotoxicity Results

Samples printed in Nylon 12 Powder were vapor smoothed and then tested for cytotoxicity, according to ISO 10993 standards, specifically ISO 10993-5 (2009), ISO 10993-1 (2021), and ISO 10993-12 (2021). These samples did not cause a cytotoxic effect. For a sterilization report of unprocessed Formlabs Nylon 12 Powder samples, click here. Sterilization reports for other Formlabs 3D printing materials can be found here.

Moisture Absorption Results

After vapor smoothing, parts were found to have greatly reduced moisture and solvent uptake. The following tables detail the percent weight gain over 24 hours for a printed 1 x 1 x 1 cm cube immersed in respective solvents for Nylon 12 Powder and Nylon 11 Powder.

Nyon 12 Powder Results

| Solvent | Control (% Weight Gain) | Vapor Smoothed (% Weight Gain) |

|---|---|---|

| Diesel Fuel | 0.28 | 0.02 |

| Isooctane (Gasoline) | 0.03 | -0.01 |

| Mineral Oil (Heavy) | 0.39 | 0.07 |

| Salt Water (3.5% NaCl) | 0.1 | 0.07 |

Nyon 11 Powder Results

| Solvent | Control (% Weight Gain) | Vapor Smoothed (% Weight Gain) |

|---|---|---|

| Diesel Fuel | 0.29 | 0.01 |

| Isooctane (Gasoline) | 0.06 | 0 |

| Mineral Oil (Heavy) | 0.42 | 0.02 |

| Salt Water (3.5% NaCl) | 0.22 | 0.08 |

Nyon 12 GF Powder Results

| Solvent | Control (% Weight Gain) | Vapor Smoothed (% Weight Gain) |

|---|---|---|

| Diesel Fuel | 0.3 | 0 |

| Isooctane (Gasoline) | 0.02 | -0.02 |

| Mineral Oil (Heavy) | 0.39 | 0.02 |

| Salt Water (3.5% NaCl) | 0.12 | 0.08 |

Nyon 11 CF Powder Results

| Solvent | Control (% Weight Gain) | Vapor Smoothed (% Weight Gain) |

|---|---|---|

| Diesel Fuel | 1.41 | 0.16 |

| Isooctane (Gasoline) | 0.05 | 0.07 |

| Mineral Oil (Heavy) | 1.74 | 0.09 |

| Salt Water (3.5% NaCl) | 0.13 | 0.06 |

TPU 90A Powder Results

| Solvent | Control (% Weight Gain) | Vapor Smoothed (% Weight Gain) |

|---|---|---|

| Diesel Fuel | 2.24 | 0.67 |

| Isooctane (Gasoline) | 0.4 | 0.37 |

| Mineral Oil (Heavy) | 1.46 | 0.06 |

| Salt Water (3.5% NaCl) | 0.45 | 0.37 |

Application Examples

Customized bike computer mount assembly and mechanical keyboard caps printed in Nylon 12 Powder and vapor smoothed.

Automotive Components

Vapor smoothing can be used to improve the surface finish and durability of automotive components, such as air intake manifolds, engine covers, and dashboard components. Moisture and solvent absorption reduction can also be useful for automotive applications in which solvents such as gasoline and diesel fuel are present, as vapor smoothing creates a sealed surface, reducing liquid and gas intake.

Flexible tube printed in TPU 90A Powder and vapor smoothed.

Medical Devices

SLS 3D printing is widely used in the production of medical devices today and vapor smoothing can be used to improve the surface finish of parts such as prosthetics, orthotics, and medical device assemblies, while maintaining the biocompatibility of the base material. Vapor smoothing also greatly reduces the surface friction that patients wearing orthotic devices may feel, as well as reducing the potential for bacteria growth.

Rigid orthotic insole shell printed in Nylon 11 Powder and vapor smoothed (left), and various medical devices printed in Nylon 11 Powder and vapor smoothed (right).

Consumer Products

Vapor smoothing can be used to enhance the appearance of consumer products, such as phone cases, eyewear, gaming components, and other electronic accessories, to that of a Class A or B surface. The surface glossiness can also be moderately controlled through this process, offering glossy to semi-matte finishes. Lastly, to achieve the best possible aesthetic, consider adding a coating on top of the vapor smoothed part, such as Cerakote on rigid SLS materials, or the BASF Ultracur3D Coat F on TPU 90A Powder.

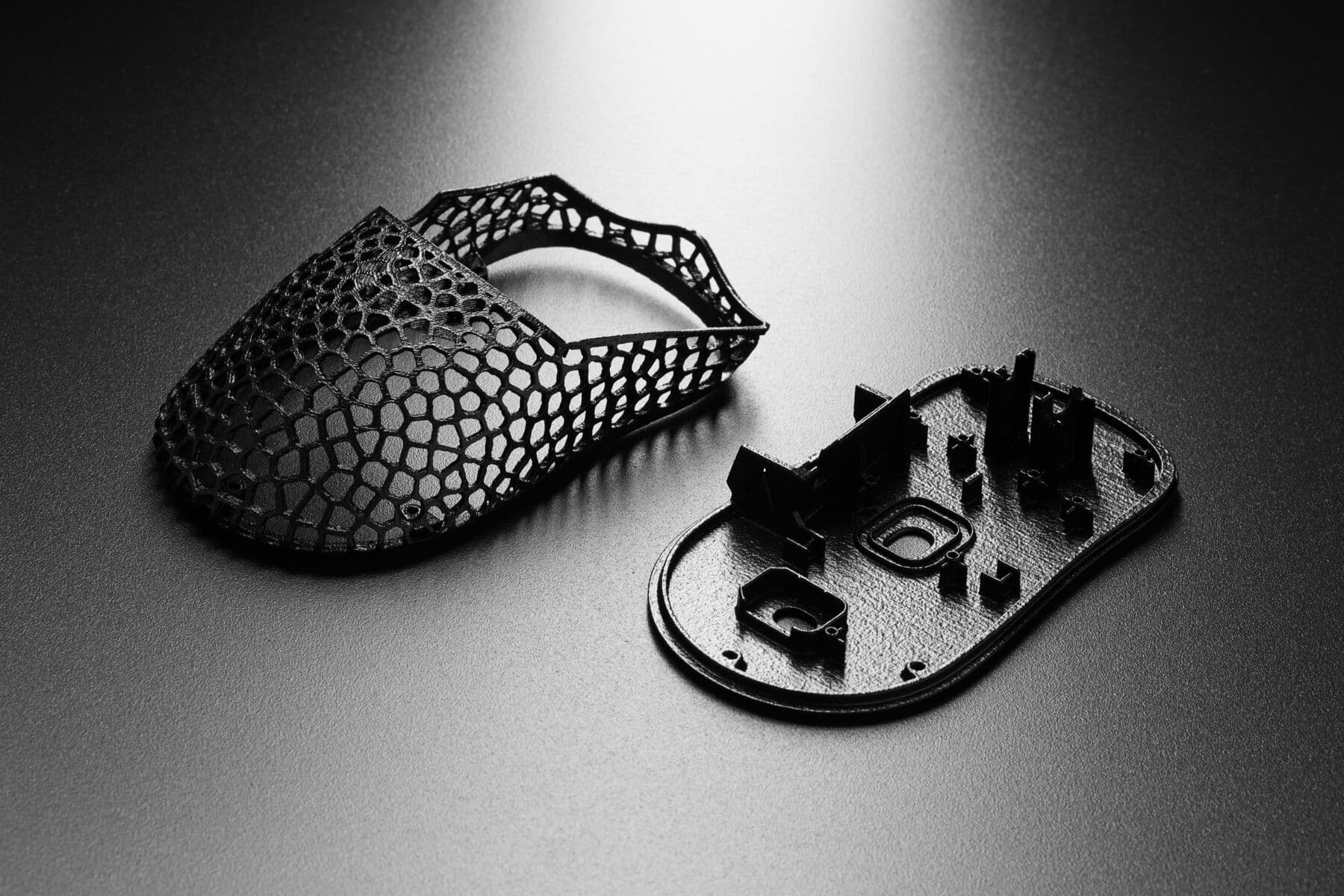

Lightweight gaming mouse assembly printed in Nylon 11 Powder and vapor smoothed.

Customer Case Study: 3D Nation

3D Nation is a professional 3D printing service provider with a focus on the automotive and aerospace industries. Located in the south of Germany, the company was founded after an engineer’s lockdown hobby of 3D printing turned into a full-scale business.

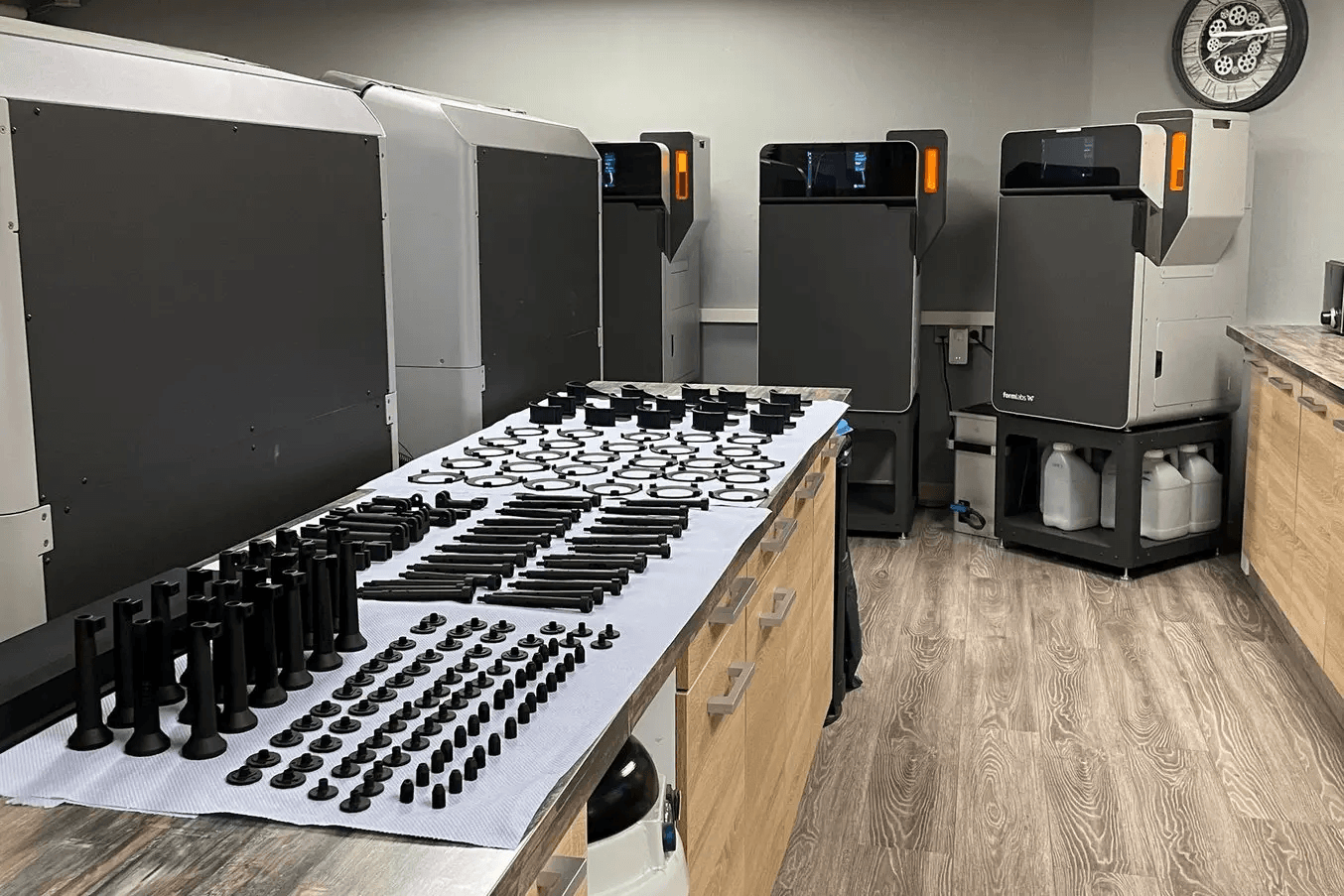

One of the company’s main focus areas is developing and prototyping new products and brand concepts for automotive companies and private airplane manufacturers. They’re currently building up their end-use production facility with a large fleet of SLA and SLS 3D printers, including eight Fuse Series selective laser sintering (SLS) 3D printers, as well as two AMT vapor smoothing machines.

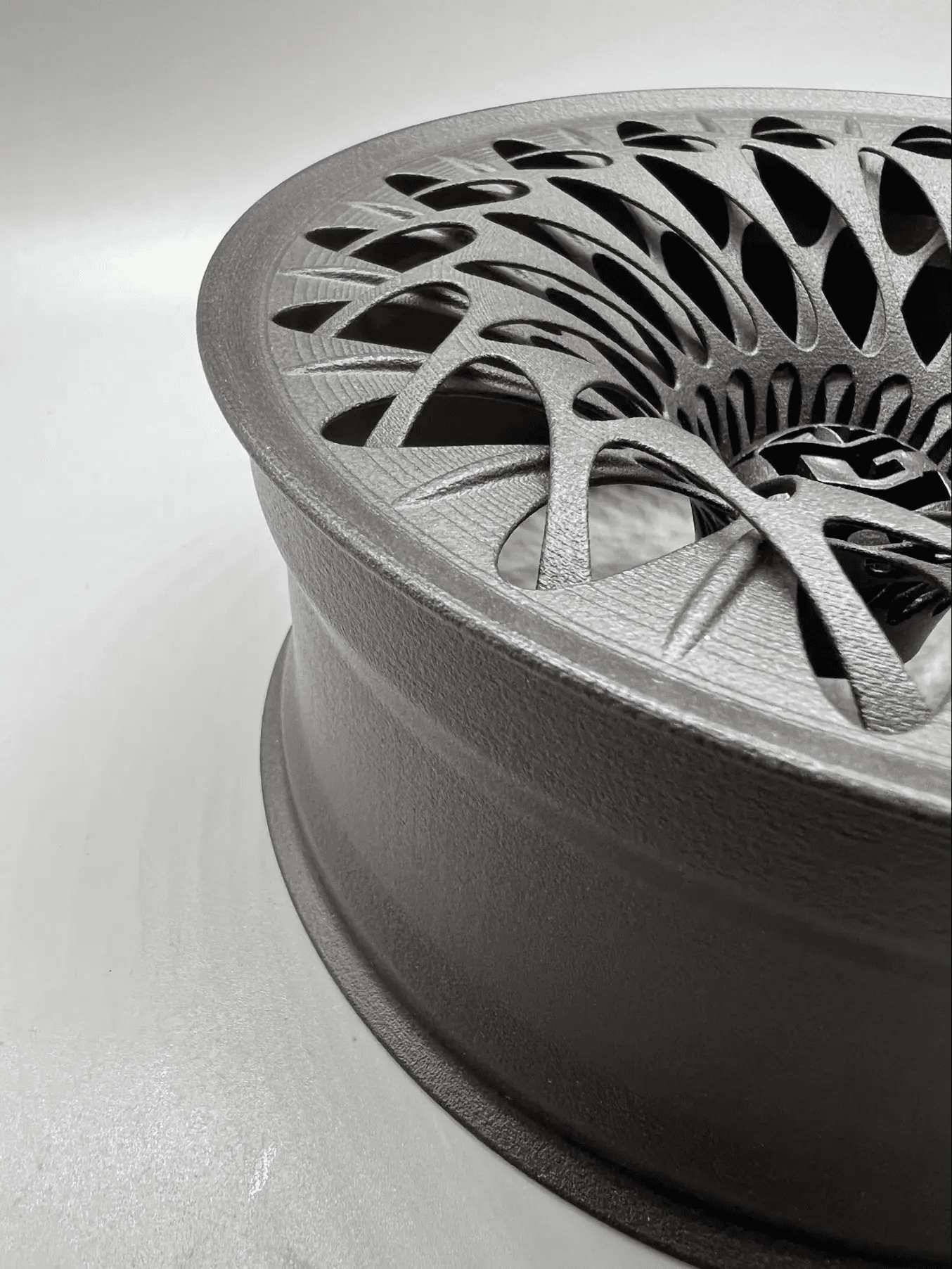

Jon Yates, founder of 3D Nation says, “By using the vapor smoothing technology we can skip the process of injection molding after the rapid prototyping phase. The parts that we print on our Fuse Series printers and post-process with a vapor smoother look very similar to an injection molded part and have very compelling material properties." The superior surface quality of vapor-smoothed parts, even without further painting or coating, makes them suitable for end-use applications, where finishes, textures, and imperfections are of paramount importance.

“For any parts that are going to be under a lot of stress or have to withstand a lot of temperature changes, we use vapor smoothing. For instance, for the ducting for cooling breaks on race cars, because at the front of the ducting, it's taking cold air in, and at the back of the ducting it can be 150 °C to 200 °C. Here, a vapor smoothed part out of Nylon 12 GF Powder does a perfect job,” Yates says.

Options for Vapor Smoothing

Own Your Own Production

There are currently two main companies that provide vapor smoothing equipment: AMT and Dyemansion. Both companies sell vapor smoothing hardware and consumables. The price of these machines varies depending on size, throughput, and material type, but typically starts around $100,000 with options for financing available.

AMT's PostProSFX is a benchtop machine that offers the same affordability, ease-of-use, and accessibility as the Fuse Series does for 3D printers.

Utilize Service Bureaus

Alternatively, there are many service bureaus that offer smoothing as a service. Not all service bureaus offer both Formlabs 3D printing and vapor smoothing; some may offer 3D printing and vapor smoothing, and some may accept printed parts for smoothing. Below is a list of some of the AMT-certified service bureaus that offer both Formlabs 3D printing and/or smoothing as a service.

| Company | Relevant Services Offered | Specialty | Location |

|---|---|---|---|

| 3DNation | Fuse Series SLS 3D Printing, Vapor Smoothing, Dyeing | Aerospace, Automotive, General Engineering | Oppurg, Germany |

| Avid Product Development | Vapor Smoothing, Cerakote, Dyeing | Product development | Colorado, USA |

| AB Corp | Vapor Smoothing, BASF Ultracur3D Coat F, TPU Coating, Dyeing | Production runs | Boston, USA |

Costs of Vapor Smoothing

The cost of vapor smoothing depends on several factors, including the size of the part, the material used, the complexity of the part surface, and the quantity of parts.

Typically, the cost of vapor smoothing is roughly proportional to the size and quantity of parts. A non-reusable amount of solvent is needed for each run of the machine, incentivizing operators to load as many similar parts as possible into a single run. The more similar-sized parts in a run, the lower the cost per part. It is not recommended to process only a single part in one process run, as this would result in a high cost per part.

Consider the following example cost scenarios in which the 3D printed part is printed by the customer and sent to Avid Product Development, a service bureau in Colorado, for vapor smoothing:

| Part | Rigid Orthotic Insole | Eyewear Frames | Watch Straps |

|---|---|---|---|

| Material | Nylon 11 Powder | Nylon 12 Powder | TPU 90A Powder |

| Model Dimensions (mm) | 157 x 23 x 80 | 144 x 36 x 47 | 262 x 13 x 37 |

| Quantity | 50 | 80 | 50 |

| Cost of Sintered Powder Per Part (Printed on Fuse 1+ 30W) | $3.98 | $0.62 | $2.88 |

| Cost of Vapor Smoothing Per Part | $0.98 | $0.49 | $0.78 |

| Total Cost Per Part | $4.96 | $1.11 | $3.66 |

Conclusion

Vapor smoothing improves the surface smoothness, antimicrobial properties, and general surface morphology of 3D printed parts. Adding vapor smoothing as a post-processing step helps SLS 3D printed parts look and behave more like injection-molded plastics.

Formlabs SLS powders are compatible with the AMT PostPro chemical vapor smoothing technology. Utilizing industrial power SLS 3D printing with the Fuse Series and AMT’s technology allows designers, engineers, and manufacturers to create high-quality, end-use parts in a variety of industries and applications.

To determine if printing on the Fuse Series and vapor smoothing through AMT’s process are right for your workflow, contact our SLS experts to learn more.